Professional Documents

Culture Documents

Carbozinc 859: Selection & Specification Data

Uploaded by

Francis BautistaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Carbozinc 859: Selection & Specification Data

Uploaded by

Francis BautistaCopyright:

Available Formats

®

Carbozinc 859

PRODUCT DATA SHEET

S E L E C T I O N & S P E C I F I C AT I O N D ATA

Generic Type Organic Zinc-Rich Epoxy

Low VOC organic zinc epoxy steel primer with extremely fast cure-to-topcoat characteristics for in-

Description shop applications and quick turnaround requirements in the field. Carbozinc 859 has less than 3

lbs/gallon (359.5 g/l) VOC (thinned) and is used extensively in virtually all industrial markets.

• Meets Class B slip co-efficient and creep testing criteria for use on faying surfaces

• Rapid cure. Dry to recoat in 30 minutes at 75°F (24°C) and 50% relative humidity.

• Complies with SSPC Paint 20 (Type II)

• Low temperature cure down to 35°F (2°C)

• Excellent adhesion

Features

• Protects against undercutting corrosion

• Field proven primer that applies well by spray methods

• Excellent touch-up primer by brush or roll for small areas.

• VOC compliant to current AIM regulations

• Approved for MPI #20

Color Green (0300); Gray (0700)

Finish Flat

Primer Self Priming

3 - 5 mils (76 - 127 microns) per coat

Dry Film Thickness

Dry film thickness in excess of 10.0 mils (250 microns) per coat is not recommended.

Total Zinc Dust in Dry By Weight: 81%

Film

By Volume 66% +/- 2%

Solids Content

Tested in accordance with ASTM D2697.

1059 ft²/gal at 1.0 mils (26.0 m²/l at 25 microns)

Theoretical Coverage 353 ft²/gal at 3.0 mils (8.7 m²/l at 75 microns)

Rate 212 ft²/gal at 5.0 mils (5.2 m²/l at 125 microns)

Allow for loss in mixing and application.

Thinner 236 E : 13 oz/gal: 2.72 lbs/gal (326 g/l)

Thinner 2 : 13 oz/gal: 3.12 lbs./gal (374 g/l)

Thinner 33 : 13 oz/gal: 3.15 lbs./gal (378 g/l)

VOC Values As Supplied : 2.72 lbs./gal (326 g/l)

These are nominal values.

*Use Thinner 76 for projects requiring non-photochemically reactive solvents.

Continuous: 400°F (204°C)

Dry Temp. Resistance

Non-Continuous: 425°F (218°C)

Acrylics, epoxies, polyurethanes and others as recommended by your Carboline sales

representative.

Topcoats

Under certain conditions, a mist coat is required to minimize topcoat bubbling.

February 2022 0486 Page 1 of 5

®

Carbozinc 859

PRODUCT DATA SHEET

S U B S T R AT E S & S U R F A C E P R E PA R AT I O N

Surfaces must be clean and dry. Employ adequate methods to remove dirt, dust, oil and all other

General

contaminants that could interfere with adhesion of the coating.

SSPC-SP6 with a 1.0-3.0 mil (25-75 micron) surface profile.

SSPC-SP2 or SP3 with a roughened surface for touch-up.

Steel

When using under fireproofing products, defer to the primer surface preparation requirements in the

product data sheet of the fireproofing product.

P E R F O R M A N C E D ATA

All test data was generated under laboratory conditions. Field testing results may vary.

Test Method System Results

A. 859 B. 859/ Polyurethane Gardner

ASTM D2794 Impact Impact Tester, Direct (Intrusion), inch- A. 160 B. 100 min.

pounds, over 1/8" (0.32 cm) steel

A. Carbozinc 859

A. 841 psi Pneumatic B. 1,100 min.

ASTM D4541 Adhesion B. 859 / Polyurethane

psi Pneumatic C. 602 psi Elcometer

C. 859 / Epoxy/Polyurethane

ASTM D522 Flexibility A. 859 B. 859/Polyurethane A. >6% B. >5%

A. Carbozinc 859/Epoxy/Polyurethane

A & B had no rusting in the scribe;

Salt Water (5% sodium chloride) at

ASTM D870 Immersion and no blistering, softening or

75°F (24°C), 30 days B. 859 / Epoxy/

discoloration with either environment

Polyurethane; Fresh Water @75°F for 30 d

Carbozinc 859 A-490 bolt spec; 6 mils

Slip Co-efficient Meets requirements for class B rating

dry film maximum 10% max thinning

Test reports and additional data available upon written request.

