Professional Documents

Culture Documents

Carbothane 133 HB PDS PDF

Uploaded by

skOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Carbothane 133 HB PDS PDF

Uploaded by

skCopyright:

Available Formats

®

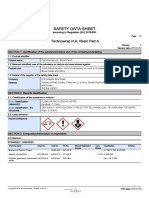

Carbothane 133 HB

PRODUCT DATA SHEET

S E L E C T I O N & S P E C I F I C AT I O N D ATA

Generic Type Aliphatic Acrylic-Polyester Polyurethane

High build, low sheen finish that has excellent resistance to corrosion, chemicals and abrasion.

Description Suitable for application over a number of Carboline primers and intermediates, this material

provides very good weathering performance in a broad range of colors.

• Outstanding performance properties in both mild and aggressive environments

• High build; suitable for many two-coat systems

• Suitable for application direct to inorganic zincs

Features

• Application by spray, brush or roller

• Indefinite recoatability

• VOC compliant to current AIM regulations

Color Refer to Carboline Color Guide. Certain colors may require multiple coats to hide.

Finish Satin

Refer to Substrates & Surface Preparation.

Primer

Topcoat with Carbothane® Clear Coat when required.

Dry Film Thickness 3 - 5 mils (75 - 125 microns) per coat

Dry film thickness in excess of 7 mils (175 microns) per coat is not recommended.

Solids Content By Volume 57% +/- 2%

914 ft²/gal at 1.0 mil (22.4 m²/l at 25 microns)

Theoretical Coverage 305 ft²/gal at 3.0 mils (7.5 m²/l at 75 microns)

Rate 183 ft²/gal at 5.0 mils (4.5 m²/l at 125 microns)

Allow for loss in mixing and application.

As Supplied : 3.2 lbs./gal (383 g/l)

Thinner 214 : 3.3 lbs/gal (403 g/l)

Thinner 241 : 3.5 lbs/gal (423 g/l)

Thinner 25 : 11 oz/gal: 3.5 lbs./gal (420 g/l)

VOC Values

Thinner 25 : 18 oz/gal: 3.7 lbs./gal (449 g/l)

1.5 oz/gal of Additive 101 adds 0.08 lbs/gal (10 g/l). These are nominal values and may vary slightly

with color.

Continuous: 200°F (93°C)

Non-Continuous: 250°F (121°C)

Dry Temp. Resistance

Discoloration and loss of gloss is observed above 200°F (93°C)

*The alignment of aluminum flakes in aluminum-filled finishes is very dependent on application

conditions and techniques. Care must be taken to keep conditions as constant as possible to

Limitations

reduce variations in final appearance. It is also advisable to work from a single batch of material

since variations can occur from batch to batch.

September 2017 Page 1 of 5

®

Carbothane 133 HB

PRODUCT DATA SHEET

S U B S T R AT E S & S U R F A C E P R E PA R AT I O N

Surfaces must be clean and dry. Employ adequate methods to remove dirt, dust, oil and all other

General contaminants that could interfere with adhesion of the coating. Refer to the specific primer’s

Product Data Sheet for detailed requirements of the specified primer.

Steel SSPC-SP6 with a 1.5-2.5 mils (37.5-62.5 micron) surface profile for maximum

protection. SSPCSP2 or SP3 as minimum requirement. Prime with specific Carboline

primers as recommended by your StonCor ME sales representative.

Prime with specific Carboline primers as recommended by your StonCor ME Sales Representative.

Galvanized Steel

Refer to the specific primer’s Product Data Sheet for substrate preparation requirements.

SSPC-SP1 and prime with appropriate Carboline primer as recommended by your StonCor ME

Aluminum

sales representative.

Lightly sand or abrade to roughen and degloss the surface. Existing paint must attain a minimum

Previously Painted

3A rating in accordance with ASTM D3359 “XScribe” adhesion test. Prime with specific Carboline

Surfaces

primers as recommended by your StonCor ME sales representative.

P E R F O R M A N C E D ATA

Test Method System Results

No rusting, or blistering on

ASTM B117 Salt Fog Blasted Steel 1 ct. IOZ 1 ct. 133 HB

plane or scribe 2,000 hours

No rusting, or blistering on

ASTM B117 Salt Fog Blasted Steel 1 ct. OZ 1 ct. 133 HB

plane or scribe 4,000 hours

ASTM D1735 Water Fog Blasted Steel 1 ct. Epoxy 1 ct. 133 HB No rusting or blistering after 8600 hours.

