Professional Documents

Culture Documents

DFT Non Slam Vs Swing - 2018

Uploaded by

shwetaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

DFT Non Slam Vs Swing - 2018

Uploaded by

shwetaCopyright:

Available Formats

DFT Valves

Non-Slam Check Valves

vs.

Swing Check Valves

© 2017 DFT Valves

Non-Slam Check Valves vs. Swing Check Valves

Check valves, which allow fluid to flow in one direction but prevent it from flowing in the other, are available in

a wide range of styles. The variety most appropriate for your project will depend on the application at hand and

the specific properties it requires in a valve.

In this eBook, we’ll discuss two of the most common varieties of check valves, non-slam check valves and swing

check valves, while comparing their unique uses and benefits.

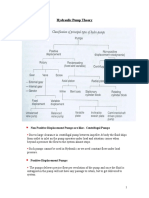

Key Differences Between Non-Slam and Swing Check Valves

Some styles of check valves are specifically designed to allow their disc, or flapper, to slam shut in certain

conditions, such as the reversal of fluid flow. This sudden shutting, or slamming, creates a wave of pressure in

the liquid that reverberates throughout the system and, depending on the precise application, can ultimately

lead to reduced process efficiency, valve damage, gasketed joint leaks and other issues. This inevitable — but

controllable — phenomenon is commonly referred to as water hammer.

Non-slam check valves are designed specifically for use in these

situations. As their name implies, these valves close without

slamming, meaning no excess pressure spikes are created. The

disc of a non-slam check valve has an internal spring opposing the

opening fluid flow pressure. When the flow of a media is strong

enough, the spring compresses and the valve opens; the disc is

smoothly pushed back toward the seating surface in the valve

by the spring as the flow decreases and stops, but before flow

direction reverses.

Often called flapper style check valves, swing check valves are a

more traditional variety. The disc of a swing check valve is secured to

the body of the valve by a trunnion and hinge arm, without the aid

of a spring. Unlike a non-slam check valve, which opens and closes

at rates comparable to the pressure of the fluid flow, a swing check

valve opens and closes more suddenly, relying on the installation

orientation, gravity, and reversing flow to close the valve.

DFT Inc. 140 Sheree Blvd. PO Box 566, Exton, PA 19341

toll-free 800-206-4013 fax 610.524.9242 e-mail dft@dft-valves.com

© 2017 DFT Valves website www.dft-valves.com 2

Applications

Both non-slam check valves and swing check valves are suitable for use in a wide range of applications. Generally,

though, non-slam check valves are ideal for vertical runs of piping, or complex applications that require constant

and controllable pressure levels. Alternatively, swing valves are often used in very large-volume applications,

horizontal pipe runs, and those applications in which varying pressures and flow rates are not a concern.

Due to the precise pressures required, non-slam check valves are commonly specified in various oil and gas,

refining, and power industry processes.

These valves can be found in the following applications:

• Gas and liquid pipelines • Gas export facilities

• Water and steam systems • Product tank farms

• Cooling towers • Gas storage caverns

• Water treatment • Mine dewatering

• Cryogenic applications

Non-slam check valves are also used in similar applications

throughout the chemical processing industry, steam condensate

systems, and in the power generation industry.

Swing valves, because of their less controlled opening and closing

mechanics, are used in less sensitive applications. They are most

commonly employed in large-scale pipeline applications, such as

liquid, gas, and steam, generally only in horizontal configurations. In

particular, they’re often used in natural gas applications, as natural

gas processing generally does not require as stringent pressure

control as the oil and refining industry or in sewage and water

treatment systems.

DFT Inc. 140 Sheree Blvd. PO Box 566, Exton, PA 19341

toll-free 800-206-4013 fax 610.524.9242 e-mail dft@dft-valves.com

© 2017 DFT Valves website www.dft-valves.com 3

Pros and Cons of Non-Slam and Swing Check Valves

Depending on the application, both non-slam check valves and swing check valves present unique advantages

and disadvantages.

Non-Slam Check Valves Swing Check Valves

One of the primary advantages of non-slam The primary benefit of swing check valves is

check valves is their ability to effectively their ability to allow a full, unobstructed flow

prevent water hammer, and, therefore, — which is particularly important in piping

eliminate resultant pressure swings, vibrations, systems that may require line cleaning. Swing

and damage. Non-slam valves have a short check valves are also ideal for use in low cost

stroke, which facilitates soft closing quickly in systems with manual valves, such as gate valves

the event of rapidly reduced flow to prevent in common use.

water hammer.