MIXING & THINNING

Power mix Part A completely. Then slowly sift in the zinc filler under agitation. Power mix Part B

separately and add slowly to the mixture. Pour mixture through a 30 mesh screen. DO NOT MIX

Mixing PARTIAL KITS.

Tip: Sifting zinc through a window screen will aid in mixing process by breaking up or catching dry

zinc lumps.

Normally not required but may be thinned up to 13 oz/gal (106.8 g/l) (10%) with Thinner 2, Thinner

76 or Thinner 236E. In hot or windy conditions, may be thinned up to 13 oz/gal (106.8 g/l) with

Thinner 33. Use of thinners other than those supplied by Carboline may adversely affect product

Thinning

performance and void product warranty, whether expressed or implied. Use of Carboline Thinner

236E to thin this product will minimize HAP and VOC emissions. Consult Carboline Technical

Service for guidance

0.80 Gal. Kit (3.03 Liters)

Part A: 0.35 gallons (1.32 L)

Part B: 0.20 gallons (0.76 L)

Zinc Filler: 14.6 lbs (6.62 kg)

Ratio

4.00 Gal. Kit (15.1 Liters)

Part A: 1.77 gallons (6.7 L)

Part B: 1 gallon (3.78 L)

Zinc Filler: 73 lbs. (33.1 kg)

February 2022 0486 Page 2 of 5

®

Carbozinc 859

PRODUCT DATA SHEET

MIXING & THINNING

4 Hours at 75°F (24°C) and less at higher temperatures. Pot life ends when coating loses body and

Pot Life

begins to sag.

A P P L I C AT I O N E Q U I P M E N T G U I D E L I N E S

Listed below are general equipment guidelines for the application of this product. Job site conditions may require modifications

to these guidelines to achieve the desired results.

Spray Application The following spray equipment has been found suitable and is available from manufacturers such

(General) as Binks, DeVilbiss and Graco. Keep material under mild agitation during application.

Agitated pressure pot equipped with dual regulators, 3/8” (0.95 cm) I.D. minimum material hose,

Conventional Spray

0.070” (0.18 cm) I.D. fluid tip and appropriate air cap.

Pump Ratio: 30:1 (min.) with pail agitator*

GPM Output: 3.0 (min.)

Material Hose: 3/8” I.D. (0.95 cm) (min.)

Airless Spray Tip Size: 0.017-0.023” (0.04-0.06 cm)

Output PSI: 2000-2200

Filter Size: 60 mesh

*PTFE packings are recommended and available from the pump manufacturer

Brush & Roller For small areas and touch-up only. Preferred method for large areas is spray application.

(General)

A P P L I C AT I O N C O N D I T I O N S

Condition Material Surface Ambient Humidity

Minimum 40°F (4°C) 35°F (2°C) 35°F (2°C) 0%

Maximum 90°F (32°C) 120°F (49°C) 110°F (43°C) 95%

Industry standards are for the substrate temperatures to be 5°F (3°C) above the dew point. This product simply requires the

substrate temperature to be above the dew point. Condensation due to substrate temperatures below the dew point can cause

flash rusting on prepared steel and interfere with proper adhesion to the substrate. Special application techniques may be required

above or below normal application conditions which are as follows: material 60-85°F (16-29°C), surface & ambient 60-90°F

(16-32°C) and humidity 0% - 90%.

February 2022 0486 Page 3 of 5

®

Carbozinc 859

PRODUCT DATA SHEET

CURING SCHEDULE

Dry to Recoat & Topcoat

Surface Temp. Dry to Handle

w/ other finishes

35°F (2°C) 8 Hours 6 Hours

50°F (10°C) 5 Hours 2 Hours

75°F (24°C) 2 Hours 30 Minutes

100°F (38°C) 1 Hour 30 Minutes

These times are based on a 3.0 mil (75 micron) dry film thickness. Higher film thickness, insufficient ventilation or cooler

temperatures will require longer cure times and could result in solvent entrapment and premature failure.

The general requirement is a 24 hour cure for Carboline epoxy intumescent applications. Maximum recoat time is unlimited. Recoat

intervals may vary from those listed above when using under intumescent fireproofing products. Consult Carboline Technical

Service for recommended cure times before applying Carboline intumescent products.

