Professional Documents

Culture Documents

Abrasive Blast Media Quick Selection Guide: Single Use Surface Preparation Media

Uploaded by

skOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Abrasive Blast Media Quick Selection Guide: Single Use Surface Preparation Media

Uploaded by

skCopyright:

Available Formats

ABRASIVE BLAST MEDIA QUICK SELECTION GUIDE

1. ABRASIVE 2. RECYCLABILITY 3. DUST FACTOR 4. SPEED OF BLAST (LIGHT TO 5. SPEED OF BLAST 6. ENVIRONMENTAL AND WORKPLACE 7. PROFILE AVAILABLE 8. SIZING 9. PACKAGING 10. COMMENTS

MEDIUM COATING REMOVAL) (HEAVY COATING REMOVAL) HEALTH & SAFETY COMPLIANCE

SINGLE USE SURFACE PREPARATION MEDIA

Garnet Excellent Very low Very high Medium Excellent Up to 80um 30 – 60#, 80# 25kg bags The nature of garnet makes it suitable for removing a broad range of

4 – 8 cycles 2t bags containments from many different substrates. In addition it provides

1t bags a high production rate and is compliant with environmental and

occupational Health and Safety requirements.

Metallic Slags Limited High Low High Contains heavy metals check with 30—50um .75mm, 1.3mm, 2.0mm 25kg paper bags Has limited use in removing elastomeric or very thick coatings.

2 cycles max relevant authorities before using 1tonne bulk bags

Produces coarse angular profile

2tonne bulk bags

which may cause difficulties in

achieving even film build over

blasted substrate.

Ilmenite Nil Very high Very high Poor Some sources of Ilmenite have registered 25kg paper bags Main applications for Ilmenite are removing lightly adhered

excessive levels of radioactivity 1tonne bulk bags mill scale on new steel and whip blending of sound coatings

2tonne bulk bags prior to recoat work.

Crushed Glass Nil Very high Medium High Airborne particles are aggressively irritating Very low .75mm, 1.0mm, 2.0mm 2tonne bulk bag Has limited use in removing elastomeric or very thick coatings.

to eyes, skin and the respiratory system

Crushed Limestone Nil Very high High Very high Can contain high levels of silica Nil Not applicable—only available in one blend of sizes 25kg paper bags Used for removing paint from brickwork and timber and existing

–wet blasting check with workplace health and safety suitable for particular application coatings from galvanised surfaces.

recommended authorities before using

Staurolite Nil Moderate Medium Very low No known problems Very Low 0.3mm 25kg paper bags A fine, low-cost abrasive that has limited application for mill scale

and light rust removal.

MULTI USE SURFACE PREPARATION MEDIA

Chilled Iron Grit Excellent Very low Very high Very high No known problems. Very fine to very coarse G05 (0.12 – 0.3mm), G07 (0.18 – 0.42mm), 25kg bags The hardest and fastest performing of the iron/steel family of abrasive

up to 200 cycles (dependent on grade) (dependent on grade) (dependent on selected size) G12 (0.3 – 0.7mm), G17 (0.42 – 0.85mm), blasting media.

G24 (0.6 – 1.0mm), G39 (0.85 – 1.2mm),

G55 (1.4 – 2.0mm)

Steel Grit Up to 1000 cycles Very low High Very high No known problems Very fine to very coarse GL07/80 (0.18 – 0.42), GL11/50 (0.3 – 0.7), 25kg bags Extremely long-lasting abrasive, longer life than chilled iron, however,

(dependent on grade) (dependent on grade) (dependent on selected size) GL17/40 (0.42 – 1.0), GL28/25 (0.7 – 1.2), ‘rounds up’ with use, reducing profile and performance.

GL39/18 (1.0 – 1.4), GL46/16 (1.2 – 1.7)

Steel Shot Excellent Very low Very Low (specialist applications Very Low (specialist No known problems Very fine to very coarse S110 (0.3 – 0.5mm), S170 (0.42 – 0.7mm), 25kg bags Designed for use in airless wheel blast machines; see detailed

up to 1000 cycles —not suited to corrosion control) applications—not suited to (dependent on selected size) S230 (0.6 – 0.85mm), S460 (1.2 – 1.7mm), description in following section for further details.

corrosion control) S550 (1.4 – 2.0mm), S660 (1.7 – 2.3mm)

Silicon Carbide/ Very good Very low Not applicable—not used for Not applicable—not used for No known problems Produces angular profile which is 10#, 12#, 14# 16#, 20#, 24#, 30#, 36#, 46#, 25kg bags Used as surface preparation prior to hot metal spraying,

aluminium Oxide up to 100 cycles corrosion control applications corrosion control applications required for anchoring metallic and 60#, 80#, 100#, 120#, 150#, 180#, 220#, 240# plating or ceramic coatings.

ceramic coatings.

