Professional Documents

Culture Documents

693b Chockfast Orange Hardener Ratio Guide For Chocking Between Steel Steel

Uploaded by

Diego PachecoOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

693b Chockfast Orange Hardener Ratio Guide For Chocking Between Steel Steel

Uploaded by

Diego PachecoCopyright:

Available Formats

CHOCKFAST ® Orange

Hardener Ratio Guide

for Chocking Between Steel & Steel

Technical Bulletin # 693B

Bulletin Description

The purpose of the hardener in every epoxy compound or coating is to cause a reaction to that will result

in the hardening of the epoxy resin. This reaction usually creates heat within the epoxy that forces the

molecules to cross-link and bond tightly together. Depending on the type and quantity of resin, additives

and hardener used, the final epoxy product will have certain physical properties such as compressive

strength, flexibility, hardness, shear strength, shock resistance, etc.

The overwhelming majority of epoxy compounds have a fixed ratio of resin to hardener that results in a

product with predictable physical properties. However, rather than specify an exact amount of hardener

to use with CHOCKFAST Orange, ITW Polymer Technologies asks the end user to determine the

correct amount for a particular installation that will cause the compound to achieve maximum physical

properties strength. The amount of hardener is determined based on the temperature of the steel of the

surrounding chock and the thickness of the chock.

By varying the amount of hardener used, the reaction that takes place between the resin and the

hardener can be managed. The goal is to achieve a relatively high exothermic heat within the

CHOCKFAST without causing it to either boil or crack. It is this high heat that gives CHOCKFAST

Orange its exceptional strength characteristics.

Using CHOCKFAST Orange between two pieces of steel is different that using it between steel and

concrete or steel and epoxy. Steel has a much greater ability to absorb heat from the CHOCKFAST

during the curing process. For this reason, slightly more hardener is used when pouring CHOCKFAST

between two pieces of steel.

Application Instructions

Note that before mixing the resin and hardener that the resin

temperature should be in the range 20º to 25ºC (68º-77ºF).

HARDENER

PR 610 TCF

The maximum amount of hardener possible should normally

be used. The graph on the following page is for guidance and

the optimum amount will usually be slightly more than it

shows.

Hardener

After puncturing the metal foil seal, the hardener bottle is Reduction Pour Squeeze in ALL

inverted and squeezed to discharge the hardener into the Lines BUT this amount

resin container. The hardener reduction lines are to be read Full Reduction

with the bottle inverted as shown. of hardener

3/4 Reduction

Dispose of excess hardener in an approved manner and do 1/2 Reduction

not collect the remainder of several bottles in one bottle as it 1/4 Reduction

may be mistaken for a complete hardener unit. It is usually

best to mix left over hardener in the empty cans of

CHOCKFAST. The hardener will combine with the left over

resin and become inert.

ITW POLYMER TECHNOLOGIES

130 Commerce Drive Montgomeryville, PA 18936 215-855-8450 Fax 215-855-4688

www.chockfastgrout.com

CHOCKFAST Orange Hardener Ratio Guide

Bulletin No. 693B, Page 2

Date 09/2005

Steel Temperature, oF

40 50 60 68 77 86 95 104 113

100 4

9

3 16

LAYERED POURS 1

80 FU 3

Chock Thickness, inches

LL 8

H

Chock Thickness, mm

AR

DE 3

NE

RR

2 4

ED 3

60 3/4 UC 2

T IO 8

RE N

1/2 DU

RE CT 2

1 /4 DU ION

RE CT

DU I ON 9

40 CT 1 16

ION

3

NO 1 16

HA

APPLY HEAT AFTER R DE

20 RESIN HARDENS NE 3/4

R RE

DU 3/8

CT

IO N

5 10 15 20 25 30 35 40 45

Steel Temperature, oC

Steel Temperature, oF

40 50 60 68 77 86 95 104 113

100 4

9

3 16

LAYERED POURS 1

80 FU 3

Chock Thickness, inches

LL 8

Example: H

Chock Thickness, mm

AR

DE 3

NE

RR

2 4

40 mm (1-9/16”) chocks 60 3/4

RE

ED

UC

TIO 2

3

8

DU N

1/2

& a steel temperature of 1/4

RE

DU

CT

CT

ION 2

RE

27o C (80o F) requires a 40 DU

CT

ION

ION

1 169

1/4 Hardener Reduction NO 1 163

HA

APPLY HEAT AFTER RD

20 RESIN HARDENS

EN

ER

3/4

RE

DU 3/8

CT

ION

5 10 15 20 25 30 35 40 45

Steel Temperature, oC

General: Every reasonable effort is made to insure the technical information and Suggestions concerning the use of products are not warranties. The purchaser

