Professional Documents

Culture Documents

Phenoline 187 Finish

Uploaded by

DuongthithuydungCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Phenoline 187 Finish

Uploaded by

DuongthithuydungCopyright:

Available Formats

Phenoline 187 Finish

PRODUCT DATA SHEET

S E L E C T I O N & S P E C I F I C AT I O N D ATA

Generic Type Amine-cured, modified epoxy phenolic

Highly cross-linked coating with exceptional chemical resistance. Widely used as a tank lining

Description system in the petrochemical industry as well as in other aggressive immersion conditions like jet

fuel, municipal and industrial wastewater.

• Excellent overall chemical resistance

• Very good abrasion resistance and flexibility

• VOC compliant to current AIM regulations

Features • Under insulation performance to 400°F (204°C)

• Meets all performance requirements of: DOD-P-23236 Type 1, Class 1 Phenoline 187 Primer &

187 Finish system

• Complies with FDA 21CFR 175.300 criteria for food contact

Gray (C703)

Color

Import: White (1898)

Finish Flat

Primer Normally used with Phenoline 187 Primer, Self-priming

102 - 152 microns (4 - 6 mils) per coat

Dry Film Thickness

(Spray application)

An additional coat of 187 Finish may be used to meet specifications or increase service life.

Solids Content By Volume 63% +/- 2%

24.8 m²/l at 25 microns (1011 ft²/gal at 1.0 mils)

Theoretical Coverage 6.2 m²/l at 100 microns (253 ft²/gal at 4.0 mils)

Rate 4.1 m²/l at 150 microns (168 ft²/gal at 6.0 mils)

Allow for loss in mixing and application.

Thinner 2 16 oz/ gal: 3.10 lbs./ gal (372 g/ L)

Thinner 33 16 oz/ gal: 3.15 lbs./ gal (380 g/ L)

VOC Values As Supplied 2.60 lbs./ gal (312 g/ L)

These are nominal values and may vary slightly with color.

February 2018 Phenoline 187 Finish Page 1 of 5

Phenoline 187 Finish

PRODUCT DATA SHEET

S E L E C T I O N & S P E C I F I C AT I O N D ATA

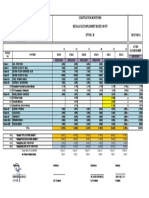

Dry Film Thickness Theoretical Practical Coverage

Application Method 2 2 *

(microns/coat) Coverage Rate (g/m ) Rate (g/m )

Spray (Gray) 25 56 100

Spray (White) 25 60 110

Spray (Gray) 100 221 400

Spray (White) 100 241 435

Spray (Gray) 150 332 600

Spray (White) 150 362 650

*: Practical Coverage Rates are estimates based on average results. Individual results may vary based on several issues including

the shape and location of the item being painted as well as environmental conditions like temperature, humidity and wing. The skill

level of those applying the paint will also impact the final results. For details, consult Japan Carboline staff. “Practical Coverage

Rates” are estimates based on average results. Individual results may vary based on several issues including the shape and

location of the item being painted as well as environmental conditions like temperature, humidity and wind. The skill level of those

applying the paint will also impact the final results. For details, consult Japan Carboline staff.

Allow for loss in mixing and application.

Continuous: 204°C (399°F)

Under Insulation Non-Continuous: 218°C (424°F)

Resistance

Discoloration and loss of gloss is observed above 200°F (93°C).

Do not use in water immersion over 130°F (54°C).

Limitations

Epoxies lose gloss, discolor and eventually chalk in sunlight exposure.

S U B S T R AT E S & S U R F A C E P R E PA R AT I O N

Surfaces must be clean and dry. Employ adequate methods to remove dirt, dust, oil and all other

General

contaminants that could interfere with adhesion of the coating.

Immersion: SSPC-SP 10

Steel Non-Immersion: SSPC-SP 6

Surface Profile: 2.0-3.0 mils (50-75 microns)

Immersion: Concrete must be cured 28 days at 75°F (24°C) and 50% relative humidity or

Concrete equivalent. Prepare surfaces in accordance with ASTM D4258-92 Surface Cleaning of Concrete

and ASTM D4259 Abrading Concrete. Voids in concrete may require surfacing.