.0027 microliters erosion rate after 100

ASTM D4213 Scrub Resistance 1 ct. 133 HB

cycles with abrasive scrub medium.

ASTM D4585 Humidity Blasted Steel 1 ct. IOZ 1 ct. 133 HB No rusting or blistering after 3000 hours.

No effect on plane area and

ASTM D5894 QUV A Prohesion 1 ct. 133 HB 78% gloss retention after 1008

hours of wet/dry salt fog cycle

No blistering, rusting or

ASTM G26 Weatherometer Blasted Steel 1 ct IOZ 1 ct. 133 HB

cracking after 3500 hours

ASTM G53 QUV (2500 Color change less than 2 McAdam units;

Blasted Steel 1 ct. Epoxy 1 ct. 133 HB

hours w/ UVA 340 bulb) no blistering, rusting, cracking or chalking.

All markings and stains removed

Graffiti Resistance Blasted Steel 1 ct. Epoxy 1 ct. 133 HB by solvent after exposure to: shoe

polish,Sharpie marker, crayon, l

Test reports and additional data available upon request.

MIXING & THINNING

Power mix Part A separately, then combine with Part B and power mix. DO NOT MIX PARTIAL

Mixing

KITS.

Spray: Up to 11 oz/gal (9%) w/ Thinner 25.

Roller: Up to 18 oz/gal (14%) w/ Thinner 25.

Use of thinners other than those supplied or recommended by Carboline may adversely affect

Thinning

product performance and void product warranty, whether expressed or implied. Thinner 214 may

also be used, up to 6 oz/gal, for either spray or brush/roller application. Carboline Thinner 236E

may also be used to minimize HAP and VOC emissions.

September 2017 Page 2 of 5

®

Carbothane 133 HB

PRODUCT DATA SHEET

MIXING & THINNING

6:1 Ratio (A to B)

.88 Gal. Kit

Part A: 1 gal. can (partial filled)

Ratio UC 133: 1 pint

5.0 Gal. Kit

Part A: 5 gal. can (partial filled)

UC 133: 1 gallon can (partial filled)

4 Hours at 75°F (24°C) and less at higher temperatures. Pot life ends when coating becomes

Pot Life too viscous to use. MOISTURE CONTAMINATION WILL SHORTEN POT LIFE AND CAUSE

GELLATION.

A P P L I C AT I O N E Q U I P M E N T G U I D E L I N E S

Listed below are general equipment guidelines for the application of this product. Job site conditions may require modifications

to these guidelines to achieve the desired results.

This is a high solids coating and may require adjustments in spray techniques. Wet film thickness

Spray Application

is easily and quickly achieved. The following spray equipment has been found suitable and is

(General)

available from manufacturers such as Binks, DeVilbiss and Graco.

Pressure pot equipped with dual regulators

Conventional Spray 3/8” I.D. minimum material hose

.070” I.D. fluid tip and appropriate air cap

Pump Ratio: 30:1 (min.)*

GPM Output: 3.0 (min.)

Material Hose: 3/8” I.D. (min.)

Airless Spray Tip Size: .013-.015”

Output PSI: 2100-2300

Filter Size: 60 mesh

*Teflon packings are recommended and available from the pump manufacturer.

Multiple coats may be required to obtain desired appearance, recommended dry film thickness and

Brush & Roller

adequate hiding. Avoid excessive re-brushing or rerolling. For best results, tie-in within 10 minutes

(General)

at 75°F (24°C).

Brush Recommended for touch-up only. Use a medium, natural bristle brush.

Roller Use a medium-nap synthetic roller cover with phenolic core.

A P P L I C AT I O N C O N D I T I O N S

Condition Material Surface Ambient Humidity

Minimum 40°F (4°C) 40°F (4°C) 40°F (4°C) 0%

Maximum 100°F (38°C) 110°F (43°C) 110°F (43°C) 90%

Industry standards are for substrate temperatures to be 5°F (3°C) above the dew point. This product simply requires the substrate

temperature to be above the dew point.

Caution: This Product is moisture sensitive in the liquid stage and until cured. Protect from high humidity, dew and direct moisture

contact until cured. Application and/or curing in humidities above maximum, or exposure to moisture from rain or dew may result in

a loss of gloss and/or microbubbling of the product.