Must have a clean, dry surface free of chalk, zinc salts, etc. per typical good painting practices. Consult Carboline Technical

Service for specific information.

CLEANUP & SAFETY

Use Thinner 2 or Acetone. In case of spillage, absorb and dispose of in accordance with local

Cleanup

applicable regulations.

Read and follow all caution statements on this product data sheet and on the SDS for this product.

Safety Employ normal workmanlike safety precautions. Hypersensitive persons should wear protective

clothing, gloves and use protective cream on face, hands and all exposed areas.

When used in enclosed areas, thorough air circulation must be used during and after application

until the coating is cured. The ventilation system should be capable of preventing the solvent vapor

concentration from reaching the lower explosion limit for the solvents used. In addition to ensuring

proper ventilation, appropriate respirators must be used by all application personnel.

Ventilation

This product contains flammable solvents. Keep away from sparks and open flames. All electrical

equipment and installations should be made and grounded in accordance with the National Electric

Code. In areas where explosion hazards exist, workmen should be required to use non-ferrous

tools and wear conductive and non-sparking shoes.

PA C K A G I N G , H A N D L I N G & S T O R A G E

Part A: 36 months at 75°F (24°C)

Part B: 24 months at 75°F (24°C)

Part C: 24 months at 75°F (24°C)

Shelf Life

*Shelf Life: (actual stated shelf life) when kept at recommended storage conditions and in original

unopened containers.

40-120°F (4-49°C) Store indoors

Storage Temperature &

Can be stored down to 20°F (-7°C) for no longer than 30 days

Humidity

0-100% Relative Humidity

Storage Store Indoors

Shipping Weight 0.80 Gallon (3.02 L) Kit - 22 lbs (10 kg)

(Approximate) 4.00 Gallon (15.1 L) Kit - 105 lbs (48 kg)

Part A: 49°F (9°C)

Flash Point (Setaflash) Part B: 38°F (3°C)

Zinc Filler: NA

February 2022 0486 Page 4 of 5

®

Carbozinc 859

PRODUCT DATA SHEET

WA R R A N T Y

To the best of our knowledge the technical data contained herein is true and accurate on the date of publication and is subject

to change without prior notice. User must contact Carboline Company to verify correctness before specifying or ordering. No

guarantee of accuracy is given or implied. We guarantee our products to conform to Carboline quality control. We assume no

responsibility for coverage, performance, injuries or damages resulting from use. Carbolines sole obligation, if any, is to replace

or refund the purchase price of the Carboline product(s) proven to be defective, at Carbolines option. Carboline shall not be liable

for any loss or damage. NO OTHER WARRANTY OR GUARANTEE OF ANY KIND IS MADE BY CARBOLINE, EXPRESS OR

IMPLIED, STATUTORY, BY OPERATION OF LAW, OR OTHERWISE, INCLUDING MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE. All of the trademarks referenced above are the property of Carboline International Corporation unless

otherwise indicated.

February 2022 0486 Page 5 of 5

You might also like

- Miracle Tank Cleaning Guide (6th Ed 2008)Document1,159 pagesMiracle Tank Cleaning Guide (6th Ed 2008)Ricardo Alarcon Millan100% (10)

- Periodic Table Packet #1: AnswersDocument6 pagesPeriodic Table Packet #1: AnswersJessa Latosa0% (1)

- Quantuam Furnace R Efractory Data SheetDocument27 pagesQuantuam Furnace R Efractory Data SheetMashiur RahmanNo ratings yet

- CHEM 211 General Chemistry I SyllabusDocument6 pagesCHEM 211 General Chemistry I SyllabusAnimesh rathiNo ratings yet

- Carbozinc - 859 - PDS JapanDocument4 pagesCarbozinc - 859 - PDS JapanFreddyNo ratings yet

- Carbozinc 859 (Organic Zinc-Rich Epoxy)Document4 pagesCarbozinc 859 (Organic Zinc-Rich Epoxy)helioxavier2No ratings yet

- Carbozinc Data SheetDocument2 pagesCarbozinc Data SheetIra Purnama SariNo ratings yet

- Carbozinc 859Document2 pagesCarbozinc 859Khemaraj PathNo ratings yet

- Carboguard 893: Selection & Specification DataDocument5 pagesCarboguard 893: Selection & Specification DataQuy RomNo ratings yet

