Professional Documents

Culture Documents

High Temperature Synthetic Thermic Fluid: Si Ma

Uploaded by

Santhosh DuraisamyOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

High Temperature Synthetic Thermic Fluid: Si Ma

Uploaded by

Santhosh DuraisamyCopyright:

Available Formats

High Temperature

Synthetic Thermic Fluid

Shreyas Petroleum Additives Limited

sigma T H E R M -K

Extended Life Thermic Fluid

Thermic Fluid and other Speciality Range

Liquid or Vapour

sigma T H E R M -A

sigma T H E R M -F Food Grade

sigma T H E R M -G

sigma T H E R M -K

sigma T H E R M -L

sigma T H E R M -N

sigma T H E R M -P

With Pressurisation

Food Grade

sigma T H E R M -S

With Pressurisation

sigma T H E R M -V

sigma T H E R M - FF 101 System Cleaner & Life Enhancer

sigma T H E R M - FF 201 Flushing Fluid

-125 -100 -75 -50 -25 0 25 50 75 100 125 150 175 200 225 250 275 300 325 350 375 400

Operating Temp. Range in Deg. Cent.

www.sigma-therm.com

Shreyas Petroleum Additives Limited

2, Hiranya Complex, Sardar Patel Chowk, Tel : +91 79 : 2674 6604

Vastrapur, Ahmedabad 380 015 India 2673 1649

E Mail : sales@shreyas.in 2676 7183 www.shreyas.in

ISO 9001

High Temperature Synthetic Heat Transfer Fluid Sigma T H E R M - K

Extended Life Thermic Fluid

Description :

sigma T H E R M ® – K is a synthetic heat transfer

fluid.

Application :

Indirect closed heat transfer systems up to 3 20°C.

For best life it should be used at or below 300°C.

Benefits :

As compared to other mineral based thermic fluid,

it has…….

ü High thermal stability.

Sigma

ü High oxidation stability

ü Very low carbon deposits.

ü Long Life. High and Low Boilers :

ü Reduced “ Low Boilers “ and “ High Boilers”

sigma T H E R M ® – K has lower Viscosity as High and low boilers are formed when heat transfer

fluids are heated to a high temperature and certain

compared to other thermic fluids - lower power

molecular bonds begin to break or thermally

consumption of circulating pump and high co-

efficient of heat transfer. degrade. Some of the new materials that form have

a lower molecular weight and typically a lower

sigma T H E R M ® – K has been thoroughly tested boiling point than the original fluid: these are low

in the laboratory with different proportionate of boilers.

mineral oil at various high temperatures for Other compounds resulting from thermal

stability and other related parameters.

degradation will polymerize into higher molecular

weight and higher boiling point molecules than the

Based on results it is proved that sigma T H E R

SYNTHETIC

® original fluid : These are high boilers.

M – K could be used for top-up purpose in the

systems already containing mineral oil based High and low boilers seen in components may not

thermic fluids or similar chemistry synthetic fluid. have the heat transfer efficiency and thermal

stability of the original heat transfer fluid

Thermic Fluids after some time of usage molecules.

Typical Properties :

Base Oil 100 % Synthetic

Appe aran ce Bright Yellow liqui d

Max. Temp erature 320˚ C / 608 ˚ F

-K

Kin. Vis. @ 40˚C 19 - 23 cSt

Specifi c Gravity @ 15˚ C 0.86 + 0.005

sigma T H E R M

Flash Point ( COC) 200 - 240˚ C

Pour point (- 60 ) - ( - 40 ) ˚C

sigma T H E R M ® – K Mineral oil Based Moisture content 50 - 100 ppm

Tota l Acid No . 0.005- 0.01 mg KOH/g

Auto Ignitio n Temperature Above 375˚ C

Packing : 210 Liters Barrel

Shreyas Petroleum Additives Limited

2

Mineral oil based Thermic Fluid V/s. Sigma T H E R M - K

Extended Life Thermic Fluid

Mineral Oil Based Thermic Fluid. sigma T H E R M® – K

- Synthetic Heat Transfer Fluid.

In the Petroleum refinery crude oil goes through

various refining processes like Distillation, ®

Since molecule of sigma T H E R M – K is

Cracking, Isomerisation, Hydrogenation etc. made by “Synthesis” process, it is called as

synthetic oil.

