Professional Documents

Culture Documents

Project Id: Ba 2018 C 011 I Schedule A: Part 2 - Page 31 Rev 0 Construction of Additional Facilities For The Community College of Qatar - Boys

Uploaded by

AnonymOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Project Id: Ba 2018 C 011 I Schedule A: Part 2 - Page 31 Rev 0 Construction of Additional Facilities For The Community College of Qatar - Boys

Uploaded by

AnonymCopyright:

Available Formats

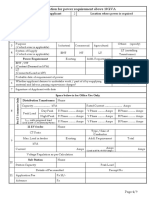

STATE OF QATAR SCHEDULE A: PROJECT BRIEF

ASHGHAL PART 2: SPECIFICATION, CODES AND REQUIREMENTS

B. PROJECT SPECIFICATION

D. IT NETWORK SOLUTION

TABLE OF CONTENTS

1.0 GENERAL

1.1 Work Description

1.2 Documentation

1.3 Manufacturer and Installer Qualifications

1.4 Reference Standards

1.5 System Description and Requirements

2.0 PRODUCTS

2.1 Augmented Category 6A S/FTP Cable

2.2 Shielded modular RJ-45 jack

2.3 Augmented Category 6A Shielded Patch Cords

2.4 Faceplate

2.5 Backboxes

2.6 Floor box outlet

2.7 Intelligent Patch Panel

2.8 Backbone cabling

2.9 Fibre Optic Patch Panel

2.10 Connectors & fiber patch leads

2.11 Splices

2.12 Pigtails

2.13 Panel Manager

2.14 Data cabinets/Rack

2.15 Intelligent power distribution units

3.0 EXECUTION

3.1 Supervision

3.2 Workshop Drawings

3.3 Coordination

3.4 Cabling System Testing

3.5 Grounding and Bonding

3.6 Labeling

3.7 Warranty

3.8 Cabling System Acceptance

3.9 Final Inspection

3.10 Test Verification

3.11 Final Acceptance

3.12 Training

PROJECT ID: BA 2018 C 011 I Schedule A: Part 2 – Page 31 Rev 0

Construction of Additional Facilities for the Community College of Qatar - Boys

STATE OF QATAR SCHEDULE A: PROJECT BRIEF

ASHGHAL PART 2: SPECIFICATION, CODES AND REQUIREMENTS

B. PROJECT SPECIFICATION

D. IT NETWORK SYSTEM

1.0 GENERAL

1.1 Work Description

This section describes the basic requirements for the supply, installation, testing and

commissioning of fully functional IT system network for the project. This shall include

horizontal cabling & backbone fibre optic cabling for data/voice, CCTV, BMS, AV system

& other ELV system.

The system is to be supplied with all equipment, hardware, software, cabling and

ancillary services as required to provide an integrated system complete and functional in

all respects. The tenderers are to familiarize themselves with all matters related to such

requirement and to account for such in the tendered price.

It is the responsibility of the tenderer to obtain clarification of all matters in which doubt

exists as to the exact intent of this document or in which a conflict appears to have

arisen. Such information must be obtained before the closing and lodging of tenders.

The response shall clearly detail all pricing for components, cabling, installation,

engineering, training, commissioning, setting to work, and 12 months comprehensive

warranty.

1.2 Documentation

The following are the list of documentations required as minimum under this contract.

1.2.1 Material Submittal

Material submittal shall be comprehensive and shall include the following as minimum

Brief description of system operation, functions and control sequences.

Schedule of all equipment with model number, names of manufacturers and country of

origin

Product data sheets highlighting the selected model of proposed equipment. Product

data sheets of all components shall be submitted.

Software provider's license agreement stating limits on use, copying, and transferring

software.

Copy of contract specifications complete with clause wise compliance statement.

1.2.2 Workshop Drawings

Lay out drawings complete with cable sizing, cable routing, containment sizing, location

of equipment, power requirements and data ports for system components, etc and

installation details of door hardware. Drawings shall also indicate requirements of access

panels, data, power etc.

PROJECT ID: BA 2018 C 011 I Schedule A: Part 2 – Page 32 Rev 0

Construction of Additional Facilities for the Community College of Qatar - Boys

STATE OF QATAR SCHEDULE A: PROJECT BRIEF

ASHGHAL PART 2: SPECIFICATION, CODES AND REQUIREMENTS

B. PROJECT SPECIFICATION

1.2.3 As-built drawings

Submit number of sets of final as-built drawings as indicated in the contract documents

including the above items marked up with labels of each component.

1.2.4 Operation & Maintenance Manual

Descriptive data of all operating, user and application software including complete

operators manuals, programmer’s manuals, and alphanumeric point name convention

sheet.

Provide final documentation to serve the diverse needs of personnel concerned with

operation, procurement, installation and maintenance.

Operation & Maintenance manuals shall be complete with preventive maintenance

schedules, procedures and troubleshooting procedures.

1.2.5 Training Manual

Shall include CV's of trainers, brief description of the installed system, preventive and

breakdown maintenance procedures and training mode.

Training agenda covering training mode, duration, number of trainees in each session

etc. shall be submitted at least three weeks prior to the training.

1.3 Manufacturer & Installer Qualifications

The system shall be engineered, commissioned and serviced by the manufacturer or

manufacturer's authorized systems integrator employing factory trained personnel for

commissioning and after sales support. Materials and equipment shall be the catalogued

products of manufacturers regularly engaged in production of access control equipment

and the products proposed shall be the latest versions commercially available at the time

of the bid.

The manufacturer shall be ISO-9002 and ISO 9001 certified for Quality Assurance in

Production, Installation and Servicing.

The specialist shall obtain and submit a written undertaking from the manufacturer that

the spare parts of the system proposed will be made available upon request for at least

10 years from the date of substantial completion. In addition, the manufacturer shall

undertake to ensure forward compatibility of the proposed equipment for at least 15

years.

1.3.1 The Structured Cabling system (SCS) contractor qualification criteria

The SCS Contractor shall be eligible to requesting the manufacturer 25-Year system

Performance warranty on the Installed systems. Copy of a valid agreement or

certification letter shall be included in the tender documents.