SINGLE USE CLEANING MEDIA

Sodium Bicarbonate Nil High (wet blasting Medium (dependent on grade As above Use protection against nuisance dust Nil Not applicable—different grades focus different 25kg bags Main use is for removing contaminants without

recommended) —will remove coatings but will formulations rather then different sizing damaging the substrate.

not profile substrates)

MULTI USE CLEANING MEDIA

Glass Bead Very good Not applicable Very good Very good Used mainly in enclosed cabinets Not applicable—used where A(850 – 600um), B (600-425um), C (425 – 250um) 25kg bags Main use is for coating and contaminant removal on soft surfaces.

(dependent on size) (dependent on size) —exposure is limited profiling of substrate is undesirable AB (300 – 780um), AC (250 – 150um),

AD (212 – 106um), AE (150 – 90um),

AH (90 – 44um), AI (<53um), INDA (300 – 106um)

Plastic Media Good Nil Very good Very good No known problems Not applicable—used where 50kg barrel Main applications is for removing coatings from plastic componentry.

(dependent on size) (dependent on size) profiling of substrate is

undesirable.

Sponge Media Excellent Nil—designed to Low (where the decision has been Low (where the decision has No known problems Varies dependent upon grade, EMB-MF (maintenance media), EMB-DM (Plastic 20, 30 or 40 bulk bags The main benefit of sponge media is it’s capacity to absorb dust and

absorb removed made to use sponge media its been made to use sponge some use soft media to minimise media), EMB-WM (Walnut media), EMB-AL220 containments resulting from the blasting operation.

containment inherent attributes will outweigh media its inherent attributes profile, others contain aluminium (220# aluminium oxide), EMB-AL80 (80# aluminium

the low production rate) will outweigh the low oxide for maximum aggression oxide), EMB-AL60 (60# aluminium oxide),

production rate) EMB-AL30 (30# aluminum oxide)

02 | ABRASIVE TYPES AND SELECTION | Understanding Corrosion Control BLASTECH BLASTECH Understanding Corrosion Control | ABRASIVE TYPES AND SELECTION | 03

You might also like

- Sika PDS - E - Icosit KC 340-65Document2 pagesSika PDS - E - Icosit KC 340-65lwin_oo2435No ratings yet

- Sika PDS - E - Icosit KC 340-65 PDFDocument2 pagesSika PDS - E - Icosit KC 340-65 PDFlwin_oo2435No ratings yet

- Rubber & Its PropertiesDocument20 pagesRubber & Its PropertieskeshunaNo ratings yet

- SITE BOOK Plaster Systems PDFDocument20 pagesSITE BOOK Plaster Systems PDFSam SadeqNo ratings yet

- Graniterior EXDocument2 pagesGraniterior EXChristinaNo ratings yet

- Ultima Protek Duralife NewDocument2 pagesUltima Protek Duralife NewBapun Ben KartikNo ratings yet

- Assignment No.-1 Study of Coir Fiber Name:-Shweta Chaudhri BATCH:-2019-23Document5 pagesAssignment No.-1 Study of Coir Fiber Name:-Shweta Chaudhri BATCH:-2019-23Shweta ChaudhriNo ratings yet

- JACOBI-TDS-AQUASORB-80-A4-ENG-C0715Document2 pagesJACOBI-TDS-AQUASORB-80-A4-ENG-C0715Hakim BenNo ratings yet

- Abecote PU: Flexible Polyurethane CoatingDocument2 pagesAbecote PU: Flexible Polyurethane Coatingengramir07No ratings yet

- Insula'on: Technical SpecificationsDocument2 pagesInsula'on: Technical SpecificationsAron GebregiorgisNo ratings yet

- Corroseal TE 321 Rev 01Document1 pageCorroseal TE 321 Rev 01Ashif AkhtarNo ratings yet