Surface profile should be a dense angular 2.0-2.5 mils (50-63 microns) and is best achieved

through abrasive blasting. Remove all surface contaminants that would interfere with the

Stainless Steel

performance of stainless steel for the intended service such as, but not limited to, embedded iron or

chlorides.

February 2018 Phenoline 187 Finish Page 2 of 5

Phenoline 187 Finish

PRODUCT DATA SHEET

P E R F O R M A N C E D ATA

Test Method System Results

No blistering, rusting,

ASTM B117 Blasted Steel cracking, or delamination;

Salt Spray 1 ct 187 Primer/ 1 ct 187 Finish less than 1/16" rust creepage

at the scribe at 1,000 hours.

ASTM D1653 Permeability 0.0076;

Blasted Steel

Permeability WVP: 0.29 metric perms, 0.44 perms;

1 ct 187 Primer/ 1 ct 187 Finish

Method B Condition C MVT 5.72

ASTM D2794 Blasted Steel Direct Impact: 5/16" diameter

Gardner Impact 1 ct 187 Primer/ 1 ct 187 Finish Reverse Impact: 1/16" diameter

ASTM D4060 Blasted Steel 163.3 mg loss

Abrasion 1 ct 187 Primer/ 1 ct 187 Finish CS17 Wheel, 1,000 g load, 1,000 cycles

ASTM D4541 Blasted Steel

840 psi

Adhesion (Elcometer) 1 ct 187 Primer/ 1 ct 187 Finish

ASTM D522 Blasted Steel 26.4% - Actual average

Mandrel Bend Test for Flexibility 1 ct 187 Primer/ 1 ct 187 Finish maximum elongation.

The Performance Data above is a Phenoline 187 Primer and Phenoline 187 Finish system. Test reports and additional data are

available upon written request.

MIXING & THINNING

Power mix separately, then combine and power mix.

Mixing

DO NOT MIX PARTIAL KITS.

May be thinned up to 32 oz/gal (25%) with Thinner #2. Use of thinners other than those supplied or

Thinning recommended by Carboline may adversely affect product performance and void product warranty,

whether expressed or implied.

Ratio 4 : 1 Ratio (A to B)

4 Hours at 75°F (24°C)

Pot Life Pot life ends when coating loses body and begins to sag. Pot life times will be less at higher

temperatures.

A P P L I C AT I O N E Q U I P M E N T G U I D E L I N E S

Listed below are general equipment guidelines for the application of this product. Job site conditions may require modifications

to these guidelines to achieve the desired results.

Spray Application The following spray equipment have been found suitable.

Pressure pot equipped with dual regulators, 3/8” I.D. minimum material hose, .055-.070” I.D. fluid

Conventional Spray

tip and appropriate air cap.

• Pump Ratio: 30:1 (min.)*

• GPM Output: 3.0 (min.)

• Material Hose: 3/8” I.D. (min.)

• Tip Size: .015-.019”

Airless Spray

• Output PSI: 2100-2300

• Filter Size: 60 mesh

*: PTFE packings are recommended and available from the pump manufacturer.

February 2018 Phenoline 187 Finish Page 3 of 5

Phenoline 187 Finish

PRODUCT DATA SHEET

A P P L I C AT I O N E Q U I P M E N T G U I D E L I N E S

Listed below are general equipment guidelines for the application of this product. Job site conditions may require modifications

to these guidelines to achieve the desired results.

Brush & Roller Not recommended for tank lining applications except when striping welds and touching up.

(General)

Brush Use a medium bristle brush.

Roller Use a short-nap solvent resistant roller.

A P P L I C AT I O N C O N D I T I O N S

Condition Material Surface Ambient Humidity

Minimum 13°C (55°F) 10°C (50°F) 10°C (50°F) 0%

Maximum 32°C (90°F) 43°C (109°F) 38°C (100°F) 85%

This product simply requires the substrate temperature to be above the dew point. Condensation due to substrate temperatures

below the dew point can cause flash rusting on prepared steel and interfere with proper adhesion to the substrate. Special

application techniques may be required above or below normal application conditions.