1.4 Reference Standards

PROJECT ID: BA 2018 C 011 I Schedule A: Part 2 – Page 33 Rev 0

Construction of Additional Facilities for the Community College of Qatar - Boys

STATE OF QATAR SCHEDULE A: PROJECT BRIEF

ASHGHAL PART 2: SPECIFICATION, CODES AND REQUIREMENTS

B. PROJECT SPECIFICATION

The cabling system described in this specification is derived in part from the

recommendations made in industry standard documents. The lists of documents below

have bearing on the desired cabling infrastructure are incorporated into this specification

by reference:

Standards Description

ISO/IEC 11801:2002

Information technology - Generic cabling for customer premises

/ Amd 2:2010

ISO/IEC TR Information technology – Customer premises cabling for

24704:2004 wireless access points (WAP)

Information technology – Generic cabling – introduction to the

ISO/IEC 29106:2007

MICE environmental classification

Information technology – telecommunications cabling

ISO/IEC 29125:2010 requirements for remote powering of terminal equipment (PoE –

End)

Implementation and operation of customer premises cabling –

ISO/IEC 14763-2

Part 2: Planning and Installation

Information technology - Generic cabling systems - Part 1:

EN 50173-1:2011

General requirements

EN 50174-2:2009 + Information technology - Cabling installation - Part 2: Installation

A1:2011 planning and practices inside buildings

Installation technology. Cabling installation. Part 3: Installation

EN 50174-3:2003

planning and practices outside buildings

TIA-568-C.0 Adm 1 Generic telecommunications cabling for customer premises

Commercial building telecommunications cabling

TIA-568-C.1

Adm. 2 -General Updates

Balanced twisted-pair telecommunications cabling and

TIA-568-C.2

components

Optical fibre cabling components

TIA-568-C.3 Adm. 1 - Addition of OM4 Cabled Optical Fibre and array

connectors

Customer-owned outside plant telecommunication infrastructure

TIA-758

standard (TR-42.4)

Commercial Building Standard for Telecommunications

TIA-569-B

Pathways and Spaces

Generic Telecommunications Bonding and Grounding (Earthing)

TIA-607-B

for customer premises

Administration standard for the commercial telecommunications

TIA-606-A

infrastructure

If a conflict exists between applicable documents, then the order in the list above shall

dictate the order of precedence in resolving conflicts. If this document and any of the

documents listed above are in conflict, then the more stringent requirement shall apply.

1.5 System Description and Requirements

The structured cabling network specified under this section includes providing complete

IP solution connectivity and cabling required for data & voice, CCTV, BMS, AV system

etc. as per IT network schematics. Contractor to connect all proposed IDF racks in each

ELV room & building to the main network rack at server room in building B1.

PROJECT ID: BA 2018 C 011 I Schedule A: Part 2 – Page 34 Rev 0

Construction of Additional Facilities for the Community College of Qatar - Boys

STATE OF QATAR SCHEDULE A: PROJECT BRIEF

ASHGHAL PART 2: SPECIFICATION, CODES AND REQUIREMENTS

B. PROJECT SPECIFICATION

Selection of all the modules, core switches, other passive & active equipment’s required

for the complete functioning of system shall be as per the client requirement & shall be

the latest models available in market.

Active equipment like switches, routers, WLAN controllers etc. required to achieve this

connectivity will be provided by the specialist employed by the client for ‘Ethernet LAN’.

1.5.1 The Structured Cabling Network

The structured cabling network shall be based on single-manufacturer solution for the

STP Category 6A and Fiber Optic (FO) System systems.

The Category 6A and FO systems shall be backed by the manufacturer 25-Year System

performance warranty. The system warranty shall be facilitated by the SCS

CONTRACTOR and be established between the Manufacturer and the Customer.

The warranty will cover the components and labor associated with the

repair/replacement of any defective link within the warranty period, when the defect is a

valid warranty claim.

1.5.2 Horizontal Cabling Product Specifications

The horizontal cabling shall be based on Shielded Cat 6A or higher category

components. The horizontal cabling system must be tested and warranted for cat6A

performance in compliance with the latest draft standard TIA/EIA 568B-10 or ISO/IEC

11801 for Class Ea that will be available at the time of the system testing.

1.5.3 Structure Cabling Infrastructure Requirements:

Structure cabling must be fully supported, contained and managed along its entire

length. Cabling must be routed and secured, fixed or positioned upon designated

‘Communication Containment’.

The SCS Contractor shall ensure the containment system is suitable and adequate

under the standards of this specification and against those set by the manufacture

company of the structure cabling system.

1.5.4 Special Requirements

The Contractor shall consult the OOREDOO not less than one month before it is

proposed to commence work to ascertain whether any underground installations will

be affected by the proposed works, in which event the Contractor shall make all

necessary arrangements with OOREDOO to safe guard the installation.

The Contractor shall give at least one week’s notice in writing to OOREDOO of the

dates upon which it is intended to operate plant or equipment or carryout work for

which permission has been given in writing by OOREDOO; such operations of work

shall only be carried out in the presence of OOREDOO unless notice shall be

obtained in writing from OOREDOO that they do not require to be present.

OOREDOO may require work to be executed on the reinstallations during the period

of the Contract; the Contractor shall afford all facilities to OOREDOO’s contractors or

workmen until their diversion work is complete. The Contractor shall co-ordinate the

work of OOREDOO and his own activities and when necessary shall amend his

PROJECT ID: BA 2018 C 011 I Schedule A: Part 2 – Page 35 Rev 0

Construction of Additional Facilities for the Community College of Qatar - Boys

STATE OF QATAR SCHEDULE A: PROJECT BRIEF

ASHGHAL PART 2: SPECIFICATION, CODES AND REQUIREMENTS

B. PROJECT SPECIFICATION

programme of work to suit all requirements of OOREDOO in connection with their

diversion work and keep the Engineer informed in writing of all arrangements made.

2.0 PRODUCTS

All components of the proposed system shall be from one of the approved

manufacturers. In the event of unavoidable use of a third party product, the base

manufacturer shall undertake the responsibility for the same and include the said third

party component in the 20 year certification.

2.1 Augmented Category 6A S/FTP Cable

Cat 6A S/FTP cables shall meet the following requirement.

Shall exceeds requirements of ISO 11801 Class EA and ANSI/TIA-568-C.2 Category

6A channel standards

Shall meets or exceeds the requirements of IEC 61156-5 Category 6A component

standards at swept frequencies up to 600 MHz

Category 6A, low smoke zero halogen (LSZH), 4-pair, S/FTP shielded copper cable.

