Professional Documents

Culture Documents

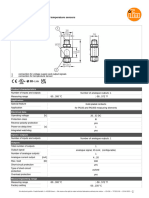

Compact Pirani Gauge: TPR 280 TPR 281

Uploaded by

Remus GhincuOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Compact Pirani Gauge: TPR 280 TPR 281

Uploaded by

Remus GhincuCopyright:

Available Formats

Safety Technical Data

Symbols Used Measurement principle thermal conductance according

to Pirani

Operating Instructions Measurement range 5×10-4 … 1000 mbar

Incl. Declaration of Conformity DANGER (air, O2, CO, N2)

Accuracy (N2)

Compact Pirani Gauge Information on preventing any kind of physical injury. 1×10-3 … 100 mbar ±15% of reading

5×10-4 … 1×10-3 mbar ±50% of reading

TPR 280 100 … 1000 mbar ±50% of reading

TPR 281 WARNING Resolution 1% of reading

Repeatability with air

Information on preventing extensive equipment and envi-

ronmental damage. 1×10-3 … 100 mbar 2% of reading

Output signal

(measurement signal)

Caution Voltage range VDC 0 … +9.0

Information on correct handling or use. Disregard can lead Measurement range VDC +2.2 … +8.5

to malfunctions or minor equipment damage. Voltage vs. pressure logarithmic

1.0 V/decade

Error signal V 0 … +0.5

(filament rupture)

Personnel Qualifications

Output impedance Ω 2×4.7

Minimum loaded kΩ 10, short-circuit proof

impedance

BG 805 178 BE / D (2006-02) Skilled personnel Response time ms 80

All work described in this document may only be carried Gauge identification 3.0 kΩ, referenced to supply

out by persons who have suitable technical training and common (voltage at pin 1 ≤5 V)

the necessary experience or who have been instructed by

Product Identification the end-user of the product.

Adjustment one tactile switch for ATM and

In all communications with Pfeiffer Vacuum, please specify HV adjustment

the information on the product nameplate. For convenient

reference copy that information into the space provided Supply

below. General Safety Instructions

• Adhere to the applicable regulations and take the nec-

Pfeiffer Vacuum, D-35614 Asslar DANGER

essary precautions for the process media used.

Typ: Consider possible reactions between the materials and the The gauge may only be connected to power

No: process media. supplies, instruments or control devices that

F-No: Consider possible reactions of the process media due to conform to the requirements of a grounded

the heat generated by the product (e.g. explosions). extra-low voltage (SELV-E according to

V W

EN 61010). The connection to the gauge has to

• Adhere to the applicable regulationsand take the neces- be fused 1).

sary precautions for all work you are going to do and

consider the safety instructions in this document.

• Before beginning to work, find out whether any vacuum Supply voltage

components are contaminated. Adhere to the relevant At gauge VDC +14 … +30

regulations and take the necessary precautions when Ripple Vpp ≤1

handling contaminated parts.

Current consumption mA <500

Communicate the safety instructions to all other users. (max. starting current)

Power consumption W ≤1

Fuse required 1) AT 1

Validity (slow)

Liability and Warranty

This document applies to products with the following part Electrical connection Hirschmann appliance

Pfeiffer Vacuum assumes no liability and the warranty be-

numbers: connector, male,

comes null and void if the end-user or third parties

TPR 280 TPR 281 type GO 6, 6 poles

(W filament) (Ni filament) • disregard the information in this document

Sensor cable 5 poles plus shielding

PTR26950 PTR21950 (DN 16 ISO-KF) • use the product in a non-conforming manner

Cable length ≤150 m (5×0.25 mm2)

PTR26951 PTR21951 (DN 16 CF-R) • make any kind of interventions (modifications, alterations ≤200 m (5×0.34 mm2)

PTR26960 PTR21960 (DN 16 ISO-KF long tube) etc.) on the product

PTR26961 PTR21961 (DN 16 CF-R long tube) • use the product with accessories not listed in the product Grounding concept → "Electrical Connection"

The part number (No) can be taken from the product name- documentation.

Vacuum connection to connected via 1 MΩ

plate. The end-user assumes the responsibility in conjunction with signal common (voltage difference <15 V)

If not indicated otherwise in the legends, the illustrations in the process media used.