Because they feature only one moving part, the Disadvantages include a high rate of wear due

disc itself, non-slam check valves experience to the rotation about the hinge pin and the

minimal wear over time. In many designs, the requirement for full and precise alignment of

spring is also fully protected from the process the disc and seat upon closing. The limitations

flow. Together, these factors help to greatly of this design restrict their use in pulsating

extend the service lives of non-slam check systems with intentionally cyclic pressures, as

valves over more traditional valves. Non-slam the constant pulsating action of the valve leads

check valves’ extended lifespan and reduced to premature wear.

maintenance requirements ultimately allow for

greatly reduced operational costs, which mean

a lower cost of ownership over the full life

cycle of the part.

Non-slam check valves’ main disadvantage is

that they cannot be used where line cleaning

maintenance requires line “pigging.”

DFT Inc. 140 Sheree Blvd. PO Box 566, Exton, PA 19341

toll-free 800-206-4013 fax 610.524.9242 e-mail dft@dft-valves.com

© 2017 DFT Valves website www.dft-valves.com 4

Learn More

Though both non-slam check valves and swing check valves offer versatility in today’s varied industrial landscape,

non-slam check valves are increasingly supplanting standard swing valves in many situations.

This is largely due to the commonality of the water hammer phenomenon, which may arise to some degree in any

liquid control system. As these systems become more complex and rely on increased process automation, water

hammer becomes a more serious issue. Non-slam check valves are proven to be very effective at mitigating

this risk.

DFT® Inc. offers a wide range of reliable check valves specially designed to accommodate diverse applications

across every industry. To learn more about your options for preventing water hammer with non-slam check

valves, check out DFT® Inc.’s comprehensive check valve literature library. For more information and examples

of return on investment (ROI) of DFT reliable check valves, read our case studies highlighting the use and long

service life of DFT check valves.

TO DISCUSS YOUR NEEDS >>

with one of our value experts,

reach out to your DFT valve

representative today.

DFT Inc. 140 Sheree Blvd. PO Box 566, Exton, PA 19341

toll-free 800-206-4013 fax 610.524.9242 e-mail dft@dft-valves.com

© 2017 DFT Valves website www.dft-valves.com 5

You might also like

- Emulsions and Oil Treating Equipment: Selection, Sizing and TroubleshootingFrom EverandEmulsions and Oil Treating Equipment: Selection, Sizing and TroubleshootingRating: 5 out of 5 stars5/5 (3)

- Check Valve Design GuideDocument14 pagesCheck Valve Design GuideVijay DaeNo ratings yet

- Anupam Catalouge Check Valve SelectionDocument7 pagesAnupam Catalouge Check Valve Selectionsunil bajpaiNo ratings yet

- Design and Selection Criteria For Check ValvesDocument26 pagesDesign and Selection Criteria For Check Valvesmhopgood100% (3)

- Axial Flow Check ValvesDocument10 pagesAxial Flow Check ValvesABRAHAM ESTRADANo ratings yet

- WWW Spiraxsarco Com Check ValveDocument8 pagesWWW Spiraxsarco Com Check ValveMashudi FikriNo ratings yet

- Surge DamageDocument12 pagesSurge DamageRajat WadhwaniNo ratings yet

- List The Main Features of Globe ValveDocument3 pagesList The Main Features of Globe ValveArvin Rei SanquilosNo ratings yet

- Understanding Check Valves: Sizing For The Application, Not The Line SizeDocument5 pagesUnderstanding Check Valves: Sizing For The Application, Not The Line SizeSCR_010101No ratings yet

- Control ValveDocument37 pagesControl ValveSagar Bhardwaj100% (4)

- Non Return ValvesDocument10 pagesNon Return ValvesDevendra Bangar100% (1)

- "Dual Plate Check Valve PDFDocument16 pages"Dual Plate Check Valve PDFMohaab NasrNo ratings yet

- Dual Plate Check ValveDocument38 pagesDual Plate Check ValveVikas Kumar PathakNo ratings yet

- Check ValvesDocument12 pagesCheck ValvesddphilosophyNo ratings yet

- Design Flow Control ValveDocument22 pagesDesign Flow Control ValveMohini RajputNo ratings yet

- DFT CatalogDocument4 pagesDFT Catalogtilakthakar1No ratings yet

- Everything You Need to Know About ValvesDocument12 pagesEverything You Need to Know About Valvesram sNo ratings yet

- Valves: Oscar Mauricio Cala Camacho - 2152815 Iván Darío Nova Uribe - 2142795 Facilidades de Superficie Grupo H1 2020-1Document34 pagesValves: Oscar Mauricio Cala Camacho - 2152815 Iván Darío Nova Uribe - 2142795 Facilidades de Superficie Grupo H1 2020-1Oscar CalaNo ratings yet

- 3590 - Marine Piping Systems - VALVES On Shipbuilding ApplicationDocument14 pages3590 - Marine Piping Systems - VALVES On Shipbuilding ApplicationZhafira OspNo ratings yet

