Professional Documents

Culture Documents

NR0609 DS/ES Simulator Instruction Manual: NR Electric Co., LTD

Uploaded by

Cheng Kean KeongOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

NR0609 DS/ES Simulator Instruction Manual: NR Electric Co., LTD

Uploaded by

Cheng Kean KeongCopyright:

Available Formats

NR0609

DS/ES Simulator

Instruction Manual

NR Electric Co., Ltd.

Preface

Preface

1.1 Introduction

This guide and the relevant operating or service manual documentation for the equipment provide

full information on safe handling, commissioning and testing of this equipment.

Documentation for equipment ordered from NR is dispatched separately from manufactured goods

and may not be received at the same time. Therefore, this guide is provided to ensure that printed

information normally present on equipment is fully understood by the recipient.

Before carrying out any work on the equipment, the user should be familiar with the contents of

this manual, and read relevant chapter carefully.

This chapter describes the safety precautions recommended when using the equipment. Before

installing and using the equipment, this chapter must be thoroughly read and understood.

1.2 Health and Safety

The information in this chapter of the equipment documentation is intended to ensure that

equipment is properly installed and handled in order to maintain it in a safe condition.

When electrical equipment is in operation, dangerous voltages will be present in certain parts of

the equipment. Failure to observe warning notices, incorrect use, or improper use may endanger

personnel and equipment and cause personal injury or physical damage.

Before working in the terminal strip area, the equipment must be isolated.

Proper and safe operation of the equipment depends on appropriate shipping and handling,

proper storage, installation and commissioning, and on careful operation, maintenance and

servicing. For this reason, only qualified personnel may work on or operate the equipment.

Qualified personnel are individuals who:

Are familiar with the installation, commissioning, and operation of the equipment and of the

system to which it is being connected;

Are able to safely perform switching operations in accordance with accepted safety

engineering practices and are authorized to energize and de-energize equipment and to

isolate, ground, and label it;

Are trained in the care and use of safety apparatus in accordance with safety engineering

practices;

Are trained in emergency procedures (first aid).

1.3 Instructions and Warnings

The following indicators and standard definitions are used:

NR0609 DS/ES Simulator i

Date: 2016-01-06

Preface

DANGER! means that death, severe personal injury and considerable equipment damage

will occur if safety precautions are disregarded.

WARNING! means that death, severe personal and considerable equipment damage

could occur if safety precautions are disregarded.

CAUTION! means that light personal injury or equipment damage may occur if safety

precautions are disregarded.

NOTICE! is particularly applies to damage to device and to resulting damage of the protected

equipment.

DANGER!

NEVER allow a open current transformer (CT) secondary circuit connected to this

device while the primary system is live. Open CT circuit will produce a dangerously high

voltage that cause death.

WARNING!

ONLY qualified personnel should work on or in the vicinity of this device. This personnel

MUST be familiar with all safety regulations and service procedures described in this

manual. During operating of electrical device, certain part of the device is under high

voltage. Severe personal injury and significant device damage could result from

improper behavior.

WARNING!

Do NOT touch the exposed terminals of this device while the power supply is on. The

generated high voltage causes death, injury, and device damage.

WARNING!

Thirty seconds is NECESSARY for discharging the voltage. Hazardous voltage can be

present in the DC circuit just after switching off the DC power supply.

CAUTION!

Earthing

Securely earthed the earthing terminal of the device.

Operating environment

ONLY use the device within the range of ambient environment and in an

environment free of abnormal vibration.

ii NR0609 DS/ES Simulator

Date: 2016-01-06

Preface

Ratings

Check the input ratings BEFORE applying AC voltage/current and power supply to

the device.

Printed circuit board

Do NOT attach or remove printed circuit board if the device is powered on.

External circuit

Check the supply voltage used when connecting the device output contacts to

external circuits, in order to prevent overheating.

Connection cable

Carefully handle connection cables without applying excessive force.

NOTICE!

The firmware may be upgraded to add new features or enhance/modify existing

features, please MAKE SURE that the version of this manual is compatible with the

product in your hand.