Supply common to conducted separately, for

this document correspond to gauges with DN 16 ISO-KF Gauge failures due to contamination, as well as expendable signal common differencial measurement

vacuum connections. They apply other vacuum connections parts (filament), are not covered by the warranty.

by analogy.

We reserve the right to make technical changes without prior Materials exposed to DIN 1.4301, DIN 1.4305,

notice. vacuum DIN 1.4435, glass, Ni,

NiFe

All dimensions in mm.

Filament

PTR26xxx W

PTR21xxx Ni

Intended Use Internal volume

The Compact Pirani Gauges TPR 280 and TPR 281 have PTR26950, PTR21950 cm3 ≈1.5

been designed for vacuum measurement of gases in the PTR26951, PTR21951 cm3 ≈1.5

pressure range of 5×10-4 … 1000 mbar. PTR26960, PTR21960 cm3 ≈10

The gauges must not be used for measuring flammable or PTR26961, PTR21961 cm3 ≈10

combustible gases which react in air. Admissible pressure bar 10, limited to inert gases

They can be operated in connection with a Pfeiffer Vacuum (abs.)

controller for Compact Gauges or with another evaluation idealvac.com

unit.

(505)872-0037

idealvac.com

1)

Pfeiffer Vacuum controllers fulfill these requirements.

Downloaded from www.Manualslib.com manuals search engine

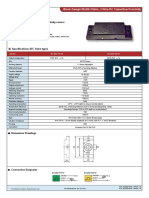

Admissible temperatures U p c U p c

Operation °C +5 … +60 [V] [mbar] 5.5 [V] [micron] 2.625 Installation

Vacuum connection [V] [µbar] 2.5 [V] [Pa] 3.5

DN 16 ISO-KF °C 80 2) in horizontal moun- [V] [Torr] 5.625 [V] [kPa] 6.5

Vacuum Connection

DN 16 CF-R °C 80 2) ting orientation [V] [mTorr] 2.625

Filament °C 110 DANGER

Storage °C –20 … +65 where p pressure

U measurement signal Caution: overpressure in the vacuum system

Relative humidity % ≤80 at temperatures up to c constant (depending on pressure unit) >1 bar

≤+31 °C, decreasing to 50 Injury caused by released parts and harm

at +40 °C caused by escaping process gases can result if

Use indoors only, altitude up to clamps are opened while the vacuum system is

2000 m NN Gas Type Dependence pressurized.

Mounting orientation any Do not open any clamps while the vacuum sys-

Pressure reading (gauge adjusted for air) tem is pressurized. Use the type clamps which

Degree of protection IP40 p (mbar) are suited to overpressure.

102

8 H2 He Ne

Dimensions mm 6 Air

O2

4

CO

N2

20.5 2

CO2

DANGER

16

101 Ar

8

6

Freon 12

Caution: overpressure in the vacuum system

4

Kr >2.5 bar

2

Xe KF connections with elastomer seals (e.g.

69

100

8 O-rings) cannot withstand such pressures. Pro-

16 6

cess media can thus leak and possibly damage

4

22.5 your health.

2

Use O-rings provided with an outer centering

10–1

8

6

ring.

33 4

2

Water vapor

10–2

8 DANGER

6

4

2

Caution: protective ground

14

15

10–3

Incorrectly grounded products can be extremely

10–3 2 4 6 10–2 2 4 6 10–1 2 4 6 100 2 4 6 101 2 4 6 102 hazardous in the event of a fault.

peff (mbar) The gauge must be electrically connected to the

DN 16 ISO-KF DN 16 CF-R

grounded vacuum chamber. This connection

must conform to the requirements of a protective

115

116

Calibration factors for the pressure range below 1 mbar connection according to EN 61010:

• CF connections fulfill this requirement.

peff = C × pressure reading • For gauges with a KF connection, use a con-

ductive metallic clamping ring

Gas Calibration Gas type Calibration

DN 16 ISO-KF type factor C factor C

long tube He 0.8 H2 0.5 Caution

DN 16 CF-R Ne 1.4 air, O2, CO, N2 1.0

long tube Ar 1.7 CO2 0.9 Caution: vacuum component

Kr 2.4 water vapor 0.5 Dirt and damages impair the function of the

Xe 3.0 freon 12 0.7 vacuum component.