In the distillation process crude oil is heated and

at different temperatures different petroleum A particular short length of Straight and

products are available like – LPG, Aviation Fuel, Saturated Chain of Alkyl group is been reacted

Petrol, SKO, Diesel, Lubricant Base Oil, LDO, FO, with particular Aromatic to produce Alkyl

Asphaltene etc. Substituted Aromatic.

This separation is purely on the basis of their Alkyl Substituted Aromatics are a base oil of

boiling ranges. It means whatever may be the

sigma T H E R M® – K

Sigma

chemical structure ( Paraffinic, Naphthenic, etc )

and if it boils within certain temperature range it

It has a definite chemical structure and very

will be classified as a certain petroleum product.

narrow range of boiling.

This fundamental is also applicable for the

lubrication base oil. It contains different class of Due to presence of Aromatic group and particular

chemistry with different structures like linear and arrangement of short and saturated alkyl group in

the molecule, it has far better properties like

branched chain with saturated and unsaturated

carbons. Oxidation resistance, Thermal stability, low carbon

depositions, low viscosity, low rate of evaporation

A particular boiling range petroleum refinery cut is loss at operating temperature etc.

being used as base oil for mineral based thermic

fluid. Since source of raw material is mineral oil Thus due to its properties its deterioration rate is

( Petroleum Crude ) it is called mineral based reduced by approx. half. In other words it has got

double the life as compared to mineral base

SYNTHETIC

thermic fluid.

thermic fluids.

Note :

Aromatics are well known for their solvency effect.

All mineral oil based thermic fluid and Presence of aromatic group in sigma T H E R

sigma T H E R M® – K are compatible with M

®

– K provides self cleaning property.

each other. So if any system is filled with

either of the fluid alternative fluids can be ®

Kin. Vis. at 40 oC of sigma T H E R M – K is

used for top up purpose.

19-23 cSt as compared to 32-36 of Mineral base

thermic fluids. Lower viscosity will increase heat

transfer rate.

-K

In summ ery as compared to mineral based oil, it has…….

sigma T H E R M

High thermal efficiency. Better oxidation stability

Reduced “Low Boilers” and “High Boilers” Lower carbon deposits.

Lower Power consumption of Pump Long Life.

Shreyas Petroleum Additives Limited

3

Thermal Stability Test Report Sigma T H E R M - K

Extended Life Thermic Fluid

The Cincinnati Milacron test (Procedure A * modified) consisted of heating 200 ml of thermal fluid in a beaker at 135 ±

3°C in a convection oven for 168 hours. Prior to heating, polished copper and steel rods were placed in the beaker with

the rods touching each other. After 168 hours, the rods were inspected for deposits and lacquer and then rated against

heat test standards on a scale from 1 to 10 where 10 indicates highly fouled rods (see Figure ). The quantity of sludge

produced in the fluid was also determined.

* Aluminum Fixture is not used

This test has been accepted worldwide as well as in ASTM standard by the Designation: D 2070 – 91 (Re-approved

2006)

Sr. No. Test Description Test Method Result

1. Rating of copper rod As per Cincinnati 2

Sigma

Milacron scale

2. Weight of sludge deposit on Weighing --

copper rod, mg

3. Metal loss on copper rod, mg Weighing - 0.8

4. Rating of steel rod As per Cincinnati 2

Milacron scale

5. Weight of lacquer deposit on Weighing + 0.2

steel rod, mg

6. Metal loss on steel rod, mg Weighing --

7. Total sludge, mg/100ml IS 1448 (P:41) NIL

SYNTHETIC Cincinnati Milacron Scale

Heat Test Standard

1

3 4 5 6 7 8 9 10

Copper Rod Corrosion Standard

-K

1

3 4 5 6 7 8 9 10

sigma T H E R M

Steel Rod Corrosion Standard

Test carried out at Independent Research laboratory – The Automotive Research Association of India,

Research Institute of the Automotive Industry with the Ministry of Heavy Industries and Public

Enterprises, Govt. Of India.