September 2017 Page 3 of 5

®

Carbothane 133 HB

PRODUCT DATA SHEET

CURING SCHEDULE

Surface Temp. Dry to Handle Dry to Recoat Final Cure General

40°F (4°C) 20 Hours 20 Hours 28 Days

50°F (10°C) 12 Hours 12 Hours 14 Days

75°F (24°C) 5 Hours 5 Hours 7 Days

90°F (32°C) 1 Hour 1 Hour 4 Days

These times are based on a 3.0-5.0 mils (75-125 microns) dry film thickness. Higher film thickness, insufficient ventilation or

cooler temperatures will require longer cure times and could result in solvent entrapment and premature failure.

*Maximum recoat times are indefinite. Surface must be clean and dry. As part of good painting practice it is recommended to

test for adhesion by wiping the surface with Thinner 25. If the film shows a slight "tack" the surface is suitable for recoating without

extensive surface preparation such as abrading.

Carboline Additive 101 can be used to accelerate the film forming process in this product for conditions outside of the parameters

of this data sheet. Carboline Additive 101 is added at a rate of 1.0-2.0 oz per mixed gallon or a maximum of 6 oz per mixed five

gallons. At this addition rate, Additive 101 will accelerate the cure rate of the urethane product between 25-40% depending on the

substrate temperature range and reduce the pot life of the product by approximately 40-50% of that stated on the product data

sheet. With the use of Additive 101, this product will continue to cure at temperatures as low as 20°F (-7°C).

CLEANUP & SAFETY

Use Thinner 2 or Acetone. In case of spillage, dispose of in accordance with local applicable

Cleanup

regulations.

Read and follow all caution statements on this product data sheet and on the MSDS for this product

Safety

and use personal protective equipment as directed.

When used in enclosed areas, thorough air circulation must be used during and after application

until the coating is cured. The ventilation system should be capable of preventing the solvent vapor

Ventilation concentration from reaching the lower explosion limit for the solvents used. User should test and

monitor exposure levels to insure all personnel are below guidelines. If not able to monitor levels,

use MSHA/NIOSH approved supplied air respirator.

PA C K A G I N G , H A N D L I N G & S T O R A G E

Part A: Min. 36 months at 75°F (24°C)

Part B: Min. 24 months at 75°F (24°C)

Shelf Life

*Shelf Life: when kept at recommended storage conditions and in original unopened containers.

Storage Temperature & 40° -110°F (4°-43°C)

Humidity 0-90% Relative Humidity

Store Indoors.

Storage This product is solvent based and not affected by excursions below these published storage

temperatures, down to 10°F, for a duration of no more than 14 days. Always inspect the product

prior to use to make sure it is smooth and homogeneous when properly mixed.

Shipping Weight .875 Gallon Kit - 11 lbs. (5 kg)

(Approximate) 5 Gallon Kit - 64 lbs. (29 kg)

Part A: 95°F (35°C)

Flash Point (Setaflash)

Part B: 91°F (33°C)

September 2017 Page 4 of 5

®

Carbothane 133 HB

PRODUCT DATA SHEET

WA R R A N T Y

To the best of our knowledge the technical data contained herein is true and accurate on the date of publication and is subject to

change without prior notice. User must contact StonCor ME to verify correctness before specifying or ordering. No guarantee of

accuracy is given or implied. We guarantee our products to conform to Carboline quality control. We assume no responsibility for

coverage, performance, injuries or damages resulting from use. StonCor ME's sole obligation, if any, is to replace or refund the

purchase price of the Carboline product(s) proven to be defective, at StonCor ME's option. StonCor ME shall not be liable for any

loss or damage. NO OTHER WARRANTY OR GUARANTEE OF ANY KIND IS MADE BY STONCOR ME, EXPRESS OR

IMPLIED, STATUTORY, BY OPERATION OF LAW, OR OTHERWISE, INCLUDING MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE. All of the trademarks referenced above are the property of Carboline International Corporation unless

otherwise indicated.