CURING SCHEDULE

Surface Temp. Final Cure Immersion Maximum Recoat Time Minimum Recoat Time

10°C (50°F) - 30 Days 4 Days

16°C (61°F) 30 Days 30 Days 2 Days

24°C (75°F) 15 Days 15 Days 24 Hours

32°C (90°F) 7 Days 7 Days 12 Hours

These times are based on a 4.0-6.0 mil (100-150 microns) dry film thickness. Higher film thickness, insufficient ventilation or cooler

temperatures will require longer cure times and could result in solvent entrapment and premature failure. Excessive humidity or

condensation on the surface during curing can interfere with the cure, can cause discoloration and may result in a surface haze.

Any haze or blush must be removed by water washing before recoating. If the maximum recoat time is exceeded, the surface must

be abraded by sweep blasting prior to the application of additional coats.

Ambient Cure Final cure temperatures below 60°F (16°C) are not recommended for tank linings.

Force curing is beneficial to the performance of all tank linings, especially for storage of food

grade products. The following schedule may be used to force cure the coating system after

the final coat is applied. Cure @ 75°F (24°C) for 4 hours followed by 8 hours @ 150°F (65°C).

Force Cure

Elevate temperature no more than 30°F (16-17°C) every 30 minutes. Final cure requirement varies

depending upon exposure. Contact Carboline Technical Service for additional force curing and

safety information.

CLEANUP & SAFETY

Use Thinner #2 or Acetone. In case of spillage, absorb and dispose of in accordance with local

Cleanup

applicable regulations.

Read and follow all caution statements on this product data sheet and on the SDS for this product.

Safety

Employ normal workmanlike safety precautions including personnel protection equipment.

February 2018 Phenoline 187 Finish Page 4 of 5

Phenoline 187 Finish

PRODUCT DATA SHEET

CLEANUP & SAFETY

When used as a tank lining or in enclosed areas, thorough air circulation must be used during and

after application until the coating is cured. The ventilation system should be capable of preventing

Ventilation the solvent vapor concentration from reaching the lower explosion limit for the solvents used. In

addition to ensuring proper ventilation, appropriate respirators must be used by all application

personnel.

This product contains flammable solvents. Keep away from sparks and open flames. All electrical

equipment and installations should be made and grounded in accordance with the National Electric

Caution

Code. In areas where explosion hazards exist, workmen should be required to use non-ferrous

tools and wear conductive and non-sparking shoes.

PA C K A G I N G , H A N D L I N G & S T O R A G E

• Part A (color 1898); 6 months at 75°F (24°C)

• Part A (color C703); 36 months at 75°F (24°C)

• Part B: Min. 36 months at 75°F (24°C)

Shelf Life

*Shelf Life: (actual stated shelf life) when kept at recommended storage conditions and in original

unopened containers.

Storage Store indoors.

Net Weight 10 kg kit 4 kg kit

Part A 8.7 kg 3.48 kg

Part B 1.3 kg 0.52 kg

Storage Temperature & 40°-110°F (4°-43°C)

Humidity 0-90% Relative Humidity

Part A: 67°F (19°C)

Flash Point (Setaflash) Part B: 68°F (20°C)

Mixed: 67°F (19°C)

U P D AT E I N F O R M AT I O N

Last Modified February, 2018

Control Number PDS125-008

WA R R A N T Y

To the best of our knowledge the technical data contained herein is true and accurate on the date of publication and is subject

to change without prior notice. User must contact Carboline Company to verify correctness before specifying or ordering. No

guarantee of accuracy is given or implied. We guarantee our products to conform to Carboline quality control. We assume no

responsibility for coverage, performance, injuries or damages resulting from use. Carbolines sole obligation, if any, is to replace

or refund the purchase price of the Carboline product(s) proven to be defective, at Carbolines option. Carboline shall not be liable

for any loss or damage. NO OTHER WARRANTY OR GUARANTEE OF ANY KIND IS MADE BY CARBOLINE, EXPRESS OR

IMPLIED, STATUTORY, BY OPERATION OF LAW, OR OTHERWISE, INCLUDING MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE. All of the trademarks referenced above are the property of Carboline International Corporation unless

otherwise indicated.