- Control Valve Sizing and Selection Guide in 40 CharactersDocument64 pagesControl Valve Sizing and Selection Guide in 40 CharactersAnonymous bZutEAphuNo ratings yet

- Valves in The Oil and Gas IndustryDocument55 pagesValves in The Oil and Gas IndustryK LandryNo ratings yet

- FS Valve HalliburtonDocument2 pagesFS Valve HalliburtonAlexandruAndreiNo ratings yet

- All About ValvesDocument16 pagesAll About Valvesmazen zaloudNo ratings yet

- Ball Butterfly Check Gate Globe Plug Valves Differences Applications SuitabilityDocument4 pagesBall Butterfly Check Gate Globe Plug Valves Differences Applications Suitabilitydattu33No ratings yet

- Valve PDFDocument18 pagesValve PDFDipakkumarNo ratings yet

- Hydraulic Multi-Purpose Gas Lift ValveDocument28 pagesHydraulic Multi-Purpose Gas Lift ValveLUIS. F RuizNo ratings yet

- Pressure ValvesDocument132 pagesPressure ValvesHassenLNo ratings yet

- Butterfly Valves for Flow ControlDocument14 pagesButterfly Valves for Flow Controlpaulo_rieloffNo ratings yet

- Control Valves Basics - Sizing & SelectionDocument64 pagesControl Valves Basics - Sizing & SelectionKajer quemar100% (1)

- Different Valve Types, Applications & SuitabilityDocument10 pagesDifferent Valve Types, Applications & SuitabilityGrazel MDNo ratings yet

- Control Valve by FenilDocument3 pagesControl Valve by FenilDEEP NariyaNo ratings yet

- Butterfly Valve Info PDFDocument14 pagesButterfly Valve Info PDFCS100% (1)

- Dynamic Characteristics Check ValvesDocument12 pagesDynamic Characteristics Check ValvesZoran DanilovNo ratings yet

- Control Valve Selection - Rising Stem or Quarter TurnDocument4 pagesControl Valve Selection - Rising Stem or Quarter TurnPeter Nai Ho100% (1)

- Isolation Valves - Linear MovementDocument9 pagesIsolation Valves - Linear MovementEmad A.AhmadNo ratings yet

- Instrumentation Course 2.Document67 pagesInstrumentation Course 2.FACE BOOK100% (1)

- Ommon Plumbing Valve TypesDocument28 pagesOmmon Plumbing Valve TypesGi SelleNo ratings yet

- Instrument 5 PDFDocument11 pagesInstrument 5 PDFAli AdnanNo ratings yet

- Check Valves (83BS)Document2 pagesCheck Valves (83BS)Anwar SyedNo ratings yet

- Basic Parts of ValveDocument5 pagesBasic Parts of ValveDivyamNo ratings yet

- Check ValvesDocument14 pagesCheck ValvesEryl YeongNo ratings yet

- Control Valve Selection PDFDocument218 pagesControl Valve Selection PDFSyed Ali100% (2)

- Delayed Float ValvesDocument6 pagesDelayed Float ValvesferasbushnaqNo ratings yet

- ValveTypesSelection - ControlsWikiDocument42 pagesValveTypesSelection - ControlsWikiMayur PatelNo ratings yet

- Orbit Article Molecular Sieve Dehydration Switching ValvesDocument12 pagesOrbit Article Molecular Sieve Dehydration Switching ValvesPasquale Sessa0% (1)

- Valves: Training Centre Wednesday, December 7, 2 016Document77 pagesValves: Training Centre Wednesday, December 7, 2 016Hoang DucNo ratings yet

- Why Piston Valves Are Better Isolation Shut Off ValveDocument2 pagesWhy Piston Valves Are Better Isolation Shut Off ValveShantanu KulkarniNo ratings yet

- Valves Renovations GuideDocument43 pagesValves Renovations GuidechaitraNo ratings yet

- Construction of A Check ValveDocument10 pagesConstruction of A Check Valvedevadoss kishoreNo ratings yet

- Making of Most of ValvesDocument12 pagesMaking of Most of ValvesShaikh MateenNo ratings yet

- Documents - Pub Knife Gate ValveDocument67 pagesDocuments - Pub Knife Gate ValveMahendra PatilNo ratings yet

- Principle Design Solenoid ValvesDocument28 pagesPrinciple Design Solenoid Valveshassan alrokabNo ratings yet

- Prevention of Valve Fugitive Emissions in the Oil and Gas IndustryFrom EverandPrevention of Valve Fugitive Emissions in the Oil and Gas IndustryNo ratings yet

- How Reverse Osmosis Works: A Look at Industrial ROFrom EverandHow Reverse Osmosis Works: A Look at Industrial RORating: 2.5 out of 5 stars2.5/5 (2)

