Professional Documents

Culture Documents

TDS 32222 Jotatemp 250 Euk GB

Uploaded by

rinaldo KurniawanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

TDS 32222 Jotatemp 250 Euk GB

Uploaded by

rinaldo KurniawanCopyright:

Available Formats

Technical Data Sheet

Approved 32222;32223;35142 1,2 32222 epoxy composite ^(ValidationDate) 1

Jotatemp 250

Product description

This is a two component glass flake reinforced epoxy composite coating. Designed as a heat resistant coating,

and it is resistant to low temperatures down to -196°C and high temperatures up to 250°C on carbon steel.

Suitable for insulated and non insulated surfaces. Suitable for properly prepared carbon steel, stainless steel,

alloyed steel (P91), galvanized steel and aluminium. It can be applied on hot substrates up to 150°C. Please

refer to the application guide for more detailed information. This product may be used as a primer, mid coat or

finish coat. It will offer proper corrosion protection at ambient conditions during construction and shut-down

periods. The product passes the standard tests used for qualifying coatings preventing corrosion under insulation

(CUI).

Typical use

Protective:

Designed as corrosion protection for surfaces operating at elevated temperatures where extended protection

against corrosion is desired. Particularly suited for use under insulation. Suitable for insulated and non insulated

surfaces.

Other

Approvals and certificates

Passing ISO 19277-2018 including CUI-2 Cryo and CUI-3 Cryo multiphase.

Tested in accordance with ISO 12944-6, high expected durability in corrosivity category C5.

Passing vertical pipe test for CUI performance as described in ISO 19277 Part 8.2:2018.

Tested in accordance with ISO 3248:2000 determination of the effect of heat 1000 hours at 250°C on carbon

steel.

Tested in accordance with ISO 3248:2000 determination of the effect of heat 1000 hours at 230°C on stainless

steel (SS304).

Tested in accordance with ISO 3248:2000 determination of the effect of heat 1000 hours at 230°C on alloyed

steel (P91).

Passing ASTM D2485 : 2018 - standard test methods for evaluating coatings for high temperature service from

-196°C to 250°C.

Additional certificates and approvals may be available on request.

Colours

white, red, light grey, aluminium

Aluminium colour shall not be overcoated.

Product data

Property Test/Standard Description

Solids by volume ISO 3233 70 ± 2 %

Gloss level (GU 60 °) ISO 2813 matt (0-35)

Flash point ISO 3679 Method 1 28 °C

Density calculated 1.5 kg/l

VOC-US/Hong Kong US EPA method 24 (tested) 270 g/l

(CARB(SCM)2007, SCAQMD rule 1113, Hong Kong)

VOC-EU IED (2010/75/EU) (theoretical) 283 g/l

VOC-China GB/T 23985-2009 (tested) 238 g/l

VOC-Korea Korea Clean Air Conservation Act (tested) 354 g/l

(Max. thinning ratio included)

Date of issue: 16 September 2022 Page: 1/5

This Technical Data Sheet supersedes those previously issued.

The Technical Data Sheet (TDS) is recommended to be read in conjunction with the Safety Data Sheet (SDS) and the

Application Guide (AG) for this product. For your nearest local Jotun office, please visit our website at www.jotun.com

Technical Data Sheet

Jotatemp 250

The provided data is typical for factory produced products, subject to slight variation depending on colour.

All data is valid for mixed paint.

Gloss description: According to Jotun Performance Coatings' definition.

Film thickness per coat

Typical recommended specification range

Dry film thickness 140 - 200 μm

Wet film thickness 200 - 300 μm

Theoretical spreading rate 5 - 3.5 m²/l

Surface preparation

Surface preparation summary table

Surface preparation

Substrate Minimum Recommended

Carbon steel St 2 (ISO 8501-1) if temperature does Sa 2½ (ISO 8501-1)

not exceed 230 °C

Stainless steel The surface shall be hand or machine Abrasive blast cleaning to achieve a

abraded with non-metallic abrasives surface profile using non-metallic

or bonded fibre machine or hand abrasive media which is suitable to

abrasive pads to impart a scratch achieve a sharp and angular surface

pattern to the surface. profile.

Aluminium The surface shall be hand or machine Abrasive blast cleaning to achieve a

abraded with non-metallic abrasives surface profile using non-metallic

or bonded fibre machine or hand abrasive media which is suitable to

abrasive pads to impart a scratch achieve a sharp and angular surface

pattern to the surface. profile.