- Carboguard 635: Selection & Specification DataDocument5 pagesCarboguard 635: Selection & Specification DataPrakashNo ratings yet

- Carboguard 893 PDSDocument5 pagesCarboguard 893 PDSUtomoNo ratings yet

- Carbozinc 11 HS PDSDocument5 pagesCarbozinc 11 HS PDSEsakki muthuNo ratings yet

- Carbothane 133 HB PDS PDFDocument5 pagesCarbothane 133 HB PDS PDFskNo ratings yet

- Carboguard 890 PDSDocument5 pagesCarboguard 890 PDSAchraf BoudayaNo ratings yet

- Carboguard 893 PDSDocument5 pagesCarboguard 893 PDSTrịnh Minh KhoaNo ratings yet

- Carboguard 893 SG MIO PDSDocument4 pagesCarboguard 893 SG MIO PDSMuthuKumarNo ratings yet

- Carboguard 893 SG: Selection & Specification DataDocument5 pagesCarboguard 893 SG: Selection & Specification DataPraveen Sreekumaran NairNo ratings yet

- Carboguard 890 PDSDocument5 pagesCarboguard 890 PDScrisNo ratings yet

- Carbothane 133 HB: Selection & Specification DataDocument5 pagesCarbothane 133 HB: Selection & Specification DatalavekushNo ratings yet

- Carboguard 890 GFDocument4 pagesCarboguard 890 GFDuongthithuydungNo ratings yet

- Carboguard 891 Product Data SheetDocument4 pagesCarboguard 891 Product Data SheetPrakashNo ratings yet

- Carbozinc 11Document4 pagesCarbozinc 11DuongthithuydungNo ratings yet

- Carbozinc 11: Selection & Specification DataDocument5 pagesCarbozinc 11: Selection & Specification DataQuy RomNo ratings yet

- Carbozinc 11 PDSDocument5 pagesCarbozinc 11 PDSSUBODHNo ratings yet

- Acrolon 218 HsDocument4 pagesAcrolon 218 HsKARENNo ratings yet

- Carboguard 890: Selection & Specification DataDocument5 pagesCarboguard 890: Selection & Specification DataMuthazhagan SaravananNo ratings yet

- Carbozinc 858 (3K)Document4 pagesCarbozinc 858 (3K)DuongthithuydungNo ratings yet

- Sanitile 120 PDSDocument4 pagesSanitile 120 PDSDuongthithuydungNo ratings yet

- Carboguard 1209: Selection & Specification DataDocument4 pagesCarboguard 1209: Selection & Specification DataQuy Dom100% (2)

- Carboguard 635 Thinned 50% - Sealer PDSDocument5 pagesCarboguard 635 Thinned 50% - Sealer PDSjakeNo ratings yet

- Carboxane 2000 PDSDocument4 pagesCarboxane 2000 PDSBERSE MAJU INDONESIANo ratings yet

- Acrolon 218 FTDocument4 pagesAcrolon 218 FTEdwin VSNo ratings yet

- Carbozinc 11: Selection & Specification DataDocument5 pagesCarbozinc 11: Selection & Specification DatajoehodohNo ratings yet

- Carbocoat 8239: Selection & Specification DataDocument4 pagesCarbocoat 8239: Selection & Specification DataSHAIK ASIMUDDINNo ratings yet

- Protective & Marine Coatings: Polysiloxane 1KDocument4 pagesProtective & Marine Coatings: Polysiloxane 1KAna CabreraNo ratings yet

- Carboguard 893 SG PDSDocument4 pagesCarboguard 893 SG PDSTrịnh Minh KhoaNo ratings yet

- Carboguard 890N PDSDocument5 pagesCarboguard 890N PDScorey jacobsNo ratings yet

- Carboline Carbothane 133 HBDocument5 pagesCarboline Carbothane 133 HBArturo SalinasNo ratings yet

- Carboguard 880 MIO PDSDocument4 pagesCarboguard 880 MIO PDSHerman EngelbrechtNo ratings yet

- Carboguard 60 LH PDSDocument4 pagesCarboguard 60 LH PDSRicardo SantosNo ratings yet

- Carboguard 636 XT PDSDocument4 pagesCarboguard 636 XT PDSCarlos Rojas HandalNo ratings yet

- Carboguard 890 GF PDSDocument2 pagesCarboguard 890 GF PDSfazeel mohammedNo ratings yet

