Professional Documents

Culture Documents

Gate Valves: Features, Benefits & Specifications

Uploaded by

Gabriel RodriguezOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Gate Valves: Features, Benefits & Specifications

Uploaded by

Gabriel RodriguezCopyright:

Available Formats

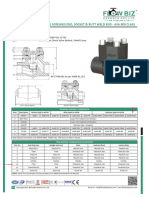

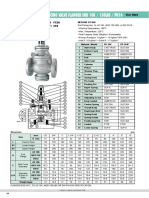

GATE VALVES

F54 F54

Gate Valve

Class 100

GENERAL VALVES

Features & Benefits

• Offer the ultimate in dependable service wherever minimum pressure

drop is important

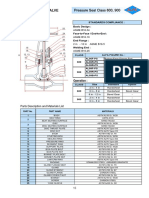

Materials

NO. PART MATERIAL SIZES

1 Body Cast Iron BS EN 1561 GJL-250 All

2 Bonnet Cast Iron BS EN 1561 GJL-250 All

3 Bonnet Gasket Asbestos Free All

4 Bonnet Bolts Steel BS4190 Gr.8.8 All

5 Bonnet Nuts Steel BS4190 Gr.8.0 All

6 Disc Cast Iron BS EN 1561 GJL-250 All

7 Stem Steel SUS410 All

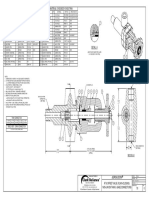

Dimensional Drawing

8 Stuffing Box Cast Iron BS EN 1561 GJL-250 All

9 Gland Cast Iron BS EN 1561 GJL-250 All

10 Gland Bolts Steel BS 4190 Gr.8.8 8 - 12

11 Gland Studs Steel BS 4439 Gr.8.8 2-6

12 Stuffing Box Gasket Asbestos Free All ØE

13 Packing Asbestos Free All

14 Handwheel Ductile Iron BS EN 1563 GJS-450-10 All

15 Body Seat Ring Cast Iron BS EN 1561 GJL-250 All

16 Disc Stem Nut Ductile Iron BS EN 1563 GJS-450-10 All

17 Disc Ring Cast Iron BS EN 1561 GJL-250 All

D

18 Handwheel Nut Steel BS4190 Gr.8.0 All

19 Gland Stud/Bolt Nuts Steel BS4190 Gr.8.0 All

20 Handwheel Washer Steel BS 4320 All

Dimensions & Weights

SIZE WEIGHT A B ØC D ØE

(inch) (lbs) (inch) (inch) (inch) (inch) (inch)

2 30.0 5.75 0.75 6.0 11.1 5.5

ØC

21/2 35.1 6.25 0.75 6.5 11.9 5.5

3 44.1 6.5 0.75 7.25 13.5 6.0

4 60.0 6.75 0.88 8.5 14.8 8.0

5 86.0 7.5 0.88 10.0 17.2 9.0

6 98.1 8.25 0.88 11.0 18.8 9.0 B

8 178.0 9.5 1.0 13.25 24.0 12.0 A

10 271.0 10.75 1.0 16.0 28.9 14.0

12 384.0 12.0 1.0 18.0 33.3 16.0

SIZE WEIGHT A B ØC D ØE ØE

(mm) (kg) (mm) (mm) (mm) (mm) (mm)

50 13.6 146.1 19.1 152.0 281.6 139.7

65 15.9 158.8 19.1 165.1 301.7 139.7

80 20.0 165.1 19.1 184.0 343.0 152.4

100 27.2 171.5 22.2 215.9 374.7 203.2

125 39.0 190.5 22.2 254.0 436.8 228.6

150 44.5 209.6 22.2 279.4 478.2 228.6 D

200 81.6 241.3 25.4 337.0 609.1 304.8

250 122.9 273.1 25.4 406.0 732.9 355.6

300 174.2 304.8 28.6 457.2 844.6 406.4

PRESSURE RATING: Class 100 SPECIFICATION: End flanges conform to BS 10 Table D or E with flat face and are

TEMPERATURE OPERATING RANGE: -10 to 170°C normally supplied drilled. Orders must specify whether Table D or Table E flanges are

UK END CONNECTION: BS10 Table D or E required. Wedge disc, non-rising stem, inside screw, all iron. Each valve is hydrostatically

tested to BS 6755 Pt 1.