recommendations on these data pages are true and accurate to the best of our assumes the responsibility for determining suitability of products and appropriate

knowledge at the date of issuance. However, this information is subject to change use. ITW Polymer Technologies’ sole liability, for breach of warranty, negligence

without notice. Prior versions of this publication are invalid with the release of this or otherwise, shall be the replacement of product or refund of the purchase price,

version. Products and information are intended for use by qualified applicators that at ITW Polymer Technologies’ election. Under no circumstances shall ITW

have the required background, technical knowledge, and equipment to perform said Polymer Technologies be liable for any indirect, incidental or consequential

tasks in a satisfactory manner. Consult your local distributor for product availability, damages.

additional product information, and technical support. Modification of Warranty: No distributor or sales representative has the authority

Warranty: ITW Polymer Technologies, a division of Illinois Tool Works Inc., warrants to change the above provisions. No change in the above provisions will be valid

that its products meet their printed specifications. This is the sole warranty. This unless in writing and signed by an officer or the Technical Director of ITW

warranty expires one year after product shipment. Polymer Technologies. No term of any purchase order shall serve to modify any

Warranty Claims: If any product fails to meet the above, ITW Polymer Technologies provision of this document.

will, at its option, either replace the product or refund the purchase price. ITW Mediation and Arbitration: If any dispute arises relating to products or product

Polymer Technologies will have no other liability for breach of warranty, negligence, or warranties, either the purchaser or ITW Polymer Technologies may a) initiate

otherwise. All warranty claims must be made in writing within one year of the date of mediation under the then current Center for Public Resources (CPR) Model

shipment. No other claims will be considered. Procedure for Mediation of Business Disputes, or b) initiate a non-binding

Disclaimer: ITW Polymer Technologies makes no other warranty, expressed or arbitration under the rules of the American Arbitration Association for the

implied, and specifically disclaims any warranty of merchantability or fitness for a resolution of commercial disputes.

particular purpose.

You might also like

- 665b Chockfast Orange Hardener Ratio Guide For Chocking Between Steel ConcrDocument2 pages665b Chockfast Orange Hardener Ratio Guide For Chocking Between Steel ConcrRizky RamadhanNo ratings yet

- 106836-PC-915-9in-X-15in Screen For Intake WaterDocument1 page106836-PC-915-9in-X-15in Screen For Intake Waterrusli bahtiarNo ratings yet

- Rim Seal Pourer Data SheetDocument3 pagesRim Seal Pourer Data Sheetadilmomin45No ratings yet

- 43 151 Throttle BushingDocument2 pages43 151 Throttle BushingJMU SELLOS MECANICOSNo ratings yet

- 1.9.1.2-80T - 18 8 Stainless SteelDocument4 pages1.9.1.2-80T - 18 8 Stainless SteelDevan ShanmughaNo ratings yet

- Kudu Bro New Pump Models Int A4 WebDocument2 pagesKudu Bro New Pump Models Int A4 WebXXXXNo ratings yet

- C 813 M Pyroflex 1080 PrimerDocument1 pageC 813 M Pyroflex 1080 PrimerJuan Piedra100% (1)

- 2018 Stonage Fittings and Accessories WebDocument35 pages2018 Stonage Fittings and Accessories WeblupiNo ratings yet

- 2024 Mahle Motorsport Porsche Application GuideDocument12 pages2024 Mahle Motorsport Porsche Application GuideYassine GhoulNo ratings yet