February 2018 Phenoline 187 Finish Page 5 of 5

You might also like

- Phenoline 187 Finish PDSDocument5 pagesPhenoline 187 Finish PDSQuy RomNo ratings yet

- Phenoline 187 Primer PDSDocument5 pagesPhenoline 187 Primer PDSQuy RomNo ratings yet

- Carboguard 890: Selection & Specification DataDocument5 pagesCarboguard 890: Selection & Specification DataMuthazhagan SaravananNo ratings yet

- Carboguard 890 PDSDocument5 pagesCarboguard 890 PDSAchraf BoudayaNo ratings yet

- Phenoline 1205 PDSDocument4 pagesPhenoline 1205 PDSonshore purchaseNo ratings yet

- Carboguard 60: Selection & Specification DataDocument5 pagesCarboguard 60: Selection & Specification DataDuongthithuydungNo ratings yet

- Phenoline 187 Primer and FinishDocument2 pagesPhenoline 187 Primer and Finish이선엽No ratings yet

- Phenoline 187 Chemical Resistant Tank LiningDocument5 pagesPhenoline 187 Chemical Resistant Tank LiningQuy RomNo ratings yet

- Carboguard 1209: Selection & Specification DataDocument4 pagesCarboguard 1209: Selection & Specification DataQuy Dom100% (2)

- Carboguard 893 SG: Selection & Specification DataDocument5 pagesCarboguard 893 SG: Selection & Specification DataPraveen Sreekumaran NairNo ratings yet

- Carboguard 893 SG MIO PDSDocument4 pagesCarboguard 893 SG MIO PDSMuthuKumarNo ratings yet

- Carboguard 890 GFDocument4 pagesCarboguard 890 GFDuongthithuydungNo ratings yet

- Carboguard 890 PDSDocument5 pagesCarboguard 890 PDScrisNo ratings yet

- Phenoline 187 Finish PDSDocument2 pagesPhenoline 187 Finish PDSalejandroNo ratings yet

- Technical Data Sheet for Epoxy Mastic CoatingDocument5 pagesTechnical Data Sheet for Epoxy Mastic CoatingBiju_PottayilNo ratings yet

- Carbothane 134 HG PDSDocument4 pagesCarbothane 134 HG PDSAnhera enterpriseNo ratings yet

- Phenoline 187 VOC: Selection & Specification DataDocument4 pagesPhenoline 187 VOC: Selection & Specification DataShahnawaz PathanNo ratings yet

- Jotamastic 87 GFDocument5 pagesJotamastic 87 GFBiju_PottayilNo ratings yet

- Jotamastic 80: Technical Data SheetDocument14 pagesJotamastic 80: Technical Data SheetCv RONATAMA GUSLHANNo ratings yet

- Carboguard 893 SG PDSDocument4 pagesCarboguard 893 SG PDSTrịnh Minh KhoaNo ratings yet

- Sanitile 120 PDSDocument4 pagesSanitile 120 PDSDuongthithuydungNo ratings yet

- Jotamastic 80: Technical Data SheetDocument5 pagesJotamastic 80: Technical Data SheetSafinahNo ratings yet

- Technical Data Sheet for Glass Flake CoatingDocument5 pagesTechnical Data Sheet for Glass Flake CoatingsmnisNo ratings yet

- Balto FlakeDocument5 pagesBalto FlakeBiju_PottayilNo ratings yet

- Bitumastic 300M: Selection & Specification DataDocument4 pagesBitumastic 300M: Selection & Specification DataSHAIK ASIMUDDINNo ratings yet

- Carboguard 635: Selection & Specification DataDocument5 pagesCarboguard 635: Selection & Specification DataPrakashNo ratings yet

- Acrolon 218 FTDocument4 pagesAcrolon 218 FTEdwin VSNo ratings yet

- Carbozinc 11 HS PDSDocument5 pagesCarbozinc 11 HS PDSEsakki muthuNo ratings yet

- Carboguard 893: Selection & Specification DataDocument5 pagesCarboguard 893: Selection & Specification DataQuy RomNo ratings yet