OPERATING INSTRUCTIONS: Handwheel.

ØC

Gate valves are best for services that require infrequent valve This valve is not suitable for use on group 1 gases or unstable fluids, as defined by the

Vaild as of 221018

operation, and where the disc is kept either fully opened or fully Pressure Equipment Directive 2014/68/EU.*

closed. They are not practical for throttling. AVAILABLE OPTIONS: P150 Locking Device

B

Every effort has been made to ensure that the information contained in this publication is accurate at theAtime of publishing. Crane Ltd assumes no responsibility or liability for typographical errors or

omissions or for any misinterpretation of the information within the publication and reserves the right to change without notice.

TECHNICAL HELPLINE: +44 (0)1473 277400

1

E: enquiries@cranefs.com W: www.cranefs.com

You might also like

- The Mechanical and Physical Properties of the British Standard EN Steels (B.S. 970 - 1955): EN 40 to EN 363From EverandThe Mechanical and Physical Properties of the British Standard EN Steels (B.S. 970 - 1955): EN 40 to EN 363No ratings yet

- Cast Iron Check Valve With Resilient Seat PN16: Features & BenefitsDocument1 pageCast Iron Check Valve With Resilient Seat PN16: Features & BenefitsmuralyyNo ratings yet

- F58 Gate Valve CraneFS DS 1220Document1 pageF58 Gate Valve CraneFS DS 1220bigboys cusat bNo ratings yet

- Gate Valves: Cast Iron Gate Valve Class 125Document1 pageGate Valves: Cast Iron Gate Valve Class 125Jorge Uribe RochaNo ratings yet

- Fig FM63 Gate CraneFS DS 1702 P133Document1 pageFig FM63 Gate CraneFS DS 1702 P133afzal_aabNo ratings yet

- Gate Valves: Cast Iron Gate Valve Class 125Document1 pageGate Valves: Cast Iron Gate Valve Class 125Daniel SanNo ratings yet

- Cast Iron Gate Valve Non Rising Stem PN16: Features & BenefitsDocument1 pageCast Iron Gate Valve Non Rising Stem PN16: Features & BenefitsMohamed RaafatNo ratings yet

- Crane FM57Document1 pageCrane FM57Agung YudistiraNo ratings yet

- 01.01. 100mm Dia. Water Meter Assembly. (Check Valve)Document1 page01.01. 100mm Dia. Water Meter Assembly. (Check Valve)Amadou MokshaNo ratings yet

- Cast Iron Globe Valve Class 125Document1 pageCast Iron Globe Valve Class 125ROHIT ARYANo ratings yet

- FM369 Globe CraneFS DS 1021 p120Document1 pageFM369 Globe CraneFS DS 1021 p120aidil luthfansyahNo ratings yet

- Dual Filter: 20mm (/ ") - 200mm (8") Model OWDocument4 pagesDual Filter: 20mm (/ ") - 200mm (8") Model OWJairo Andrés FANo ratings yet

- AMLA BATCH MIXING TANK BOQDocument4 pagesAMLA BATCH MIXING TANK BOQMD Abu Bakar SiddiqueNo ratings yet

- TS - 19series SafetyDocument4 pagesTS - 19series SafetykicsnerNo ratings yet

- Valvula Check SwingDocument1 pageValvula Check SwingDenis Huamani QuispeNo ratings yet

- 3-Piece Firesafe Ball Valve Figure Numbering System: E Seswbw A 305 A CDocument5 pages3-Piece Firesafe Ball Valve Figure Numbering System: E Seswbw A 305 A CAbigail Lupe Aguilar YapuraNo ratings yet

- Carbon Steel Ball Valve: Design FeaturesDocument1 pageCarbon Steel Ball Valve: Design FeaturesChanchal K SankaranNo ratings yet