- Jackson Industries Fluoropolymer Hose CatalogDocument24 pagesJackson Industries Fluoropolymer Hose CatalogUS Hose CorporationNo ratings yet

- 4300 lf4300 TFDocument2 pages4300 lf4300 TFArguetaManuelNo ratings yet

- SHEET No 10 FLANGE GUSSETS AND REINFORCEMENTS DETAILDocument1 pageSHEET No 10 FLANGE GUSSETS AND REINFORCEMENTS DETAILKarikalan JayNo ratings yet

- ContinueDocument2 pagesContinueTANNo ratings yet

- Basf Masterroc Sa 190 TdsDocument3 pagesBasf Masterroc Sa 190 TdsHalit Baris SertbakanNo ratings yet

- Colourplex Pigments RockwoodDocument2 pagesColourplex Pigments Rockwoodwe_alteregoNo ratings yet

- Manual de Instalación y Operación Compas Autohelm ST 30 CompDocument39 pagesManual de Instalación y Operación Compas Autohelm ST 30 ComppevalpevalNo ratings yet

- 55 Emerson Catalog PDFDocument82 pages55 Emerson Catalog PDFBRLSwamyNo ratings yet

- Ascotran: Flash-Rust / In-Can ProtectionDocument6 pagesAscotran: Flash-Rust / In-Can ProtectiondiablomatiNo ratings yet

- ABB Motor Painting SpecificationDocument2 pagesABB Motor Painting SpecificationNhien ManNo ratings yet

- 1.9.1.2-85T - 316 Stainless SteelDocument4 pages1.9.1.2-85T - 316 Stainless SteelfendynovapamelaNo ratings yet

- Waukesha C Series Pump Seal Parts Uid2132010814401Document5 pagesWaukesha C Series Pump Seal Parts Uid2132010814401Ибрагим НурмамедовNo ratings yet

- Rim Seal Foam Pourer: Model - Rpa & Rpa-SDocument2 pagesRim Seal Foam Pourer: Model - Rpa & Rpa-SEdward Chan AcostaNo ratings yet

- Chempump 500 SeriesDocument20 pagesChempump 500 Seriesozeias.rosaNo ratings yet

- NC 559 Asm TF PDFDocument2 pagesNC 559 Asm TF PDFroto44No ratings yet

- HD - SPS-9 Foam MakerDocument4 pagesHD - SPS-9 Foam MakerJavier Hinojosa Garrido LeccaNo ratings yet

- Ia120-B KTX PDFDocument2 pagesIa120-B KTX PDFRuddy Fabrizio Galvez JustinianoNo ratings yet

- MS27971ADocument1 pageMS27971ABogdan RusuNo ratings yet

- Ptfe Bellows Seals: Product Description Performance CapabilitiesDocument8 pagesPtfe Bellows Seals: Product Description Performance CapabilitiesHortensia Faundes VenegasNo ratings yet

- 18CO5009-10-It2-C04 Bill of MaterialsDocument7 pages18CO5009-10-It2-C04 Bill of MaterialsGerencia Rigar Colombia SASNo ratings yet

- Napca Bulletins 1-65-94 Thru 17-98Document72 pagesNapca Bulletins 1-65-94 Thru 17-98lemuel bacsaNo ratings yet

- Tapping Saddle DimensionsDocument4 pagesTapping Saddle DimensionsAnonymous IgzACaiNo ratings yet

- Chemical Resistance Chart: What We Need To KnowDocument7 pagesChemical Resistance Chart: What We Need To Knowcipta karyaNo ratings yet

- HC95 - LQDocument20 pagesHC95 - LQonur tezmanNo ratings yet

- Tafa Arc Spray Wire 1.9.1.2-60T - Arc Spray 13% Chrome SteelDocument5 pagesTafa Arc Spray Wire 1.9.1.2-60T - Arc Spray 13% Chrome SteelCarlos Gabriel EstergaardNo ratings yet

- 09 TL-SH26-0001 Cementing PlugDocument6 pages09 TL-SH26-0001 Cementing PlugMaria ArdilaNo ratings yet