- Conveyor Belt BandoDocument6 pagesConveyor Belt BandohadiNo ratings yet

- Industrial Product List A P.U. Paint: SR - No. Product Name Availability Packing Details Unithane 900 Exterior DurabilityDocument3 pagesIndustrial Product List A P.U. Paint: SR - No. Product Name Availability Packing Details Unithane 900 Exterior DurabilityS.MadhanNo ratings yet

- Synthetic FiberDocument20 pagesSynthetic FiberLengamo L AppostilicNo ratings yet

- Nanotechnology Applications in TextilesDocument24 pagesNanotechnology Applications in Textilessathieswaran80% (5)

- Hetron 922 Infusion Resin 45 en A4Document1 pageHetron 922 Infusion Resin 45 en A4uzzy2No ratings yet

- CemFIL AntiCrak HP 6736 Product Sheet WW 10-2014 Rev8 en FinalDocument2 pagesCemFIL AntiCrak HP 6736 Product Sheet WW 10-2014 Rev8 en FinalvliegenkristofNo ratings yet

- PolyethyleneDocument31 pagesPolyethyleneHesham chemecology100% (1)

- Protect Metal Surfaces with Asian Paints Grey Epoxy PrimerDocument2 pagesProtect Metal Surfaces with Asian Paints Grey Epoxy PrimerSubish PunnooseNo ratings yet

- An Investigation On The Effect of Partial Replacement of Cement by Zeolite On The Properties of ConcreteDocument5 pagesAn Investigation On The Effect of Partial Replacement of Cement by Zeolite On The Properties of ConcreteAnonymous kw8Yrp0R5rNo ratings yet

- Product Data Sheet: 24K Carbon TowDocument1 pageProduct Data Sheet: 24K Carbon TowsaadnaumanNo ratings yet

- Cellulose Fibre EngDocument4 pagesCellulose Fibre EngMAKRONNo ratings yet

- (Pds b.02 005) Bostik Ultracote Rc2Document2 pages(Pds b.02 005) Bostik Ultracote Rc2LexyNo ratings yet

- Seminor On Basalt Rock Fibre: Rajeev Gandhi Memorial College of Engineering and Technology AutonomousDocument22 pagesSeminor On Basalt Rock Fibre: Rajeev Gandhi Memorial College of Engineering and Technology AutonomousGuttha Sravan Kumar ChowdharyNo ratings yet

- VT Corp Cement BroucherDocument9 pagesVT Corp Cement BrouchersanketvtcorpNo ratings yet

- Ropes and Wires: Malaysian Maritime Academy/Seamanship/May2003 1 of 6Document6 pagesRopes and Wires: Malaysian Maritime Academy/Seamanship/May2003 1 of 6Rohit SinghNo ratings yet

- Experimental Studies On Coconut Fibre and Banana Fibre Reinforced ConcreteDocument5 pagesExperimental Studies On Coconut Fibre and Banana Fibre Reinforced ConcreteChegue BureNo ratings yet

- Materials For Membrane Structures: R. Houtman, M. OrpanaDocument7 pagesMaterials For Membrane Structures: R. Houtman, M. Orpanam,narNo ratings yet

- Analysis of Mechanical Properties of Natural Waste Particle Reinforced Polymer CompositesDocument10 pagesAnalysis of Mechanical Properties of Natural Waste Particle Reinforced Polymer CompositesGODWIN GNo ratings yet

- Sikatop 107 Seal Pds enDocument3 pagesSikatop 107 Seal Pds ensahal_akNo ratings yet

- SUB Theme 3 - Full PaperDocument81 pagesSUB Theme 3 - Full PaperDedi ApriadiNo ratings yet

- Trucare Grey 1-Pack Epoxy Primer: Product BenefitsDocument2 pagesTrucare Grey 1-Pack Epoxy Primer: Product BenefitsSakthivelNo ratings yet

- Finals Compilation MatsciDocument10 pagesFinals Compilation MatscitleeanneraNo ratings yet

- A Report On Green Material - Jute FibresDocument7 pagesA Report On Green Material - Jute FibresvaibhavNo ratings yet

- Sika Raintite: Liquid Membrane Waterproofing SystemDocument2 pagesSika Raintite: Liquid Membrane Waterproofing SystemMoatz HamedNo ratings yet