Galvanised steel The surface shall be clean, dry and Sweep blast-cleaning using non-

appear with a rough and dull profile. metallic abrasive leaving a clean,

rough and even pattern.

Shop primed steel Dry, clean and approved inorganic Sa 2½ (ISO 8501-1)

zinc shopprimer.

Coated surfaces Clean, dry and undamaged compatible Clean, dry and undamaged compatible

coating coating

Application

Application methods

The product can be applied by

Date of issue: 16 September 2022 Page: 2/5

This Technical Data Sheet supersedes those previously issued.

The Technical Data Sheet (TDS) is recommended to be read in conjunction with the Safety Data Sheet (SDS) and the

Application Guide (AG) for this product. For your nearest local Jotun office, please visit our website at www.jotun.com

Technical Data Sheet

Jotatemp 250

Spray: Use airless spray.

Brush: Recommended for stripe coating and small areas. Care must be taken to achieve the

specified dry film thickness.

Product mixing ratio (by volume)

Jotatemp 250 Comp A 5 part(s)

Jotatemp 250 Comp B 1 part(s)

Thinner/Cleaning solvent

Thinner: Jotun Thinner No. 23

Thinning max.: 10 %

Thinning is not normally required. Consult the local representative for advice during application in extreme

conditions. Do not thin more than allowed by local environmental legislation.

Note: Korean VOC regulation "Korea Clean Air Conservation Act" and its corresponding thinning limit will prevail

over recommended thinning volumes.

Guiding data for airless spray

Nozzle tip (inch/1000): 19-21

Pressure at nozzle (minimum): 150 bar/2100 psi

Drying and Curing time

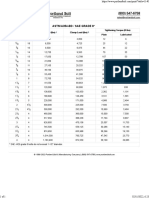

Substrate temperature 10 °C 15 °C 23 °C 40 °C 100 °C

Surface (touch) dry 12 h 6h 2.5 h 1.5 h 20 min

Walk-on-dry 24 h 13 h 7h 2.5 h 20 min

Dry to over coat, minimum 13 h 6h 2.5 h 1.5 h 0 min

Dried/cured for service 25 d 21 d 18 d 3d 1d

For maximum overcoating intervals, refer to the Application Guide (AG) for this product.

Due to the fast evaporation above 100°C, instant drying is expected. Drying and curing times are determined

under controlled temperatures and relative humidity below 85 %, and at average of the DFT range for the

product.

Surface (touch) dry: The state of drying when slight pressure with a finger does not leave an imprint or reveal

tackiness.

Walk-on-dry: Minimum time before the coating can tolerate normal foot traffic without permanent marks,

imprints or other physical damage.

Dry to over coat, minimum: The recommended shortest time before the next coat can be applied.

Dried/cured for service: Minimum time before the coating can be permanently exposed to the intended

environment/medium.

Date of issue: 16 September 2022 Page: 3/5

This Technical Data Sheet supersedes those previously issued.

The Technical Data Sheet (TDS) is recommended to be read in conjunction with the Safety Data Sheet (SDS) and the

Application Guide (AG) for this product. For your nearest local Jotun office, please visit our website at www.jotun.com

Technical Data Sheet

Jotatemp 250

Induction time and Pot life

Paint temperature 23 °C

Induction time 20 min

Pot life 2h

Reduced at higher temperatures.

Heat resistance

Carbon steel:

Continuous: 250°C

Peak: 300°C

Stainless steel:

Continuous: 230°C

Alloyed steel:

Continuous: 230°C

Galvanised steel:

Continuous:204°C

Aluminium

Continuous: 204°C

The continuous operational temperature limits are based on the substrate’s heat resistant properties.

Product compatibility

Depending on the actual exposure of the coating system, various primers and topcoats can be used in

combination with this product. Some examples are shown below. Contact Jotun for specific system

recommendation.

Previous coat: inorganic zinc ethyl silicate, itself

Subsequent coat: glass flake reinforced epoxy composite, silicone acrylic *

* Maximum heat resistance is 230 °C (446 °F)

Packaging (typical)

Volume Size of containers

(litres) (litres)

Jotatemp 250 Comp A 4.17/15 5/20

Jotatemp 250 Comp B 0.83/3 1/3

The volume stated is for factory made colours. Note that local variants in pack size and filled volumes can vary

due to local regulations.

Date of issue: 16 September 2022 Page: 4/5

This Technical Data Sheet supersedes those previously issued.

