Professional Documents

Culture Documents

Manual Taller Motor Honda gcv140 gcv160 gcv190 gsv190 English

Uploaded by

kexavadasOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Manual Taller Motor Honda gcv140 gcv160 gcv190 gsv190 English

Uploaded by

kexavadasCopyright:

Available Formats

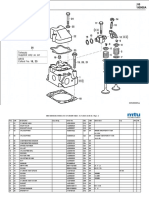

GCV140 ・ GCV160 ・ GCV190 ・ GSV190 Engine Assembly

PISTON CRANKCASE COVER/GOVERNOR VALVES/FLYWHEEL

TOP RING (CHROME PLATED) 6 mm THRUST WASHER GOVERNOR SLIDER VALVE SPRING VALVE SPRING (2) 14 mm SPECIAL NUT

PISTON RINGS MARK MODEL MARK

OIL

RETAINER (2) Aluminum flywheel:

T

VALVE STEM

T

GROOVE 52 N•m (38 ft-lb)

OIL

TOP RING GOVERNOR HOLDER CLIP NOTICE: SEAL (Intake

(CHROME PLATED) Cast iron flywheel:

SECOND GOVERNOR WEIGHT Do not remove the valve only) 52 N•m (38 ft-lb)

RING 6 x 14 (2) HOLDER ASSEMBLY valve spring SPARK PLUG

10 mm SIDE RAIL (1) GOVERNOR 12 N•m (8.7 ft-lb) retainer while the

SECOND RING 6 mm WASHER SPARK PLUG

HOLDER SHAFT piston is installed, Lawn Mowers:

SPACER FLYWHEEL

10 mm (0.4 in) GOVERNOR Install inside the case. or the valves will BPR5ES (NGK)

SIDE RAIL (2) drop into the All others:

OIL RING ARM SHAFT

(COMBINATION RINGS) cylinder. BPR6ES (NGK)

PISTON CONNECTING The lock pin must be installed

ROD WITH THE with the straight side of the pin

PISTON PIN CLIP (2) PISTON PIN against the groove in the shaft. VALVE GUIDE

LONG END CYLINDER 25 x 18 mm

REASSEMBLY: BARREL SPECIAL

CLIP NOTICE:

Do not align the WOODRUFF KEY

Take care not to INTAKE VALVE

OIL

end gap of the GOVERNOR EXHAUST VALVE

break the piston When installing the

clip with the ARM Be careful not

OIL

ring when installing VALVE HEAD flywheel, check to be sure

SHAFT to damage the

OIL

cutout in the the piston DIAMETER: that the woodruff key

piston pin assembly in the IN: 25 mm (0.98 in) valve stem seal remains in its slot on the

CONNECTING 8 mm

CUTOUT OIL PAN LOCK PIN EX: 24 mm (0.94 in) when installing.

bore. ROD cylinder. LOCK PIN crankshaft.

OIL PAN/CRANKSHAFT/CYLINDER BARREL CAM PULLEY/ROCKER ARM/CYLINDER HEAD COVER

28 x 41.25 x 6 mm OIL SEAL LIQUID GASKET CYLINDER CYLINDER HEAD 6 x 12 (4)

GREASE (Apply grease to the oil seal lips.) 12 N·m (1.2 kgf·m, VIEW FROM CRANKSHAFT PTO SIDE

CRANKCASE COVER, CRANKSHAFT, PISTON

INSTALLATION: APPLICATION BARREL COVER

AREA 9 lbf·ft) ALIGNMENT

6 x 25 (8) Be careful not to damage the lip of the CAM PULLEY

VALVE MARKS

12 N•m oil seal when installing the crankcase

ADJUSTING CYLINDER

(8.7 ft-lb) cover with the oil seal. HEAD COVER

SCREW (2)

EXHAUST MATING

OIL PAN ASSEMBLY SURFACE

ROCKER ARM

8 x 20 mm DOWEL PIN (2)

OIL

OIL

OIL

DIPPER PROJECTIONS VALVE

CRANKSHAFT

ADJUSTING

OIL

INSTALLATION:

LOCK NUT (2)

・Be careful not to damage the

oil seal. CAM

・After installation, clean the PULLEY

OIL

THRUST THRUST ROCKER

Apply a liquid gasket (Hondabond HT,

WASHER crankshaft tapered surface. WASHER ARM

ThreeBond 1216, or equivalent).

