Professional Documents

Culture Documents

Miginox 316lsi: Aws A/Sfa 5.9 EN ISO 14343-A

Uploaded by

Jagannath SahuOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Miginox 316lsi: Aws A/Sfa 5.9 EN ISO 14343-A

Uploaded by

Jagannath SahuCopyright:

Available Formats

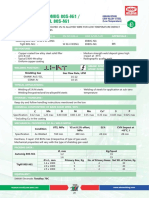

GMAW / GTAW

MIGINOX 316LSi STAINLESS STEEL

316LSi TYPE STAINLESS STEEL SOLID WIRE

CLASSIFICATION : EN ISO 14343-A AWS A/SFA 5.9 APPROVALS :

G 19 12 3 Lsi ER316LSi -

KEY FEATURES :

• An extra low carbon 19Cr/12Ni/Mo type stainless • Resistant to SCC, hot cracking and chemical

steel solid wire attack up to 850°C

• High Si content improves wetting characteristics • Offers improved corrosion & pitting resistance

• High resistance against intergranular corrosion in marine and industrial environment

• Radiographic quality welds

WELDING POSITION : DCEP

Shielding Gas Gas Flow Rate, LPM Stickout, mm

98Ar/2O2 or Ar/1-5CO2 15-22 10-20

TYPICAL APPLICATIONS :

• Welding austenitic alloys represented by AISI 316, • Application in textile processing, Naval and

316L, 317, 317L, 318 types Chemical environments, Paper and pulp, Paint

• Joining similar grade wrought and cast material and dye industries

• Cladding stainless steels

STORAGE / HANDLING :

Keep dry and follow handling instructions mentioned on the box

CHEMICAL COMPOSITION OF BARE SOLID WIRE, Wt% :

C Mn Si Cr Ni Mo S P

Specification 0.03 max 1.0-2.5 0.65-1.0 18.0-20.0 11.0-14.0 2.0-3.0 0.03 max 0.03 max

MECHANICAL PROPERTIES OF ALL WELD METAL :

Condition UTS, MPa EL%

Specification As Welded 490 min 30 min

Mechanical properties will vary with the type of shielding gas used.

PACKING DATA :

Ø, mm Kg/Spool

0.8 12.5

1.2 12.5

1.6 12.5

2.0 12.5

PASSION FOR WELDING SINCE 1951 www.adorwelding.com

37

You might also like

- Case 08-29 Cravat Sales CompanyDocument5 pagesCase 08-29 Cravat Sales Companysubash1111@gmail.comNo ratings yet

- BUS 1101 Principles of Business Management Written Assignment Unit 2Document4 pagesBUS 1101 Principles of Business Management Written Assignment Unit 2Azalia Delgado Vera100% (1)

- Study On Green Supply Chain ManagementDocument36 pagesStudy On Green Supply Chain ManagementDeep Choudhary0% (1)

- F6 SMART Notes FA20 Till March-2022 byDocument44 pagesF6 SMART Notes FA20 Till March-2022 byAshfaq Ul Haq OniNo ratings yet

- Software Test Automation Mark Fewster PDFDocument2 pagesSoftware Test Automation Mark Fewster PDFshchandhuNo ratings yet

- Miginox 308lsi: Aws A/Sfa 5.9 EN ISO 14343-ADocument1 pageMiginox 308lsi: Aws A/Sfa 5.9 EN ISO 14343-AJagannath SahuNo ratings yet

- GMAW GTAW MIGINOX 347Si STAINLESS STEELDocument1 pageGMAW GTAW MIGINOX 347Si STAINLESS STEELJagannath SahuNo ratings yet

- CWC-BookletF1 36 PDFDocument1 pageCWC-BookletF1 36 PDFJagannath SahuNo ratings yet

- Miginox 307: Classification: en Iso 14343-ADocument1 pageMiginox 307: Classification: en Iso 14343-AJagannath SahuNo ratings yet

- Electrode Booklet F Web 100Document1 pageElectrode Booklet F Web 100satnamNo ratings yet