The Technical Data Sheet (TDS) is recommended to be read in conjunction with the Safety Data Sheet (SDS) and the

Application Guide (AG) for this product. For your nearest local Jotun office, please visit our website at www.jotun.com

Technical Data Sheet

Jotatemp 250

Storage

The product must be stored in accordance with national regulations. Keep the containers in a dry, cool, well

ventilated space and away from sources of heat and ignition. Containers must be kept tightly closed. Handle

with care.

Shelf life at 23 °C

Jotatemp 250 Comp A 24 month(s)

Jotatemp 250 Comp B 24 month(s)

In some markets commercial shelf life can be dictated shorter by local legislation. The above is minimum shelf

life, thereafter the paint quality is subject to re-inspection.

Caution

This product is for professional use only. The applicators and operators shall be trained, experienced and have

the capability and equipment to mix/stir and apply the coatings correctly and according to Jotun's technical

documentation. Applicators and operators shall use appropriate personal protection equipment when using this

product. This guideline is given based on the current knowledge of the product. Any suggested deviation to suit

the site conditions shall be forwarded to the responsible Jotun representative for approval before commencing

the work.

Health and safety

Please observe the precautionary notices displayed on the container. Use under well ventilated conditions. Do

not inhale spray mist. Avoid skin contact. Spillage on the skin should immediately be removed with suitable

cleanser, soap and water. Eyes should be well flushed with water and medical attention sought immediately.

Colour variation

When applicable, products primarily meant for use as primers or antifoulings may have slight colour variations

from batch to batch. Such products and epoxy based products used as a finish coat may chalk when exposed to

sunlight and weathering.

Colour and gloss retention on topcoats/finish coats may vary depending on type of colour, exposure

environment such as temperature, UV intensity etc., application quality and generic type of paint. Contact your

local Jotun office for further information.

Disclaimer

The information in this document is given to the best of Jotun's knowledge, based on laboratory testing and

practical experience. Jotun's products are considered as semi-finished goods and as such, products are often

used under conditions beyond Jotun's control. Jotun cannot guarantee anything but the quality of the product

itself. Minor product variations may be implemented in order to comply with local requirements. Jotun reserves

the right to change the given data without further notice.

Users should always consult Jotun for specific guidance on the general suitability of this product for their needs

and specific application practices.

If there is any inconsistency between different language issues of this document, the English (United Kingdom)

version will prevail.

Date of issue: 16 September 2022 Page: 5/5

This Technical Data Sheet supersedes those previously issued.

The Technical Data Sheet (TDS) is recommended to be read in conjunction with the Safety Data Sheet (SDS) and the

Application Guide (AG) for this product. For your nearest local Jotun office, please visit our website at www.jotun.com

You might also like

- Brochure NL Module R3 PDFDocument2 pagesBrochure NL Module R3 PDFdononoNo ratings yet

- Arcoplate TecnologiaPresentationDocument75 pagesArcoplate TecnologiaPresentationrinaldo KurniawanNo ratings yet

- BS 1449-1 - 1983Document39 pagesBS 1449-1 - 1983عمر عمر100% (7)

- E413 Bolting en Us 0Document88 pagesE413 Bolting en Us 0rickcy herdianNo ratings yet

- Welding NotesDocument47 pagesWelding NotesAparna KumarNo ratings yet

- 20 TMSS 02 R1Document26 pages20 TMSS 02 R1Anonymous NrBbhHuZyiNo ratings yet

- SN200Document111 pagesSN200tajinder231280% (5)

- ISO 10816-1 Normativa VibracionesDocument10 pagesISO 10816-1 Normativa Vibracionesumendibil100% (1)

- Jotatemp 1000 Ceramic High-Heat Protective Coating TDSDocument5 pagesJotatemp 1000 Ceramic High-Heat Protective Coating TDSGurdeep Sungh AroraNo ratings yet

- Tks 324 Mechanical Design of Process Equipment-01Document62 pagesTks 324 Mechanical Design of Process Equipment-01Rahani Hyuga100% (1)

- Jotamastic 90 Jotun PaintDocument6 pagesJotamastic 90 Jotun PaintGurdeep Sungh AroraNo ratings yet

- Corrosion: Corrosion ControlFrom EverandCorrosion: Corrosion ControlL L ShreirRating: 5 out of 5 stars5/5 (1)

- Jotaguard 100: Technical Data SheetDocument6 pagesJotaguard 100: Technical Data SheetHector MacavilcaNo ratings yet