Copper conductors are 23 AWG constructions with foamed skin PE insulation.

Conductors are twisted in pairs, each covered by a foil shield, surrounded by an

overall braided shield, and protected by a LSZH jacket. Performance tested up to

1000 MHz

Individually foiled pairs prevent the coupling near-end and alien crosstalk between

twisted pairs to ensure 10GBASE-T transmission performance

Braided shield provides superior structural integrity and reduces low frequency

external interference to ensure exceptional cable performance at all swept

frequencies up to 1500 MHz

Flame rated to meet IEC 60754-2, IEC 61034 and IEC 60332-1-24

Installation temperature range: 0°C to 50°C (32°F to 122°F)

Operating temperature range: -20°C to 60°C (-4°F to 140°F)

Channel characterized to 1000 MHz, 400 MHz beyond the standard

Descending cable length markings enable easy identification of remaining cable

which reduces installation time and cable scrap

2.2 Shielded Modular RJ45 Jack

Cable terminations must be LSA or 110 Insulation Displacement Connectors (IDC).

Connector style to be RJ45

Toolless Termination

Maximum outlet depth of 29mm

Lifetime Product Warranty

Must have current independent third party approval status to a minimum of ISO/IEC

11801 component level.

2.3 Augmented Category 6A Shielded Patch Cords

Category 6A/Class EA STP interconnect patch cords shall be constructed of 26 AWG

stranded copper cable with Intelligent Patch Panel Plug on one end and a LED

switch modular plug on the other end.

Copper conductors in patch cable shall be twisted in pairs and separated by a

quadrant separator.

All four pairs shall be surrounded by MaTriX tape. An additional 26 AWG conductor

PROJECT ID: BA 2018 C 011 I Schedule A: Part 2 – Page 36 Rev 0

Construction of Additional Facilities for the Community College of Qatar - Boys

STATE OF QATAR SCHEDULE A: PROJECT BRIEF

ASHGHAL PART 2: SPECIFICATION, CODES AND REQUIREMENTS

B. PROJECT SPECIFICATION

pair shall surround the MaTriX tape to connect the LED switch plug to 9th and 10th

contacts on the intelligent Patch Panel Plug.

A flame retardant jacket shall cover all conductors.

The MaTriX tape shall suppress alien crosstalk and allow 10 Gb/s transmission.

Patch cords shall be used in conjunction with intelligent patch panels and exclusively

for interconnect architectures.

Certified channel performance in a 4-connector configuration up to100 meters and

exceeds the requirements of ANSI/TIA-568-C.2 Category 6A and ISO 11801 Class

EA standards for supporting 10GBASE-T transmission over twisted-pair cabling

systems

Certified component performance to the ANSI/TIA-968-A component standard for

supporting 10GBASE-T transmission over twisted-pair cabling systems

Shall meet IEC 60603-7

Shall meet requirements of IEEE 802.3af and IEEE 802.3at for PoE applications

Switch/server Communicates connection status between switch/server port detection

and Intelligent Patch Panels

LEDs aid in patch cord tracing and connectivity changes at the switch end and to

identify unauthorized removals or insertions

Ninth conductor shall provide continuity through the patch cord enabling the

intelligent System to monitor connectivity without interfering with Ethernet

performance

2.4 Faceplate

Drywall faceplates are to be white plastic and flush mounted. Faceplate shall be UK size

standard single gang 1 or 2-Port angled with shutters, or double gang 3 or 4-port angles

with shutters.

2.5 Back Boxes

These shall be supplied by others. Back boxes should be UK size standard, and of a

sufficient depth of 2 inches minimum as to allow the jack and terminated cable to be

installed, without exceeding the manufacturers recommended cable bend radius.

2.6 Floor box outlet

The floor box shall provide sufficient depth of 2 inches minimum as to allow the jack

and terminated cable to be installed, without exceeding the manufacturers recommended

cable bend radius.

Floor box shall support minimum of 2 jacks and 2 power sockets.

2.7 Intelligent Patch Panel

Patch panel shall be cross connect intelligent smart type. Patch panels shall comply with

the following minimum specification.

The modular patch panel shall be choice of an installation that is fully intelligent or

“intelligent ready” for future upgrades. The modular patch panel design shall

accommodate copper RJ45 jack modules. The front of the panel shall include multi-

colored LEDs located above each port that indicate the connectivity status, as well as

multi-functional push buttons (when intelligence modules have been connected) for

diagnostic and configuration navigation. The panel shall offer a “common” method for

labeling in compliance with TIA/EIA 606-A-1 labeling standards.

Shall support fully intelligent interconnect and cross-connect architectures

Accommodates intelligence modules on the back of the panel that utilize no

PROJECT ID: BA 2018 C 011 I Schedule A: Part 2 – Page 37 Rev 0

Construction of Additional Facilities for the Community College of Qatar - Boys

STATE OF QATAR SCHEDULE A: PROJECT BRIEF

ASHGHAL PART 2: SPECIFICATION, CODES AND REQUIREMENTS

B. PROJECT SPECIFICATION

additional rack space (zero RU)

Support visual guidance (such as LEDs) for patch cord tracing and

Move/Add/Change (MAC) orders

Mount to standard EIA 19" rack or 23" racks with optional extender bracket

Accepts pre-terminated cassette and jack Module Modules

Accepts 9th Pin patch cord

Shall have Life time product warranty

2.8 Backbone Cabling

Fiber optic backbone shall be provided to connect the IDF rack in each ELV room/

building to the network rack at server room at building B1.

It is the SCS responsibility to ensure that all FO backbone links are correctly polarized in

order to have a transmit fiber at one end connected to a receive fiber at the other end of

a Link.

The performance of the installed fibre optic cable plant shall support bandwidth-intensive

applications including 1Gbit/s through 10Gbit/s and beyond as defined in IEEE 802.3z,

802.3ae, 802.3aq and 802.3ak Standards.

OS2, Optical Cable Performance levels:

Wave Length Max. Fibre Typical Cabled

(nm) Attenuation (dB/Km) Attenuation (dB/KM)

1310 0.40 0.32

1550 0.30 0.21

2.9 Fiber Optic Patch Panel

Intelligent Fiber optic patch shall meet with the following minimum specification.