Shreyas Petroleum Additives Limited

4

Thermal Stability Test Photos Sigma T H E R M - K

Extended Life Thermic Fluid

-K

sigma T H E R M

Shreyas Petroleum Additives Limited

5

Benefits of Low Viscosity - I Sigma T H E R M - K

Extended Life Thermic Fluid

sigma T H E R M ® – K All Other Thermic Fluids

o

Kin. Vis . @ 40 C, cSt 19-23 32 - 38

High Co efficient of Heat Transfer :

Heat transfer of co-efficient ( h ) is calculated by below given formula.

Where

k w . Nu kw = thermal conductivity

h= Nu = Nusselt number

DH

= 0.024.Re0.8 . Pr0.4

Dittus-Boelter correlation for pipe flow with fluid heated by wall

Sigma

Pr = Prandtl number = Cp . V

Kw

Re = Reynolds number = m.DH

V. A

DH = Hydraulic diameter

m = mass flow rate

V = viscosity

Cp = heat capacity at constant pressure

A = cross-sectional area of flow

By solving above formula it is proved that heat transfer co-efficient is inversely proportionate to the

viscosity of the fluid.

1

h ∝

V

SYNTHETIC

° ®

At 40 C Kin. Vis. of sigma T H E R M – K is just 19 - 23 cSt as compared to 32 - 38 of all other mineral

based or synthetic thermic fluids. Lower viscosity of sigma T H E R M® – K provides very high co-

efficient of heat transfer as compared to any other thermic fluid.

Viscosity Index of sigma T H E R M ® – K is very low as compared to 95 of mineral oil based thermic

®

fluid. It means as the temperature increases sigma T H E R M – K will be thinner as compared to

mineral oil. At operating temperature difference between Kinematic Viscosity will be further increased.

This in tern increases heat transfer co-efficient at operating temperature.

-K

In thermopack system heat transfer oil gets below 1 minute to get heat from both the coils. Same way this

sigma T H E R M

much short time is available on machine side. In this circumstances speed at which it gets and releases heat

is very important. Speed of heat transfer is Co efficient of heat transfer. So lower the viscosity of oil - faster

heat tr ansfer.

Reduced load on circulating pump

High Flow Rate of thermic fluid with the same power usage.

High co efficient of heat transfer gives higher thermal efficiency and thus reduces fuel

consumption.

Shreyas Petroleum Additives Limited

6

Benefits of Low Viscosity - II Sigma T H E R M - K

Extended Life Thermic Fluid

To maintain turbulent flow inside the tube is very important for any thermic fluid based heat

transfer system. Now to maintain turbulent flow Viscosity of oil should not exceed certain limit.

Turbulent flow is important for better heat transfer and long life of thermic fluid.

Max. Viscosity of the Fluid for Turbulent Flow

K i n . Vi s .

of the Fluid

Sigma

Mineral Based Thermic Fluid

sigma T H E R M® – K

Since thermal stability of mineral based thermic fluid is lower as compared to synthetic thermic

fluid normal life of synthetic thermic fluid is 2 to 3 times.

®

Viscosity and Viscosity Index of sigma T H E R M – K is very low as compared to all other

mineral and synthetic fluids. So it takes longer duration to reach viscosity where turbulent flow

SYNTHETIC

is not possible.

-K

sigma T H E R M

Shreyas Petroleum Additives Limited

7

Properties Sigma T H E R M - K

Extended Life Thermic Fluid

Sp ecific Thermal K inematic Vapou r Volumetric

T emp °C Den sity

Heat Cond uctivity Viscosity Pressure Expansion

3

kg/m K J/Kg K W/m K cSt psia %

-25 902 1.74 0.1336 1450 0 -

0 885 1.83 0.1306 172 0 0

25 869 1.92 0.1278 40 0 1.8

Sigma

50 851 2.01 0.125 13 0 3.8

75 835 2.1 0.122 6.21 0 5.6

100 818 2.2 0.119 3.52 0.00495 7.6

125 801 2.28 0.1162 2.32 0.0157 9.5

150 783 2.36 0.1133 1.65 0.0484 11.5

175 766 2.45 0.1103 1.2 0.117 13.4

200 748 2.55 0.1074 0.97 0.319 15.5

SYNTHETIC

225 730 2.64 0.1045 0.823 0.686 17.5

250 711 2.72 0.1016 0.686 1.41 19.7

275 692 2.81 0.0985 0.581 2.76 21.6

300 671 2.9 0.0954 0.496 5.06 23.6

325 650 3 0.0925 0.425 9 25.5

-K

sigma T H E R M

Liability Disclaimer : This inforamation and our technical advice – whether verbal, in writing or by way of trials – are given in good faith but

without warranty, and this also applies wh ere proprietary rights of third parties are involved. Our advice does not releas e you from the obligation to

verify the in formation curretly provided –esp ecially that contained in our safety data and technical information sheets – and to test our products as

to their suitability for the intended process es and uses. Th e application, u se and processing of our products and the products manufactured by you

on the bas is of our technical ad vice are beyond our control and , therefore, entirely your own resp on sibility. Our Products are sold in accordance

with th e curren t version of our General Conditions of Sale and Delivery.