September 2017 Page 5 of 5

You might also like

- Heating, Ventilation and Air Conditioning For Plant BuildingsDocument48 pagesHeating, Ventilation and Air Conditioning For Plant Buildingssk50% (4)

- Certificates For Belzona 1391 & Belzona 1511 PDFDocument2 pagesCertificates For Belzona 1391 & Belzona 1511 PDFskNo ratings yet

- Chimneys Selection, Design and Engineering (BASED ON EN 1992-1-1, EN 1993-3-2, EN 1443, EN 13084-PARTS 1, 2, 4, 5, 6, 7 AND 8)Document34 pagesChimneys Selection, Design and Engineering (BASED ON EN 1992-1-1, EN 1993-3-2, EN 1443, EN 13084-PARTS 1, 2, 4, 5, 6, 7 AND 8)skNo ratings yet

- Technowrap 2K PDFDocument1 pageTechnowrap 2K PDFskNo ratings yet

- Carbothane 133 HB: Selection & Specification DataDocument5 pagesCarbothane 133 HB: Selection & Specification DatalavekushNo ratings yet

- Carboline Carbothane 133 HBDocument5 pagesCarboline Carbothane 133 HBArturo SalinasNo ratings yet

- Carbothane 134 HG PDSDocument5 pagesCarbothane 134 HG PDSsanthoshkumarplNo ratings yet

- Carboguard 890 PDSDocument5 pagesCarboguard 890 PDScrisNo ratings yet

- Carboguard 890 PDSDocument5 pagesCarboguard 890 PDSAchraf BoudayaNo ratings yet

- Carboguard 893 PDSDocument5 pagesCarboguard 893 PDSUtomoNo ratings yet

- Carboguard 893: Selection & Specification DataDocument5 pagesCarboguard 893: Selection & Specification DataQuy RomNo ratings yet

- Carboguard 893 PDSDocument5 pagesCarboguard 893 PDSTrịnh Minh KhoaNo ratings yet

- Carbozinc 11 PDSDocument5 pagesCarbozinc 11 PDSSUBODHNo ratings yet

- Carbothane 134 HG PDSDocument2 pagesCarbothane 134 HG PDSKhemaraj Path100% (1)

- Carbomastic 15 PDSDocument4 pagesCarbomastic 15 PDSRiyaz Basheer100% (1)

- Carbozinc 11: Selection & Specification DataDocument5 pagesCarbozinc 11: Selection & Specification DatajoehodohNo ratings yet

- Carbozinc 11Document4 pagesCarbozinc 11DuongthithuydungNo ratings yet

- Carbozinc 11 HS PDSDocument5 pagesCarbozinc 11 HS PDSEsakki muthuNo ratings yet

- Carbozinc - 859 - PDS JapanDocument4 pagesCarbozinc - 859 - PDS JapanFreddyNo ratings yet

- Carbozinc 859: Selection & Specification DataDocument5 pagesCarbozinc 859: Selection & Specification DataFrancis BautistaNo ratings yet

- Phenoline 187 Finish PDSDocument5 pagesPhenoline 187 Finish PDSQuy RomNo ratings yet

- Carbothane 134 HG PDSDocument2 pagesCarbothane 134 HG PDSfazeel mohammedNo ratings yet

- Carbozinc 11: Selection & Specification DataDocument5 pagesCarbozinc 11: Selection & Specification DataQuy RomNo ratings yet

- Carbozinc 859 (Organic Zinc-Rich Epoxy)Document4 pagesCarbozinc 859 (Organic Zinc-Rich Epoxy)helioxavier2No ratings yet

- Carboguard 193: Selection & Specification DataDocument4 pagesCarboguard 193: Selection & Specification DataGraciele SantosNo ratings yet

- Carboguard 1209: Selection & Specification DataDocument4 pagesCarboguard 1209: Selection & Specification DataQuy Dom100% (2)

- Carboguard 890 GFDocument4 pagesCarboguard 890 GFDuongthithuydungNo ratings yet

- Carboguard 893 SG MIO PDSDocument4 pagesCarboguard 893 SG MIO PDSMuthuKumarNo ratings yet

- Carboguard 890: Selection & Specification DataDocument5 pagesCarboguard 890: Selection & Specification DataMuthazhagan SaravananNo ratings yet

- Carboguard 893 PDSDocument2 pagesCarboguard 893 PDSNguyễn Thị Châu TâyNo ratings yet

- Sanitile 120 PDSDocument4 pagesSanitile 120 PDSDuongthithuydungNo ratings yet

- Phenoline 187 Primer PDSDocument5 pagesPhenoline 187 Primer PDSQuy RomNo ratings yet

- Carbozinc Data SheetDocument2 pagesCarbozinc Data SheetIra Purnama SariNo ratings yet

- Carboguard 890N PDSDocument5 pagesCarboguard 890N PDScorey jacobsNo ratings yet