Assemble within 10 minutes after SHAFT (2) WOODRUFF KEY GROOVE (2)

PISTON ASSEMBLY

TIMING BELT applying the liquid gasket. INTAKE Set the cam pulley on the timing belt

INSTALLATION: Turn the crankshaft so the two woodruff

INSTALLATION: ROCKER

Install with the model mark

OIL

ARM key grooves on the PTO side face away

Check that the belt is not and connecting rod long end from the cylinder block. Install the cam

worn or cracked and didIDo to the right side of the cylinder. TIMING 5 6 pulley on the timing belt o the cam pulley

not bend or twist the belt. BELT alignment marks are in line with the

cylinder head cover mating surfaces.

2 TIMING BELT

1 6.8 x 1.9 mm O-RING

CAM PULLEY SHAFT

Do not reuse.

OIL

ROCKER

CRANK CYLINDER HEAD ARM

CONNECTING SHAFT ・Apply a liquid gasket SHAFT

COVER VIEWED

ROD BOLT (2)

OIL

FROM BACK SIDE: (Hondabond HT, ThreeBond

12 N•m MARK 1216, or equivalent) to the

CYLINDER 3

(8.7 ft-lb) BLOCK 4 cylinder head cover.

CYLINDER BARREL ・Assemble within 10 minutes

8 7 CAM PULLEY

after applying the liquid gasket.

MARK Tighten evenly in 2~3 steps in the ・Wait for approximately 20 minutes

CONNECTING GREASE Install the rocker arm shaft from

order shown. Wait for approximately after assembly before filling with

ROD CAP the opposite side from the cam

OIL DIPPER 25.4 x 62 x 6 mm (Apply grease to 20 minutes after assembly before

LIQUID GASKET oil and starting the engine. pulley as shown.

OIL SEAL the oil seal lips.) filling with oil and starting the

APPLICATION AREA

See the shop manual for additional information. © Honda Motor Co., Ltd. 2014

S2ZDM300

You might also like

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- St:Ül::Ð M:Aös:M:Y::Ð DÐH:Ð S:Üxm:H Sy:A As:N:Am:Y:H - Wan:Km:Ðüendóy:Òh S:Ad:Üö D:I) An::Ò T:Ccrirg::Ò .. 1.Document9 pagesSt:Ül::Ð M:Aös:M:Y::Ð DÐH:Ð S:Üxm:H Sy:A As:N:Am:Y:H - Wan:Km:Ðüendóy:Òh S:Ad:Üö D:I) An::Ò T:Ccrirg::Ò .. 1.min4chuNo ratings yet

- Despiece y Funciomamiento Carburador Honda gx25 gx35 Ingles PDFDocument1 pageDespiece y Funciomamiento Carburador Honda gx25 gx35 Ingles PDFkexavadasNo ratings yet

- 637Document4 pages637kexavadasNo ratings yet

- Pathways Through SpaceDocument10 pagesPathways Through SpacekexavadasNo ratings yet

- Lines of IntelligenceDocument1 pageLines of IntelligencekexavadasNo ratings yet

- Diploma Studies in YogaDocument14 pagesDiploma Studies in Yogakexavadas100% (1)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Wa180-1b Engine Jan.30.08 PDFDocument60 pagesWa180-1b Engine Jan.30.08 PDFWellington Pereira JosafaNo ratings yet

- Deutz 2013 TCD 2V Workshop Manual Level3Document471 pagesDeutz 2013 TCD 2V Workshop Manual Level3richardtlas92% (37)