Weight When handling vacuum components, take ap-

PTR26950, PTR21950 g 80 propriate measures to ensure cleanliness and

PTR26951, PTR21951 g 100 prevent damages.

PTR26960, PTR21960 g 130

PTR26961, PTR21961 g 140

Caution

Caution: dirt sensitive area

Measurement Signal vs. Pressure Touching the product or parts thereof with bare

Pressure p hands increases the desorption rate.

1E+05 Always wear clean, lint-free gloves and use

Pa clean tools when working in this area.

1E+04

1E+03 mbar

1E+02 torr

The gauge may be mounted in any orientation. To

sensor error

underrange

1E+01 keep condensates and particles from getting into the

overrange

1E+00 measuring chamber preferably choose a horizontal

1E–01

to upright position and possibly use a seal with a

centering ring and filter. If adjustment should be pos-

1E–02 sible after the gauge has been installed, be sure to

1E–03 install it so that the tactile switch can be accessed

1E–04

with a pin (→ "Adjusting the Gauge").

1E–05

0.0 0.5 1.0 1.5 2.0 2.5 3.0 3.5 4.0 4.5 5.0 5.5 6.0 6.5 7.0 7.5 8.0 8.5 9.0 9.5 10.0

10.3

Measurement signal U[V]

(U-c)

p = 10 ⇔ U = c + log10 p

valid in the range 5×10-4 mbar <p< 1000 mbar

3.75×10-4 Torr <p< 750 Torr

5×10-2 Pa <p< 1×105 Pa

bg805178be/ d (2006-02)

2) Original: German BG 805 178 BD / D (2006-02)

250 °C with long tube.

Downloaded from www.Manualslib.com manuals search engine

Remove the protective lid and install the product to the

vacuum system. Operation Deinstallation

When the supply voltage is applied, the measurement signal

is available between pins 2 and 3 (relationship between DANGER

measurement signal and pressure → "Technical Data").

Seal with centering ring Allow a stabilization period of at least 10 minutes. It is advis- Caution: contaminated parts

able to operate the gauge continuously, irrespective of the Contaminated parts can be detrimental to health

pressure. and environment.

Clamp

or Before beginning to work, find out whether any

parts are contaminated. Adhere to the relevant

Protective lid regulations and take the necessary precautions

Gas Type Dependence when handling contaminated parts.

The measurement value is gas dependent. The pressure

Seal with center- reading applies to dry air, O2, CO and N2. For other gases, it

ing ring and filter has to be corrected (→ "Technical Data"). Caution

If the gauge is operated with a Pfeiffer Vacuum controller for

Compact Gauges, a calibration factor for correction of the Caution: vacuum component

actual reading can be applied (→ of the corresponding Dirt and damages impair the function of the

Keep the protective lid.

controller). vacuum component.

When handling vacuum components, take ap-

propriate measures to ensure cleanliness and

prevent damages.

Adjusting the Gauge

Electrical Connection The gauge is factory calibrated. Due to long time operation or

contamination, a zero drift could occur. Periodically check the Caution

Make sure the vacuum connection is properly made zero and adjust it if necessary.

(→ "Vacuum Connection"). For adjusting the zero, operate the gauge under the same Caution: dirt sensitive area

ambient conditions and in the same mounting orientation as Touching the product or parts thereof with bare

normally. hands increases the desorption rate.

If no sensor cable is available, make one according to The gauge is adjusted to default values. However, it can also Always wear clean, lint-free gloves and use

the following diagram. be adjusted to other pressure values, if the exact pressure clean tools when working in this area.

value is known (reference measurement).

If you are using a seal with centering ring and filter, Vent the vacuum system.

check that they are clean and replace them if

necessary (→ "Deinstallation").

Turn the gauge off.

Activate the gauge and operate it at atmospheric pres-

sure for at least 10 minutes. Unfasten the lock screw and unplug the sensor cable.

Press the button with a pin (max. ø1.1 mm) and the

ATM adjustment is carried out: The gauge is adjusted

to 1000 mbar (8.50 VDC) by default. By pressing the

button >5 s the pressure value is increased towards

1200 mbar (or, by pressing it again, decreased towards

500 mbar) until the button is released or the limit is

reached.