- Primer Table Sikaflex / Sikasil: Descriptions of Sika PrimersDocument4 pagesPrimer Table Sikaflex / Sikasil: Descriptions of Sika PrimersjakeNo ratings yet

- Crack-Bridging Roof Waterproofing SystemDocument2 pagesCrack-Bridging Roof Waterproofing SystemIgor HornNo ratings yet

- DiaphragmSwitch 2010Document2 pagesDiaphragmSwitch 2010Masood NizamNo ratings yet

- Loctite 3090: Large-Gap Filling 2-Component Instant AdhesiveDocument2 pagesLoctite 3090: Large-Gap Filling 2-Component Instant Adhesivenice guyNo ratings yet

- Hempadur Multi-Strength 45540 Product Data SheetDocument3 pagesHempadur Multi-Strength 45540 Product Data SheetAhmad Syafiq B Che RahimNo ratings yet

- Damp Proof - PIS PDFDocument2 pagesDamp Proof - PIS PDFArun KumarNo ratings yet

- HDPE Product Catalouge - RevisedDocument2 pagesHDPE Product Catalouge - RevisedEfvan Adhe Putra PradanaNo ratings yet

- TSL - L: Mechanical PropertiesDocument2 pagesTSL - L: Mechanical PropertiesJose Manuel ReyesNo ratings yet

- HMEL Polysure Grade Leaflet-1Document6 pagesHMEL Polysure Grade Leaflet-1Animesh JainNo ratings yet

- WITCHLINER isolation products for stainless steel and cupro-nickel pipesDocument10 pagesWITCHLINER isolation products for stainless steel and cupro-nickel pipesjamesNo ratings yet

- Alccobond BM_TB_GPDocument6 pagesAlccobond BM_TB_GPzuber shaikhNo ratings yet

- Sl. No. Export Item Quantity Import Item Qty. Allowed: Miscellaneous ProductsDocument21 pagesSl. No. Export Item Quantity Import Item Qty. Allowed: Miscellaneous ProductsKaran SaxenaNo ratings yet

- Porotherm BricksDocument2 pagesPorotherm BricksMoulis 31100% (1)

- Ultima Protec Shyne PisDocument2 pagesUltima Protec Shyne Pissuman samratNo ratings yet

- Abecote PU PDFDocument2 pagesAbecote PU PDFAshvin ParmessurNo ratings yet

- Estimating Guide. Intercrete 2019Document8 pagesEstimating Guide. Intercrete 2019Milagros MorantesNo ratings yet

- Product Innovation, Safety Commitment & Carbon Fiber Composite SystemDocument2 pagesProduct Innovation, Safety Commitment & Carbon Fiber Composite SystemJohn Rheynor MayoNo ratings yet

- Design and Structural Materials: EnvelopeDocument7 pagesDesign and Structural Materials: EnvelopeSurendarNo ratings yet

- Mondo Liquid Seal BrochureDocument2 pagesMondo Liquid Seal BrochureWynle OrgilNo ratings yet

- Structural InsulationDocument36 pagesStructural InsulationAhmed MohammedNo ratings yet

- Durable & Abrasion Resistant ElastomerDocument2 pagesDurable & Abrasion Resistant ElastomerIsrael Alejandro Diaz LindaoNo ratings yet

- Sikacrete® 114 4Document2 pagesSikacrete® 114 4aslam baigNo ratings yet

- Apex Ultima Protek: Product BenefitsDocument2 pagesApex Ultima Protek: Product BenefitssudhatryNo ratings yet

- EC Tech Report High Performance Polyurethanes: PDFFrom EverandEC Tech Report High Performance Polyurethanes: PDFVincentz Network GmbH & Co. KGNo ratings yet

- Heating, Ventilation and Air Conditioning For Plant BuildingsDocument48 pagesHeating, Ventilation and Air Conditioning For Plant Buildingssk50% (4)

- Chimneys Selection, Design and Engineering (BASED ON EN 1992-1-1, EN 1993-3-2, EN 1443, EN 13084-PARTS 1, 2, 4, 5, 6, 7 AND 8)Document34 pagesChimneys Selection, Design and Engineering (BASED ON EN 1992-1-1, EN 1993-3-2, EN 1443, EN 13084-PARTS 1, 2, 4, 5, 6, 7 AND 8)skNo ratings yet

- Onshore Ancillary Steel Structures: Dep SpecificationDocument19 pagesOnshore Ancillary Steel Structures: Dep Specificationsk100% (4)