- Repair WeldsDocument57 pagesRepair WeldsJoseph Jordan Aguilar OndeNo ratings yet

- Welding Engineer Exam SyllubusDocument2 pagesWelding Engineer Exam SyllubuskapsarcNo ratings yet

- Corrosion Testing for Metal Finishing: Institute of Metal FinishingFrom EverandCorrosion Testing for Metal Finishing: Institute of Metal FinishingNo ratings yet

- ASTM A403 - A403M-22bDocument11 pagesASTM A403 - A403M-22b1965karanfil6100% (1)

- Jotatemp 250: Technical Data SheetDocument5 pagesJotatemp 250: Technical Data SheetMedhat Merzek100% (1)

- Jotatem 250Document5 pagesJotatem 250Quach AnNo ratings yet

- TDS Penguard Pro JotunDocument5 pagesTDS Penguard Pro JotunLuka BornaNo ratings yet

- Epoxy HR: Technical Data SheetDocument5 pagesEpoxy HR: Technical Data SheetOrgünOzarNo ratings yet

- TDS 29140 Penguard Express CF Euk GBDocument5 pagesTDS 29140 Penguard Express CF Euk GBKf LiauNo ratings yet

- Technical Data Sheet for Penguard Express Epoxy CoatingDocument5 pagesTechnical Data Sheet for Penguard Express Epoxy CoatingGurdeep Sungh AroraNo ratings yet

- Epoxy HRDocument5 pagesEpoxy HRMuthuKumarNo ratings yet

- TDS GB BeetDocument5 pagesTDS GB BeetRonnalyn TorresNo ratings yet

- Technical Data Sheet for Penguard Express Epoxy CoatingDocument5 pagesTechnical Data Sheet for Penguard Express Epoxy CoatingImam SitumeangNo ratings yet

- TDS Jotamastic 90Document7 pagesTDS Jotamastic 90Syamsul MaripNo ratings yet

- TDS Jotamastic 90Document7 pagesTDS Jotamastic 90Syamsul MaripNo ratings yet

- TDS 15360 Jotacote+Universal+N10 Euk GBDocument5 pagesTDS 15360 Jotacote+Universal+N10 Euk GBIsyfi QulubanaNo ratings yet

- Jotacote Universal N10: Technical Data SheetDocument6 pagesJotacote Universal N10: Technical Data Sheetary rizkiNo ratings yet

- Penguard Special: Technical Data SheetDocument5 pagesPenguard Special: Technical Data SheetCyril J PadiyathNo ratings yet

- Jota EP15P 快干环氧底漆EP15P(0XT) (United Kingdom - English)Document5 pagesJota EP15P 快干环氧底漆EP15P(0XT) (United Kingdom - English)long chanNo ratings yet

- Jota EP15 快干环氧底漆 (6VM) (United Kingdom - English)Document5 pagesJota EP15 快干环氧底漆 (6VM) (United Kingdom - English)long chanNo ratings yet

- 2 FsDocument7 pages2 Fsrajiv_quantumNo ratings yet

- TDS 1493 Solvalitt Midtherm Euk GBDocument5 pagesTDS 1493 Solvalitt Midtherm Euk GByusri jaafarNo ratings yet

- Tankguard HB Classic Jotun PaintDocument5 pagesTankguard HB Classic Jotun PaintGurdeep Sungh AroraNo ratings yet

- Jotatemp 1000 CeramicDocument5 pagesJotatemp 1000 CeramicNabeel K SNo ratings yet

- Marathon 500: Technical Data SheetDocument5 pagesMarathon 500: Technical Data Sheetalfad maulaNo ratings yet

- Marathon 500 Technical Data SheetDocument5 pagesMarathon 500 Technical Data SheetGurdeep Sungh AroraNo ratings yet

- Jotun Penguard Express CF TDSDocument5 pagesJotun Penguard Express CF TDSnihad_mNo ratings yet

- Technical Data Sheet for Epoxy CoatingDocument5 pagesTechnical Data Sheet for Epoxy CoatingajuhaseenNo ratings yet

- TDS 48382 Solvalitt 600 Euk GBDocument5 pagesTDS 48382 Solvalitt 600 Euk GBMhd EbalNo ratings yet

- Penguard Primer: Technical Data SheetDocument5 pagesPenguard Primer: Technical Data SheetRekhis OussamaNo ratings yet

- TDS 27800 Penguard Universal Euk GBDocument5 pagesTDS 27800 Penguard Universal Euk GBLâm Trần BáNo ratings yet