- File 1557373151Document17 pagesFile 1557373151JOWAN PERKASANo ratings yet

- Nabic Fig 500FN Pressure Relief Valve SpecificationDocument2 pagesNabic Fig 500FN Pressure Relief Valve SpecificationtechnicalNo ratings yet

- PN25 Rating Valves SpecificationsDocument2 pagesPN25 Rating Valves SpecificationsSenoPati KudusNo ratings yet

- Globe Valve DimensionsDocument3 pagesGlobe Valve Dimensionsangelufc99No ratings yet

- Type 180 Pressure Relief Valve: The 180/180-S Pressure Relief Valves Are Suitable For UseDocument2 pagesType 180 Pressure Relief Valve: The 180/180-S Pressure Relief Valves Are Suitable For UseClarkFedele27No ratings yet

- FlowBiz-FORGED-STEEL-CHECK-VALVE 800 ClassDocument2 pagesFlowBiz-FORGED-STEEL-CHECK-VALVE 800 ClassShakir AnsariNo ratings yet

- Gate Valve Drawing and SpecificationsDocument1 pageGate Valve Drawing and SpecificationsismailNo ratings yet

- FJP R1Document4 pagesFJP R1Amr ATTIANo ratings yet

- Cast Steel Globe Valve Pressure Seal Class 1500, 2500Document3 pagesCast Steel Globe Valve Pressure Seal Class 1500, 2500Andri AjaNo ratings yet

- All Globe Valves Have 3 Years WarrantyDocument22 pagesAll Globe Valves Have 3 Years WarrantyAli RasheedNo ratings yet

- MECH - ValvesDocument31 pagesMECH - Valvesdesai_tejasNo ratings yet

- Fig 47xu F Gate Cranefs Ds 1702 p136 1Document1 pageFig 47xu F Gate Cranefs Ds 1702 p136 1RonaldNo ratings yet

- 01.01. 100mm Dia. Water Meter Assembly. (Gate Valve)Document1 page01.01. 100mm Dia. Water Meter Assembly. (Gate Valve)Amadou MokshaNo ratings yet

- 1087 Bronze Double Regulating BalveDocument2 pages1087 Bronze Double Regulating BalveSanket PhatangareNo ratings yet

- Bill of Material (Cs Body/416Ss Trim) Bill of Material (316Ss Body/316Ss Trim)Document1 pageBill of Material (Cs Body/416Ss Trim) Bill of Material (316Ss Body/316Ss Trim)Jayesh SanganiNo ratings yet

- 4044 SERIES: Model 4044 Swivel JointDocument1 page4044 SERIES: Model 4044 Swivel JointshijuNo ratings yet

- Bronze Gate Valve Non Rising Stem PN20: Features & BenefitsDocument1 pageBronze Gate Valve Non Rising Stem PN20: Features & Benefitsumair186No ratings yet

- Series 45114 Flanged Globe ValveDocument4 pagesSeries 45114 Flanged Globe Valveeduardo goveaNo ratings yet

- D138 Check Valve CraneDocument1 pageD138 Check Valve CranesalesNo ratings yet

- FlowBiz Forged Steel Globe Valve Reduced BoreDocument2 pagesFlowBiz Forged Steel Globe Valve Reduced BoreFlowBiz Exports Pvt. Ltd.No ratings yet

- B3000 & Eb3000Document1 pageB3000 & Eb3000husamNo ratings yet

- Valvulas OS&YDocument1 pageValvulas OS&Ydaniel manuel garces davilaNo ratings yet

- 2-pc. Screwed End Ball Valve THB Series, Type AV02-121Document3 pages2-pc. Screwed End Ball Valve THB Series, Type AV02-121FCNo ratings yet

- Cast Steel Gate Valves: Class 150 - Outside Screw & Yoke - Flexible Wedge DiscDocument3 pagesCast Steel Gate Valves: Class 150 - Outside Screw & Yoke - Flexible Wedge DiscMina MagdyNo ratings yet

- Hidrante Seco Mod F0733Document1 pageHidrante Seco Mod F0733Julio FloresNo ratings yet

