Professional Documents

Culture Documents

The Importance of WheelRail Interface Management On Energy Savings and Sustainability PDF

Uploaded by

Okghi 'AlimmeOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

The Importance of WheelRail Interface Management On Energy Savings and Sustainability PDF

Uploaded by

Okghi 'AlimmeCopyright:

Available Formats

Part I: The Importance of Wheel/Rail Interface

Management on Energy Savings and Sustainability

North American railroads have Railroad wheels and rails are made of high strength steel. A steel wheel

about 17‐million tons of rail in some requires very little energy to roll on a steel rail; indeed, care must be

70,000 miles of track that carries taken that a car does not run away on level track on a windy day. This is

more than 20 million gross tons of because the wheel and rail deform very little under load, unlike a rubber

rail traffic. A recent railroad survey tire rolling on asphalt.

conducted by TTCI indicates that

the typical rail life varies from about The cross-sectional shape (profile) of both wheel and the rail also plays

1,300 MGT in tangent track to an essential role in steering a railroad car with minimum energy

about 380 MGT in a 10‐degree expenditure (and thus the fuel consumption). Incorrectly designed and

curved track. There are about 16‐ maintained profiles can result in wheels that:

million wheels in revenue service,

• Do not align to the track similarly to that of misaligned wheels in an

with about 400,000 removed each

automobile

year, generally for defects such as

spalls, shells, flat, out‐of‐round • Rub their flanges hard up against the rail similarly to the side walls of

wheels, and built up treads. About the tires of an automobile rubbing along the curb

200,000 wheels approach their

maximum amount of allowable Wheelset misalignment and rubbing flanges can increase train fuel

wear. The numbers demonstrate consumption significantly. In addition, poor wheel and rail profile match

that wheels and rails are major can cause metal fatigue, wear, corrugations, and other defects that require

railroad assets. maintenance and untimely replacement. This requires, in turn, the

Nonconformal wheel/rail profiles

expenditure of much energy to either re-machine these components or re-

melt steel to cast wheels and roll rails.

and hollow worn wheels do not steer

properly in curves, resulting in Wheel/rail wear and surface fatigue depend greatly on the contact stress,

increased fuel consumption. Instead, which in turn is controlled by the wheel/rail profiles and the way they

the trucks often warp, a situation in interact. This interaction also affects fuel consumption, derailment risk,

which the truck bolster rotates and vehicle stability. A key part of reducing railroad costs and improving

horizontally relative to the side safety is through better management of wheel and rail profiles to extend

frames such that both rails develop life, reduce vehicle and track maintenance, and improve vehicle stability.

large angles of attack and laterally

move towards flange contact with The increased energy dissipated at the wheel/rail interface from wheel/rail

the outer rail. The rolling resistance profile mismatch and friction directly affects the fuel required to haul a

of a warped truck is much larger than

train. Wheel and rail replacement require not only steels to be

that of a steered truck. Fuel is

manufactured, but transport and installation costs can also have

considerable impact on environment and energy. New wheel and rail

expended to overcome wheel/rail

require significant recourses (raw materials, energy and transport) to be

resistance, and since wheel/rail

produced. Likewise, the effort and activities required to remove worn

profile mismatch increase rolling

and damaged wheels and rail, install, and then transport used

resistances, matching profiles rail has a significant energy and environmental footprint.

through improved designs and

maintenance in service gives savings

in fuel.