Provides ready real-time physical layer management to the fiber channels in the

network

An easily-accessible future integrated mechanism for mounting intelligent module

simplifies installation and maintenance

Enhances usability and maintainability through an enclosure and drawer design that

allows for easy access to the fiber connectivity

An easily-accessible integrated mechanism for mounting a Management module

simplifies installation and maintenance

Support fully intelligent interconnect and cross-connect architectures

Accommodates intelligence modules in the back of the patch panel that utilize no

additional rack space (zero RU)

Support visual guidance (such as LEDs) for patch cord tracing and

Move/Add/Change (MAC) orders

Provides the capability to map and monitor the fiber channels to efficiently manage

resources and substantially reduce network operations cost

Provides the capability to automate network documentation and maintenance

procedures for the physical layer, which in turn supports improved reliability, security,

and increased overall network management efficiency

Accepts 9th Pin technology patch cord

Installable in a 19" standard TIA/EIA rack or cabinet utilizing 1RU of space

2.10 Connectors & Fiber Patch Leads

PROJECT ID: BA 2018 C 011 I Schedule A: Part 2 – Page 38 Rev 0

Construction of Additional Facilities for the Community College of Qatar - Boys

STATE OF QATAR SCHEDULE A: PROJECT BRIEF

ASHGHAL PART 2: SPECIFICATION, CODES AND REQUIREMENTS

B. PROJECT SPECIFICATION

Optical fibre cables shall be terminated LC-Duplex connectors that conform to EN

186000 Part 1, by means of fusion splicing using factory terminated pigtails.

The average loss for all connector pairs shall be less than 0.3dB, including the loss due

to splicing.

2.11 Splices

Splices shall be retained within a protective sleeve by either friction or adhesive bonds

to the optical fibre and additional strain relief for the completed joint shall be provided.

All splice, joints and their strain relief shall be fixed within the optical fibre management

system of the enclosure. The insertion loss through any splice shall not be greater than

0.15dB.

2.12 Pigtails

Fibre optic pigtails shall be made from the same fibre type as the fixed cabling. Pigtails

shall be kept slack when the cable is terminated.

2.13 Panel manager:

The panel manager shall attach directly to the back of Intelligent Patch Panel (via a

mounting bracket) to provide physical infrastructure management functionality to

Intelligent Patch Panels Eliminates the need for additional rack space.

Panel Manager Installations shall also require the installation of an include interface

module to the front of Intelligent Patch Panels for local configuration and user

navigation.

Panel Manager Intelligence Modules shall enable the Intelligent Patch Panels to

sense connections and disconnections from each port and relay status information to

the Physical Infrastructure Manage Software Platform database. The intelligence

modules also shall accept trace mode and MAC commands to provide guidance via

the Interface Unit and Patch Panel LEDs.

Shall Enables quick addition, removal, or replacement of intelligence modules to add

management capabilities

Interface unit Snaps into the front of the Intelligent Patch Panel to enable patch cord

tracing and diagnostic navigation using multi-function push buttons and LED’s,

improving speed and accuracy of maintenance and troubleshooting

Supports both cross-connect or interconnect installations

The panel manager module shall provide networking interface, power connection and

expansion port connections, the expansion module receives all power and data

signals from the panel manager through the expansion port.

2.14 Data Cabinet/Racks

All data patch panels – copper and fiber shall be housed in 19” equipment cabinet

complete with glass front lockable door with provision for air circulation, Steel rear

door, Jacking Feet, and with horizontal cable managers and 2 Vertical cable

managers. The cabinet shall be of standard size, as mentioned in the schematics.

The floor-mount cabinet shall be supplied with 4-fan module (or 2x 2-fan modules).

The cabinet shall be supplied with castor group and 6 way power distribution frame.

The floor-mount cabinet shall be grounded by the SCS CONTRACTOR using a

minimum # 6 AWG copper conductor bonded to the ground bus.

PROJECT ID: BA 2018 C 011 I Schedule A: Part 2 – Page 39 Rev 0

Construction of Additional Facilities for the Community College of Qatar - Boys

STATE OF QATAR SCHEDULE A: PROJECT BRIEF

ASHGHAL PART 2: SPECIFICATION, CODES AND REQUIREMENTS

B. PROJECT SPECIFICATION

Cabinet shall be securely attached to the concrete floor.

2.15 Intelligent Power Distribution Units

It is the requirement of The Client that Intelligent PDU’s be installed within each

Equipment Rack or Server Rack.

Select the appropriate iPDU according to the size and load bearing requirements, and

pay particular attention to the required equipment termination plugs.

3.0 EXECUTION

3.1 Supervision

All works associated with implementation of the IT network system shall be carried out

under the direct supervision of a representative of the approved specialist systems

integrator. Installations shall be carried out by skilled technicians.

3.2 Workshop Drawings

Detailed engineering shall be the carried out by a factory trained engineer working with

the approved specialist systems integrator. Workshop drawings shall detail all cable

types, conduits, back box/power requirements, mounting details etc. Workshop

drawings submitted for THE ENGINEER approval shall be duly signed and stamped by

the specialist systems integrator. Detailed system schematic diagram showing cable

sizes and types, exact locations of devices, server, workstations etc. shall be

submitted along with the workshop drawings. Detailed lay out of the modified existing

telecom room with all equipment’s and furniture shall be submitted separately for THE

ENGINEER approval.

3.3 Coordination

The supervisor of installation shall be fully responsible for coordination with specialist’s

integrators of other systems to which the system has an interface or integration.

3.4 Cabling system Testing

All cables and termination hardware shall be 100% tested by the SCS CONTRACTOR

for defects in installation and to verify cable performance under installed conditions.

All conductors of each installed cable shall be verified useable by the SCS

CONTRACTOR prior to system acceptance. Any defect in the cabling system

installation including but not limited to cable, connectors, feed-through couplers, patch

panels, and connector blocks shall be repaired or replaced in order to ensure 100%

useable conductors in all cables installed. All cables shall be tested in accordance

with this document and best industry practices. If any of these are in conflict, the SCS

CONTRACTOR shall be responsible to bring any discrepancies to the attention of the

project team for clarification and/or resolution.