Shreyas Petroleum Additives Limited

CIN : U23209GJ2003PLC042731

8

You might also like

- Paratherm HR: Heat Transfer FluidDocument2 pagesParatherm HR: Heat Transfer FluidshyamNo ratings yet

- Habor enDocument28 pagesHabor enEmerson TerrelNo ratings yet

- Burger King Case StudyDocument11 pagesBurger King Case StudySanthosh Duraisamy67% (3)

- Burger King Case StudyDocument11 pagesBurger King Case StudySanthosh Duraisamy67% (3)

- Sigma FG 10 PDFDocument4 pagesSigma FG 10 PDFdhanu2399No ratings yet

- MT10741Document8 pagesMT10741Business DevelopmentNo ratings yet

- Refrigeration Compressor LubricationDocument3 pagesRefrigeration Compressor LubricationYutt WattNo ratings yet

- Sumoil R-717 Premium Ammonia Refrigeration Compressor LubricantDocument2 pagesSumoil R-717 Premium Ammonia Refrigeration Compressor LubricantFajar EkoNo ratings yet

- Pso Heat Transfer OilDocument1 pagePso Heat Transfer OilMuhammad EhsanNo ratings yet

- Gas Sec 1 PDFDocument40 pagesGas Sec 1 PDFJose Manuel MatossNo ratings yet

- Primalec Air Conditioning Solutions enDocument8 pagesPrimalec Air Conditioning Solutions enKapil Kumar VermaNo ratings yet

- Emkarate RL Refrigeration LubricantsDocument6 pagesEmkarate RL Refrigeration LubricantsBrayan MejiaNo ratings yet

- PDF HK Productline e 07 2017.en.15Document13 pagesPDF HK Productline e 07 2017.en.15Henry Sunarko100% (1)

- q8 Formula f1 10w 50Document1 pageq8 Formula f1 10w 50Márton MolnárNo ratings yet

- Cepsa Fundicol Synt Ehc: Lubricants For Industrial UseDocument2 pagesCepsa Fundicol Synt Ehc: Lubricants For Industrial UseVladislav TrempoletsNo ratings yet

- Marco Material Datasheet Z1028Document3 pagesMarco Material Datasheet Z1028radziNo ratings yet

- Water Jet Ejector SystemDocument8 pagesWater Jet Ejector SystemKumarNo ratings yet

- P R O D U C T: Product DescriptionDocument1 pageP R O D U C T: Product DescriptionKamran AliNo ratings yet

- Refrigerating OilsDocument4 pagesRefrigerating OilsSuprastowo Bin SarinoNo ratings yet

- Gas TurbineDocument18 pagesGas TurbinenivasssvNo ratings yet

- REPSOL TRANSMISSION EP 80W90 & 85w140 PDFDocument1 pageREPSOL TRANSMISSION EP 80W90 & 85w140 PDFrandi100% (1)

- Servosystem HLPDocument1 pageServosystem HLPRAHULGUNDHER25No ratings yet

- Best Practice LGP Series ENDocument10 pagesBest Practice LGP Series ENMohsenNo ratings yet

- Serviços de Manutenção de TratoresDocument36 pagesServiços de Manutenção de TratoresTelma Nsai Messias Gomes DiasNo ratings yet

- MAK Thermic Fluid ADocument4 pagesMAK Thermic Fluid AprimnnitNo ratings yet

- MHT-Unit 5Document12 pagesMHT-Unit 5Aariyan K. ArkoNo ratings yet

- Gems Pressure Transducer PDFDocument5 pagesGems Pressure Transducer PDFFelix Alex de Vera100% (1)