- Self Study Book 360 The 3.2I and 3.6I FSI EngineDocument72 pagesSelf Study Book 360 The 3.2I and 3.6I FSI EngineGildardo Casarrubias Segura100% (1)

- Cursor 770 c13 Ent m77Document226 pagesCursor 770 c13 Ent m77jvega_534120No ratings yet

- Citroen Engine Correspondence TablesDocument462 pagesCitroen Engine Correspondence TablesPanait Salcianu100% (2)

- Specifications: 800C Industrial EngineDocument28 pagesSpecifications: 800C Industrial EngineJacques Van NiekerkNo ratings yet

- TA1 Visual Hydraulic Excavator InspectionDocument13 pagesTA1 Visual Hydraulic Excavator InspectionJoel RodríguezNo ratings yet

- Auto 101notesDocument88 pagesAuto 101notesskandha sharmaNo ratings yet

- Electronic Parts Catalog - Option DetailDocument3 pagesElectronic Parts Catalog - Option DetailmunhNo ratings yet

- Caliber 2 PDFDocument80 pagesCaliber 2 PDFDinesh WikramasingheNo ratings yet

- 030402en PDFDocument55 pages030402en PDFdaniel_jorge_10No ratings yet

- SSP 508 10l 44kw 55kw Mpi EngineDocument36 pagesSSP 508 10l 44kw 55kw Mpi Engine01fe19bme028No ratings yet

- Catalogo Cat 2009-2011Document658 pagesCatalogo Cat 2009-2011Jose Angel Fabri100% (2)

- Onan generator set parts catalogDocument62 pagesOnan generator set parts catalogroger pozo100% (1)

- K-Series Cyl Head Repair Kit Launch PPC5555Document13 pagesK-Series Cyl Head Repair Kit Launch PPC5555ALVARO OLACHICANo ratings yet

- RS Customer Sat Program LetterDocument2 pagesRS Customer Sat Program LetterDavid TNo ratings yet

- ISX Rocker Arm Torque PDFDocument13 pagesISX Rocker Arm Torque PDFBrangan Hulley100% (3)

- Ford Engine Specs - FullDocument11 pagesFord Engine Specs - FullMurat UçmanNo ratings yet

- Engine Overhaul Minggu 11Document63 pagesEngine Overhaul Minggu 11Renaldi Ardiansyah100% (6)

- 2000 Oldsmobile Alero Engine Overhaul GuideDocument216 pages2000 Oldsmobile Alero Engine Overhaul GuidequetecojaunburroNo ratings yet

- Deutz m2011 Construction SpecsDocument2 pagesDeutz m2011 Construction SpecsY.EbadiNo ratings yet

- Cat 3406 Engine Parts ManualDocument78 pagesCat 3406 Engine Parts ManualCarlos Manzoni100% (6)

- TOYOTA 1CD-FTV D4D Engine FuelDocument27 pagesTOYOTA 1CD-FTV D4D Engine FuelLuis Daniel Cortes100% (16)

- 04 Cylinder HeadDocument17 pages04 Cylinder HeadTayfun SezişNo ratings yet

- FZ 150Document58 pagesFZ 150عبدول ناصير عبدول رحيمNo ratings yet

- Diesel Engine ComponentsDocument33 pagesDiesel Engine ComponentsMurtaza AhmedNo ratings yet

- Airtrek Workshop ManualDocument2,035 pagesAirtrek Workshop ManualRick Avlonitis100% (9)

- Perkins 1104DDocument158 pagesPerkins 1104Dsj1202100% (17)

- Ford Ranger 2010 2.3LDocument256 pagesFord Ranger 2010 2.3LLuis Ramon Arguello RealNo ratings yet

- Direct Petrol Injection and Ignition System (8-Cyl 4 2 LTR 4-Valve)Document87 pagesDirect Petrol Injection and Ignition System (8-Cyl 4 2 LTR 4-Valve)ergdegNo ratings yet