- Miginox 309L / Tiginox 309L: Aws A/Sfa 5.9 EN ISO 14343-ADocument1 pageMiginox 309L / Tiginox 309L: Aws A/Sfa 5.9 EN ISO 14343-AJagannath SahuNo ratings yet

- Miginox 347 / Tiginox 347: Classification: ApprovalsDocument1 pageMiginox 347 / Tiginox 347: Classification: ApprovalsJagannath SahuNo ratings yet

- Tiginox 385: Classification: en Iso 14343-ADocument1 pageTiginox 385: Classification: en Iso 14343-AJagannath SahuNo ratings yet

- Automig 80s G Tigfil 80s GDocument1 pageAutomig 80s G Tigfil 80s Gvijaysvm999No ratings yet

- Automig 70S A1 - Tigfil 70S A1Document1 pageAutomig 70S A1 - Tigfil 70S A1Vaibhavi ganganeNo ratings yet

- CWC-BookletF1 12Document1 pageCWC-BookletF1 12satnamNo ratings yet

- MIGINOX 2209 / TIGINOX 2209: Gmaw / Gtaw Duplex Stainless SteelDocument1 pageMIGINOX 2209 / TIGINOX 2209: Gmaw / Gtaw Duplex Stainless SteelV U P RaoNo ratings yet

- CWC-BookletF1 24Document1 pageCWC-BookletF1 24Jagannath SahuNo ratings yet

- CWC-BookletF1 29 PDFDocument1 pageCWC-BookletF1 29 PDFJagannath SahuNo ratings yet

- Aluminium Casting Alloy (AL - Si12) : Home About Us Processes Design Quality Products Technical ContactDocument3 pagesAluminium Casting Alloy (AL - Si12) : Home About Us Processes Design Quality Products Technical Contactrafdinal.sNo ratings yet

- NiCu-7 solid wire for welding nickel-copper alloysDocument1 pageNiCu-7 solid wire for welding nickel-copper alloyssatnamNo ratings yet

- Miginox 310 / Tiginox 310: Classification: en Iso 14343-ADocument1 pageMiginox 310 / Tiginox 310: Classification: en Iso 14343-AJagannath SahuNo ratings yet

- Electrode Booklet F Web 97Document1 pageElectrode Booklet F Web 97satnamNo ratings yet

- Electrode Booklet F Web 93Document1 pageElectrode Booklet F Web 93satnamNo ratings yet

- Automig 80S-B2 / Tigfil 80S-B2: Classification: ApprovalsDocument1 pageAutomig 80S-B2 / Tigfil 80S-B2: Classification: ApprovalssatnamNo ratings yet

- Automig 80S-G / Tigfil 80S-G: AWS A/SFA 5.28Document1 pageAutomig 80S-G / Tigfil 80S-G: AWS A/SFA 5.28Jagannath SahuNo ratings yet

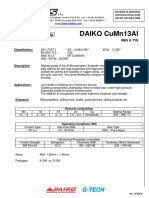

- 6030P Daiko CuMn13AlDocument1 page6030P Daiko CuMn13AlAris WicaksonoNo ratings yet

- Betanox D Welding ElectrodeDocument1 pageBetanox D Welding ElectrodearavindpeetaNo ratings yet

- AUTOMIG 5183 / TIGFIL 5183: Classification: ApprovalsDocument1 pageAUTOMIG 5183 / TIGFIL 5183: Classification: ApprovalssatnamNo ratings yet

- Automig 90S-G / Tigfil 90S-G: Classification: ApprovalsDocument1 pageAutomig 90S-G / Tigfil 90S-G: Classification: ApprovalsJagannath SahuNo ratings yet

- Al600 UNS N06600Document4 pagesAl600 UNS N06600kart_rlNo ratings yet

- Merit S-6: Lincoln Electric China Gmaw Solid WireDocument2 pagesMerit S-6: Lincoln Electric China Gmaw Solid Wirelovaldes62No ratings yet

- LM6 Alloy DetailDocument4 pagesLM6 Alloy DetaildsoNo ratings yet

- LM6 Alloy Detail PDFDocument4 pagesLM6 Alloy Detail PDFramashishNo ratings yet

- AUTOMIG 80S-Ni1 / TIGFIL 80S-Ni1: AWS A/SFA 5.28 EN ISO 14341-A EN ISO 636-ADocument1 pageAUTOMIG 80S-Ni1 / TIGFIL 80S-Ni1: AWS A/SFA 5.28 EN ISO 14341-A EN ISO 636-AsatnamNo ratings yet