- Acrolon 218 HS Acrylic PolyurethaneDocument4 pagesAcrolon 218 HS Acrylic PolyurethaneJohn ReevesNo ratings yet

- Carboguard 880 MIO PDSDocument4 pagesCarboguard 880 MIO PDSHerman EngelbrechtNo ratings yet

- Phenoline 1205: Selection & Specification DataDocument4 pagesPhenoline 1205: Selection & Specification DataKris WilliamsNo ratings yet

- Carbothane 133 HB PDS PDFDocument5 pagesCarbothane 133 HB PDS PDFskNo ratings yet

- Carbothane 134 HG PDSDocument4 pagesCarbothane 134 HG PDSTeknik produksi wikonNo ratings yet

- Acrolon 218 HsDocument4 pagesAcrolon 218 HsKARENNo ratings yet

- Carboline Carbothane 133 HBDocument5 pagesCarboline Carbothane 133 HBArturo SalinasNo ratings yet

- 1-Technical Data Sheet Baltoflake Ecolife (750 Μm)Document5 pages1-Technical Data Sheet Baltoflake Ecolife (750 Μm)Akram AlhaddadNo ratings yet

- Technical Data Sheet Baltoflake EcolifeDocument5 pagesTechnical Data Sheet Baltoflake EcolifeAkram AlhaddadNo ratings yet

- Carboxane 2000 PDSDocument4 pagesCarboxane 2000 PDSBERSE MAJU INDONESIANo ratings yet

- Protective & Marine Coatings: Acrolon™ 218 HsDocument4 pagesProtective & Marine Coatings: Acrolon™ 218 HsAna CabreraNo ratings yet

- Carboguard 890 EF PDS 9-06Document2 pagesCarboguard 890 EF PDS 9-06Ckaal74No ratings yet

- Hi Solid PolyurethaneDocument4 pagesHi Solid PolyurethaneafvasquezNo ratings yet

- Carboguard 893 PDSDocument5 pagesCarboguard 893 PDSUtomoNo ratings yet

- Carbomastic 15 PDSDocument4 pagesCarbomastic 15 PDSRiyaz Basheer100% (1)

- TDS 32222 Jotatemp 250 Euk GBDocument5 pagesTDS 32222 Jotatemp 250 Euk GBrinaldo KurniawanNo ratings yet

- Technical Data Sheet for Baltoflake CoatingDocument6 pagesTechnical Data Sheet for Baltoflake CoatingSaul AntayhuaNo ratings yet

- Epoxy HRDocument5 pagesEpoxy HRMuthuKumarNo ratings yet

- Carbozinc 11 PDSDocument5 pagesCarbozinc 11 PDSSUBODHNo ratings yet

- Jotamastic 87 AluminiumDocument5 pagesJotamastic 87 AluminiumBiju_PottayilNo ratings yet

- Carbozinc 11: Selection & Specification DataDocument5 pagesCarbozinc 11: Selection & Specification DatajoehodohNo ratings yet

- Phenoline 187 VOC: Selection & Specification DataDocument4 pagesPhenoline 187 VOC: Selection & Specification Datarajiv_quantumNo ratings yet

- Baltoflake S2000Document5 pagesBaltoflake S2000Mhd EbalNo ratings yet

- Carboquick 200 PDSDocument4 pagesCarboquick 200 PDSMarcelo Alejandro MarinoNo ratings yet

- Epoxy HR: Technical Data SheetDocument5 pagesEpoxy HR: Technical Data SheetOrgünOzarNo ratings yet

- TDS Penguard Pro JotunDocument5 pagesTDS Penguard Pro JotunLuka BornaNo ratings yet

- Epoxy HR: Technical Data SheetDocument5 pagesEpoxy HR: Technical Data SheetMohamed FarhanNo ratings yet

- Plastics in Building Structures: Proceedings of a Conference Held in London, 14-16 June 1965From EverandPlastics in Building Structures: Proceedings of a Conference Held in London, 14-16 June 1965No ratings yet

- Essential Rubber Formulary: Formulas for PractitionersFrom EverandEssential Rubber Formulary: Formulas for PractitionersRating: 3 out of 5 stars3/5 (1)