2 +

4.7

3 –

4.7 ATM

Ident 1

HV

4

1M +

5 – Remove the gauge from the vacuum system.

6

max. ø1.1 mm

3 2

Electrical connection 1

Pin 1 Identification

Pin 2 Signal output (measurement signal)

Pin 3 Signal common

Pin 4 Supply 6

4 5

Pin 5 Supply common

Pin 6 Screening Connector

soldering side Evacuate to p << 10-4 mbar (recommended) or to a

pressure in the range of 10-4 … 10-2 mbar and wait at Protective lid

least 2 minutes.

Connect the sensor cable to the gauge and secure the

connector with the lock screw. Press the button with a pin and the HV adjustment is

carried out: The gauge is adjusted to 1×10-4 mbar

(1.50 VDC) by default. By pressing the button >5 s the

pressure value is increased toward 1×10-2 mbar until

the button is released or the limit is reached. Maintenance, Repair

In case of severe contamination or a malfunction, the sensor

can be replaced.

Gauge failures due to contamination, as well as ex-

pendable parts (filament), are not covered by the

warranty.

Pfeiffer Vacuum assumes no liability and the warranty be-

comes null and void if any repair work is carried out by the

Connect the sensor cable to the controller. end-user or third parties.

Downloaded from www.Manualslib.com manuals search engine

Spare Parts Declaration of Contamination Declaration of Conformity

When ordering spare parts, always indicate: The service, repair, and/or disposal of vacuum equipment and com-

ponents will only be carried out if a correctly completed declaration

We, Pfeiffer Vacuum, hereby declare that the

• all information on the product nameplate has been submitted. Non-completion will result in delay. equipment mentioned below complies with the

• description and ordering number according to the spare This declaration may only be completed (in block letters) and signed provisions of the Directive relating to electrical

parts list by authorized and qualified staff. equipment designed for use within certain vol-

tage limits 73/23/EEC and the Directive rela-

Description of product ting to electromagnetic compatibility

W sensor Ordering Ni sensor Ordering 89/336/EEC.

for gauge number for gauge number Type

Part number

PTR26950 PT120133-T PTR21950 PT120141-T

Serial number

PTR26951 PT120135-T PTR21951 PT120143-T

PTR26960 PT120134-T PTR21960 PT120142-T

PTR26961 PT120136-T PTR21961 PT120144-T

Reason for return Compact Pirani Gauge

TPR 280

TPR 281

Returning the Product Operating fluid(s) used

(Must be drained before shipping.)

Part numbers

PTR26950 PTR21950

WARNING PTR26951 PTR21951

Caution: forwarding contaminated products PTR26960 PTR21960

PTR26961 PTR21961

Contaminated products (e.g. radioactive, toxic, Used in copper process

caustic or microbiological hazard) can be detri- Seal product in plastic

no yes

mental to health and environment. bag and mark it with a

corresponding label.

Products returned to Pfeiffer Vacuum should pre- Standards

ferably be free of harmful substances. Adhere to

the forwarding regulations of all involved coun- Harmonized and international/national standards and specifi-

tries and forwarding companies and enclose a cations:

duly completed declaration of contamination. Process related contamination of product: • EN 61000-6-2 (Electromagnetic compatibility: generic

toxic no 1) yes immunity standard)

corrosive no 1) yes

biological hazard no yes 2) • EN 61000-6-3 (Electromagnetic compatibility: generic

Products that are not clearly declared as "free of harmful sub-

explosive no yes 2) emission standard)

stances" are decontaminated at the expense of the customer.

radioactive no yes 2) • EN 61010 (Safety requirements for electrical equip-

Products not accompanied by a duly completed declaration of other harmful substances no 1) yes ment for measurement, control and labora-

contamination are returned to the sender at his own expense. tory use)

1) or not containing any 2) Products thus

amount of hazardous contaminated

residues that exceed the will not be

permissible exposure limits accepted with-

out written

evidence of Signature

The product is free decontami - Pfeiffer Vacuum GmbH, Asslar

of any substances nation.

yes

which are damaging 19 December 2005

Disposal to health.