- Protective & Marine Coatings: Acrolon™ 218 HsDocument4 pagesProtective & Marine Coatings: Acrolon™ 218 HsAna CabreraNo ratings yet

- Acrolon 218 HS Acrylic PolyurethaneDocument4 pagesAcrolon 218 HS Acrylic PolyurethaneJohn ReevesNo ratings yet

- Corothane® I Galvapac 1K Zinc Primer PDFDocument4 pagesCorothane® I Galvapac 1K Zinc Primer PDFImam Situmeang100% (1)

- Carboquick 200 PDSDocument4 pagesCarboquick 200 PDSMarcelo Alejandro MarinoNo ratings yet

- WBEpoxyCoating Data SheetDocument2 pagesWBEpoxyCoating Data SheetkaleshNo ratings yet

- Macropoxy 646 SEDocument4 pagesMacropoxy 646 SESleyda MunozNo ratings yet

- Carbozinc 11 WB: Selection & Specification Data Substrates & Surface PreparationDocument2 pagesCarbozinc 11 WB: Selection & Specification Data Substrates & Surface PreparationPurwanto ritzaNo ratings yet

- Reactamine 760: Selection & Specification DataDocument4 pagesReactamine 760: Selection & Specification DataPrakashNo ratings yet

- Carbothane 134 HG PDSDocument4 pagesCarbothane 134 HG PDSAnhera enterpriseNo ratings yet

- Thermo-Lag 270 PDSDocument5 pagesThermo-Lag 270 PDSBERSE MAJU INDONESIANo ratings yet

- Bitumastic 300M: Selection & Specification DataDocument4 pagesBitumastic 300M: Selection & Specification DataSHAIK ASIMUDDINNo ratings yet

- Carbothane 134 HG PDSDocument4 pagesCarbothane 134 HG PDSTeknik produksi wikonNo ratings yet

- Carbozinc 858 PDSDocument4 pagesCarbozinc 858 PDShuycongvuNo ratings yet

- Carboguard 60: Selection & Specification DataDocument5 pagesCarboguard 60: Selection & Specification DataDuongthithuydungNo ratings yet

- Plasite 4100 PDS-3Document5 pagesPlasite 4100 PDS-3Linnie McleodNo ratings yet

- Carbomastic 15 PDSDocument4 pagesCarbomastic 15 PDSRiyaz Basheer100% (1)

- Polyclad 777 PL PDSDocument4 pagesPolyclad 777 PL PDShakkianilNo ratings yet

- Protective & Marine Coatings: Acrolon™ 218 HsDocument4 pagesProtective & Marine Coatings: Acrolon™ 218 Hshector gomezNo ratings yet

- Tankguard SF: Technical Data SheetDocument5 pagesTankguard SF: Technical Data SheetRifki ArifinNo ratings yet

- Corothane I Galvapac 1K Zinc Primer NSF: Protective & Marine CoatingsDocument4 pagesCorothane I Galvapac 1K Zinc Primer NSF: Protective & Marine CoatingsScott NorrisNo ratings yet

- Plastics in Building Structures: Proceedings of a Conference Held in London, 14-16 June 1965From EverandPlastics in Building Structures: Proceedings of a Conference Held in London, 14-16 June 1965No ratings yet

- Functional Polymer Coatings: Principles, Methods, and ApplicationsFrom EverandFunctional Polymer Coatings: Principles, Methods, and ApplicationsRating: 1 out of 5 stars1/5 (1)

- Wedge_Anchor_BZ_plus_A4Document4 pagesWedge_Anchor_BZ_plus_A4Francis BautistaNo ratings yet

- D1D2-MAR-A-0572 Rev.00Document54 pagesD1D2-MAR-A-0572 Rev.00Francis BautistaNo ratings yet

- Forte D1D2 Ewc TRN 00114Document1 pageForte D1D2 Ewc TRN 00114Francis BautistaNo ratings yet

- Flyer_davitrac_235055-03_00_EN_V14Document5 pagesFlyer_davitrac_235055-03_00_EN_V14Francis BautistaNo ratings yet

- Forte D1D23 Ewc TRN 00102Document1 pageForte D1D23 Ewc TRN 00102Francis BautistaNo ratings yet

- Forte D1D2 Ewc TRN 00118Document1 pageForte D1D2 Ewc TRN 00118Francis BautistaNo ratings yet