- Phenoline 187 Chemical Resistant Tank LiningDocument5 pagesPhenoline 187 Chemical Resistant Tank LiningQuy RomNo ratings yet

- Carbothane 134 HG Polyurethane Coating MSDSDocument13 pagesCarbothane 134 HG Polyurethane Coating MSDSjgzlzNo ratings yet

- Acrolon 218 HsDocument4 pagesAcrolon 218 HsKARENNo ratings yet

- Carbozinc 859Document2 pagesCarbozinc 859Khemaraj PathNo ratings yet

- Carboguard 893 SG: Selection & Specification DataDocument5 pagesCarboguard 893 SG: Selection & Specification DataPraveen Sreekumaran NairNo ratings yet

- Carboguard 893 SG PDSDocument4 pagesCarboguard 893 SG PDSTrịnh Minh KhoaNo ratings yet

- Carbothane 134 HG PDSDocument4 pagesCarbothane 134 HG PDSAnhera enterpriseNo ratings yet

- Protective & Marine Coatings: Polysiloxane 1KDocument4 pagesProtective & Marine Coatings: Polysiloxane 1KAna CabreraNo ratings yet

- Bitumastic 300M: Selection & Specification DataDocument4 pagesBitumastic 300M: Selection & Specification DataSHAIK ASIMUDDINNo ratings yet

- Carboxane 2000 PDSDocument4 pagesCarboxane 2000 PDSBERSE MAJU INDONESIANo ratings yet

- Acrolon 218 HS Acrylic PolyurethaneDocument4 pagesAcrolon 218 HS Acrylic PolyurethaneJohn ReevesNo ratings yet

- Acrolon 218 FTDocument4 pagesAcrolon 218 FTEdwin VSNo ratings yet

- Carbothane 134 HG PDSDocument4 pagesCarbothane 134 HG PDSTeknik produksi wikonNo ratings yet

- Carboguard 60: Selection & Specification DataDocument5 pagesCarboguard 60: Selection & Specification DataDuongthithuydungNo ratings yet

- Carboquick 200 PDSDocument4 pagesCarboquick 200 PDSMarcelo Alejandro MarinoNo ratings yet

- Protective & Marine Coatings: Acrolon™ 218 HsDocument4 pagesProtective & Marine Coatings: Acrolon™ 218 HsAna CabreraNo ratings yet

- Fast Clad HB Acrylic: Protective & Marine CoatingsDocument4 pagesFast Clad HB Acrylic: Protective & Marine CoatingsAna CabreraNo ratings yet

- Corothane® I Galvapac 1K Zinc Primer PDFDocument4 pagesCorothane® I Galvapac 1K Zinc Primer PDFImam Situmeang100% (1)

- Carboguard 635: Selection & Specification DataDocument5 pagesCarboguard 635: Selection & Specification DataPrakashNo ratings yet

- Phenoline 187 Primer and FinishDocument2 pagesPhenoline 187 Primer and Finish이선엽No ratings yet

- Carbothane 134 HG PDSDocument4 pagesCarbothane 134 HG PDSpradnyeyNo ratings yet

- Carboguard 636 XT PDSDocument4 pagesCarboguard 636 XT PDSCarlos Rojas HandalNo ratings yet

- Carbotherm 3300 PDSDocument4 pagesCarbotherm 3300 PDS이선엽No ratings yet

- Carbozinc 11 WB: Selection & Specification Data Substrates & Surface PreparationDocument2 pagesCarbozinc 11 WB: Selection & Specification Data Substrates & Surface PreparationPurwanto ritzaNo ratings yet

- Phenoline 187 FinishDocument5 pagesPhenoline 187 FinishDuongthithuydungNo ratings yet

- Corothane I Galvapac 1K Zinc Primer NSF: Protective & Marine CoatingsDocument4 pagesCorothane I Galvapac 1K Zinc Primer NSF: Protective & Marine CoatingsScott NorrisNo ratings yet

- Carbozinc 11 HS PDSDocument2 pagesCarbozinc 11 HS PDSvietrossNo ratings yet

- Polyclad ARO PDSDocument4 pagesPolyclad ARO PDSPammy JainNo ratings yet

- Plastics in Building Structures: Proceedings of a Conference Held in London, 14-16 June 1965From EverandPlastics in Building Structures: Proceedings of a Conference Held in London, 14-16 June 1965No ratings yet

- Corrosion Testing for Metal Finishing: Institute of Metal FinishingFrom EverandCorrosion Testing for Metal Finishing: Institute of Metal FinishingNo ratings yet