Copyright © 2016 NR. All rights reserved.

We reserve all rights to this document and to the information contained herein. Improper use in particular reproduction and dissemination

to third parties is strictly forbidden except where expressly authorized.

The information in this manual is carefully checked periodically, and necessary corrections will be included in future editions. If

nevertheless any errors are detected, suggestions for correction or improvement are greatly appreciated.

We reserve the rights to make technical improvements without notice.

NR ELECTRIC CO., LTD. Tel: +86-25-87178888

Headquarters: 69, Suyuan Avenue, Jiangning, Nanjing 211102, China Fax: +86-25-87178999

Manufactory: 18, Xinfeng Road, Jiangning, Nanjing 211111, China Website: www.nrelect.com, www.nrec.com

PN: ZL_NR0609_X_Instruction Manual_EN_Overseas General_X Version: R1.00

NR0609 DS/ES Simulator iii

Date: 2016-01-06

Preface

Documentation Structure

The manual provides a functional and technical description of this relay and a comprehensive set

of instructions for the relay’s use and application.

All contents provided by this manual are summarized as below:

1 Function Introduction

Introduce the application, functions and typical wiring about NR0609 DS/ES simulator.

2 Technical Data

Introduce the technical data about NR0609 DS/ES simulator, such as electrical specifications,

mechanical specifications, ambient temperature and humidity range, type tests and the

certifications that our products have passed.

3 Hardware and Installation

Introduce the panel arrangement and the terminal definition of NR0609 DS/ES simulator. A guide

to the mechanical and electrical installation of this relay is also provided, incorporating earthing

recommendations.

4 Manual Version History

List the instruction manual version and the modification history records.

iv NR0609 DS/ES Simulator

Date: 2016-01-06

1 Function Introduction

1 Function Introduction

Table of Contents

1 Function Introduction ....................................................................... 1-a

1.1 Application....................................................................................................... 1-1

1.2 Function Configuration .................................................................................. 1-1

1.3 Typical Wiring .................................................................................................. 1-1

NR0609 DS/ES Simulator 1-a

Date: 2016-01-06

1 Function Introduction

1-b NR0609 DS/ES Simulator

Date: 2016-01-06

1 Function Introduction

1.1 Application

NR0609 disconnector switch/earth switch (DS/ES) simulator is designed according to the usage

characteristic of the actual DS/ES, it can simulate the operating characteristic of DS/ES. It can be

used to replace multi-channel DS/ES to coordinate with secondary equipment to accomplish

related function tests.

1.2 Function Configuration

NR0609 can be used to simulate eight groups of DS/ES, per group of DS/ES can be operated

independently, its functions include:

1) Use the magnetic latching relay to realize the simulation of DS/ES operating characteristic

(status holding after operation);

2) Manually operating button: simulating manually opening and closing operation;

3) Control input interface: accomplishing the opening and closing operation of DS/ES via

external input;

4) Position indicator: indicating the position status of DS/ES;

5) Output contact: simulating DS/ES auxiliary contact.

NR0609 includes internal power transform module, it can transform the external input power to

24V DC power which can be used for internal.

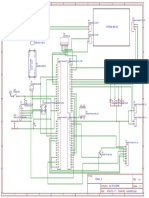

1.3 Typical Wiring

The typical wiring of NR0609 is shown in following figure.

The power transform module will transform the external input power to 24V DC power, which can

be used for DS/ES simulator.

The bottons of the figure can simulate the manually opening and closing operation of DS/ES.

Control input interfaces are equipped with NR0609, the control output of secondary equipment can

be connected to it, then the opening and closing operation of DS/ES can be realized.

The indicators of the figure can be used to indicate the DS/ES position status, the output contact is

the auxiliary contact of DS/ES.