- Double Eccentric Butterfly Valve With Manual Gear Operator - AWWA C504 - Water Works PDFDocument1 pageDouble Eccentric Butterfly Valve With Manual Gear Operator - AWWA C504 - Water Works PDFPriyanka rajpurohitNo ratings yet

- 47XU Gate CraneFS DS p103 0620Document1 page47XU Gate CraneFS DS p103 0620Younis JanNo ratings yet

- Fig 143XU Globe CraneFS DS 1702 P153 - 1Document1 pageFig 143XU Globe CraneFS DS 1702 P153 - 1atnkpr_vn9368No ratings yet

- L N T Ball Valve Pricelist PDFDocument10 pagesL N T Ball Valve Pricelist PDFRANJINI02VNo ratings yet

- Technical Data Sheet for Safety and Relief ValvesDocument16 pagesTechnical Data Sheet for Safety and Relief Valvesisa.cuenta.26No ratings yet

- KITZ - Cast Iron - 125FCL&125FCYDocument2 pagesKITZ - Cast Iron - 125FCL&125FCYdanang hadi saputroNo ratings yet

- Pressure Reducing Valve Flanged End 10K / 150Lbs / Pn16: Model: Pr-3Af Cast Iron Fc20 PR-304F ASTM A351 CF8Document1 pagePressure Reducing Valve Flanged End 10K / 150Lbs / Pn16: Model: Pr-3Af Cast Iron Fc20 PR-304F ASTM A351 CF8Mohamed RaafatNo ratings yet

- KITZ CAST IRON VALVESDocument1 pageKITZ CAST IRON VALVESAndy SetyawanNo ratings yet

- D151 Gate Crane+FS DS 0922Document1 pageD151 Gate Crane+FS DS 0922Salah ArafehNo ratings yet

- 47XU F Gate CraneFS DS 1021 p103Document1 page47XU F Gate CraneFS DS 1021 p103Alexander HuamanNo ratings yet

- Bronze Safety Relief Valves-Models SV5601 SV5708-Technical InformationDocument5 pagesBronze Safety Relief Valves-Models SV5601 SV5708-Technical InformationMarco ChablaNo ratings yet

- FlowBiz Forged Steel Globe Valve Full BoreDocument2 pagesFlowBiz Forged Steel Globe Valve Full BoreFlowBiz Exports Pvt. Ltd.No ratings yet

- Lug & Wafer Style Butterfly Valves: Smart Solutions. Powerful ProductsDocument4 pagesLug & Wafer Style Butterfly Valves: Smart Solutions. Powerful ProductstrifiloNo ratings yet

- Piping B.O.Q - BreakupDocument26 pagesPiping B.O.Q - BreakupBalaji PNo ratings yet

- MDT 2021 Bro Gtfe 10K FCDocument1 pageMDT 2021 Bro Gtfe 10K FCsuwono radukNo ratings yet

- Valvulas Compuerta VGADocument1 pageValvulas Compuerta VGAOscar David Benavides CastilloNo ratings yet

- Cast Steel Float & Thermostatic Steam Trap FT450: Construction MaterialsDocument2 pagesCast Steel Float & Thermostatic Steam Trap FT450: Construction MaterialsPedroNo ratings yet

- Valves BrochureDocument16 pagesValves BrochurePeradNo ratings yet

- BS NA EN 1998-2 UK National Annex To Eurocode 8. Design of Structures For Earthquake Resistance. Bridges PDFDocument18 pagesBS NA EN 1998-2 UK National Annex To Eurocode 8. Design of Structures For Earthquake Resistance. Bridges PDFliuhoyinNo ratings yet

- 1 3 6 Overview of Eq Design UK NA For EN1998 2 PD 6698Document9 pages1 3 6 Overview of Eq Design UK NA For EN1998 2 PD 6698Chirianu MarianNo ratings yet

- BS en 1708-1-2010Document76 pagesBS en 1708-1-2010Giovanni Alfieri100% (3)

- Plastic PE Pipes - Operating Vs TempDocument5 pagesPlastic PE Pipes - Operating Vs TempGabriel RodriguezNo ratings yet

- Background To UK NA BS en 1991-1-4Document24 pagesBackground To UK NA BS en 1991-1-4batteekh100% (2)