DANGER

Harmful substances, gases and/or Wolfgang Dondorf

Caution: contaminated parts by-products Managing director

Please list all substances, gases, and by-products

Contaminated parts can be detrimental to health

which the product may have come into contact with:

and environment. Trade/product name Chemical name

Before beginning to work, find out whether any manufacturer (or symbol)

parts are contaminated. Adhere to the relevant

regulations and take the necessary precautions

when handling contaminated parts.

WARNING Precautions associated with Action if human

substance contact

N

Caution: substances detrimental to the environ-

ment

Products or parts thereof (mechanical and elec-

tric components, operating fluids etc.) can be

detrimental to the environment.

Dispose of such substances in accordance with

the relevant local regulations.

Legally binding declaration:

We hereby declare that the information on this form is

Separating the components

complete and accurate and that we will assume any further

After disassembling the product, separate its components costs that may arise. The contaminated product will be dis-

according to the following criteria: patched in accordance with the applicable regulations.

Organization/company

• Contaminated components

Address

Contaminated components (radioactive, toxic, caustic, or

biological hazard etc.) must be decontaminated in accor- Post code, place

dance with the relevant national regulations, separated Phone Fax

according to their materials, and disposed of. Email

• Other components Name

Such components must be separated according to their Company stamp

materials and recycled.

Date and legally binding signature

Berliner Strasse 43

D–35614 Asslar

This form can be downloaded from our website.

Deutschland

Copies: Original for addressee

1 copy for accompanying documents Tel +49 (0) 6441 802-0

1 copy for file of sender Fax +49 (0) 6441 802-202

info@pfeiffer-vacuum.de

www.pfeiffer-vacuum.net

Downloaded from www.Manualslib.com manuals search engine

You might also like

- Wireless Communications Design Handbook: Interference into Circuits: Aspects of Noise, Interference, and Environmental ConcernsFrom EverandWireless Communications Design Handbook: Interference into Circuits: Aspects of Noise, Interference, and Environmental ConcernsNo ratings yet

- Leybold TTR91 ManualDocument4 pagesLeybold TTR91 ManualMatteo BargiacchiNo ratings yet

- Safety Technical Data: Operating InstructionsDocument4 pagesSafety Technical Data: Operating InstructionsanildhakeNo ratings yet

- TINA44E1 G WebDocument4 pagesTINA44E1 G WebMagalaNo ratings yet

- PW10 HBMDocument6 pagesPW10 HBMBogdan MoldovanNo ratings yet

- Data Sheet MLSL123Document2 pagesData Sheet MLSL123bengo montNo ratings yet

- User - Manual - en - Hu - Ro - SKDocument9 pagesUser - Manual - en - Hu - Ro - SKRosu VladNo ratings yet

- TC20-11GWA: 50 MM (2.0 Inch) 5 X 7 Dot Matrix DisplayDocument5 pagesTC20-11GWA: 50 MM (2.0 Inch) 5 X 7 Dot Matrix DisplayAdrian GarciaNo ratings yet

- WM03PCT2 WenglorDocument2 pagesWM03PCT2 WengloralizanelectronicNo ratings yet

- Datasheet BTL1W39 250251 enDocument2 pagesDatasheet BTL1W39 250251 enMatej CvetkoNo ratings yet

- 402 Pressure SensorDocument5 pages402 Pressure SensorMihai IavorschiNo ratings yet

- Datasheet BES05RM 272792 enDocument2 pagesDatasheet BES05RM 272792 enAleksandar MarkovićNo ratings yet

- 4600X Series - Thick Film Conformal Sips: FeaturesDocument4 pages4600X Series - Thick Film Conformal Sips: FeaturesГеннадий ДармоедовNo ratings yet

- PROFIBUS InterfaceDocument1 pagePROFIBUS InterfacepiterNo ratings yet

- E3FA Photoelectric Sensor With Adjustable Distance - 英Document2 pagesE3FA Photoelectric Sensor With Adjustable Distance - 英zheng zhengNo ratings yet

- KJ4-M18MB80-ANU: Product Description Inductive Sensor AnalogueDocument2 pagesKJ4-M18MB80-ANU: Product Description Inductive Sensor AnalogueBAHARO ALYAUMA IEDNo ratings yet