- Jotatemp 1000 - TDSDocument5 pagesJotatemp 1000 - TDSTopik Budi Oetomo100% (1)

- Technical Data Sheet for Heat Resistant Epoxy CoatingDocument5 pagesTechnical Data Sheet for Heat Resistant Epoxy CoatingJayaraman KamarajNo ratings yet

- TDS 24100 Penguard WF Euk GBDocument6 pagesTDS 24100 Penguard WF Euk GBpradnyeyNo ratings yet

- JT TDSDocument5 pagesJT TDSKingsman 86No ratings yet

- Epoxy HR: Technical Data SheetDocument5 pagesEpoxy HR: Technical Data SheetMohamed FarhanNo ratings yet

- TDS 429 Conseal Touch-Up Euk GBDocument4 pagesTDS 429 Conseal Touch-Up Euk GBGalih WicaksonoNo ratings yet

- TDS 33343 Marathon 550 Euk GBDocument5 pagesTDS 33343 Marathon 550 Euk GBBozo CovicNo ratings yet

- Jotacote Universal Al TDSDocument5 pagesJotacote Universal Al TDSAlex KuvoricNo ratings yet

- Jotacote-F60-6A.TDS .EngDocument5 pagesJotacote-F60-6A.TDS .EngDedy YuniarchoNo ratings yet

- Technical Data Sheet for Penguard FCDocument5 pagesTechnical Data Sheet for Penguard FCPappu Kishore KumarNo ratings yet

- Aluminium Paint HR Technical Data SheetDocument4 pagesAluminium Paint HR Technical Data SheetGurdeep Sungh AroraNo ratings yet

- Tankguard SF: Technical Data SheetDocument5 pagesTankguard SF: Technical Data SheetRifki ArifinNo ratings yet

- Jotun - Penguard FC (Second Coat)Document5 pagesJotun - Penguard FC (Second Coat)Satria IstanaNo ratings yet

- Penguard HSP MIO E: Technical Data SheetDocument5 pagesPenguard HSP MIO E: Technical Data Sheethardik033No ratings yet

- Aluminium Paint HR TDSDocument4 pagesAluminium Paint HR TDSRaja S0% (1)

- Jotacote F60: Technical Data SheetDocument5 pagesJotacote F60: Technical Data SheetPeter PetersenNo ratings yet

- Penguard FC Technical Data SheetDocument5 pagesPenguard FC Technical Data SheetGurdeep Sungh AroraNo ratings yet

- Jotatemp 540 Zinc Technical Data SheetDocument5 pagesJotatemp 540 Zinc Technical Data SheetGurdeep Sungh AroraNo ratings yet

- Jotamastic 80 Aluminium - TDSDocument6 pagesJotamastic 80 Aluminium - TDSTeknik produksi wikonNo ratings yet

- Technical Data Sheet for Glass Flake CoatingDocument5 pagesTechnical Data Sheet for Glass Flake CoatingsmnisNo ratings yet

- Technical Data Sheet for Barrier 80 S Zinc Epoxy PrimerDocument5 pagesTechnical Data Sheet for Barrier 80 S Zinc Epoxy PrimerHung Mai VanNo ratings yet

- TDS-Penguard HSP-GB-English-ProtectiveDocument5 pagesTDS-Penguard HSP-GB-English-ProtectiveyugandharNo ratings yet

- Marathon 1000XHB Technical Data SheetDocument5 pagesMarathon 1000XHB Technical Data SheetGurdeep Sungh AroraNo ratings yet

- Technical Data Sheet for Tankguard HB CoatingDocument5 pagesTechnical Data Sheet for Tankguard HB Coatingabet_singkong8930No ratings yet

- Industrial Inorganic PigmentsFrom EverandIndustrial Inorganic PigmentsGunter BuxbaumRating: 5 out of 5 stars5/5 (1)

- SKF TMBH 1-2heating Clamp (Including. Cable and Plug) SpecificationDocument2 pagesSKF TMBH 1-2heating Clamp (Including. Cable and Plug) Specificationrinaldo KurniawanNo ratings yet

- Flender FlexibleCouplings FLE10 2 ENDocument116 pagesFlender FlexibleCouplings FLE10 2 ENNenad DeusicNo ratings yet

- SKF SY 508 M SpecificationDocument4 pagesSKF SY 508 M Specificationrinaldo KurniawanNo ratings yet

