Professional Documents

Culture Documents

Technical Data Sheet: Threadlocker Blue 242

Uploaded by

NICKYOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Technical Data Sheet: Threadlocker Blue 242

Uploaded by

NICKYCopyright:

Available Formats

Revision: April 9, 2018

Supersedes: March 25, 2014

Ref. #: 150233

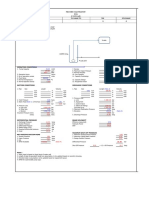

TECHNICAL DATA SHEET

Henkel Corporation

Professional and Consumer Adhesives

Rocky Hill, CT

Phone 1-800-624-7767

www.henkel.com www.loctiteproducts.com

THREADLOCKER BLUE

242

DESCRIPTION:

Loctite® Threadlocker Blue 242® is designed for the locking and sealing of threaded fasteners which

require normal disassembly with standard hand tools. The product cures anaerobically, when there

is an absence of air between close fitting metal surfaces. It protects threads from rust and corrosion

and prevents loosening from shock and vibration. Loctite® Threadlocker Blue 242® is particularly

suited for applications on less active substrates such as stainless steel and plated surfaces, where

disassembly is required for servicing.

RECOMMENDED FOR:

Use on metal fasteners 1/4” (6 mm) to 3/4” (19 mm) in diameter in a wide variety of applications

including:

Automotive – Valve covers, water pumps, alternators, oil pans

Maintenance – Light machinery, light conveyors, door hardware, tow motors

Home – Lawn mowers, grills, locksets, bicycles

LIMITATIONS:

▪ Not for use on plastic parts, particularly thermoplastic materials where stress cracking of

the plastic could result

▪ Not for use in pure oxygen and/or oxygen rich systems and should not be selected as a

sealant for chlorine or other strong oxidizing materials

▪ If two inactive metals are used, use of a primer is required

▪ Not for use in applications requiring “food safe” locking and sealing of fasteners

FEATURES & BENEFITS:

Feature Benefits

Item # Package Size Protects threads.……………………………. Prevents rusting of threads

209728 Carded 0.20 fl. oz. Medium strength…………………................ Can be removed with hand tools

Tube (6 ml)

Locks threads………….……………………. Prevents loosening of metal fasteners

caused by vibrations

TECHNICAL DATA

Typical Uncured Physical Properties Typical Application Properties

Color: Blue Application Temperature: Apply above 50F (10C)

Appearance: Liquid Odor: Minimal

Base: Dimethylacrylate ester Set Time: 10 minutes on active metals (steel). Longer for

less active metals.

Specific Gravity: 1.1 Cure Time: 24* hours

*Cure time is dependent on temperature, and

type of metal being bonded

VOC Content 6.17 g/l, SCAQMD Method 316B Viscosity: 900 – 1,400 cP

Flashpoint: >199.9°F (93°C)

Shelf Life: 24 months from date of manufacture Lot Code Explanation: 7GAA2230

(unopened) Y= Last digit of year of manufacture (7= 2017)

G= Month of Year (1=Jan., B= Feb., C= March, etc.)

Example: 7G = July 2017

Loctite® Threadlocker Blue 242

Page 1 of 4

Revision: April 9, 2018

Supersedes: March 25, 2014

Ref. #: 150233

TECHNICAL DATA SHEET

TECHNICAL DATA

Typical Cured Performance Properties

Color: Blue Cured form: Non-flammable, hard solid.

Service Temperature: -65°F (-54°C) to 300°F (149°C) Moisture Resistant: Yes

Clean-Up:

Uncured: Wipe with damp cloth.

Cured: Remove with a combination of soaking in methylene chloride and mechanical abrasion such as a wire brush.

For disassembly: Shear with hand tools and remove with methylene chloride. In rare instances where hand tools do not work because of

excessive engagement length, apply localized heat to nut or bolt to approximately 250°C and dissemble while hot.