- Automig FC 71 T1Document1 pageAutomig FC 71 T1Sushil BhansaliNo ratings yet

- 316 Tubeing TrisDocument1 page316 Tubeing Triscenter steel110No ratings yet

- CuZn20-convertedDocument2 pagesCuZn20-convertedwjjt6chgtmNo ratings yet

- High Quality Products For Welding and CladdingDocument25 pagesHigh Quality Products For Welding and Claddingsanketpavi21100% (1)

- CuZn10-convertedDocument2 pagesCuZn10-convertedwjjt6chgtmNo ratings yet

- GBTDocument1 pageGBTRaviTeja BhamidiNo ratings yet

- Alu MN: Description and ApplicationDocument1 pageAlu MN: Description and Applicationmohamed AdelNo ratings yet

- CuZn05-convertedDocument2 pagesCuZn05-convertedwjjt6chgtmNo ratings yet

- Tigfil 90S-B3 SPL: Classification: Aws A/Sfa 5.28Document1 pageTigfil 90S-B3 SPL: Classification: Aws A/Sfa 5.28satnamNo ratings yet

- Railrod: Data SheetDocument1 pageRailrod: Data Sheetmohamed AdelNo ratings yet

- CWC-BookletF1 15Document1 pageCWC-BookletF1 15satnamNo ratings yet

- 321 Stainless Steel TubeDocument1 page321 Stainless Steel Tubesaeedmahboob05No ratings yet

- Structural Stainless Steel Designing With Stainless Steel: Ing. Maarten FortanDocument153 pagesStructural Stainless Steel Designing With Stainless Steel: Ing. Maarten FortanJohn Philip Neri BesedillasNo ratings yet

- DSMTS-0010.6 ZN WireDocument4 pagesDSMTS-0010.6 ZN WireMario Cortes FariasNo ratings yet

- CWC-BookletF1 10Document1 pageCWC-BookletF1 10satnamNo ratings yet

- 316 LSDocument5 pages316 LSRouse ToxquiNo ratings yet

- CWC-BookletF1 17Document1 pageCWC-BookletF1 17satnamNo ratings yet

- Duplex Stainless Steel WeldingDocument25 pagesDuplex Stainless Steel WeldingcfcshakerNo ratings yet

- Aalco Metals LTD Stainless Steel ASTM A815 S31803 261Document2 pagesAalco Metals LTD Stainless Steel ASTM A815 S31803 261Irvin PajueloNo ratings yet

- Aisi 321 Stainless Steel Uns s32100 Din 1.4541Document3 pagesAisi 321 Stainless Steel Uns s32100 Din 1.4541Shariq KhanNo ratings yet

- Automig 70S-6: AWS A/SFA 5.18 Csa W48Document1 pageAutomig 70S-6: AWS A/SFA 5.18 Csa W48satnamNo ratings yet

- Automig 70S-61Document1 pageAutomig 70S-61tarun kaushalNo ratings yet

- item22-LNT 502Document1 pageitem22-LNT 502VVan TanNo ratings yet

- LM6 Aluminium Casting Alloyhb11Document4 pagesLM6 Aluminium Casting Alloyhb11Nader MohamedNo ratings yet

- Electrode Booklet F Web 121Document1 pageElectrode Booklet F Web 121satnamNo ratings yet

- Aluminium Alloy 5083H116 Data SheetDocument1 pageAluminium Alloy 5083H116 Data SheetTarek MassimoNo ratings yet

- Bronze C86300 SpecificationsDocument2 pagesBronze C86300 SpecificationsDoss MartinNo ratings yet

- Data Sheet A-10: Alloy TypeDocument3 pagesData Sheet A-10: Alloy Typemohamed AdelNo ratings yet

- High-Temperature Brazing in Controlled Atmospheres: The Pergamon Materials Engineering Practice SeriesFrom EverandHigh-Temperature Brazing in Controlled Atmospheres: The Pergamon Materials Engineering Practice SeriesNo ratings yet