- Project Management Co. Consultant Approves Safety Line SystemDocument4 pagesProject Management Co. Consultant Approves Safety Line SystemFrancis BautistaNo ratings yet

- Ertalyte: (Indicative ValuesDocument1 pageErtalyte: (Indicative ValuesChristina Christina ChristinaNo ratings yet

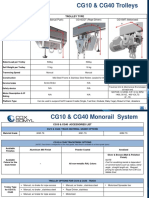

- Cg20 Trolley Type: CG20MPT (Manual Push) CG20CDT (Rope Driven) CG20MT (Motorized)Document3 pagesCg20 Trolley Type: CG20MPT (Manual Push) CG20CDT (Rope Driven) CG20MT (Motorized)Francis BautistaNo ratings yet

- M508 Datasheet R01.bDocument3 pagesM508 Datasheet R01.bFrancis BautistaNo ratings yet

- CG40Document1 pageCG40Francis BautistaNo ratings yet

- Expo 2020 Al Wasl Trellis Steel Work: Method Statement For PaintingDocument54 pagesExpo 2020 Al Wasl Trellis Steel Work: Method Statement For PaintingFrancis BautistaNo ratings yet

- 4870 Future Tower III - H.O. To Serv.Document200 pages4870 Future Tower III - H.O. To Serv.Francis BautistaNo ratings yet

- Future Tower Iii, Sharjah: Operation & Maintenance Manual Building Maintenance UnitDocument107 pagesFuture Tower Iii, Sharjah: Operation & Maintenance Manual Building Maintenance UnitFrancis BautistaNo ratings yet

- CG20Document1 pageCG20Francis BautistaNo ratings yet

- 1000 SERIES POWERED SLIDING DAVITSDocument29 pages1000 SERIES POWERED SLIDING DAVITSFrancis BautistaNo ratings yet

- Trolley Type: (CG10MPT (Manual Push) CG10CDT (Rope Driven) CG10MT (Motorized)Document3 pagesTrolley Type: (CG10MPT (Manual Push) CG10CDT (Rope Driven) CG10MT (Motorized)Francis BautistaNo ratings yet

- Cruz Residence Plans & ScheduleDocument36 pagesCruz Residence Plans & ScheduleFrancis BautistaNo ratings yet

- MC Bus Introtodiff 2009 1Document2 pagesMC Bus Introtodiff 2009 1Francis BautistaNo ratings yet

- CG10Document1 pageCG10Francis BautistaNo ratings yet

- Schedule of Contents: Proposal & Quotation (Rev-A) O-40056-Resid Tower Rt2 C-18 Reem Island 02 April 2020Document19 pagesSchedule of Contents: Proposal & Quotation (Rev-A) O-40056-Resid Tower Rt2 C-18 Reem Island 02 April 2020Francis BautistaNo ratings yet

- Sliding Davit With Self Powered Cradle Technical Passport - Rev ADocument42 pagesSliding Davit With Self Powered Cradle Technical Passport - Rev AFrancis BautistaNo ratings yet

- Saif Zone - Environmental Assessment Sheet InformationDocument236 pagesSaif Zone - Environmental Assessment Sheet InformationFrancis BautistaNo ratings yet

- Building Maintenance Unit Material SubmittalDocument56 pagesBuilding Maintenance Unit Material SubmittalFrancis BautistaNo ratings yet

- Wire Rope Reeving & De-Reeving ProcedureDocument2 pagesWire Rope Reeving & De-Reeving ProcedureFrancis BautistaNo ratings yet

- Two Man Self Powered Cradle - Emergency Procedure (Manual Cradle Descent)Document6 pagesTwo Man Self Powered Cradle - Emergency Procedure (Manual Cradle Descent)Francis BautistaNo ratings yet

- Sliding Davit With Standard Cradle - O&M ManualDocument81 pagesSliding Davit With Standard Cradle - O&M ManualFrancis BautistaNo ratings yet

- Single Man Cradle Tech DataDocument5 pagesSingle Man Cradle Tech DataFrancis BautistaNo ratings yet

- Front Angle Guide Machine (Kookaburra) : NO. Part Description NO. Part DescriptionDocument8 pagesFront Angle Guide Machine (Kookaburra) : NO. Part Description NO. Part DescriptionFrancis BautistaNo ratings yet