3.4.1 Horizontal cabling

Horizontal Copper Links shall be performance verified using cable analyzer. Test

results shall be automatically evaluated by the equipment, using the most up-to-date

criteria from the ANSI/TIA/EIA –568-B.2.10 or ISO/IEC11801 for Class Ea Standard,

PROJECT ID: BA 2018 C 011 I Schedule A: Part 2 – Page 40 Rev 0

Construction of Additional Facilities for the Community College of Qatar - Boys

STATE OF QATAR SCHEDULE A: PROJECT BRIEF

ASHGHAL PART 2: SPECIFICATION, CODES AND REQUIREMENTS

B. PROJECT SPECIFICATION

and the result shown as pass/fail. Test results shall be printed directly from the test

unit or from a download file using an application from the test equipment manufacturer.

The printed test results shall include all tests performed, the expected test result and

the actual test result achieved

Copper Horizontal Cabling shall be tested u in a “Channel” or “Permanent” testing

configuration.

3.4.2 Performance Verification

Horizontal link shall be performance verified using an automated test set. This test set

shall be capable of testing for the continuity and length parameters defined above, and

provide results for the following tests:

a. Length

b. Continuity

c. Near End Cross-Talk (NEXT)

d. Attenuation

e. Attenuation to Cross-Talk Ratio (ACR)

f. Power Sum NEXT

g. Power Sum ELFEXT

h. Return Loss

i. Propagation Delay and Skew

j. AXT (Alien Cross Talk) testing is optional for the F/FTP cable.

The test should provide the shield continuity.

Test results shall be automatically evaluated by the equipment, using the most up-to-

date criteria from the ANSI/TIA/EIA –568-B.2.10 or ISO/IEC11801 for Class Ea

Standard, and the result shown as pass/fail. Test results shall be printed directly from

the test unit or from a download file using an application from the test equipment

manufacturer. The printed test results shall include all tests performed, the expected

test result and the actual test result achieved

The test equipment shall be configured on “Channel” link testing.

List of Approved test equipment manufacturer

- Fluke DTX 1800

- Agilent WireScope Pro Hand Held Tester

Note: Test equipment should be factory-calibrated every 2 year period.

3.4.3 Fiber Optic Testing

Backbone, horizontal and centralized links shall be tested at the appropriate operating

wavelengths for anomalies and to ensure uniformity of cable attenuation and

connector insertion loss.

a. Each fibre link and channel shall be tested in both directions wavelengths

b. A launch cable shall be installed between the OTDR and the first link connection.

c. A tail cable shall be installed after the last link connection.

d. The length of each fibre shall be recorded.

3.5 Grounding and Bonding

PROJECT ID: BA 2018 C 011 I Schedule A: Part 2 – Page 41 Rev 0

Construction of Additional Facilities for the Community College of Qatar - Boys

STATE OF QATAR SCHEDULE A: PROJECT BRIEF

ASHGHAL PART 2: SPECIFICATION, CODES AND REQUIREMENTS

B. PROJECT SPECIFICATION

The facility shall be equipped with a Telecommunications Bonding Backbone (TBB).

This backbone shall be used to ground all telecommunications cable shields,

equipment, racks, cabinets, raceways, and other associated hardware that has the

potential for acting as a current carrying conductor. The TBB shall be installed

independent of the buildings electrical and building ground and shall be designed in

accordance with the recommendations contained in the IEC 60364 and ISO/IEC

14763-2 standards.

The main entrance facility/equipment room in each building shall be equipped with a

telecommunications main grounding bus bar (TMGB). Each telecommunications

closet shall be provided with a telecommunications ground bus bar (TGB). The TMGB

shall be connected to the building electrical entrance grounding facility. The intent of

this system is to provide a grounding system that is equal in potential to the building

electrical ground system. Therefore, ground loop current potential is minimized

between telecommunications equipment and the electrical system to which it is

attached.

3.5.1 Product Specifications

All racks, metallic backboards, cable sheaths, metallic strength members, splice

cases, cable trays, etc. entering or residing shall be grounded to the respective TGB or

TMGB using a minimum #6 AWG (4.1mm) stranded copper bonding conductor and

compression connectors. Where metallic panels attached to the rack to not have

sufficient metal to metal contact to provide an adequate path to ground, they shall be

bonded to the rack using a minimum #14 AWG (1.6mm) copper conductor. The

copper conductor size shall be upgraded based on the largest power conductor

feeding any rack mount equipment. The conductor shall be continuous; attaching all

isolated components in a daisy chain fashion from top to bottom and bonded to the

rack using an appropriate compression connector.

All wires used for telecommunications grounding purposes shall be identified with a

green insulation. Non-insulated wires shall be identified at each termination point with

a wrap of green tape. All cables and bus bars shall be identified and labelled in

accordance with the System Documentation Section of this specification.

3.5.2 Ground System Installation

The TBB shall adhere to the recommendations of the IEC 60364 and ISO/IEC 14763-2

standards, and shall be installed in accordance with best industry practices. A

licensed electrical contractor shall perform installation and termination of the main

bonding conductor to the building service entrance ground, at a minimum.

3.6 Labeling

The SCS CONTRACTOR shall develop and submit for approval a labeling system for

the cable installation. The Customer will negotiate an appropriate labeling scheme

with the successful SCS CONTRACTOR. At a minimum, the labeling system shall

clearly identify all components of the system: racks, cables, panels and outlets. Racks

and patch panels shall be labeled to identify the location within the cabling system

infrastructure. All labeling information shall be recorded on the as-built drawings and

all test documents shall reflect the appropriate labeling scheme.

All label printing will be machine generated using indelible ink ribbons or cartridges.

Self-laminating labels will be used on cable jackets, appropriately sized to the OD of

PROJECT ID: BA 2018 C 011 I Schedule A: Part 2 – Page 42 Rev 0

Construction of Additional Facilities for the Community College of Qatar - Boys

STATE OF QATAR SCHEDULE A: PROJECT BRIEF

ASHGHAL PART 2: SPECIFICATION, CODES AND REQUIREMENTS

B. PROJECT SPECIFICATION

the cable, and placed within view at the termination point on each end. Outlet shall be

labeled on the space provided on the faceplate.

3.7 Warranty

The SCS CONTRACTOR shall facilitate the 25-year Cat6A System Performance

warranty and FO cable 25-Year Component warranty between the manufacturer and

the Customer. Horizontal links shall be warranted against the link performance

minimum expected results defined in ANSI/TIA/EIA-568-B.2-10 or ISO/IEC11801 latest

edition Class Ea. Fiber optic cable shall be warranted against the performance

minimum expected results defined in TIA/EIA-568-B.1.