- Water-Based Paint Formulations, Vol. 3From EverandWater-Based Paint Formulations, Vol. 3Rating: 4.5 out of 5 stars4.5/5 (6)

- SSPC QP1Document36 pagesSSPC QP1DuongthithuydungNo ratings yet

- Aaac 4671Document3 pagesAaac 4671DuongthithuydungNo ratings yet

- Neoprene Cladding SystemsDocument2 pagesNeoprene Cladding SystemsDuongthithuydungNo ratings yet

- 3095 DatasheetDocument2 pages3095 DatasheetDuongthithuydungNo ratings yet

- 8Vhu*Xlghhq: (OFRPHWHU䄎含祮 (OFRPHWHU䄎含懽Document65 pages8Vhu*Xlghhq: (OFRPHWHU䄎含祮 (OFRPHWHU䄎含懽DuongthithuydungNo ratings yet

- NEURTEK Paint Coatings ENDocument88 pagesNEURTEK Paint Coatings ENDuongthithuydungNo ratings yet

- Enviroline 399ABR UKDocument17 pagesEnviroline 399ABR UKDuongthithuydungNo ratings yet

- Protecting Splash Zones of Offshore PlatformsDocument7 pagesProtecting Splash Zones of Offshore PlatformsDuongthithuydungNo ratings yet

- 118PB1NL 2 UsansiDocument9 pages118PB1NL 2 UsansiDuongthithuydungNo ratings yet

- Bond Datasheet Ds 113 enDocument2 pagesBond Datasheet Ds 113 enDuongthithuydungNo ratings yet

- Plasite 4550 S: Selection & Specification DataDocument4 pagesPlasite 4550 S: Selection & Specification DataSHAIK ASIMUDDINNo ratings yet

- Cilbond Elastomer Bonding GuideDocument3 pagesCilbond Elastomer Bonding GuideDuongthithuydungNo ratings yet

- FBE RIDOTT Compressed-1Document2 pagesFBE RIDOTT Compressed-1DuongthithuydungNo ratings yet

- FBE Product Info Sheet 1802 1Document1 pageFBE Product Info Sheet 1802 1DuongthithuydungNo ratings yet

- Interthane 990Document4 pagesInterthane 990DuongthithuydungNo ratings yet

- 118PB1NL 2 UsansiDocument9 pages118PB1NL 2 UsansiDuongthithuydungNo ratings yet

- Abrasive Profile GuidelineDocument1 pageAbrasive Profile GuidelineDuongthithuydungNo ratings yet

- Intergard 269 DatasheetDocument4 pagesIntergard 269 DatasheetBalasubramanian AnanthNo ratings yet

- High Temp Mesh PDSDocument2 pagesHigh Temp Mesh PDSDuongthithuydungNo ratings yet

- Intergard 475HSDocument4 pagesIntergard 475HSDilip VaradharajanNo ratings yet

- PDS Hempel's Galvosil 15700 en-GBDocument2 pagesPDS Hempel's Galvosil 15700 en-GBbayuNo ratings yet

- Sanitile 120 PDSDocument4 pagesSanitile 120 PDSDuongthithuydungNo ratings yet

- Carboglas 1601 SG Product Data SheetDocument5 pagesCarboglas 1601 SG Product Data SheetWifi wpa wepNo ratings yet

- Carbozinc 858 (3K)Document4 pagesCarbozinc 858 (3K)DuongthithuydungNo ratings yet

- Carbozinc 11Document4 pagesCarbozinc 11DuongthithuydungNo ratings yet

- Carboguard 703 GF PDSDocument4 pagesCarboguard 703 GF PDSDuongthithuydungNo ratings yet

- Carbothane 134 HS PDSDocument4 pagesCarbothane 134 HS PDSDuongthithuydungNo ratings yet

- Carbozinc 858: Selection & Specification DataDocument4 pagesCarbozinc 858: Selection & Specification DataNico RoisnerNo ratings yet

- Thermaline 450 EP PDSDocument3 pagesThermaline 450 EP PDSNguyễn Duy BiênNo ratings yet

- Pyroclad X1: Selection & Specification DataDocument6 pagesPyroclad X1: Selection & Specification DataDuongthithuydungNo ratings yet