- 4" End Port Pressure Vessel: Working Pressure: Assembly Drawing: Working Temperature: Design CodeDocument2 pages4" End Port Pressure Vessel: Working Pressure: Assembly Drawing: Working Temperature: Design CodeStathis MoumousisNo ratings yet

- Pro Catalog FinalDocument12 pagesPro Catalog FinalPatrick NowickNo ratings yet

- Newlegalline Brochure PT600 EN NEW PrevDocument4 pagesNewlegalline Brochure PT600 EN NEW PrevKennedy TavaresNo ratings yet

- CFP Threaded Quick Couplings: DescriptionDocument1 pageCFP Threaded Quick Couplings: DescriptionJhonny MorenoNo ratings yet

- 200 SeriesDocument4 pages200 Serieslacsmm982No ratings yet

- Long Retractable Sootblower: EAPC Poppet ValveDocument2 pagesLong Retractable Sootblower: EAPC Poppet Valvekvsagar100% (1)

- NC-559-ASM, No-Clean Solder Paste: Product Data SheetDocument2 pagesNC-559-ASM, No-Clean Solder Paste: Product Data SheetAkhmad MukhsinNo ratings yet

- Metco105TechnicalBulletin PDFDocument8 pagesMetco105TechnicalBulletin PDF張政雄100% (1)

- Basket Strainer F85CS FabrotechDocument1 pageBasket Strainer F85CS FabrotechhugoheloNo ratings yet

- Production Testing Solutions Choke Manifold: FeaturesDocument1 pageProduction Testing Solutions Choke Manifold: FeaturesTiffany DacinoNo ratings yet

- LP15 Blow Out Preventer: Key Features Lp15 BopDocument2 pagesLP15 Blow Out Preventer: Key Features Lp15 Bopjesf_2014No ratings yet

- Simacover EP Tar Epoxy 3404-00Document4 pagesSimacover EP Tar Epoxy 3404-00Perseroan MustikaNo ratings yet

- S Fsd165 TurboDocument4 pagesS Fsd165 Turbobillel limaneNo ratings yet

- Bulletin 6853 New! Series 60 90 Optional EPR SiC SiC Seal 7 2010 PDFDocument4 pagesBulletin 6853 New! Series 60 90 Optional EPR SiC SiC Seal 7 2010 PDFAnonymous 7xHNgoKE6eNo ratings yet

- Roduct Ata Heet Chivacure TPODocument2 pagesRoduct Ata Heet Chivacure TPOmario3312No ratings yet

- Pressure Control GroupDocument4 pagesPressure Control GroupAbdelhamid HaramiNo ratings yet

- LM Folder Na EngDocument4 pagesLM Folder Na EngBesar WicaksonoNo ratings yet

- Protech Seal BrochureDocument10 pagesProtech Seal BrochureRodrigo Jechéla Barrios0% (1)

- Installation Method For Pro Series Head Bolt Kits: 200,000 PSI 7/16 Inch DiameterDocument1 pageInstallation Method For Pro Series Head Bolt Kits: 200,000 PSI 7/16 Inch DiameterDamien DrakeNo ratings yet

- Kosiarka - Birgs - Spare-PartsDocument12 pagesKosiarka - Birgs - Spare-Partsallegro.ds.spinNo ratings yet

- Hd115 - Pressur GaugeDocument2 pagesHd115 - Pressur GaugeKumararaja KonikkiNo ratings yet

- Innovate Confidently: Exxonmobil Advanced Synthetic Base StocksDocument19 pagesInnovate Confidently: Exxonmobil Advanced Synthetic Base StocksDamienNo ratings yet

- 5700B Sootblower Set: Chemical ResistanceDocument1 page5700B Sootblower Set: Chemical Resistanceadkon mksNo ratings yet

- Solder Paste LiteratureDocument1 pageSolder Paste LiteraturescmeswarNo ratings yet

- Voltaic Cell - Yale UniversityDocument4 pagesVoltaic Cell - Yale UniversityBelenNo ratings yet

- Epoxy CuringDocument8 pagesEpoxy CuringUrban Renewal Development100% (1)

- ACE Hammer CatalogueDocument8 pagesACE Hammer CatalogueAgung NgurahNo ratings yet