NR0609 DS/ES Simulator 1-1

Date: 2016-01-06

1 Function Introduction

101 201 Close DS/ES 1

DS/ES 1 is open

202 Open DS/ES 1

102

DS/ES 1 is closed

103 203 Close DS/ES 2

DS/ES 2 is open

204 Open DS/ES 2

104

DS/ES 2 is closed

105 205 Close DS/ES 3

DS/ES 3 is open

206 Open DS/ES 3

106

DS/ES 3 is closed

107 207 Close DS/ES 4

DS/ES 4 is open

208 Open DS/ES 4

108

DS/ES 4 is closed

109 209 Close DS/ES 5

DS/ES 5 is open

210 Open DS/ES 5

110

DS/ES 5 is closed

111 211 Close DS/ES 6

DS/ES 6 is open

212 Open DS/ES 6

112

DS/ES 6 is closed

113 213 Close DS/ES 7

DS/ES 7 is open

214 Open DS/ES 7

114

DS/ES 7 is closed

115 215 Close DS/ES 8

DS/ES 8 is open

216 Open DS/ES 8

116

DS/ES 8 is closed

117 217

118 218

119 219 24V_IN+

Position 120 220

common 24V_IN-

terminal

Power

transform

301

302

303

304

305

306

24V_OUT+

24V_OUT-

PWR GND

PWR+

PWR-

Figure 1.3-1 Typical wiring diagram of NR0609

1-2 NR0609 DS/ES Simulator

Date: 2016-01-06

2 Technical Data

2 Technical Data

Table of Contents

2 Technical Data ................................................................................... 2-a

2.1 Electrical Specifications ................................................................................. 2-1

2.2 Mechanical Specifications.............................................................................. 2-1

2.3 Ambient Temperature and Humidity Range .................................................. 2-1

2.4 Type Tests ........................................................................................................ 2-2

2.5 Certifications ................................................................................................... 2-2

NR0609 DS/ES Simulator 2-a

Date: 2016-01-06

2 Technical Data

2-b NR0609 DS/ES Simulator

Date: 2016-01-06

2 Technical Data

2.1 Electrical Specifications

2.1.1 Power Supply

Rated voltage 110Vdc/125Vdc/220Vdc/250Vdc or 110/220Vac

Quiescent condition <3W

Burden

Operating condition <5W

2.1.2 Control Input

Rated voltage 24Vdc

Rated current Approximately 25mA

Burden under operating condition 500Vac

2.1.3 Contact Output

Output mode Potential free contact

Maximal working voltage 380Vac, 250Vdc

Test voltage across open contact 1000V RMS for 1min

5A@380Vac

Continuous carry

5A@250Vdc

6A@3s

Short duration current 15A@0.5s

30A@0.2s

Pickup time <8ms

Dropoff time <8ms

0.65A@48Vdc

Breaking capacity (L/R=40ms) 0.30A@110Vdc

0.15A@220Vdc

Durability (Loaded contact) 10000 operations

2.2 Mechanical Specifications

Housing color Silver grey

Weight per device Approx. 1kg

Pollution degree Ⅱ

Protection class

Front side IP40

Other sides IP40

Rear side IP30

2.3 Ambient Temperature and Humidity Range

Operating temperature -20°C to +55°C

Transport and storage temperature

-40°C to +70°C

range

Permissible humidity 5%-95%, without condensation

NR0609 DS/ES Simulator 2-1

Date: 2016-01-06

2 Technical Data

2.4 Type Tests

2.4.1 Environmental Tests

Dry cold test IEC 60068-2-1:2007 (16 h at -25°C)

Dry heat test IEC 60068-2-2:2007 (16 h at +55°C)

IEC 60068-2-30:2005 (Two (12+12) hour cycles 95%RH, low

Damp heat test, cyclic

temperature -25°C, high temperature +55°C)