- Reflex Sensor: With Background SuppressionDocument2 pagesReflex Sensor: With Background SuppressionAmila BalasooriyaNo ratings yet

- Células de Carga - FH5399gb - PWSDocument2 pagesCélulas de Carga - FH5399gb - PWSVinícius OliveiraNo ratings yet

- LevelDocument5 pagesLevelnemoneoNo ratings yet

- E2Q6-N20F3-H - OMRON Industrial AutomationDocument6 pagesE2Q6-N20F3-H - OMRON Industrial AutomationRonald Paul Torrejon InfanteNo ratings yet

- XD-2 enDocument2 pagesXD-2 enRicardoNo ratings yet

- EN: TH Is Dat Asheet Is Present Ed by T He M Anuf Act UrerDocument10 pagesEN: TH Is Dat Asheet Is Present Ed by T He M Anuf Act UrerGyarmati László100% (1)

- Cas WBKDocument1 pageCas WBKTakaSenseiNo ratings yet

- Instruction Manual: Digital MultimeterDocument2 pagesInstruction Manual: Digital MultimeterAbdalhakeem AlturkyNo ratings yet

- GMR100 Brochure ENDocument1 pageGMR100 Brochure ENArkin CobanNo ratings yet

- Power Your Signal MBMF-65-18TDE-IN-43-VDI: Antenna SpecificationsDocument3 pagesPower Your Signal MBMF-65-18TDE-IN-43-VDI: Antenna SpecificationsMariNo ratings yet

- AED9401A: Basic Device For AD103CDocument2 pagesAED9401A: Basic Device For AD103CSANTOS DALLACQUANo ratings yet

- TP3231 00 - en GBDocument3 pagesTP3231 00 - en GBعبد الله عبد الحيNo ratings yet

- TTS 809014de 70FDocument1 pageTTS 809014de 70FEzequiel SarmientoNo ratings yet

- TDJ 709017 172718de 65F PDFDocument1 pageTDJ 709017 172718de 65F PDFyevobimNo ratings yet

- BES M12EN-PAC20B-BV03 Ordercode: BES057P: Inductive SensorsDocument2 pagesBES M12EN-PAC20B-BV03 Ordercode: BES057P: Inductive SensorsAlexander GochevNo ratings yet

- Igm201 02 - en GBDocument3 pagesIgm201 02 - en GBchzakiabbas5250No ratings yet

- 1 - Installation: User'S ManualDocument12 pages1 - Installation: User'S ManualKonrad KissNo ratings yet

- Fisa Tehnica Detector de Miscare PIR Si MW SIM-03Document1 pageFisa Tehnica Detector de Miscare PIR Si MW SIM-03Emanuel KszenicsNo ratings yet

- Load Cell (UTM)Document1 pageLoad Cell (UTM)José Rubén Ramos GarzaNo ratings yet

- Capacitor For Power Electronics: R Tanδδδδ CxrDocument6 pagesCapacitor For Power Electronics: R Tanδδδδ Cxrraza239No ratings yet

- Metravi DIT-321 & DIT-322 - Digital Insulation Tester - Catalogue - June 2022Document2 pagesMetravi DIT-321 & DIT-322 - Digital Insulation Tester - Catalogue - June 2022Satyavan L RoundhalNo ratings yet

- Wenglor Ultrasonic Data Sheet UMD123U035Document2 pagesWenglor Ultrasonic Data Sheet UMD123U035Paun Al100% (1)

- Magenta: Digital Glass Break DetectorDocument1 pageMagenta: Digital Glass Break Detectorgav oviNo ratings yet

- APHHS1005QBC/D: 1.0 X 0.5 MM SMD Chip LED LampDocument4 pagesAPHHS1005QBC/D: 1.0 X 0.5 MM SMD Chip LED Lampn tanevarNo ratings yet

- Power Your Signal: Antenna SpecificationsDocument3 pagesPower Your Signal: Antenna SpecificationsАлександрNo ratings yet

- BHS B265V-PSD25-S04-003 Order Code: BHS0062: Inductive SensorsDocument2 pagesBHS B265V-PSD25-S04-003 Order Code: BHS0062: Inductive SensorsQuy HoangNo ratings yet