You might also like

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5795)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Chapter 5 - SteeringDocument15 pagesChapter 5 - SteeringLalith Koushik Ganganapalli100% (1)

- h8 18xd r007 TG 09 2022 Eu Rev01 Lores enDocument9 pagesh8 18xd r007 TG 09 2022 Eu Rev01 Lores enjesus.manhaesNo ratings yet

- What Should You Consider When Choosing A Wet-Mix Shotcrete Pump?Document3 pagesWhat Should You Consider When Choosing A Wet-Mix Shotcrete Pump?aeoiuNo ratings yet

- Clutch Booster Japanese Commercial VehiclesDocument12 pagesClutch Booster Japanese Commercial VehiclesferNo ratings yet

- Renault Clio II: CABIN AIR FILTERS - Installation Instruction CABIN AIR FILTERS - Installation InstructionDocument1 pageRenault Clio II: CABIN AIR FILTERS - Installation Instruction CABIN AIR FILTERS - Installation Instructiongringo973No ratings yet

- KTC Heavy Trucks Trailer PartsDocument278 pagesKTC Heavy Trucks Trailer Partsgestada023No ratings yet

- Cars Ger Eu PCDocument157 pagesCars Ger Eu PCsergeyNo ratings yet

- 1 Product-List 4 PagesDocument4 pages1 Product-List 4 PagesKamal SabNo ratings yet

- Project Report AUTOMATIC JACKDocument27 pagesProject Report AUTOMATIC JACKRohan Arora62% (13)

- Project ProposalDocument10 pagesProject ProposalPrincessNo ratings yet

- Verna - CRDI - Billing Invoice - Done PDFDocument3 pagesVerna - CRDI - Billing Invoice - Done PDFVinayNo ratings yet

- JT&T Bestconnection Cat2014sm2Document158 pagesJT&T Bestconnection Cat2014sm2DizzixxNo ratings yet

- Mack Mdrive Ss 0316 HRDocument2 pagesMack Mdrive Ss 0316 HRShane LinNo ratings yet

- Resume Sample For Bus DriverDocument5 pagesResume Sample For Bus Driverafaybiikh100% (2)

- Registration of Motor VehiclesDocument2 pagesRegistration of Motor VehiclesFrederick EboñaNo ratings yet

- Practice of Truck ArtDocument4 pagesPractice of Truck ArtTooba ZafarNo ratings yet

- Uk CT06 Web PDFDocument32 pagesUk CT06 Web PDFMaletic Đoko100% (1)

- 2020 Iam Product Catalogue PDFDocument41 pages2020 Iam Product Catalogue PDFmimotobiz OriNo ratings yet

- Chapter 1Document180 pagesChapter 1Ananta Kumar NandiNo ratings yet

- XL FW10066SG - en USDocument92 pagesXL FW10066SG - en USBrijith ShenoiNo ratings yet

- 8m3 9m3 Concrete Mixer Machine Agitator Truck - Concrete Mixer Truck - China Cement Mixer Machinery, Construction MachineDocument11 pages8m3 9m3 Concrete Mixer Machine Agitator Truck - Concrete Mixer Truck - China Cement Mixer Machinery, Construction MachineBudi PrayitnoNo ratings yet

- Cover Letter Sample For Truck Driving JobDocument7 pagesCover Letter Sample For Truck Driving Jobdndcafegf100% (1)

- Linked PDFDocument400 pagesLinked PDFиван Троянов100% (1)

- WBHO Training Matrix 24.02.2020Document1 pageWBHO Training Matrix 24.02.2020Edson Mauro Thomas NobregaNo ratings yet

- Bingo Bilingüe: Means of TransportDocument1 pageBingo Bilingüe: Means of TransportRaquel Sánchez De LahozNo ratings yet

- Assignment 1 PDFDocument9 pagesAssignment 1 PDFAnubhav AroraNo ratings yet

- Tabla de Aceites JD FabricaDocument3 pagesTabla de Aceites JD FabricaJesus Fco Garcia PerezNo ratings yet

- Catalogue 2016Document68 pagesCatalogue 2016Abenezer BirhanuNo ratings yet

- Equipment Rental Computed Operated HourDocument14 pagesEquipment Rental Computed Operated HourAlan MilanNo ratings yet

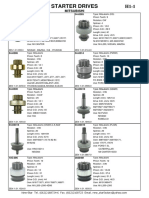

- Starter Drives: MitsubishiDocument17 pagesStarter Drives: Mitsubishiعلی چیواییNo ratings yet