Adhesive Properties:

After 1 hour@ 72°C (22°C)

Breakaway Torque (ISO 10964):

3/8 x 16 steel nuts (grade 2) and bolts (grade 5) 50 to 150 lb.in. (5.6 to 17 N.m)

Prevail Torque (ISO 10964):

3/8 x 16 steel nuts (grade 2) and bolts (grade 5) 15 to 60 lb.in. (1.7 to 6.8 N.m)

After 1 hour@ 72°C (22°C)

Breakaway Torque (ISO 10964):

3/8 X 16 steel nuts (grade 2) and bolts (grade 5) 70 to 150 lb·in (7.9 to 17 N·m)

3/8 x 16 cadmium nuts and bolts 10 to 60 lb·in (1.1 to 6.8 N·m)

3/8 x 16 zinc nuts and bolts 20 to 60 lb·in (2.3 to 6.8 N·m)

M10 black oxide steel nuts and bolts 71 to 168 lb·in (8 to 19 N·m)

Prevail Torque (ISO 10964):

3/8 x 16 steel nuts (grade 2) and bolts (grade 5) 25 to 60 lb·in (2.8 to 6.8 N·m)

3/8 x 16 cadmium nuts and bolts 4 to 40 lb.in (0.5 to 4.5 N.m)

3/8 x 16 zinc nuts and bolts 10 to 40 lb.in (1.1 to 4.5 N.m)

Applicable Specifications:

Tested to the requirements of: ▪ Military Specification Mil-S-46163A

▪ ASTM D 5363

Chemical/Solvent Resistance, aged under conditions indicated and tested @ 22ºC

Temperature % of initial strength

Environment ºF 1000 h

Motor Oil (MIL-L-46152) 257 100

Unleaded gasoline 72 95

Leaded gasoline I 72 100

Brake fluid 72 100

Ethanol 72 95

Acetone 72 85

1,1,1 Trichloroethane 72 90

Water/glycol 50/50 189 70

Loctite® Threadlocker Blue 242

Page 2 of 4

Revision: April 9, 2018

Supersedes: March 25, 2014

Ref. #: 150233

TECHNICAL DATA SHEET

DIRECTIONS

Tools Typically Required:

Utility knife, damp cloth.

Safety Precautions:

Keep out of reach of children.

Preparation:

Protect work area. Parts to be sealed must be clean and dry. Shake the product thoroughly before use.

Note: To prevent the product from clogging in the nozzle, avoid touching the bottle tip to the metal surface.

Application:

For Thru Holes:

Apply several drops of the product onto the bolt at the nut engagement area.

For Blind Holes:

Apply several drops of the product down the internal threads to the bottom of the hole.

For Sealing Applications:

Apply a 360° bead of product to the leading threads of the male fitting, leaving the first thread free. Force the material into the threads to

thoroughly fill the voids. For bigger threads and voids, adjust product amount accordingly and apply a 360° bead of product on the female

threads also.

Assemble parts and tighten as required. Sets in approximately 10 minutes and fully cures in 24 hours.

Clean-up

Clean adhesive residue immediately with a damp cloth. Cured product can be removed with a combination of soaking in methylene chloride

and mechanical abrasion such as a wire brush.

For disassembly, shear with standard hand tools and remove with methylene chloride. In rare instances where hand tools do not work because

of excessive engagement length, apply localized heat to nut or bolt to approximately 482°F (250°C). Disassemble while hot.

STORAGE AND DISPOSAL

Not damaged by freezing. Close the tube tightly after each use. Store product in the unopened container in a dry location. Optimal storage

is between 46°F (8°C) to 70°F (21°C).

LABEL PRECAUTIONS

WARNING: Contains methacrylate ester. May cause allergic skin reaction and eye irritation.

Avoid eye and skin contact. Avoid breathing vapors. Use only with adequate ventilation.

FIRST AID: For eye contact, flush with water for 15 minutes; call a physician. For skin contact,

wash thoroughly with soap and water. If inhaled, move to fresh air. If swallowed, do not induce

vomiting. Obtain medical attention. KEEP OUT OF REACH OF CHILDREN.