3.8 Cabling system Acceptance

The Customer’s Technical Representative will make periodic inspection of the project

in progress. One inspection will be performed at the conclusion of cable pulling, prior

to closing of the false ceiling, to inspect the method of cable routing and support. A

second inspection will be performed at completion of cable termination to validate that

cables were dressed and terminated in accordance with ANSI/TIA/EIA or ISO/IEC

100801 specifications for jacket removal and pair untwist, compliance with

manufacturer’s minimum bend radius, and that cable ends are dressed neatly and

orderly.

3.9 Final Inspection

Upon completion of the project, The Customer’s Technical Representative will perform

a final inspection of the installed cabling system with the SCS CONTRACTOR’s

Project Foreman. The final inspection will be performed to validate that all horizontal

and backbone cables were installed as defined in the drawing package, and that the

installation meets the aesthetic expectations of the Customer.

3.10 Test Verification

Upon receipt of the test documentation, The Customer reserves the right to perform

spot testing of a representative sample of the cabling system to validate test results

provided in the test document. Customer testing will use the same method employed

by the SCS CONTRACTOR, and minor variations will be allowed to account for

differences in test equipment. If significant discrepancies are found, the SCS

contractor will be notified for resolution.

3.11 Final Acceptance

Completion of: the installation; in-progress and final inspections; receipt of the test and

as-built documentation will constitute acceptance of the system.

3.12 Training

If required, the SCS CONTRACTOR will provide training for Customer’s qualified staff

to ensure knowledge transfer regarding the usage of the cabling infrastructure. The

SCS CONTRACTOR shall provide minimum of 12 hours training to the Customer

appropriate staff to explain and orient the staff on how to use and maintain the cabling

plant

PROJECT ID: BA 2018 C 011 I Schedule A: Part 2 – Page 43 Rev 0

Construction of Additional Facilities for the Community College of Qatar - Boys

STATE OF QATAR SCHEDULE A: PROJECT BRIEF

ASHGHAL PART 2: SPECIFICATION, CODES AND REQUIREMENTS

B. PROJECT SPECIFICATION

PROJECT ID: BA 2018 C 011 I Schedule A: Part 2 – Page 44 Rev 0

Construction of Additional Facilities for the Community College of Qatar - Boys

You might also like

- CM570 Wiring Diagram Sheets for 31-Pin & 50-Pin OEM ConnectorsDocument5 pagesCM570 Wiring Diagram Sheets for 31-Pin & 50-Pin OEM ConnectorsJose Alanis85% (20)

- Idirect COTM Design Considerations - White PaperDocument9 pagesIdirect COTM Design Considerations - White Paperkira019No ratings yet

- Telecommunications Design Standards: Revision 21.5 - October 4, 2017 Colorado State UniversityDocument29 pagesTelecommunications Design Standards: Revision 21.5 - October 4, 2017 Colorado State Universityvenkat RaoNo ratings yet

- Advanced View Arduino Projects List - Use Arduino For Projects-4Document62 pagesAdvanced View Arduino Projects List - Use Arduino For Projects-4Bilal AfzalNo ratings yet

- Tesla CoilDocument12 pagesTesla CoilVeerath தமிழன்100% (1)

- Basic Process Control Systems Requirements PDFDocument32 pagesBasic Process Control Systems Requirements PDFwq22030202100% (1)

- V07 (Architectural FOH Lighting)Document231 pagesV07 (Architectural FOH Lighting)Parth WankhedeNo ratings yet

- Communications Cabling Installation GuideDocument21 pagesCommunications Cabling Installation GuidesherifNo ratings yet

- Practical Data Acquisition for Instrumentation and Control SystemsFrom EverandPractical Data Acquisition for Instrumentation and Control SystemsNo ratings yet

- Commissioning Checklist 3.11.10Document5 pagesCommissioning Checklist 3.11.10shoukat14No ratings yet

- SPC-0804.02-60.05 Rev D2 DCS SpecificationDocument31 pagesSPC-0804.02-60.05 Rev D2 DCS SpecificationharmlesdragonNo ratings yet

- Protect Medium Voltage Networks with ABB's Feeder TerminalDocument68 pagesProtect Medium Voltage Networks with ABB's Feeder Terminal021804No ratings yet

- Saes T 570 PDFDocument18 pagesSaes T 570 PDFQa QcNo ratings yet

- Infrastructure Cabling Works SECTION 27 13 23: Part 1 - General 1.1 Related DocumentsDocument14 pagesInfrastructure Cabling Works SECTION 27 13 23: Part 1 - General 1.1 Related DocumentsGamal Ahmed100% (1)

- After VendorDocument8 pagesAfter VendorAnonymNo ratings yet

- Qcs 2010 Part 10.02 Telemetry-SCADADocument29 pagesQcs 2010 Part 10.02 Telemetry-SCADARotsapNayrb100% (1)

- Technicalspecificationforcpsystem 151216044929 PDFDocument62 pagesTechnicalspecificationforcpsystem 151216044929 PDFsouheil boussaidNo ratings yet

- EIL - CCTV - 6922 - 6-52-090Document16 pagesEIL - CCTV - 6922 - 6-52-090fraihafraiha100% (2)

- Technical Specification For Communication EquipmentDocument79 pagesTechnical Specification For Communication EquipmentumamaheshwarraoNo ratings yet

- A Low-Cost Compliant 7-DOF Robotic Manipulator: Morgan Quigley, Alan Asbeck, and Andrew Y. NGDocument8 pagesA Low-Cost Compliant 7-DOF Robotic Manipulator: Morgan Quigley, Alan Asbeck, and Andrew Y. NGsigmateNo ratings yet

- 4 - FMCS PDFDocument19 pages4 - FMCS PDFsohoNo ratings yet

- Building Management SystemDocument39 pagesBuilding Management SystemSameh AbiedNo ratings yet

- CCTV Surveillance System: Technical Specifications Chapter: A General A.1 Scope of WorkDocument2 pagesCCTV Surveillance System: Technical Specifications Chapter: A General A.1 Scope of WorkRabin ShresthaNo ratings yet

- Physics Quick Notes by MDCATDocument23 pagesPhysics Quick Notes by MDCATZaryab Khan100% (1)

- MEEZA CRAC and Downflow SpecificationDocument57 pagesMEEZA CRAC and Downflow SpecificationSwamy Dhas DhasNo ratings yet