- MGB 532-XX First Ballot 02122019 Part7Document1 pageMGB 532-XX First Ballot 02122019 Part7Jagannath SahuNo ratings yet

- NAAMM Metal Bar Grating Manual 531 - Part2Document2 pagesNAAMM Metal Bar Grating Manual 531 - Part2Jagannath SahuNo ratings yet

- Iso 10721-1-1997Document119 pagesIso 10721-1-1997Jagannath SahuNo ratings yet

- MGB 532-XX First Ballot 02122019 Part2Document1 pageMGB 532-XX First Ballot 02122019 Part2Jagannath SahuNo ratings yet

- NAAMM Metal Bar Grating Manual 531 - Part17Document2 pagesNAAMM Metal Bar Grating Manual 531 - Part17Jagannath SahuNo ratings yet

- SSPC PA1 2016 - Part10Document1 pageSSPC PA1 2016 - Part10Jagannath SahuNo ratings yet

- SSPC PA1 2016 - Part1Document1 pageSSPC PA1 2016 - Part1Jagannath SahuNo ratings yet

- 10 PRICE ACTION CANDLESTICK PATTERNS YOU MUST KNOW - Part6Document2 pages10 PRICE ACTION CANDLESTICK PATTERNS YOU MUST KNOW - Part6Jagannath SahuNo ratings yet

- 10 PRICE ACTION CANDLESTICK PATTERNS YOU MUST KNOW - Part2Document2 pages10 PRICE ACTION CANDLESTICK PATTERNS YOU MUST KNOW - Part2Jagannath SahuNo ratings yet

- 10 Price Action Candlestick Patterns You Must Know - Part4Document2 pages10 Price Action Candlestick Patterns You Must Know - Part4Jagannath SahuNo ratings yet

- Interpreting SNT TC 1A PDF 7Document1 pageInterpreting SNT TC 1A PDF 7Jagannath SahuNo ratings yet

- 10 PRICE ACTION CANDLESTICK PATTERNS YOU MUST KNOW - Part3Document2 pages10 PRICE ACTION CANDLESTICK PATTERNS YOU MUST KNOW - Part3Jagannath SahuNo ratings yet

- Current SSPC Standards June2019Document7 pagesCurrent SSPC Standards June2019Aleksander Segura Tinoco100% (1)

- 10 Price Action Candlestick Patterns You Must Know - Part10Document2 pages10 Price Action Candlestick Patterns You Must Know - Part10Jagannath SahuNo ratings yet

- Interpreting SNT TC 1A PDF 3Document1 pageInterpreting SNT TC 1A PDF 3Jagannath SahuNo ratings yet

- Piercing Line and Dark Cloud Cover candlestick patternsDocument2 pagesPiercing Line and Dark Cloud Cover candlestick patternsJagannath SahuNo ratings yet

- Interpreting SNT TC 1a - Part3 PDFDocument2 pagesInterpreting SNT TC 1a - Part3 PDFஅன்புடன் அஸ்வின்No ratings yet

- Interpreting SNT TC 1A PDF 2Document1 pageInterpreting SNT TC 1A PDF 2Jagannath SahuNo ratings yet

- Mary Kom's Journey to Becoming India's Most Decorated BoxerDocument16 pagesMary Kom's Journey to Becoming India's Most Decorated BoxerJagannath SahuNo ratings yet

- Interpreting SNT TC 1A PDF 6Document1 pageInterpreting SNT TC 1A PDF 6Jagannath SahuNo ratings yet

- Interpreting SNT TC 1A PDF 1Document1 pageInterpreting SNT TC 1A PDF 1Jagannath SahuNo ratings yet

- Tiginox 385: Classification: en Iso 14343-ADocument1 pageTiginox 385: Classification: en Iso 14343-AJagannath SahuNo ratings yet

- Miginox 347 / Tiginox 347: Classification: ApprovalsDocument1 pageMiginox 347 / Tiginox 347: Classification: ApprovalsJagannath SahuNo ratings yet