2.4.2 Insulation Tests

Standard IEC 60255-27-2013

Input power and output contact part: Test voltage 2kV, 50Hz, 1min

Dielectric tests

24V power and control input part: Test voltage 0.5kV, 50Hz, 1min

Insulation resistance measurements Isolation resistance >100MΩ@500VdC

Input power and output contact part: 5kV

Impulse voltage tests

24V power and control input part: 1kV

2.5 Certifications

ISO9001:2008

ISO14001:2004

OHSAS18001:2007

ISO10012:2003

CMMI L5

EMC: 2004/108/EC, EN50263:1999

Products safety(PS): 2006/95/EC, EN61010-1:2001

2-2 NR0609 DS/ES Simulator

Date: 2016-01-06

3 Hardware and Installation

3 Hardware and Installation

Table of Contents

3 Hardware and Installation ................................................................ 3-a

3.1 Panel Arrangement ......................................................................................... 3-1

3.2 Terminal Definition .......................................................................................... 3-1

3.3 Structure and Installation ............................................................................... 3-2

NR0609 DS/ES Simulator 3-a

Date: 2016-01-06

3 Hardware and Installation

3-b NR0609 DS/ES Simulator

Date: 2016-01-06

3 Hardware and Installation

3.1 Panel Arrangement

The front panel of NR0609 is shown as below:

OPN 1 OPEN 1 CLOSED 1 CLS 1

OPN 2 OPEN 2 CLOSED 2 CLS 2

OPN 3 OPEN 3 CLOSED 3 CLS 3

OPN 4 OPEN 4 CLOSED 4 CLS 4

OPN 5 OPEN 5 CLOSED 5 CLS 5

OPN 6 OPEN 6 CLOSED 6 CLS 6

OPN 7 OPEN 7 CLOSED 7 CLS 7

OPN 8 OPEN 8 CLOSED 8 CLS 8

NR0609

DS/ES SIMULATOR

Figure 3.1-1 Front panel of NR0609

Where:

The button “OPN 1”~”OPN 8” is manually opening button;

The button “CLS 1”~”CLS 8” is manually closing button;

The signal indicator “OPEN 1”~”OPEN 8” is the open position indicator of corresponding DS/ES;

The signal indicator “CLOSED 1”~”CLOSED 8” is the closed position indicator of corresponding

DS/ES.

3.2 Terminal Definition

The terminal definition of NR0609 is shown as below:

NR0609 DS/ES Simulator 3-1

Date: 2016-01-06

3 Hardware and Installation

101 OPEN 1 CLS 1 201

102 CLOSED 1 OPN 1 202

103 OPEN 2 CLS 2 203

104 CLOSED 2 OPN 2 204

105 OPEN 3 CLS 3 205

106 CLOSED 3 OPN 3 206

107 OPEN 4 CLS 4 207

108 CLOSED 4 OPN 4 208

109 OPEN 5 CLS 5 209

110 CLOSED 5 OPN 5 210

111 OPEN 6 CLS 6 211

112 CLOSED 6 OPN 6 212

113 OPEN 7 CLS 7 213

114 CLOSED 7 OPN 7 214

115 OPEN 8 CLS 8 215

116 CLOSED 8 OPN 8 216

117 217

118 218

119 24V_IN+ 219

120 BO_COM 24V_IN- 220

24V_OUT+

24V_OUT-

PWR+

PWR-

PE

301

302

303

304

305

306

Figure 3.2-1 Rear panel terminal definition

3.3 Structure and Installation

3.3.1 Mechanical Dimension

NOTICE!

It is necessary to leave enough space top and bottom of the cut-out in the cubicle for

heat emission of it.

Following figure shows the dimensions of NR0609 for reference in mounting.

3-2 NR0609 DS/ES Simulator

Date: 2016-01-06

3 Hardware and Installation

110 111

80 35.1

80±0.2 4-Φ3.5

167±0.2

167

177

156

Figure 3.3-1 Dimensions of NR0609

3.3.2 Grounding Guidelines

NOTICE!

All these precautions can only be effective if the station ground is of good quality.

Switching operations in HV installations generate transient over voltages on control signal cables.

There is also a background of electromagnetic RF fields in electrical installations that can induce

spurious currents in the devices themselves or the leads connected to them.

All these influences can influence the operation of electronic apparatus.

On the other hand, electronic apparatus can transmit interference that can disrupt the operation of

other apparatus.