- En1514 2Document18 pagesEn1514 2ozkanhasan100% (2)

- European Standard Norme Europeenne Europaische Norm: Metallic Products - Types of Inspection DocumentsDocument10 pagesEuropean Standard Norme Europeenne Europaische Norm: Metallic Products - Types of Inspection DocumentsGabriel RodriguezNo ratings yet

- BS EN 1515-1 Flanges and Their Joints - Bolting PDFDocument12 pagesBS EN 1515-1 Flanges and Their Joints - Bolting PDFGabriel RodriguezNo ratings yet

- BS en 1561 PDFDocument21 pagesBS en 1561 PDFGabriel RodriguezNo ratings yet

- Iso 9624Document12 pagesIso 9624Ayman S. AshourNo ratings yet

- BS en 1515 2 PDFDocument22 pagesBS en 1515 2 PDFCristian G. Ciocoi100% (1)

- BS en 1514 1 1997Document22 pagesBS en 1514 1 1997Phaneendra Tirumani100% (2)

- System Specification - : For Ecofit Piping Systems in Polyethylene (Pe)Document29 pagesSystem Specification - : For Ecofit Piping Systems in Polyethylene (Pe)Gabriel RodriguezNo ratings yet

- BS EN 558-2008 Industrial Valves. Face-To-Face and Centre-To-Face Dimensions of Metal Valves For Use in Flanged Pipe Systems PDFDocument32 pagesBS EN 558-2008 Industrial Valves. Face-To-Face and Centre-To-Face Dimensions of Metal Valves For Use in Flanged Pipe Systems PDFLC ChongNo ratings yet

- ISO - TR - 15608 - Welding Guide Line PDFDocument10 pagesISO - TR - 15608 - Welding Guide Line PDFDacher DanielNo ratings yet

- Rockwool Insulation DSDocument1 pageRockwool Insulation DSGabriel RodriguezNo ratings yet

- Bs en Iso 1127-1997 不锈钢管.尺寸、公差和单位长度的规范质量Document14 pagesBs en Iso 1127-1997 不锈钢管.尺寸、公差和单位长度的规范质量Jason100% (2)

- INSTA SBC EN 12201 January 2017 - UK PDFDocument26 pagesINSTA SBC EN 12201 January 2017 - UK PDFGabriel RodriguezNo ratings yet

- Directive 97 23 EcDocument36 pagesDirective 97 23 EcManish SiroyaNo ratings yet

- Y-Strainer: Type VC64 DN 15 - DN400 PN16-PN 40Document4 pagesY-Strainer: Type VC64 DN 15 - DN400 PN16-PN 40Gabriel RodriguezNo ratings yet

- 2014 68 Eu PDFDocument96 pages2014 68 Eu PDFAlienshow100% (1)

- Strainer PN32: Features & BenefitsDocument1 pageStrainer PN32: Features & BenefitsGabriel RodriguezNo ratings yet

- PED 2014-68-EU Guidelines en v5.1Document241 pagesPED 2014-68-EU Guidelines en v5.1Uğur özdemirNo ratings yet

- Bs-En-Iso 15609-1 PDFDocument14 pagesBs-En-Iso 15609-1 PDFMatija BušićNo ratings yet

- Equivalent ASME and EN Materials ChartDocument3 pagesEquivalent ASME and EN Materials CharttvsshindeNo ratings yet

- GPS Datasheet - PE100 Geothermal Pipe - 010217Document2 pagesGPS Datasheet - PE100 Geothermal Pipe - 010217Gabriel RodriguezNo ratings yet

- BS en 1514 1 1997Document22 pagesBS en 1514 1 1997Phaneendra Tirumani100% (2)

- Y Strainers: Technical CatalogueDocument16 pagesY Strainers: Technical Cataloguecavillalobosb8167No ratings yet

- BS EN ISO 12241 - Insulation CalculationDocument11 pagesBS EN ISO 12241 - Insulation CalculationGabriel RodriguezNo ratings yet