WARNING: Cancer – www.P65Warnings.ca.gov

Refer to the Safety Data Sheet (SDS) for further information

DISCLAIMER

The information and recommendations contained herein are based on our research and are believed to be accurate, but no warranty, express

or implied, is made or should be inferred. Henkel recommends purchasers/users should test the products to determine acceptable quality and

suitability for the intended use. All adhesive/sealant applications should be tested under simulated or actual end use conditions to ensure the

adhesive/sealant meets or exceeds all required project specifications. Since assembly conditions may be critical to adhesive/sealant

performance, it is also recommended that testing be performed on specimens assembled under simulated or actual production conditions.

Nothing contained herein shall be construed to imply the nonexistence of any relevant patents or to constitute a permission, inducement or

recommendation to practice any invention covered by any patent, without authority from the owner of the patent.

Loctite® Threadlocker Blue 242

Page 3 of 4

Revision: April 9, 2018

Supersedes: March 25, 2014

Ref. #: 150233

TECHNICAL DATA SHEET

Trusted Performance. Proven Results. For over 50 years, Loctite Brand adhesives and sealants have

taken on the toughest jobs. Used in race cars, airplanes, and even in the space-shuttle, Loctite provides

solutions for the most demanding industrial, and consumer applications. Loctite gives you not the

specialization, power and performance to not only get your job done, but to get it done right.

For Technical Assistance call : 1-800-624-7767 – Mon-Fri - 9:00a – 4:00p ET

www.loctiteproducts.com

Loctite Brand is part of the Henkel family of brands. Founded in 1876, Henkel is a global leader in the

consumer and industrial businesses. Henkel operates worldwide with leading brands and technologies

in three business areas: Laundry & Home Care, Beauty Care and Adhesive Technologies.

Henkel Corporation - Professional & Consumer Adhesives Headquarters - Rocky Hill, CT 06067

www.henkelna.com

Loctite® Threadlocker Blue 242

Page 4 of 4

You might also like

- LOCTITE SI 5927 RED en - GLDocument2 pagesLOCTITE SI 5927 RED en - GLOmer IkhlasNo ratings yet

- Loctite 2432: Technical Data SheetDocument2 pagesLoctite 2432: Technical Data SheetFabio ParceroNo ratings yet

- Unidad de Servicio Tecnica On-Off ToolDocument20 pagesUnidad de Servicio Tecnica On-Off ToolGeorge MartinezNo ratings yet

- JOINLEADER 880 Weatherproof Silicone Sealant TDSDocument5 pagesJOINLEADER 880 Weatherproof Silicone Sealant TDSdasaNo ratings yet

- Bondloc B270 Studlock TDSDocument2 pagesBondloc B270 Studlock TDSsean jukesNo ratings yet

- Loctite Fixmaster Metal Magic Steel™: Technical Data SheetDocument3 pagesLoctite Fixmaster Metal Magic Steel™: Technical Data SheetHamzaNoumanNo ratings yet

- TDS of Metlok 703Document2 pagesTDS of Metlok 703idrees.theheroNo ratings yet

- Sikabond® at Metal: Product Data SheetDocument3 pagesSikabond® at Metal: Product Data SheetHarjasa AdhiNo ratings yet

- Machine Tool Slideway Oil Technical Data SheetDocument3 pagesMachine Tool Slideway Oil Technical Data SheetNoah DoeserNo ratings yet

- Dynacoll S 1401: General DescriptionDocument2 pagesDynacoll S 1401: General DescriptionMehmet DuayenNo ratings yet

- Ea 3463 enDocument3 pagesEa 3463 enasistengerenciasigsNo ratings yet

- Ambersil Copper High Temperature Anti Seize Paste TDSDocument2 pagesAmbersil Copper High Temperature Anti Seize Paste TDSjawnuolisNo ratings yet

- 8009 Heavy Duty Anti-Seize Product SheetDocument2 pages8009 Heavy Duty Anti-Seize Product SheetFabio ParceroNo ratings yet