In order to minimize these influences as far as possible, certain standards have to be observed

with respect to grounding, wiring and screening.

3.3.3 Cubicle Grounding

The cubicle must be designed and fitted out such that the impedance for RF interference of the

ground path from the electronic device to the cubicle ground terminal is as low as possible.

Metal accessories such as side plates, blanking plates etc., must be effectively connected

surface-to-surface to the grounded frame to ensure a low-impedance path to ground for RF

interference. The contact surfaces must not only conduct well, they must also be non-corroding.

NOTICE!

If the above conditions are not fulfilled, there is a possibility of the cubicle or parts of it

forming a resonant circuit at certain frequencies that would amplify the transmission of

NR0609 DS/ES Simulator 3-3

Date: 2016-01-06

3 Hardware and Installation

interference by the devices installed and also reduce their immunity to induced

interference.

Movable parts of the cubicle such as doors (front and back) or hinged equipment frames must be

effectively grounded to the frame by three braided copper strips (see Figure 3.3-2).

The metal parts of the cubicle housing and the ground rail are interconnected electrically

conducting and corrosion proof. The contact surfaces shall be as large as possible.

NOTICE!

For metallic connections please observe the voltage difference of both materials

according to the electrochemical code.

The cubicle ground rail must be effectively connected to the station ground rail by a

grounding strip (braided copper).

Figure 3.3-2 Cubicle grounding system

3-4 NR0609 DS/ES Simulator

Date: 2016-01-06

4 Manual Version History

4 Manual Version History

In the latest version of the instruction manual, several descriptions on existing features have been

modified.

Manual version and modification history records

Manual Version

Date Description of change

Source New

R1.00 2016-01-06 Form the original manual.

NR0609 DS/ES Simulator 4-1

Date: 2016-01-06

4 Manual Version History

4-2 NR0609 DS/ES Simulator

Date: 2016-01-06

You might also like

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- PDF Created With Pdffactory Pro Trial Version: Wed Jul 19 10:32:37 2006Document96 pagesPDF Created With Pdffactory Pro Trial Version: Wed Jul 19 10:32:37 2006Cheng Kean KeongNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- General Technical Specification and Execution Procedures For Transmission and Subtransmission Networks Substation Insulators (63 kv-400 KV)Document27 pagesGeneral Technical Specification and Execution Procedures For Transmission and Subtransmission Networks Substation Insulators (63 kv-400 KV)Cheng Kean KeongNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- NIKKON S2090N LEDXION K10128 90W LED ECO Floodlight (WB) (5000K) PDFDocument11 pagesNIKKON S2090N LEDXION K10128 90W LED ECO Floodlight (WB) (5000K) PDFCheng Kean KeongNo ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Brochure-Universal Relays V2.1 ENGaDocument12 pagesBrochure-Universal Relays V2.1 ENGaCheng Kean KeongNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Mcag 14/34Document8 pagesMcag 14/34Cheng Kean KeongNo ratings yet

- ML40P Kullanim KilavuzuDocument23 pagesML40P Kullanim KilavuzumuaadhNo ratings yet

- 2SC4236 PDFDocument12 pages2SC4236 PDFsNo ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Lecture Note 01 - Introduction and The History of MicroprocessorsDocument74 pagesLecture Note 01 - Introduction and The History of MicroprocessorsPANDHU ARDI PRASETYONo ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Lightning Rabbit - An Application of Sound EnergyDocument6 pagesLightning Rabbit - An Application of Sound EnergyMuntarin RahmanNo ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- MSCMS Issue 6 Rev-0-Pages-32Document1 pageMSCMS Issue 6 Rev-0-Pages-32Bilal JavaidNo ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- 50471071M - Tilly 1Document120 pages50471071M - Tilly 1Nate Dimple-MaxNo ratings yet

- Lan8710A/Lan8710Ai: Small Footprint Mii/Rmii 10/100 Ethernet Transceiver With HP Auto-Mdix and Flexpwr TechnologyDocument80 pagesLan8710A/Lan8710Ai: Small Footprint Mii/Rmii 10/100 Ethernet Transceiver With HP Auto-Mdix and Flexpwr TechnologyseborgNo ratings yet