- Rubber DurabilityDocument19 pagesRubber DurabilityZelzozo Zel ZozoNo ratings yet

- TriNano Ultra Precision CMM (White Paper)Document6 pagesTriNano Ultra Precision CMM (White Paper)TriNanoNo ratings yet

- Datasheet of ESPSHC 410-450 (166x166)Document2 pagesDatasheet of ESPSHC 410-450 (166x166)Engetaic engenhariaNo ratings yet

- Commscope Trunk & Distribution Cable ProductsDocument51 pagesCommscope Trunk & Distribution Cable ProductsMauro Barragan SanchezNo ratings yet

- Aqua Mats 2005 SDFspecsheet R6Document1 pageAqua Mats 2005 SDFspecsheet R6indomie11No ratings yet

- Quab Cationization of PolymersDocument11 pagesQuab Cationization of PolymersJose Luis Recalde AriasNo ratings yet

- BS 4514 2001 PDFDocument18 pagesBS 4514 2001 PDFanas shehabi100% (1)

- TD Operators ManualDocument84 pagesTD Operators Manualsivan_sg1800No ratings yet

- Analysis of Ink by TLCDocument7 pagesAnalysis of Ink by TLCkeshavNo ratings yet

- CAT8 EN 100dpi Gesamt PDFDocument391 pagesCAT8 EN 100dpi Gesamt PDFaleksandarpmauNo ratings yet

- Acroni PDFDocument15 pagesAcroni PDFIgor GrujićNo ratings yet

- A Method of Approximate Tool Wear Analysis in Cold Roll FormingDocument6 pagesA Method of Approximate Tool Wear Analysis in Cold Roll FormingAly MahdyNo ratings yet

- 30 Years of Successes and Failures in Geopolymer Applications. Market Trends and Potential BreakthroughsDocument1,167 pages30 Years of Successes and Failures in Geopolymer Applications. Market Trends and Potential Breakthroughsknight1729100% (1)

- Downhole Gas CompressionDocument40 pagesDownhole Gas CompressionYasir Mumtaz100% (2)

- Pannaipatty - Compound WallDocument38 pagesPannaipatty - Compound WallrkpragadeeshNo ratings yet

- 6-Absorption Stripping Pt1Document18 pages6-Absorption Stripping Pt1Naufal FasaNo ratings yet

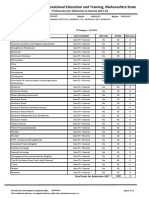

- DVET Amravati Govt ITIDocument32 pagesDVET Amravati Govt ITIVaibhav KaleNo ratings yet

- Randhol - Ensuring Well Integrity in Connection With CO2 InjectionDocument59 pagesRandhol - Ensuring Well Integrity in Connection With CO2 InjectionLauren AndersonNo ratings yet

- Polyamide (PA) - Grilamid TR 90Document36 pagesPolyamide (PA) - Grilamid TR 90anilsamuel0077418No ratings yet

- Cold StorageDocument5 pagesCold StorageNilesh ThoraveNo ratings yet

- Long Life Bearing Series: CAT - NO.199EDocument5 pagesLong Life Bearing Series: CAT - NO.199EJhefferson FreitasNo ratings yet

- Recycle and Management of Waste Lead Acid BatteriesDocument9 pagesRecycle and Management of Waste Lead Acid BatteriesJoyce Wm WongNo ratings yet

- Best Practices On Solid Waste Management of Mandaue CityDocument85 pagesBest Practices On Solid Waste Management of Mandaue Cityjoanna gurtiza100% (1)

- Chapter 1Document16 pagesChapter 1Robeam SolomonNo ratings yet

- Lecture 02 01 Process DevelopmentDocument20 pagesLecture 02 01 Process DevelopmentDon ReloNo ratings yet

- Bondek User GuideDocument0 pagesBondek User GuidemarioxguzmanNo ratings yet

- Summer Internship At: Haldia Petrochemicals LTDDocument11 pagesSummer Internship At: Haldia Petrochemicals LTDJyoti PrakashNo ratings yet