- Si 596 Red-EnDocument3 pagesSi 596 Red-EnkabiriscNo ratings yet

- Sikasil PoolDocument4 pagesSikasil PoolRockweed InternationalNo ratings yet

- Build: Builders Silicone SealantsDocument3 pagesBuild: Builders Silicone SealantsAhmed KhameisNo ratings yet

- Bpxe 9Q932NDocument2 pagesBpxe 9Q932NArthur Sanda LayukNo ratings yet

- Roller Bearing GreaseDocument2 pagesRoller Bearing GreaseYoong TanNo ratings yet

- Metal-Silicone-2-Sealant-Technical-Data-SheetDocument6 pagesMetal-Silicone-2-Sealant-Technical-Data-Sheetremarkhb.maintenanceNo ratings yet

- Compressor Oil SDocument2 pagesCompressor Oil SQuy CocanhNo ratings yet

- MOLYKOTE 3400A Anti-Friction Coating LF 80-3061C-01Document2 pagesMOLYKOTE 3400A Anti-Friction Coating LF 80-3061C-01MAHESH BELENo ratings yet

- Technical Data SheetDocument6 pagesTechnical Data SheetDevaraj BaulNo ratings yet

- UNIREX™ N Series UNIREX™ N Series UNIREX™ N Series UNIREX™ N SeriesDocument3 pagesUNIREX™ N Series UNIREX™ N Series UNIREX™ N Series UNIREX™ N Series121212No ratings yet

- CT-90 Cutting Fluid Multi-UseDocument2 pagesCT-90 Cutting Fluid Multi-UsePaulNo ratings yet

- Polyester 827 Architectural Powder Coating Technical DatasheetDocument2 pagesPolyester 827 Architectural Powder Coating Technical DatasheetMichael McQueenNo ratings yet

- Molylub GoldTex T 32 KnittingDocument1 pageMolylub GoldTex T 32 KnittingismoyoNo ratings yet

- Ea 3463 New-EnDocument2 pagesEa 3463 New-EnRonald Mario Quiroz SerrateNo ratings yet

- Mar Painting 2Document24 pagesMar Painting 2Teguh IndrawanNo ratings yet

- Ficha Tecnica Castrol Ilocut 5770Document2 pagesFicha Tecnica Castrol Ilocut 5770Victor Manuel Gonzalez PerezNo ratings yet

- PDS - CHASSIS GREASE (EN) Rev.18-00Document2 pagesPDS - CHASSIS GREASE (EN) Rev.18-00dicha gilangNo ratings yet

- Aquafin Pakistan MS Hybrid Polymer SealantDocument2 pagesAquafin Pakistan MS Hybrid Polymer SealantKhizar HayatNo ratings yet

- Bpxe 8Z56LRDocument2 pagesBpxe 8Z56LRVusal HasanovNo ratings yet

- High-performance synthetic air compressor oilDocument2 pagesHigh-performance synthetic air compressor oilToppy ToppyNo ratings yet

- VT-638FC MS Seam Sealant: Vital Technical Sdn. BHDDocument2 pagesVT-638FC MS Seam Sealant: Vital Technical Sdn. BHDal varezNo ratings yet

- Loctite PC 7222Document3 pagesLoctite PC 7222YuvarajNo ratings yet

- TDS Loctite Nickel LB 771-EnDocument2 pagesTDS Loctite Nickel LB 771-EnGregory Alan Francisco IINo ratings yet

- Redux 312: Product DataDocument4 pagesRedux 312: Product Dataaman guptaNo ratings yet

- Loctite 384Document2 pagesLoctite 384A DamiánNo ratings yet

- Design of Thin-Film Coater BladeDocument24 pagesDesign of Thin-Film Coater BladeNtuthuko ZuluNo ratings yet

- Technical Data Sheets: Fluid FilmDocument5 pagesTechnical Data Sheets: Fluid FilmRAHULNo ratings yet

- Perfecto T Range: DescriptionDocument2 pagesPerfecto T Range: Descriptiondforsythe639No ratings yet