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- 019-201 Weather Pak Connector Series: Pin ReplacementDocument9 pages019-201 Weather Pak Connector Series: Pin ReplacementMohamed ZakiNo ratings yet

- G04 - Mobile Incoming Call IndicatorDocument13 pagesG04 - Mobile Incoming Call IndicatorIamlionelpavi PavithranNo ratings yet

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Manual Report-Digital Electronics (Circuits) - Iqra TabassumDocument50 pagesManual Report-Digital Electronics (Circuits) - Iqra TabassumIqra TabassumNo ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Catalogue 7ug0 and 7pv0 1Document28 pagesCatalogue 7ug0 and 7pv0 1Maintenance Unit Anil GroupNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Datasheet - HK F30u60dn 2216470 PDFDocument4 pagesDatasheet - HK F30u60dn 2216470 PDFHeri AltisNo ratings yet

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- 2.0 Annexure A, I, II and V Has Been Amended As Under Instead of ExistingDocument42 pages2.0 Annexure A, I, II and V Has Been Amended As Under Instead of Existingsri_lntNo ratings yet

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Simulation On Sic Based Three Phase Boost Power 16 Annas ArchiveDocument6 pagesSimulation On Sic Based Three Phase Boost Power 16 Annas Archivetakaca40No ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Chapter Four: DC-DC Conversion: DC ChoppersDocument55 pagesChapter Four: DC-DC Conversion: DC Choppersfor lifeNo ratings yet

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Term Paper: LCD (Liqued Crystal Display)Document14 pagesTerm Paper: LCD (Liqued Crystal Display)Saif TaureanNo ratings yet

- Proyecto 3 Sem 1 EnglishDocument2 pagesProyecto 3 Sem 1 EnglishGrafic MediaNo ratings yet

- MLC 16Document78 pagesMLC 16yeiber celyNo ratings yet

- 0564 03 Component Maintenance Manual For Learjet 45Document41 pages0564 03 Component Maintenance Manual For Learjet 45Aka MonuNo ratings yet

- Service Manual: Publication AP5296Document54 pagesService Manual: Publication AP5296stefano blu100% (2)

- Ms 1000Document2 pagesMs 1000E.E. Bracho PernaleteNo ratings yet

- Delta Ia-Mds Me300 Um en 20210809Document457 pagesDelta Ia-Mds Me300 Um en 20210809Anand PuntambekarNo ratings yet

- Cap. 13 Overall DimensionsDocument62 pagesCap. 13 Overall DimensionsElsonAlfredoEscobarArosNo ratings yet

- Schematic ESSA2 Sheet 2 20200318230036Document1 pageSchematic ESSA2 Sheet 2 20200318230036Sumedh S VijayNo ratings yet

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Paket Prewedd+wedding New Exclusive Middle HighDocument6 pagesPaket Prewedd+wedding New Exclusive Middle Highalvina tri koesnadyNo ratings yet

- SITOP Power Supplies Catalog KT 10.1 2008Document144 pagesSITOP Power Supplies Catalog KT 10.1 2008hwblomeNo ratings yet

- M5 and M10 Routers Power Supply and Power Cord Component Replacement InstructionsDocument12 pagesM5 and M10 Routers Power Supply and Power Cord Component Replacement InstructionsAnnA___86No ratings yet

- Distributor: Breaker & Switchgears Overseas Sales DeptDocument58 pagesDistributor: Breaker & Switchgears Overseas Sales DeptLUATNo ratings yet

- Multiplexer and De-MultiplexerDocument29 pagesMultiplexer and De-Multiplexerkid uniqueNo ratings yet

- Tib 620 GB 0622 Shapoli sdb3 Bridge Panel PCDocument36 pagesTib 620 GB 0622 Shapoli sdb3 Bridge Panel PCweieno2020No ratings yet

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)