- METALCLAD CeramAlloy CPAC PDFDocument2 pagesMETALCLAD CeramAlloy CPAC PDFskNo ratings yet

- Onshore Ancillary Steel Structures: Dep SpecificationDocument19 pagesOnshore Ancillary Steel Structures: Dep Specificationsk100% (4)

- Engineering Standard for Refractory SystemsDocument25 pagesEngineering Standard for Refractory SystemszsmithNo ratings yet

- Chemclad SC PDFDocument2 pagesChemclad SC PDFskNo ratings yet

- DuralloyDocument2 pagesDuralloyAlfred GomoeliaNo ratings yet

- Thermo-Lag 3000-P PDS PDFDocument7 pagesThermo-Lag 3000-P PDS PDFskNo ratings yet

- METALCLAD CeramAlloy CLAC PDFDocument2 pagesMETALCLAD CeramAlloy CLAC PDFskNo ratings yet

- Technowrap H.A. Resin (Part A) PDFDocument6 pagesTechnowrap H.A. Resin (Part A) PDFskNo ratings yet

- Technowrap H.A. Hardener (Part B) PDFDocument6 pagesTechnowrap H.A. Hardener (Part B) PDFskNo ratings yet

- Technowrap 2K Cloth CS PDFDocument2 pagesTechnowrap 2K Cloth CS PDFskNo ratings yet

- ICR Gulf Brochure PDFDocument2 pagesICR Gulf Brochure PDFskNo ratings yet

- Loctite SDS PDFDocument15 pagesLoctite SDS PDFskNo ratings yet

- World Class: Integrity & Maintenance SolutionsDocument2 pagesWorld Class: Integrity & Maintenance SolutionsskNo ratings yet

- Abrasive Blast Media Quick Selection Guide: Single Use Surface Preparation MediaDocument1 pageAbrasive Blast Media Quick Selection Guide: Single Use Surface Preparation MediaskNo ratings yet

- Avme Export-04.09.19Document5,350 pagesAvme Export-04.09.19skNo ratings yet

- Plural Component XP70 Graco MachineDocument8 pagesPlural Component XP70 Graco MachineskNo ratings yet

- Enviroline 2405 Application Guidelines: Protective Coatings Technical SupportDocument12 pagesEnviroline 2405 Application Guidelines: Protective Coatings Technical SupportskNo ratings yet

- Enviroline 405HTR+wp+eng PDFDocument12 pagesEnviroline 405HTR+wp+eng PDFskNo ratings yet

- Details of AbrasivesDocument6 pagesDetails of AbrasivesskNo ratings yet

- Duqm Refinery RAM ChecklistDocument8 pagesDuqm Refinery RAM ChecklistskNo ratings yet

- Material Safety Data SheetDocument4 pagesMaterial Safety Data SheetskNo ratings yet

- Garnet SpecificationDocument2 pagesGarnet SpecificationskNo ratings yet

- Garnet Technical Data Sheet: Distribution Can Be Expected To Be Within The Above Value. For: Salgo MineralsDocument1 pageGarnet Technical Data Sheet: Distribution Can Be Expected To Be Within The Above Value. For: Salgo MineralsskNo ratings yet

- Details of AbrasivesDocument6 pagesDetails of AbrasivesskNo ratings yet

- Duqm Refinery RAM ChecklistDocument8 pagesDuqm Refinery RAM ChecklistskNo ratings yet

- 693b Chockfast Orange Hardener Ratio Guide For Chocking Between Steel SteelDocument2 pages693b Chockfast Orange Hardener Ratio Guide For Chocking Between Steel SteelDiego PachecoNo ratings yet

- The Effect of Eggshell Powder As Partial Supplement of Ordinary Portland Cement On The Compressive Strength of Sandcrete BlocksDocument4 pagesThe Effect of Eggshell Powder As Partial Supplement of Ordinary Portland Cement On The Compressive Strength of Sandcrete BlocksArun anandNo ratings yet

- BS en 1708-1 (2010)Document76 pagesBS en 1708-1 (2010)Peter TvardzíkNo ratings yet

- Aluminium SulphateDocument3 pagesAluminium SulphateAbinov Kumar KTNo ratings yet

- FormulaShell SAE 10W 40 Motor Oil DatasheetDocument3 pagesFormulaShell SAE 10W 40 Motor Oil DatasheetAnonymous YjoCCKNo ratings yet