- CG52B Contact Lubricants en 23mar22 TBDocument4 pagesCG52B Contact Lubricants en 23mar22 TBKukuh MRNo ratings yet

- LOCTITE SI 5331 en - GLDocument2 pagesLOCTITE SI 5331 en - GLkaplanuygarNo ratings yet

- 587 enDocument2 pages587 enabhayundaleNo ratings yet

- CirRenew C14 LD2420DDocument3 pagesCirRenew C14 LD2420DJaime222No ratings yet

- PDS - Mobilgrease XHP 460 SeriesDocument3 pagesPDS - Mobilgrease XHP 460 SeriesJuanSantillanNo ratings yet

- Loctite 518™: Technical Data SheetDocument3 pagesLoctite 518™: Technical Data Sheetsaurabhjerps231221No ratings yet

- Glo Sikagrout 800 en Corp 01 2023Document5 pagesGlo Sikagrout 800 en Corp 01 2023jpantazis1975No ratings yet

- 93 Sinopec Extreme Pressure Lithium Complex GreaseDocument3 pages93 Sinopec Extreme Pressure Lithium Complex GreaseAmadeus CocaNo ratings yet

- 57301eمواصفات اللكر الذهبيDocument1 page57301eمواصفات اللكر الذهبيأحمد الحسنNo ratings yet

- Sicomet 9020Document2 pagesSicomet 9020Gilad KorenNo ratings yet

- Technical Data Sheet for Anabond 666T Max Silicone SealantDocument3 pagesTechnical Data Sheet for Anabond 666T Max Silicone SealantDinesh SaravanaNo ratings yet

- Nippon Metal Primer Red Oxide TDSDocument2 pagesNippon Metal Primer Red Oxide TDSPraveen KumarNo ratings yet

- Sumo For Panel Technical Data Sheet Rev 1 010122Document6 pagesSumo For Panel Technical Data Sheet Rev 1 010122Nam Hoàng HảiNo ratings yet

- Loctitie Fix Master Ea 3463-Na-EnDocument3 pagesLoctitie Fix Master Ea 3463-Na-EnImran KhanNo ratings yet

- Tec7 Technical Data SheetDocument3 pagesTec7 Technical Data SheetMohamed WahdanNo ratings yet

- Henk Loctite Superflex Red TdsDocument2 pagesHenk Loctite Superflex Red TdsMariano DomenechNo ratings yet

- TDS Total Azolla-Zs-32 157 202111 en IdnDocument1 pageTDS Total Azolla-Zs-32 157 202111 en IdnAnya J PamungkasNo ratings yet

- TDS PC 7218-EnDocument3 pagesTDS PC 7218-Enangga alvianNo ratings yet

- GRP and Buildings: A Design Guide for Architects and EngineersFrom EverandGRP and Buildings: A Design Guide for Architects and EngineersNo ratings yet

- Safety Data Sheet: SECTION 1: Identification of The Substance/mixture and of The Company/ UndertakingDocument16 pagesSafety Data Sheet: SECTION 1: Identification of The Substance/mixture and of The Company/ UndertakingNICKYNo ratings yet

- Everlube 626 DilutedDocument9 pagesEverlube 626 DilutedNICKYNo ratings yet

- Epocast 1619Document23 pagesEpocast 1619NICKYNo ratings yet

- Revision Date: 23-4-2009 Print Date: 8-10-2009Document7 pagesRevision Date: 23-4-2009 Print Date: 8-10-2009NICKYNo ratings yet

- Epocast 1628 BDocument10 pagesEpocast 1628 BNICKYNo ratings yet

- Epocast 50a1-9816Document22 pagesEpocast 50a1-9816NICKYNo ratings yet

- Safety Data Sheet: Section 1. IdentificationDocument17 pagesSafety Data Sheet: Section 1. IdentificationNICKYNo ratings yet

- ACC Silicones LTD Silcoset 101: Safety Data SheetDocument6 pagesACC Silicones LTD Silcoset 101: Safety Data SheetNICKYNo ratings yet