- Miginox 310 / Tiginox 310: Classification: en Iso 14343-ADocument1 pageMiginox 310 / Tiginox 310: Classification: en Iso 14343-AJagannath SahuNo ratings yet

- STD 2nd MathsDocument2 pagesSTD 2nd MathsJagannath SahuNo ratings yet

- Miginox 309L / Tiginox 309L: Aws A/Sfa 5.9 EN ISO 14343-ADocument1 pageMiginox 309L / Tiginox 309L: Aws A/Sfa 5.9 EN ISO 14343-AJagannath SahuNo ratings yet

- Ananas Marketing ChannelsDocument48 pagesAnanas Marketing ChannelsPham Tri TaiNo ratings yet

- Career Testing Services Pakistan: Assistant Sub Station Attendant (ASSA) (Open Merit) Eligibility CriteriaDocument3 pagesCareer Testing Services Pakistan: Assistant Sub Station Attendant (ASSA) (Open Merit) Eligibility CriteriaM. UsamaNo ratings yet

- Reliable internet for all with green fiber opticsDocument2 pagesReliable internet for all with green fiber opticsNicaNo ratings yet

- PLDT V City of Davao August 2001Document3 pagesPLDT V City of Davao August 2001owenNo ratings yet

- Roles You Could Play at The RBIDocument1 pageRoles You Could Play at The RBIshelharNo ratings yet

- PowerPoint presentation history and featuresDocument7 pagesPowerPoint presentation history and featuresJL SabioNo ratings yet

- Brand ManagementDocument3 pagesBrand ManagementMoovitha MenezesNo ratings yet

- Chapter 2 Thinking Like An EconomistsDocument30 pagesChapter 2 Thinking Like An EconomistsGiang NguyễnNo ratings yet

- OSE - Business Top Trumps - Lesson 3Document4 pagesOSE - Business Top Trumps - Lesson 3Joan GomezNo ratings yet

- AI-Powered Innovation and LeadershipDocument28 pagesAI-Powered Innovation and LeadershipSahil MathurNo ratings yet

- Theoretical Framework Quality Development TheoryDocument2 pagesTheoretical Framework Quality Development TheoryMiguel VienesNo ratings yet

- Unit4 - 488 - Assignment 1 Frontsheet (Group)Document40 pagesUnit4 - 488 - Assignment 1 Frontsheet (Group)Minh Thi TrầnNo ratings yet

- Gopi M. Patel: Summary of QualificationsDocument2 pagesGopi M. Patel: Summary of QualificationsAshwani kumarNo ratings yet

- Fee Challan 22 Oct 2021Document1 pageFee Challan 22 Oct 2021Rana HammadNo ratings yet

- First Offer Adam GalinskyDocument3 pagesFirst Offer Adam GalinskyMark SchultzNo ratings yet

- It ResumeDocument4 pagesIt Resumedy9pmkq3100% (1)

- Industrial Machinery & Tractor TyresDocument2 pagesIndustrial Machinery & Tractor TyresFelipe HernándezNo ratings yet

- State and Non-State InstitutionDocument29 pagesState and Non-State InstitutionLawrence DumpNo ratings yet

- Famous People: Charles GoodyearDocument4 pagesFamous People: Charles GoodyearFigen ErgürbüzNo ratings yet

- FPL TVL q2 Mod1 Liham PangnegosyoDocument24 pagesFPL TVL q2 Mod1 Liham PangnegosyoJeff Marges100% (4)

- Glyndon Volunteer Fire Department: Application For EmploymentDocument8 pagesGlyndon Volunteer Fire Department: Application For EmploymentAaron RubalskyNo ratings yet

- Theory of Consumer BehaviourDocument81 pagesTheory of Consumer Behavioursupriya dasNo ratings yet

- FY-7.4 Lesson Guide - Google DocsDocument4 pagesFY-7.4 Lesson Guide - Google Docstarikhero755No ratings yet

- Unit 9: Joint Products, Cost Allocation and by Products ContentDocument20 pagesUnit 9: Joint Products, Cost Allocation and by Products Contentዝምታ ተሻለNo ratings yet

- 317 626 1 PBDocument6 pages317 626 1 PBBang ELMUNo ratings yet