- Polymers 15 00276 v3 1Document13 pagesPolymers 15 00276 v3 1Vadim LevinNo ratings yet

- 0620 w17 QP 22 PDFDocument16 pages0620 w17 QP 22 PDFyuke kristinaNo ratings yet

- Final Real Muhammad ThesisDocument67 pagesFinal Real Muhammad ThesisBeckyNo ratings yet

- Measuring and Cutting Tools for SewingDocument4 pagesMeasuring and Cutting Tools for SewingRodnick Bodino100% (1)

- Panlite® L-1225YDocument3 pagesPanlite® L-1225YLiew FongNo ratings yet

- Muhammad Tunggal Rifat Case StudyDocument5 pagesMuhammad Tunggal Rifat Case StudyAdib RizqullohNo ratings yet

- Te ML 03 Am Pracovni Stroje Planetove Prevodovky en PDFDocument12 pagesTe ML 03 Am Pracovni Stroje Planetove Prevodovky en PDFMiroslav MilosevskiNo ratings yet

- Activity 13Document13 pagesActivity 13Lielannie CarasiNo ratings yet

- Industrial Training Presentation on Spare Parts of Hot Mix PlantDocument19 pagesIndustrial Training Presentation on Spare Parts of Hot Mix PlantRiya Tripathi100% (1)

- JIS G3452: Carbon Steel Pipes For Ordinary PipingDocument1 pageJIS G3452: Carbon Steel Pipes For Ordinary PipingHoJienHauNo ratings yet

- Jake Joonyong Choi Balancing Equations Master Problem Set KISJ 2022 2Document17 pagesJake Joonyong Choi Balancing Equations Master Problem Set KISJ 2022 2Jonghyun (Justin) YangNo ratings yet

- Friction and Wear of PTFE - A Review: S. K. BiswasDocument19 pagesFriction and Wear of PTFE - A Review: S. K. BiswasAnnamalai PalaniappanNo ratings yet

- Steps in production of titanium from ore to ingotsDocument4 pagesSteps in production of titanium from ore to ingotsUyGrEdSQNo ratings yet

- Chemical Bonding KSSMDocument39 pagesChemical Bonding KSSMjayaselan100% (1)

- Week010 LaboratoryExercise003 AcidsandBasesSolubilityEquilibriaDocument9 pagesWeek010 LaboratoryExercise003 AcidsandBasesSolubilityEquilibriarejlarracasNo ratings yet

- Reclamation of Recycled Aggregate Base (RAB) Material: Standard Practice ForDocument5 pagesReclamation of Recycled Aggregate Base (RAB) Material: Standard Practice ForRed RedNo ratings yet

- SECTION 09 65 16.33 SECTION TITLE: Rubber Sheet Flooring: 1.1 Related DocumentsDocument3 pagesSECTION 09 65 16.33 SECTION TITLE: Rubber Sheet Flooring: 1.1 Related DocumentsTheJohnnyBravoooNo ratings yet

- Ferrous: AlloysDocument18 pagesFerrous: AlloyssunsirNo ratings yet

- Asmeviii Uw EDocument196 pagesAsmeviii Uw ETâm NgôNo ratings yet

- Design of Concrete Mixes .Hw3Document12 pagesDesign of Concrete Mixes .Hw3RawandAlbarodyNo ratings yet

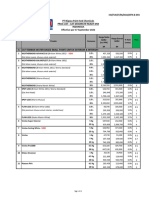

- PT Nipsea Paint and Chemicals Price List - Cat Dekoratif Ready Mix Indonesia Effective Per 17 September 2022Document12 pagesPT Nipsea Paint and Chemicals Price List - Cat Dekoratif Ready Mix Indonesia Effective Per 17 September 2022Ade Ihsan MaulanaNo ratings yet

- AireFrig Flyer 2016 V25Document2 pagesAireFrig Flyer 2016 V25Ong MatNo ratings yet

- COD Practical 6Document11 pagesCOD Practical 6Gilbert NdibeNo ratings yet

- Product Catalog Butterfly 2018Document7 pagesProduct Catalog Butterfly 2018Jamal MeliNo ratings yet

- STYLE 4400 / 4000 / 4100 SPECIFICATIONS: With Dow EcolibriumDocument4 pagesSTYLE 4400 / 4000 / 4100 SPECIFICATIONS: With Dow EcolibriumEfrain LangaricaNo ratings yet