- Laser GraftingDocument5 pagesLaser GraftingpcnferreiraNo ratings yet

- Jarissa Banner Nitration of Bromobnzene LabDocument15 pagesJarissa Banner Nitration of Bromobnzene LabJuiloNo ratings yet

- The Common Ion Effect and Buffer SolutionsDocument11 pagesThe Common Ion Effect and Buffer SolutionsAhmed goldenNo ratings yet

- Flange Guard and Its ImportanceDocument6 pagesFlange Guard and Its ImportanceCelestine OzokechiNo ratings yet

- Phase Diagrams Study NotesDocument13 pagesPhase Diagrams Study NotesSushilNo ratings yet

- Diffractometric Debye-Scherrer Patterns of Powder SamplesDocument7 pagesDiffractometric Debye-Scherrer Patterns of Powder SamplesJose GalvanNo ratings yet

- (Plastics Design Library) Carlos Federico Jasso-Gastinel, José M. Kenny - Modification of Polymer Properties-William Andrew (2017)Document222 pages(Plastics Design Library) Carlos Federico Jasso-Gastinel, José M. Kenny - Modification of Polymer Properties-William Andrew (2017)Monique BarretoNo ratings yet

- Chemistry: NEET - 2020-21Document1 pageChemistry: NEET - 2020-21pratikNo ratings yet

- Specification For Hot Weather Concreting: Reported ACI Committee 305Document9 pagesSpecification For Hot Weather Concreting: Reported ACI Committee 305Thonthowi SyahNo ratings yet

- Overview of Bowtie Methodology of Risk Analysis and Its ApplicationDocument6 pagesOverview of Bowtie Methodology of Risk Analysis and Its ApplicationakhyudinNo ratings yet

- The Sintering Temperature Effect On Electrochemical Properties of Limn ODocument7 pagesThe Sintering Temperature Effect On Electrochemical Properties of Limn OSalsa NisaNo ratings yet

- Sulfur Dioxide Removal: An Overview of Regenerative Flue Gas Desulfurization and Factors Affecting Desulfurization Capacity and Sorbent RegenerationDocument26 pagesSulfur Dioxide Removal: An Overview of Regenerative Flue Gas Desulfurization and Factors Affecting Desulfurization Capacity and Sorbent RegenerationKrittika ChandranNo ratings yet

- 23465Document15 pages23465sbiasotoNo ratings yet

- Chemistry Practical Class 12Document23 pagesChemistry Practical Class 12SURAJ GAMINGNo ratings yet

- Drew Ameroid - Tank Cleaning ManualDocument99 pagesDrew Ameroid - Tank Cleaning ManualВиталий МакошибаNo ratings yet

- 37 MolaritywebDocument10 pages37 MolaritywebpenisNo ratings yet

- Thẻ ghi nhớ - Career Paths Medical-Book 1 - Unit 12 - QuizletDocument5 pagesThẻ ghi nhớ - Career Paths Medical-Book 1 - Unit 12 - Quizletvũ cườngNo ratings yet

- 422 - Report TCP PUREDocument3 pages422 - Report TCP PURENazar JabbarNo ratings yet

- Cold Heading and Cold Phosphate Coating ProcessDocument4 pagesCold Heading and Cold Phosphate Coating ProcessRestu SihotangNo ratings yet

- Solute Mass and Solution Concentration CalculationsDocument6 pagesSolute Mass and Solution Concentration CalculationsZinzinNo ratings yet

- 9701 Scheme of Work (For Examination From 2022) - 3Document1 page9701 Scheme of Work (For Examination From 2022) - 3DuckyNo ratings yet

- 7 Compare The Caffeine Content EX 2Document2 pages7 Compare The Caffeine Content EX 2Atul rajNo ratings yet

- FDA Code of Federal Regulations DISINFECTANTDocument8 pagesFDA Code of Federal Regulations DISINFECTANTmilena RodriguezNo ratings yet

- I N F O R M A T I O N: Drop Volume Tensiometer DVT50Document4 pagesI N F O R M A T I O N: Drop Volume Tensiometer DVT50MiguelNo ratings yet

- Agrement Mastic Acrilic Antifoc CFS-S - ACR - J RosturiDocument18 pagesAgrement Mastic Acrilic Antifoc CFS-S - ACR - J RosturiOvidiu NeaguNo ratings yet

- 5 Rhenocure TMTD CDocument3 pages5 Rhenocure TMTD CKeremNo ratings yet