- KC16 - Alloy Steel: CanisterDocument1 pageKC16 - Alloy Steel: CanisterIsrael Rodriguez VenturaNo ratings yet

- NIC Components NSRN SeriesDocument5 pagesNIC Components NSRN SeriesNICCompNo ratings yet

- BTH Block Design 50x20x10mm, 3 Wire DC Capacitive ProximityDocument1 pageBTH Block Design 50x20x10mm, 3 Wire DC Capacitive Proximitykanhav joshiNo ratings yet

- Power Your Signal: Antenna SpecificationsDocument3 pagesPower Your Signal: Antenna SpecificationsДмитрийNo ratings yet

- Features Quark C12x Quark T12xDocument1 pageFeatures Quark C12x Quark T12xjuan pablo tripodiNo ratings yet

- PC420V Series Spec (99009) B.1Document2 pagesPC420V Series Spec (99009) B.1Jhon BaldeonNo ratings yet

- Power Your Signal: Antenna SpecificationsDocument3 pagesPower Your Signal: Antenna SpecificationsДмитрийNo ratings yet

- Type XK3190-A12E Indicator: Short DescriptionDocument3 pagesType XK3190-A12E Indicator: Short DescriptionAnand SaravananNo ratings yet

- BYT 13-600-1000 - DiodaDocument4 pagesBYT 13-600-1000 - DiodaEdzNo ratings yet

- RG58Document2 pagesRG58grasia77No ratings yet

- Tfms 5360Document6 pagesTfms 5360Ecaterina IrimiaNo ratings yet

- Specifications, 132A: Wireless 3-Axis Accelerometer: Performance - by Model: Vs +3.7VDC, TC +25°CDocument1 pageSpecifications, 132A: Wireless 3-Axis Accelerometer: Performance - by Model: Vs +3.7VDC, TC +25°Ctaehyun KimNo ratings yet

- Data Sheet HK12PA7 ENDocument2 pagesData Sheet HK12PA7 ENkhaledNo ratings yet

- Reflective Optoswitch: VTR17D1Document2 pagesReflective Optoswitch: VTR17D1Andy ZhuNo ratings yet

- GUT741Document1 pageGUT741Arun GuptaNo ratings yet

- ZADM 023H871.0001 - Edge SensorsDocument1 pageZADM 023H871.0001 - Edge SensorstirthNo ratings yet

- BES 517-224-M5-E: Inductive SensorsDocument1 pageBES 517-224-M5-E: Inductive SensorsKrzysztof WypasekNo ratings yet

- Fisa Tehnica Seria AK - Valiadis GreeceDocument15 pagesFisa Tehnica Seria AK - Valiadis GreeceRemus GhincuNo ratings yet

- 4p Lses 100l 2,2kw Ift-Ie2 b14Document3 pages4p Lses 100l 2,2kw Ift-Ie2 b14Remus GhincuNo ratings yet

- #168 - 'Motoare Electrice Trifazate Standard - Proconsil Grup' - WWW - ProconsilgrupDocument1 page#168 - 'Motoare Electrice Trifazate Standard - Proconsil Grup' - WWW - ProconsilgrupRemus GhincuNo ratings yet

- 4p Lses 90l 1,5kw Ift-Ie2 b14Document3 pages4p Lses 90l 1,5kw Ift-Ie2 b14Remus GhincuNo ratings yet

- MKS Type 247D Four-Channel Readout: 120714-P1 Rev A, 7/97 Instruction ManualDocument100 pagesMKS Type 247D Four-Channel Readout: 120714-P1 Rev A, 7/97 Instruction ManualRemus GhincuNo ratings yet

- PFEIFFER TPR 260 Short - enDocument4 pagesPFEIFFER TPR 260 Short - enRemus GhincuNo ratings yet

- Market Brief Daily: Revista Presei Economice Interne Şi ExterneDocument5 pagesMarket Brief Daily: Revista Presei Economice Interne Şi ExterneRemus GhincuNo ratings yet

- Data Pengukuran BFPT ADocument3 pagesData Pengukuran BFPT AazisyuswandiNo ratings yet