- Epocast 1618 DBDocument5 pagesEpocast 1618 DBNICKYNo ratings yet

- Ardrox 185 L: Safety Data SheetDocument9 pagesArdrox 185 L: Safety Data SheetNICKYNo ratings yet

- Material Safety Data Sheet: 1. Product and Company IdentificationDocument11 pagesMaterial Safety Data Sheet: 1. Product and Company IdentificationNICKYNo ratings yet

- Material Safety Data Sheet: Product and Company Identification 1Document16 pagesMaterial Safety Data Sheet: Product and Company Identification 1NICKYNo ratings yet

- Safety Data Sheet: 3M™ Aerospace Sealant AC-665 B-2Document25 pagesSafety Data Sheet: 3M™ Aerospace Sealant AC-665 B-2NICKYNo ratings yet

- Tectyl 891D CL2Document4 pagesTectyl 891D CL2NICKYNo ratings yet

- Ardrox 3966: Safety Data SheetDocument16 pagesArdrox 3966: Safety Data SheetNICKYNo ratings yet

- Ardrox 3965: Safety Data SheetDocument13 pagesArdrox 3965: Safety Data SheetNICKYNo ratings yet

- Ardrox 6025: Safety Data SheetDocument20 pagesArdrox 6025: Safety Data SheetNICKYNo ratings yet

- Product and Company Identification: Material Safety Data SheetDocument7 pagesProduct and Company Identification: Material Safety Data SheetNICKYNo ratings yet

- Material Safety Data Sheet AC - 770 Catalyst: 1. Chemical Product and Company InformationDocument6 pagesMaterial Safety Data Sheet AC - 770 Catalyst: 1. Chemical Product and Company InformationNICKYNo ratings yet

- AC240B Base PDFDocument7 pagesAC240B Base PDFNICKYNo ratings yet

- Aeroshell Fluid 3 PDFDocument8 pagesAeroshell Fluid 3 PDFNICKYNo ratings yet

- Molykote G - Rapid PlusDocument9 pagesMolykote G - Rapid PlusNICKYNo ratings yet

- Material Safety Data Sheet AC - 770 Class B Base: MSDS No: 37702-09 Effective: 02/09/09 Supercedes: 12/12/07 Page: 1 of 5Document5 pagesMaterial Safety Data Sheet AC - 770 Class B Base: MSDS No: 37702-09 Effective: 02/09/09 Supercedes: 12/12/07 Page: 1 of 5NICKYNo ratings yet

- Molykote 33M PDFDocument7 pagesMolykote 33M PDFNICKYNo ratings yet

- Loctite 274Document9 pagesLoctite 274NICKYNo ratings yet

- Safety Data Sheet: Section 1. IdentificationDocument12 pagesSafety Data Sheet: Section 1. IdentificationNICKYNo ratings yet

- Molykote (R) 33 L Grease: Dow Corning Toray Co., Ltd. Material Safety Data SheetDocument5 pagesMolykote (R) 33 L Grease: Dow Corning Toray Co., Ltd. Material Safety Data SheetNICKYNo ratings yet

- PTFE Release Agent Safety Data SheetDocument7 pagesPTFE Release Agent Safety Data SheetNICKYNo ratings yet

- Molykote 33M PDFDocument7 pagesMolykote 33M PDFNICKYNo ratings yet

- Aeroshell Grease 64: Main Applications Specifications, Approvals & RecommendationsDocument3 pagesAeroshell Grease 64: Main Applications Specifications, Approvals & RecommendationsNICKYNo ratings yet

- HistoryDocument13 pagesHistoryMuhamed Zimić ZimaNo ratings yet

- Gliffy Public Diagram - ATM FlowchartDocument3 pagesGliffy Public Diagram - ATM Flowchartmy nNo ratings yet

- Test IMO EnglezaDocument4 pagesTest IMO EnglezaCristina PopovNo ratings yet

- Subhasis Patra CV V3Document5 pagesSubhasis Patra CV V3Shubh SahooNo ratings yet