- TDI-13680 Spec SheetDocument1 pageTDI-13680 Spec SheetMike PerryNo ratings yet

- Royal Petro Energy: Bridging The GapDocument1 pageRoyal Petro Energy: Bridging The GapgenebabaNo ratings yet

- Servotherm Oils: Description ApplicationDocument1 pageServotherm Oils: Description Applicationsofiane aliNo ratings yet

- AISI 321 SpecificationsDocument1 pageAISI 321 SpecificationsMatija BušićNo ratings yet

- Royal Petro Energy: Bridging The GapDocument1 pageRoyal Petro Energy: Bridging The GapgenebabaNo ratings yet

- Pertamina Grease em SeriesDocument1 pagePertamina Grease em SeriesmanroNo ratings yet

- Emkarate Refrigeration 32 68Document2 pagesEmkarate Refrigeration 32 68Israel YepezNo ratings yet

- Accelerator-3000A ®: DescriptionDocument3 pagesAccelerator-3000A ®: DescriptionGizem D.No ratings yet

- 25hbc3 2pd PDFDocument88 pages25hbc3 2pd PDFsuhasNo ratings yet

- Calculation of An Oil/air CoolerDocument1 pageCalculation of An Oil/air CoolerFabianEnriquePerezVarelaNo ratings yet

- Royal Petro Energy: Bridging The GapDocument1 pageRoyal Petro Energy: Bridging The GapgenebabaNo ratings yet

- Bluegard 3000Document3 pagesBluegard 3000Operaciones 05No ratings yet

- Kromatis TrafficDocument1 pageKromatis TrafficOmar HadriNo ratings yet

- Royal Petro Energy: Bridging The GapDocument1 pageRoyal Petro Energy: Bridging The GapgenebabaNo ratings yet

- 2nd Law of Thermodynamics and Entropy RK RajputDocument40 pages2nd Law of Thermodynamics and Entropy RK RajputKshitij PatleNo ratings yet

- Coolant Pro S+Document3 pagesCoolant Pro S+Bernad OrlandoNo ratings yet

- CfsdfsfwcereDocument28 pagesCfsdfsfwcerevinicius schwabNo ratings yet

- Heat Transfer Oil - Total Seriola K 3120 SpecDocument3 pagesHeat Transfer Oil - Total Seriola K 3120 SpecQuang VũNo ratings yet

- ยาง O-ringDocument78 pagesยาง O-ringJirakom LimmongkolkulNo ratings yet

- AC Pressure Chart R-134a Temperature Pressure ChartDocument3 pagesAC Pressure Chart R-134a Temperature Pressure ChartJoseph Tchagou PoumoNo ratings yet

- 31ca 32ca Series 20 Aug 19Document4 pages31ca 32ca Series 20 Aug 19djelen32No ratings yet

- Gate Vale Ductile Iron - KITZ10SMSDocument1 pageGate Vale Ductile Iron - KITZ10SMSarman azi putraNo ratings yet

- Various Refrigeration Systems A Part III 17062020Document14 pagesVarious Refrigeration Systems A Part III 17062020khanmattani123No ratings yet

- Bearing Lubrication: Grease Quantity 0.05 X D X B GmsDocument2 pagesBearing Lubrication: Grease Quantity 0.05 X D X B GmsMH MNo ratings yet

- Royal Petro Energy: Bridging The GapDocument1 pageRoyal Petro Energy: Bridging The GapgenebabaNo ratings yet

- Refrigerant Pipe SizingDocument90 pagesRefrigerant Pipe SizingHasib KhanNo ratings yet

- Globaltherm Omnipure Product Information SheetDocument4 pagesGlobaltherm Omnipure Product Information SheetMalek MahmoudNo ratings yet

- Sentishield 4000 DatasheetDocument1 pageSentishield 4000 DatasheetAlfredo YongNo ratings yet

- TF-10 Therminol ADX-10Document8 pagesTF-10 Therminol ADX-10vaboc48647No ratings yet

- HGE-PyramidSeries BrochureDocument4 pagesHGE-PyramidSeries BrochureCesar HernandezNo ratings yet

- PR 1750 Class ADocument2 pagesPR 1750 Class AMeed Bin HameedNo ratings yet

- S02 Lub DD310 - DL330 - DS310Document2 pagesS02 Lub DD310 - DL330 - DS310Luis JosueNo ratings yet