- METALCLAD CeramAlloy CLAC PDFDocument2 pagesMETALCLAD CeramAlloy CLAC PDFskNo ratings yet

- Carbothane 133 HB PDS PDFDocument5 pagesCarbothane 133 HB PDS PDFskNo ratings yet

- Technowrap 2K PDFDocument1 pageTechnowrap 2K PDFskNo ratings yet

- METALCLAD CeramAlloy CPAC PDFDocument2 pagesMETALCLAD CeramAlloy CPAC PDFskNo ratings yet

- Engineering Standard for Refractory SystemsDocument25 pagesEngineering Standard for Refractory SystemszsmithNo ratings yet

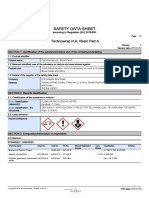

- Technowrap H.A. Resin (Part A) PDFDocument6 pagesTechnowrap H.A. Resin (Part A) PDFskNo ratings yet

- Thermo-Lag 3000-P PDS PDFDocument7 pagesThermo-Lag 3000-P PDS PDFskNo ratings yet

- Chemclad SC PDFDocument2 pagesChemclad SC PDFskNo ratings yet

- Plural Component XP70 Graco MachineDocument8 pagesPlural Component XP70 Graco MachineskNo ratings yet

- Technowrap H.A. Hardener (Part B) PDFDocument6 pagesTechnowrap H.A. Hardener (Part B) PDFskNo ratings yet

- DuralloyDocument2 pagesDuralloyAlfred GomoeliaNo ratings yet

- Loctite SDS PDFDocument15 pagesLoctite SDS PDFskNo ratings yet

- ICR Gulf Brochure PDFDocument2 pagesICR Gulf Brochure PDFskNo ratings yet

- Technowrap 2K Cloth CS PDFDocument2 pagesTechnowrap 2K Cloth CS PDFskNo ratings yet

- Enviroline 2405 Application Guidelines: Protective Coatings Technical SupportDocument12 pagesEnviroline 2405 Application Guidelines: Protective Coatings Technical SupportskNo ratings yet

- Avme Export-04.09.19Document5,350 pagesAvme Export-04.09.19skNo ratings yet

- Certificates For Belzona 1391 & Belzona 1511 PDFDocument2 pagesCertificates For Belzona 1391 & Belzona 1511 PDFskNo ratings yet

- Material Safety Data SheetDocument4 pagesMaterial Safety Data SheetskNo ratings yet

- Garnet SpecificationDocument2 pagesGarnet SpecificationskNo ratings yet

- Enviroline 405HTR+wp+eng PDFDocument12 pagesEnviroline 405HTR+wp+eng PDFskNo ratings yet

- World Class: Integrity & Maintenance SolutionsDocument2 pagesWorld Class: Integrity & Maintenance SolutionsskNo ratings yet

- Duqm Refinery RAM ChecklistDocument8 pagesDuqm Refinery RAM ChecklistskNo ratings yet

- Abrasive Blast Media Quick Selection Guide: Single Use Surface Preparation MediaDocument1 pageAbrasive Blast Media Quick Selection Guide: Single Use Surface Preparation MediaskNo ratings yet

- Details of AbrasivesDocument6 pagesDetails of AbrasivesskNo ratings yet

- Duqm Refinery RAM ChecklistDocument8 pagesDuqm Refinery RAM ChecklistskNo ratings yet

- Details of AbrasivesDocument6 pagesDetails of AbrasivesskNo ratings yet

- Garnet Technical Data Sheet: Distribution Can Be Expected To Be Within The Above Value. For: Salgo MineralsDocument1 pageGarnet Technical Data Sheet: Distribution Can Be Expected To Be Within The Above Value. For: Salgo MineralsskNo ratings yet

- Raw Material Handling and Coke Oven ProcessesDocument36 pagesRaw Material Handling and Coke Oven ProcessesJaved AlamNo ratings yet

- CaseHard BS970-1955EN36ADocument2 pagesCaseHard BS970-1955EN36AtechzonesNo ratings yet

- ASTM A153 Zinc Coating (Hot Dip) On Iron and Steel HardwareDocument5 pagesASTM A153 Zinc Coating (Hot Dip) On Iron and Steel HardwareConhydra AcoaguaNo ratings yet