- TriPAD Seminar Provides Guidance for TeachersDocument2 pagesTriPAD Seminar Provides Guidance for TeachersKingJames Lindo BarrogaNo ratings yet

- Pump Sizing SpreadsheetDocument2 pagesPump Sizing Spreadsheetandrew rachmanNo ratings yet

- Floor MatsDocument3 pagesFloor MatsGhayas JawedNo ratings yet

- Full download book Neurology Neonatology Questions And Controversies Neonatology Questions Controversies Pdf pdfDocument41 pagesFull download book Neurology Neonatology Questions And Controversies Neonatology Questions Controversies Pdf pdfzelma.lansberry528100% (12)

- Tle 6 Ict Q4 M9Document16 pagesTle 6 Ict Q4 M9Christ Khayzee R. BacalsoNo ratings yet

- ChecklistDocument2 pagesChecklistKyra AlesonNo ratings yet

- Cylinder PDFDocument22 pagesCylinder PDFhossein soltanipourNo ratings yet

- Petitioner Vs Vs Respondents Marcial Esposo Eulogio F. Lerum M. A. FerrerDocument4 pagesPetitioner Vs Vs Respondents Marcial Esposo Eulogio F. Lerum M. A. Ferrerclarisse lyka hattonNo ratings yet

- Philips LCD Monitor 220EW9FB Service ManualDocument10 pagesPhilips LCD Monitor 220EW9FB Service Manualpagy snvNo ratings yet

- Certified Elder Law Attorney Middletown NyDocument8 pagesCertified Elder Law Attorney Middletown NymidhudsonlawNo ratings yet

- COVID-19 Vaccination Appointment Details: Center Preferred Time SlotDocument1 pageCOVID-19 Vaccination Appointment Details: Center Preferred Time SlotRmillionsque FinserveNo ratings yet

- New Product Development ProcessDocument29 pagesNew Product Development ProcessGAURAV SHARMA100% (1)

- Modern History Notes (Sample Notes For JPSC Mains Exam)Document21 pagesModern History Notes (Sample Notes For JPSC Mains Exam)Ijhar AhmadNo ratings yet

- PDF-Product Sheet-H100 EURODocument2 pagesPDF-Product Sheet-H100 EUROJhonny SarmientoNo ratings yet

- HQ 170aDocument82 pagesHQ 170aTony WellsNo ratings yet

- Technical Data About The Production of Steel StructuresDocument2 pagesTechnical Data About The Production of Steel StructuresPress EscapeNo ratings yet

- Production AnalysisDocument15 pagesProduction AnalysisAman -BCOMNo ratings yet

- Parent DC Promo Ui LogDocument193 pagesParent DC Promo Ui LogRachell SmithNo ratings yet

- PTL Ls Programme HandbookDocument34 pagesPTL Ls Programme Handbooksalak946290No ratings yet

- RTD Temperature Transmitter Calibration Report TemplateDocument1 pageRTD Temperature Transmitter Calibration Report TemplateSuswantoro ToroNo ratings yet

- EJN-00625 Installation of Manual Pull Valves in Deluge Systems For SOLPEDocument4 pagesEJN-00625 Installation of Manual Pull Valves in Deluge Systems For SOLPESARAVANAN ARUMUGAMNo ratings yet

- Instruction Manual For Spider S3 and Spider S4Document6 pagesInstruction Manual For Spider S3 and Spider S4Syah KamalNo ratings yet

- Static GK For Iift Snap and XatDocument19 pagesStatic GK For Iift Snap and XatnavinkumargNo ratings yet

- Trace Log 20131229152625Document3 pagesTrace Log 20131229152625Razvan PaleaNo ratings yet

- Improved Line Maze Solving Algorithm For PDFDocument2 pagesImproved Line Maze Solving Algorithm For PDFRaja Joko MusridhoNo ratings yet

- Oracle ASMDocument46 pagesOracle ASMWaqas ChaudhryNo ratings yet