- Gulf Therm Aug12 - 20120903171744Document1 pageGulf Therm Aug12 - 20120903171744Nashrul HakimNo ratings yet

- Contact Lens Prescription: Delivery AddressDocument2 pagesContact Lens Prescription: Delivery AddressSanthosh DuraisamyNo ratings yet

- Auto Components September 2017 PDFDocument44 pagesAuto Components September 2017 PDFSanthosh DuraisamyNo ratings yet

- Pet 8 Rustpreventatives en PDFDocument7 pagesPet 8 Rustpreventatives en PDFSanthosh DuraisamyNo ratings yet

- McDonald Case PDFDocument10 pagesMcDonald Case PDFSanthosh DuraisamyNo ratings yet

- Rust Preventives PDFDocument6 pagesRust Preventives PDFSanthosh DuraisamyNo ratings yet

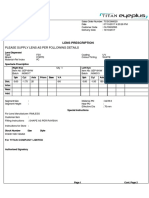

- Please Supply Lens As Per Following DetailsDocument2 pagesPlease Supply Lens As Per Following DetailsSanthosh DuraisamyNo ratings yet

- Worl Steel 2017Document17 pagesWorl Steel 2017Gurnam SinghNo ratings yet

- The Road To 2020 and BeyondDocument24 pagesThe Road To 2020 and BeyondGreen WoodNo ratings yet

- Safety Data Sheet: SECTION 1: Identification of The Substance/mixture and of The Company/undertakingDocument13 pagesSafety Data Sheet: SECTION 1: Identification of The Substance/mixture and of The Company/undertakingSanthosh DuraisamyNo ratings yet

- PDS - TO 335 H - Type IIDocument1 pagePDS - TO 335 H - Type IISanthosh DuraisamyNo ratings yet

- Signature Not Verified: Digitally Signed by C SATHISH Date: 2020.02.19 17:27:07 IST Location: Tamil Nadu-TNDocument1 pageSignature Not Verified: Digitally Signed by C SATHISH Date: 2020.02.19 17:27:07 IST Location: Tamil Nadu-TNSanthosh DuraisamyNo ratings yet

- 22 Immutable LawsDocument23 pages22 Immutable LawsSanthosh DuraisamyNo ratings yet

- Castrol Techniclean AS 58: DescriptionDocument2 pagesCastrol Techniclean AS 58: DescriptionSanthosh DuraisamyNo ratings yet

- What Is A Global Manager?: by Christopher A. Barlett and Sumantra GhoshalDocument5 pagesWhat Is A Global Manager?: by Christopher A. Barlett and Sumantra GhoshalSanthosh DuraisamyNo ratings yet

- Travelgenio Terms and ConditionsDocument3 pagesTravelgenio Terms and ConditionsSanthosh DuraisamyNo ratings yet

- Tata Corus DealDocument2 pagesTata Corus DealSanthosh DuraisamyNo ratings yet

- Sale of Goods ActDocument21 pagesSale of Goods ActSanthosh DuraisamyNo ratings yet

- Presented To:: Dr. Dibyojyoti BhattacharjeeDocument35 pagesPresented To:: Dr. Dibyojyoti BhattacharjeeSanthosh DuraisamyNo ratings yet

- Airborne Group4 Section ADocument20 pagesAirborne Group4 Section ASanthosh DuraisamyNo ratings yet

- IT in Business & LifeDocument27 pagesIT in Business & LifeSanthosh DuraisamyNo ratings yet

- 22 Immutable LawsDocument23 pages22 Immutable LawsSanthosh DuraisamyNo ratings yet

- FevicolDocument34 pagesFevicolYogesh SanganiNo ratings yet

- Wave Cal Tail PipeDocument9 pagesWave Cal Tail PipeSanthosh DuraisamyNo ratings yet

- Conducting Market ResearchDocument24 pagesConducting Market ResearchSanthosh DuraisamyNo ratings yet

- Assorted Deodarant: Efforts byDocument32 pagesAssorted Deodarant: Efforts byRajat SinghNo ratings yet

- Pepsi - Market StudyDocument16 pagesPepsi - Market StudySanthosh DuraisamyNo ratings yet

- Brain Drain in IndiaDocument1 pageBrain Drain in IndiaSanthosh DuraisamyNo ratings yet