- Zapi Sem-2 ManualDocument38 pagesZapi Sem-2 ManualSamy ElmiligyNo ratings yet

- ICT SpecificationDocument99 pagesICT SpecificationZaid HijjawiNo ratings yet

- AP - Smart Grids 61850 (EN) 2017.01Document34 pagesAP - Smart Grids 61850 (EN) 2017.01Assis JúniorNo ratings yet

- 2 Wire Digital Communication Clock System Engineering SpecDocument10 pages2 Wire Digital Communication Clock System Engineering SpecsameeraNo ratings yet

- Structured CablingDocument22 pagesStructured CablingJorge Arturo Zuñiga VargasNo ratings yet

- 27 51 13 - Paging Systems 07 - 28 - 2010Document35 pages27 51 13 - Paging Systems 07 - 28 - 2010Ahmed KhattabNo ratings yet

- 4/22/2019 Document1Document18 pages4/22/2019 Document1JKNo ratings yet

- CommunicationDocument168 pagesCommunicationmrizal23No ratings yet

- Asicot-Sse-2022-178 Technical Offer Vnip 19-03-2022Document42 pagesAsicot-Sse-2022-178 Technical Offer Vnip 19-03-2022Anand BagadeNo ratings yet

- Structured Cabling System Specification: Section 271010-Telephone and Data Distribution 11/2017Document27 pagesStructured Cabling System Specification: Section 271010-Telephone and Data Distribution 11/2017gate 2012No ratings yet

- Ian Banham and Associates Part C - Section 1 Building Management SystemDocument51 pagesIan Banham and Associates Part C - Section 1 Building Management SystemNayeemuddinNo ratings yet

- Spec CommunicationcablesDocument12 pagesSpec CommunicationcablesDolyNo ratings yet

- 26 09 44wenDocument8 pages26 09 44wenAbed samadsureyft7vewyrNo ratings yet

- 16740-Telephone System (IP Telephony)Document12 pages16740-Telephone System (IP Telephony)Ali SaifNo ratings yet

- Bacnet Building Automation System Direct Digital Controls Guide SpecificationDocument58 pagesBacnet Building Automation System Direct Digital Controls Guide SpecificationSergio Andrade100% (1)

- IA Series BACnet Guide SpecDocument33 pagesIA Series BACnet Guide SpecNATHANNo ratings yet

- SECTION 16725 Ip Access Control and Security Management SystemsDocument35 pagesSECTION 16725 Ip Access Control and Security Management SystemsAhver ChaudharyNo ratings yet

- SECTION 27 52 23 Nurse Call and Code Blue Systems Part 1 - General 1.1 Section SummaryDocument74 pagesSECTION 27 52 23 Nurse Call and Code Blue Systems Part 1 - General 1.1 Section SummaryAmira HassanNo ratings yet

- SOW Scope of Work MAHKAMAH PPDocument14 pagesSOW Scope of Work MAHKAMAH PPadah MuzakirNo ratings yet

- Ian Banham and Associates Part C - Section 1 Building Management SystemDocument46 pagesIan Banham and Associates Part C - Section 1 Building Management SystemUri BabaNo ratings yet

- MATV Division 16781Document37 pagesMATV Division 16781Sachin MohiteNo ratings yet

- 16740-Telephone System (IP Telephony)Document13 pages16740-Telephone System (IP Telephony)Ali SaifNo ratings yet

- DS-Courtyard-2005Jan-M13-Building SystemsDocument79 pagesDS-Courtyard-2005Jan-M13-Building SystemsPietrus NimbusNo ratings yet

- 27 05 53 Identification For Communications Systems-DarDocument6 pages27 05 53 Identification For Communications Systems-DarMohamed Abou El hassanNo ratings yet

- S Civ Site - 00Document8 pagesS Civ Site - 00HARINo ratings yet

- PO07218 Installation Requirements For Telecommunication Equipment On Evoenergy AssetsDocument29 pagesPO07218 Installation Requirements For Telecommunication Equipment On Evoenergy AssetsNikola BoskovicNo ratings yet

- WIN-PAK PRO A&E SpecificationDocument44 pagesWIN-PAK PRO A&E SpecificationWaleed AhmedNo ratings yet

- SCADA IntegrationDocument16 pagesSCADA IntegrationSreejith SasisekharanNo ratings yet

- Karnataka Power Transmission Corporation Limited: Bid Enquiry No. Kptcl/Cee/T&P/220Kv/Mittemari/Ptk/ Tlss-701Document397 pagesKarnataka Power Transmission Corporation Limited: Bid Enquiry No. Kptcl/Cee/T&P/220Kv/Mittemari/Ptk/ Tlss-701harishNo ratings yet

- Qcs 2010 Section 10 Part 2 Telemetry SCADADocument29 pagesQcs 2010 Section 10 Part 2 Telemetry SCADAbryanpastor106No ratings yet

- Building Design GuidelinesDocument36 pagesBuilding Design GuidelinesrogerchetcutiNo ratings yet

- 2600 Corporate Telecom Cabling Standard Rev 1A - (66778120)Document182 pages2600 Corporate Telecom Cabling Standard Rev 1A - (66778120)avadhoot_1206817114No ratings yet

- 132kV Connection Guide Version 8Document43 pages132kV Connection Guide Version 8Austin Ronald RayNo ratings yet

- Switchboards SECTION 16441Document12 pagesSwitchboards SECTION 16441NATHANNo ratings yet

- 16453-Grounding & Bonding Telecommunication SystemDocument6 pages16453-Grounding & Bonding Telecommunication SystemuddinnadeemNo ratings yet

- UntitledDocument202 pagesUntitledOngwae Mathew TeyaNo ratings yet

- Tec GR It PTP 003 01 Mar 12Document21 pagesTec GR It PTP 003 01 Mar 12Santhakrishnan AdhinarayananNo ratings yet

- Standards Reading FineDocument47 pagesStandards Reading FineUmairChJalandhariNo ratings yet

- Av, CCTV, Acs, Pa SpecsDocument85 pagesAv, CCTV, Acs, Pa SpecsMohamed Abou El hassanNo ratings yet

- ESP32-MINI-1 CE CertificationDocument3 pagesESP32-MINI-1 CE CertificationDavide FilippiNo ratings yet