- Sewage Disposal Works: Their Design and ConstructionFrom EverandSewage Disposal Works: Their Design and ConstructionNo ratings yet

- Damages on Pumps and Systems: The Handbook for the Operation of Centrifugal PumpsFrom EverandDamages on Pumps and Systems: The Handbook for the Operation of Centrifugal PumpsRating: 4.5 out of 5 stars4.5/5 (2)

- Popular Mechanics: How to Fix Anything: Essential Home Repairs Anyone Can DoFrom EverandPopular Mechanics: How to Fix Anything: Essential Home Repairs Anyone Can DoRating: 4 out of 5 stars4/5 (2)

- DesuperheaterDocument14 pagesDesuperheatervon18100% (1)

- Chapter - 7 - External Flow-ZoomDocument54 pagesChapter - 7 - External Flow-ZoomAhmad Alifian LirajabiNo ratings yet

- Chapter Fluid Machinery - PART 2Document27 pagesChapter Fluid Machinery - PART 2Winter NaiNo ratings yet

- Henry's Law - WikipediaDocument14 pagesHenry's Law - WikipediaZakria Shah100% (1)

- PRV Sizing For Exchanger Tube RuptureDocument5 pagesPRV Sizing For Exchanger Tube RuptureNavid Sajedi80% (5)

- A Basic But Helpful Guide On Framo SystemDocument29 pagesA Basic But Helpful Guide On Framo SystemCharlie Mak100% (1)

- 06 Petrucci10e CSMDocument54 pages06 Petrucci10e CSMAlexNo ratings yet

- FlowserveDocument118 pagesFlowserveCesar Cedano VivarNo ratings yet

- Filtro Combustible 6.62Document4 pagesFiltro Combustible 6.62Adrian MartulewiczNo ratings yet

- TAR FinalDocument17 pagesTAR FinalKiran KumarNo ratings yet

- SPE-184314-MS PVT Analysis: Validity Checks and EOS Tuning Techniques For Retrograde Gas Condensate ReservoirsDocument12 pagesSPE-184314-MS PVT Analysis: Validity Checks and EOS Tuning Techniques For Retrograde Gas Condensate ReservoirshusseinhshNo ratings yet

- LyoDocument22 pagesLyoAjay Kumar100% (1)

- Avoiding Pressure SurgeDocument33 pagesAvoiding Pressure SurgeManas KarnureNo ratings yet

- Principle of Operation: SpecificationsDocument2 pagesPrinciple of Operation: SpecificationsAlberto CastellanosNo ratings yet

- Most Reliable and Easiest to Maintain Heat Exchangers in IndiaDocument23 pagesMost Reliable and Easiest to Maintain Heat Exchangers in IndiaKarthik AnandanNo ratings yet

- CCNY LabManualDocument29 pagesCCNY LabManualShady HegazyNo ratings yet

- Centrifugal PumpsDocument5 pagesCentrifugal PumpsWaleed NasirNo ratings yet

- Control Valve CV Calculation - Valve Sizing Formula - InstrumentationToolsDocument16 pagesControl Valve CV Calculation - Valve Sizing Formula - InstrumentationToolskaustavNo ratings yet

- All Auxilary PumpsDocument10 pagesAll Auxilary PumpsRana Yasir AyubNo ratings yet

- Handling of Turbine During EmergencyDocument17 pagesHandling of Turbine During EmergencyManohar TatwawadiNo ratings yet

- Pcpumps: ProiexDocument3 pagesPcpumps: ProiexSavalia HardikNo ratings yet

- © Oxford University PressDocument71 pages© Oxford University PressMaden betoNo ratings yet

- IESOBJDocument387 pagesIESOBJsabya512No ratings yet

- What Is Pump Priming and Why It Is Required With PDFDocument9 pagesWhat Is Pump Priming and Why It Is Required With PDFAnas Al’BazzazNo ratings yet

- US Maritime Service Training Manual - Engineering Branch TrainingDocument152 pagesUS Maritime Service Training Manual - Engineering Branch Trainingmihalikj2190No ratings yet

- Drafts Andchimney PDFDocument3 pagesDrafts Andchimney PDFJayson Ben ArbasNo ratings yet

- Technical InformationDocument81 pagesTechnical InformationDan Nicole DadivasNo ratings yet

- Various Valves Arrangement For Machinery Spaces Piping SystemDocument10 pagesVarious Valves Arrangement For Machinery Spaces Piping SystemRaj GraffitiNo ratings yet

- Santosh G Kelshekar - AssortedDocument10 pagesSantosh G Kelshekar - AssortedscemanjuNo ratings yet

- Accurately Calculate Nitrogen RequirementDocument6 pagesAccurately Calculate Nitrogen RequirementRachel BaileyNo ratings yet