- Video Links For 7 Week Primer-NewDocument14 pagesVideo Links For 7 Week Primer-NewmaxnealblogNo ratings yet

- AEC-Course Completed Students For Certification - DepartmentwiseDocument8 pagesAEC-Course Completed Students For Certification - DepartmentwiseAnurag KumarNo ratings yet

- Significance of 248 in Man Part 3Document8 pagesSignificance of 248 in Man Part 3tunetown187No ratings yet

- Generation of ComputerDocument3 pagesGeneration of ComputerShivam KumarNo ratings yet

- Road Work & DrainageDocument17 pagesRoad Work & Drainagentah84No ratings yet

- Introduction To Tel-X-Ometer Equipment-Manual ProcedureDocument7 pagesIntroduction To Tel-X-Ometer Equipment-Manual ProcedurehannaNo ratings yet

- Colour Code - WordDocument1 pageColour Code - WordDivy NaiNo ratings yet

- Saas 1000Document69 pagesSaas 1000rjnemoNo ratings yet

- JSWAS A2 - en PDFDocument88 pagesJSWAS A2 - en PDFSintflut75% (4)

- XML Quiz with AnswersDocument17 pagesXML Quiz with AnswersManoj GuptaNo ratings yet

- Math 54 Exam 2 ReviewDocument11 pagesMath 54 Exam 2 ReviewBea DucaoNo ratings yet

- What Makes A Planet Habitable?Document3 pagesWhat Makes A Planet Habitable?Willie WilliowNo ratings yet

- Chap2 (B) Fits and TolerancesDocument20 pagesChap2 (B) Fits and TolerancesjojoNo ratings yet

- Bally 5500 SetUpandOperationDocument34 pagesBally 5500 SetUpandOperationFreder AngelNo ratings yet

- Chapter 4-Piezoelectric CeramicsDocument33 pagesChapter 4-Piezoelectric Ceramicssantsex111No ratings yet

- 13/15/19-Wire Installation Guide: D2proDocument1 page13/15/19-Wire Installation Guide: D2proerickNo ratings yet

- GCB HVR BrochureDocument8 pagesGCB HVR BrochureHan HuangNo ratings yet

- Horizontal Axis Wind Turbines Passive Flow Control Methods: A ReviewDocument18 pagesHorizontal Axis Wind Turbines Passive Flow Control Methods: A ReviewHavaldar, SanjayNo ratings yet

- Chapter 3b - MP DSBDocument32 pagesChapter 3b - MP DSBsheham ihjamNo ratings yet

- The Difference Between The Academic Performance of Woking and NonDocument8 pagesThe Difference Between The Academic Performance of Woking and NonMr.nutshell CoronelNo ratings yet

- SAP PM T - CodesDocument4 pagesSAP PM T - CodesBujjibabu Katta0% (1)

- AnInvestigationofPhaetonPlanetIIwrite Upv2Document14 pagesAnInvestigationofPhaetonPlanetIIwrite Upv2Divine Zen Love GoddessNo ratings yet

- Magnetic Water TreatmentDocument66 pagesMagnetic Water Treatmentmdkadry100% (2)

- High Productivity Scalable Pick-and-Place HandlerDocument2 pagesHigh Productivity Scalable Pick-and-Place HandlermhafizanNo ratings yet

- Bca Question Paper PDFDocument4 pagesBca Question Paper PDFdrharpreet singh100% (1)

- Shop Inspection and Test Plan for FRP Water TroughDocument29 pagesShop Inspection and Test Plan for FRP Water TroughEljo AndsNo ratings yet

- Good Practice Guide For Form and Diameter Measurements For Large ShaftsDocument14 pagesGood Practice Guide For Form and Diameter Measurements For Large ShaftsNg Wei LihNo ratings yet

- Harmonic OscillatorDocument15 pagesHarmonic OscillatorccNo ratings yet

- Biology Class X For 2017 18Document204 pagesBiology Class X For 2017 18krish9422No ratings yet

- Plane Wave Reflection Coefficient From Near Field MeasurementsDocument7 pagesPlane Wave Reflection Coefficient From Near Field MeasurementsraulreyesvillagranaNo ratings yet