- C R Panel (With Automation) Nov 2016 - 17.03.2017Document88 pagesC R Panel (With Automation) Nov 2016 - 17.03.2017Ratheesh KumarNo ratings yet

- Design Planning 3M VolitionDocument179 pagesDesign Planning 3M VolitionMarian Ilie0% (1)

- Configure JELinux Server Network SettingsDocument4 pagesConfigure JELinux Server Network SettingsAnonymNo ratings yet

- Floor plan layout for 2 and 3 bedroom apartmentsDocument1 pageFloor plan layout for 2 and 3 bedroom apartmentsAnonymNo ratings yet

- Guide to Living and Dining Room LayoutsDocument1 pageGuide to Living and Dining Room LayoutsAnonymNo ratings yet

- Floor plan layout for multi-bedroom apartmentDocument1 pageFloor plan layout for multi-bedroom apartmentAnonymNo ratings yet

- CR-1020 1ST Basement PlanDocument1 pageCR-1020 1ST Basement PlanAnonymNo ratings yet

- GTC CCTV 027 2017Document101 pagesGTC CCTV 027 2017AnonymNo ratings yet

- Configuring Date and TimeDocument2 pagesConfiguring Date and TimeAnonymNo ratings yet

- CR-1010 2ND Basement PlanDocument1 pageCR-1010 2ND Basement PlanAnonymNo ratings yet

- Uploading Packages: in Web InterfaceDocument2 pagesUploading Packages: in Web InterfaceAnonymNo ratings yet

- Adfqerq PDFDocument8 pagesAdfqerq PDFAnonymNo ratings yet

- 26608449Document36 pages26608449AnonymNo ratings yet

- Manual Product 65Document21 pagesManual Product 65AnonymNo ratings yet

- PUE Access Control Door ScheduleDocument1 pagePUE Access Control Door ScheduleAnonymNo ratings yet

- ComparisonDocument14 pagesComparisonAnonymNo ratings yet

- A Oups CatalogueDocument44 pagesA Oups CatalogueAnonymNo ratings yet

- 2031519Document2 pages2031519AnonymNo ratings yet

- App B Part II - BOQDocument18 pagesApp B Part II - BOQAnonymNo ratings yet

- ElectlDocument37 pagesElectlAnonymNo ratings yet

- SCS - BoqDocument2 pagesSCS - BoqAnonymNo ratings yet

- DimensionsDocument1 pageDimensionsAnonymNo ratings yet

- Hamad Bin Khalifa Medical City MEP Vendor ListDocument1 pageHamad Bin Khalifa Medical City MEP Vendor ListAnonymNo ratings yet

- Qfe084 Pro DWG 09 3002 01Document1 pageQfe084 Pro DWG 09 3002 01AnonymNo ratings yet

- E001 01 0Document1 pageE001 01 0AnonymNo ratings yet

- Bill 2 - Middle School: Closed Circuit Television (CCTV) Surveillance SystemDocument5 pagesBill 2 - Middle School: Closed Circuit Television (CCTV) Surveillance SystemAnonymNo ratings yet

- O & M Submittal (Wh-Ihc) v2Document95 pagesO & M Submittal (Wh-Ihc) v2AnonymNo ratings yet

- Dutton Marcus F 201105 PHD PDFDocument230 pagesDutton Marcus F 201105 PHD PDFBharat NarumanchiNo ratings yet

- Description and Operation: Unison Industries Component Maintenance Manual Ignition LeadsDocument2 pagesDescription and Operation: Unison Industries Component Maintenance Manual Ignition Leadsmaty englerNo ratings yet

- Ant DS y (B) 4506 0115Document1 pageAnt DS y (B) 4506 0115SentaNo ratings yet

- Gen4 Size 10 WebDocument2 pagesGen4 Size 10 WebMoisi DragosNo ratings yet

- 6P3S EtcDocument2 pages6P3S EtcR .GNo ratings yet

- Technical Service Manual for 13SEER Comfortstar Plus Air ConditionersDocument34 pagesTechnical Service Manual for 13SEER Comfortstar Plus Air Conditionerstitomotta0% (2)

- XLM35 DS T140088en eDocument2 pagesXLM35 DS T140088en eStefanos BokiNo ratings yet

- Coimbatore Energy Meter Manufacturer ProfileDocument8 pagesCoimbatore Energy Meter Manufacturer ProfileKumar ChandanNo ratings yet

- BTC Pump Data SheetDocument10 pagesBTC Pump Data SheetПенови ИнженерингNo ratings yet

- Bangladesh Customs Tariff Chapter on Electrical MachineryDocument13 pagesBangladesh Customs Tariff Chapter on Electrical MachineryAtiqur RahmanNo ratings yet

- EP1116-0 ControlUnits Relays 060217Document404 pagesEP1116-0 ControlUnits Relays 060217Muhamad PriyatnaNo ratings yet

- Traynor 30Document10 pagesTraynor 30checker810% (1)

- Protection and Grid Connection Integrated Into One Device: SACE Emax 2Document4 pagesProtection and Grid Connection Integrated Into One Device: SACE Emax 2Santiago BNo ratings yet

- Overline Assessment of Coatings and Cathodic Protection Corrosion ControlDocument50 pagesOverline Assessment of Coatings and Cathodic Protection Corrosion Control김원재No ratings yet

- Sensata CKM Din Rail Mount Relay Datasheet-2933674Document4 pagesSensata CKM Din Rail Mount Relay Datasheet-2933674OscarNo ratings yet

- ATLAN 24 Thiet Bi Chong Set LAN Data 24 PortDocument2 pagesATLAN 24 Thiet Bi Chong Set LAN Data 24 PortKenh Nhat DatNo ratings yet

- L330 LowPowerOpAmps 2UPDocument7 pagesL330 LowPowerOpAmps 2UPVan Nguyen Huu VanNo ratings yet

- Vip 1200LDocument1 pageVip 1200LJorgeNo ratings yet

- BEEE - LAB Manual-Intro - Part 2Document6 pagesBEEE - LAB Manual-Intro - Part 2Anant UpadhiyayNo ratings yet

- ELEKTROTOM HiTT 106 GBDocument8 pagesELEKTROTOM HiTT 106 GBBo ScoobmanNo ratings yet

- KSEB Power Application LT FormDocument2 pagesKSEB Power Application LT FormJoel Joy100% (1)