- Merck Anaerocult A (Generador de Anaerobiosis P Jarra)Document1 pageMerck Anaerocult A (Generador de Anaerobiosis P Jarra)linamas14No ratings yet

- Causes and Prevention of Pump Cavitation DamageDocument2 pagesCauses and Prevention of Pump Cavitation DamageJJNo ratings yet

- Amana Gph13 Service Manual InstallationDocument43 pagesAmana Gph13 Service Manual Installationmazda8616No ratings yet

- Tata Chemicals - WikipediaDocument22 pagesTata Chemicals - WikipediaRavi NayakaNo ratings yet

- Ashrae-2011-Hvac-Applications-swimming PoolDocument3 pagesAshrae-2011-Hvac-Applications-swimming Poolmhmdjdgmailcom100% (1)

- Additional Technical Requirements for Pipes & FittingsDocument3 pagesAdditional Technical Requirements for Pipes & FittingsSaid Ahmed SalemNo ratings yet

- Materials Science and Engineering-Chapter 11Document3 pagesMaterials Science and Engineering-Chapter 11JurgenNo ratings yet

- Soil Treatment With Lime For Fine Clayey Soils: An Economical Solution For Subgrade, Sub Base, Base & Capping LayersDocument6 pagesSoil Treatment With Lime For Fine Clayey Soils: An Economical Solution For Subgrade, Sub Base, Base & Capping Layersyash_monu05No ratings yet

- Presenter: Dr. Nishant Shah M.V.Sc. (Medicine)Document104 pagesPresenter: Dr. Nishant Shah M.V.Sc. (Medicine)Santosh BhandariNo ratings yet

- Mycotoxins in Fruits, Fruit Juices, and Dried Fruits: ReviewDocument14 pagesMycotoxins in Fruits, Fruit Juices, and Dried Fruits: ReviewHesna MlanNo ratings yet

- AHRI Standard 410-2001 With Addenda 1 2 and 3Document67 pagesAHRI Standard 410-2001 With Addenda 1 2 and 3Oziel Reyes100% (1)

- State Board of PharmacyDocument66 pagesState Board of PharmacyAnonymous hF5zAdvwCC100% (1)

- ITS96 5-14 LoDocument8 pagesITS96 5-14 Loemil_tase949No ratings yet

- Seawater and Marine Structure CorrosionDocument11 pagesSeawater and Marine Structure CorrosioniraprobotNo ratings yet

- 1.4 Water Conservation: Water Monitoring and ManagementDocument3 pages1.4 Water Conservation: Water Monitoring and ManagementGaurav DuttaNo ratings yet

- How To Make A SanitizerDocument7 pagesHow To Make A SanitizerSunny TiwariNo ratings yet

- Acid Base Equilibria and StrengthsDocument81 pagesAcid Base Equilibria and StrengthsHooiQIngNo ratings yet

- Balflex 24o Tube Fittings Adapters 2020Document85 pagesBalflex 24o Tube Fittings Adapters 2020Francisco Rojas MarinNo ratings yet

- Process CheckLists P&ID Rev 3Document3 pagesProcess CheckLists P&ID Rev 3Farhan AhmedNo ratings yet

- Acetic Acid MainDocument58 pagesAcetic Acid MainGopal Agarwal50% (2)

- Analysis of Chocolates CHEMISTRY PROJECTDocument18 pagesAnalysis of Chocolates CHEMISTRY PROJECTnavee mishraNo ratings yet

- Begg Cousland Envirotec - Mist Elimination Equipment - 2018Document12 pagesBegg Cousland Envirotec - Mist Elimination Equipment - 2018Dũng LêNo ratings yet

- Gases for welding and cutting guideDocument1 pageGases for welding and cutting guideVladan TimotijevicNo ratings yet

- Carboguard 888 PDSDocument3 pagesCarboguard 888 PDSCane CirpoNo ratings yet

- Cruciferous VegetablesDocument13 pagesCruciferous Vegetablesapi-271257230No ratings yet

- Alcohols, Phenols and Ethers Test SeriesDocument5 pagesAlcohols, Phenols and Ethers Test SeriesCR foreverNo ratings yet

- 3-1.1U & 3.2U MCOQ With AnswersDocument24 pages3-1.1U & 3.2U MCOQ With Answershoratio.hornblower9262% (13)