- Handrails - Brochure (EN)Document4 pagesHandrails - Brochure (EN)rinaldo KurniawanNo ratings yet

- Selection 38-39Document2 pagesSelection 38-39rinaldo KurniawanNo ratings yet

- SteelMaster 1200HPEDocument6 pagesSteelMaster 1200HPErinaldo KurniawanNo ratings yet

- KS-SG2 125-260 (2900rpm, 240mm) Data SheetDocument1 pageKS-SG2 125-260 (2900rpm, 240mm) Data Sheetrinaldo KurniawanNo ratings yet

- Bolt Torque ASTM A 490Document1 pageBolt Torque ASTM A 490rinaldo KurniawanNo ratings yet

- E500KGM-B Automatic Kammpro Grooving MachineDocument2 pagesE500KGM-B Automatic Kammpro Grooving Machinerinaldo KurniawanNo ratings yet

- Bolt Torque ASTM A 354-BD OR SAE GR 8Document1 pageBolt Torque ASTM A 354-BD OR SAE GR 8rinaldo KurniawanNo ratings yet

- BIS0116 - C1L7P3 - Technical Guide - Drilling - Countersinking - Tapping - WebDocument8 pagesBIS0116 - C1L7P3 - Technical Guide - Drilling - Countersinking - Tapping - WebkenNo ratings yet

- 19 Welding Catalog 10Document8 pages19 Welding Catalog 10Rizal NasutionNo ratings yet

- XST Oo TH Sys TemDocument8 pagesXST Oo TH Sys Temrinaldo KurniawanNo ratings yet

- Plastic WeldingDocument9 pagesPlastic WeldingTrecita BacoNo ratings yet

- Data Table For Grades Stainless Steels SUS 410 J1Document3 pagesData Table For Grades Stainless Steels SUS 410 J1retrogradesNo ratings yet

- Submerged Arc Welding GuideDocument2 pagesSubmerged Arc Welding GuidecalcedaNo ratings yet

- E 7016 Spezial electrode-oerlikon-en-TN110089Document2 pagesE 7016 Spezial electrode-oerlikon-en-TN110089Khhg AgddsNo ratings yet

- KENCO CHEMICAL INJECTORS for Natural Gas & Oil IndustriesDocument2 pagesKENCO CHEMICAL INJECTORS for Natural Gas & Oil IndustriesMEHDINo ratings yet

- DVC 99straightwayDocument2 pagesDVC 99straightwayMohamed ElmakkyNo ratings yet

- Cutting Tool Materials and Machinability GuideDocument63 pagesCutting Tool Materials and Machinability GuideTharunNo ratings yet

- MMKB31 044063000 PDFDocument548 pagesMMKB31 044063000 PDFajiNo ratings yet

- H2O2 Materials of Construction For The Storage of H2O2Document2 pagesH2O2 Materials of Construction For The Storage of H2O2Umar khanNo ratings yet

- Satinless Steel Boq PDFDocument1 pageSatinless Steel Boq PDFSoumya RanjanNo ratings yet

- CV SUMMARYDocument14 pagesCV SUMMARYBanerjee SuvranilNo ratings yet

- Gayathri Manilal DSR Micro Project PDFDocument27 pagesGayathri Manilal DSR Micro Project PDFVikas LakadaNo ratings yet

- Sa-530 For Flattening HeightDocument10 pagesSa-530 For Flattening HeightmaheshNo ratings yet

- Resolving The CRGO ConundrumDocument7 pagesResolving The CRGO Conundrumvipin51No ratings yet

- MG 20Document1 pageMG 20raduonoNo ratings yet

- Stainless SteelDocument4 pagesStainless SteelSrinivasHarshanNo ratings yet

- 002 DEW Warmarbeitsstahl GB PDFDocument76 pages002 DEW Warmarbeitsstahl GB PDFSinan Yıldız100% (1)

- A36 Specifications: Standard Low Carbon Steel, Without Advanced AlloyingDocument1 pageA36 Specifications: Standard Low Carbon Steel, Without Advanced AlloyingArmandoZacariasAcostaNo ratings yet

- Seminar ReportDocument22 pagesSeminar ReportVishnu Prasad100% (1)

- Advances in Boiler Tube Cladding TechnologyDocument6 pagesAdvances in Boiler Tube Cladding Technologyavm4343No ratings yet

- Miller - Joint Design and Weld TypeDocument8 pagesMiller - Joint Design and Weld Typed_beachboyzNo ratings yet