- An Introduction To Thin FilmsDocument20 pagesAn Introduction To Thin FilmsSmitha Kollerahithlu100% (1)

- Carradale Antler - 190 - July 2008Document18 pagesCarradale Antler - 190 - July 2008Kintyre On RecordNo ratings yet

- Power System Planning and ManagementDocument41 pagesPower System Planning and ManagementMulugeta AlewaNo ratings yet

- Leakage Current Measurement BasicsDocument4 pagesLeakage Current Measurement Basicsyasararafat12010100% (1)

- Multi-Level Parking SystemDocument24 pagesMulti-Level Parking Systemnikhil100% (3)

- AGN 233 - Generating Set Assembly - Mounting ArrangementsDocument12 pagesAGN 233 - Generating Set Assembly - Mounting ArrangementsariwibowoNo ratings yet

- Tutorial 2 Air-Standard CyclesDocument3 pagesTutorial 2 Air-Standard CyclesPhineas sehoanaNo ratings yet

- PHD Thesis Energy StorageDocument4 pagesPHD Thesis Energy Storagelodyicxff100% (2)

- DFINITI Electric Heater BrochureDocument12 pagesDFINITI Electric Heater BrochurePillai S KumarNo ratings yet

- ASTM - STP 801 Corrosion FatigueDocument538 pagesASTM - STP 801 Corrosion FatigueKYAW SOE100% (1)

- Fault Level CalculationDocument10 pagesFault Level CalculationJeya Kannan100% (1)

- SEWDocument64 pagesSEWCasHeerNo ratings yet

- Transformers For Renewable Energy ApplicationsDocument13 pagesTransformers For Renewable Energy Applicationskrmurali2000No ratings yet

- Mining Management and Safety Regulations 1990 PDFDocument120 pagesMining Management and Safety Regulations 1990 PDFaxe100% (1)

- Biomimetics For Architecture - Design Nature - Analogies - TechnologyDocument353 pagesBiomimetics For Architecture - Design Nature - Analogies - Technologyvictorcalixto100% (1)

- LM1036 Dual DC Operated Tone/Volume/Balance Circuit: General Description FeaturesDocument12 pagesLM1036 Dual DC Operated Tone/Volume/Balance Circuit: General Description Featuresjasoo__No ratings yet

- Townsends Theory of Conduction and Breakdown in GasesDocument8 pagesTownsends Theory of Conduction and Breakdown in GasesDeepak VapraniNo ratings yet

- Single Phase Dual ConverterDocument15 pagesSingle Phase Dual ConverterBhavin Bhanushali100% (11)

- Blank 2404 UnprotectedDocument15 pagesBlank 2404 UnprotectedSaintjinx21No ratings yet

- AAS or ICP-OES-Are They Competing TechniquesDocument8 pagesAAS or ICP-OES-Are They Competing TechniquesKim HiềnNo ratings yet

- HPLF Sulphur enDocument4 pagesHPLF Sulphur enMuhamad Ekbar SeninNo ratings yet

- Pedro Pérez-Soriano, Salvador Llana Belloch - Biomecanica Basica Aplicada A La Actividad Fisica y El Deporte-Paidotribo (2015)Document7 pagesPedro Pérez-Soriano, Salvador Llana Belloch - Biomecanica Basica Aplicada A La Actividad Fisica y El Deporte-Paidotribo (2015)Osorio Miguel OsorioNo ratings yet

- FM 101-10-1-2 Staff Officers Field ManualDocument72 pagesFM 101-10-1-2 Staff Officers Field Manualsteve_fondacaroNo ratings yet

- Jotashield Colourxtreme SilkDocument3 pagesJotashield Colourxtreme Silkمحمد عزتNo ratings yet

- 4878 PaperDocument13 pages4878 PaperLawrence Lim Ah KowNo ratings yet

- PHYS2002 Thermal Physics Q&ADocument3 pagesPHYS2002 Thermal Physics Q&ASaraNo ratings yet

- XYLEM Water PumpsDocument268 pagesXYLEM Water PumpsKamal DeshapriyaNo ratings yet

- IS 3844 Code For Internal Fire HydrantDocument22 pagesIS 3844 Code For Internal Fire HydrantNanu PatelNo ratings yet