- Astm A179 PDFDocument1 pageAstm A179 PDFgaminNo ratings yet

- ChillersDocument7 pagesChillersBRANDONNo ratings yet

- Gap Slab ForcesDocument2 pagesGap Slab ForcesvivekNo ratings yet

- Report of Inspection, Testing & Maintenance: of Fire Pump AssembliesDocument6 pagesReport of Inspection, Testing & Maintenance: of Fire Pump AssembliesMatel Franklin AnastaNo ratings yet

- NTP 20Document1 pageNTP 20RBV DESIGN & BUILD SERVICESNo ratings yet

- Al2O3 Material Properties GuideDocument3 pagesAl2O3 Material Properties GuideRing MasterNo ratings yet

- Branz BU578 Ventilation Drying Behind Wall CladdingsDocument8 pagesBranz BU578 Ventilation Drying Behind Wall CladdingsYanina MashkinaNo ratings yet

- CPP Lab Report 4Document11 pagesCPP Lab Report 4Muhammad Danial KhairuddinNo ratings yet

- Synthesis of CuCrFeNiTiAl High Entropy Alloy via Selective Laser MeltingDocument1 pageSynthesis of CuCrFeNiTiAl High Entropy Alloy via Selective Laser MeltingJoni Chandra DharNo ratings yet

- ApsDocument6 pagesApsJames HsuNo ratings yet

- Chapter 02 - Analysis and Design For Axial TensionDocument52 pagesChapter 02 - Analysis and Design For Axial Tensionyolo louoNo ratings yet

- Traditional and ModernDocument1 pageTraditional and ModernMark Daniel de JesusNo ratings yet

- 1.EPV NORTH SEA Exploded PartviewDocument45 pages1.EPV NORTH SEA Exploded PartviewPSC RFQNo ratings yet

- BoilerDocument48 pagesBoilerAbdallah Mansour100% (2)

- ACI Structural Journal 1-4 PDFDocument4 pagesACI Structural Journal 1-4 PDFFerry Wijaya100% (1)

- Arch Bridge Code-ACS-8 PDFDocument8 pagesArch Bridge Code-ACS-8 PDFshobhit mohtaNo ratings yet

- Heat Exchanger InspectionDocument7 pagesHeat Exchanger InspectionHamid Albashir100% (1)

- CEE 9628b Prestressed Concrete Assignment 1 ProblemsDocument2 pagesCEE 9628b Prestressed Concrete Assignment 1 ProblemsWasim AbbassNo ratings yet

- Sugano Seismic Rehabilitation of Concrete StructuresDocument8 pagesSugano Seismic Rehabilitation of Concrete StructuresJames ClaytonNo ratings yet

- Power Generation From Piezoelectric Lead Zirconate Titanate Fiber CompositesDocument6 pagesPower Generation From Piezoelectric Lead Zirconate Titanate Fiber Compositesnewton_1987No ratings yet

- Plans For Bringing Property Up To Code ReportDocument9 pagesPlans For Bringing Property Up To Code ReportJennifer R Allen HestiaCapitalHoldingsNo ratings yet

- BOULABDocument1 pageBOULABbenchinounNo ratings yet

- 2 - Stress, Strain - Axial LoadDocument58 pages2 - Stress, Strain - Axial LoadPhước Trần NguyênNo ratings yet

- 3.3-Design of Shallow FoundationDocument32 pages3.3-Design of Shallow FoundationSamson YonasNo ratings yet

- LW5014 Manual HDP MFL67987301Document40 pagesLW5014 Manual HDP MFL67987301asdNo ratings yet

- Saflex Structural GuideDocument51 pagesSaflex Structural Guidemercab15No ratings yet

- PFT019 - TVR6G50 HZ Engineering ManualDocument192 pagesPFT019 - TVR6G50 HZ Engineering ManualJoseph100% (4)

- Rotor Hot Spot Treatment PDFDocument10 pagesRotor Hot Spot Treatment PDFramnadh803181No ratings yet

- Kuripan-Ciseeng (Ma)Document86 pagesKuripan-Ciseeng (Ma)Muhammad Rifky RiansyahNo ratings yet