Professional Documents

Culture Documents

Us2407049a Tire Inflation Guard

Us2407049a Tire Inflation Guard

Uploaded by

Jimmy Cuevas Monsalve0 ratings0% found this document useful (0 votes)

6 views3 pagesTIRE INFLATION GUARD

Original Title

US2407049A TIRE INFLATION GUARD

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentTIRE INFLATION GUARD

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

6 views3 pagesUs2407049a Tire Inflation Guard

Us2407049a Tire Inflation Guard

Uploaded by

Jimmy Cuevas MonsalveTIRE INFLATION GUARD

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 3

GaN UIE ree

ar}

g $3

= $6

3 #3

DG

z

c Bs ASS &

pie 4 NESE Ss

Bs 3 = —— 85

28d Se Se

Sept. 3, 1946.

AND RELATED DEVICES.

49.5

109, SAFES, BANK PROTECHON

wy.

4

9

DATES, BANA rHUTcur

AND RELATED DEVICES.

~5

Patented Sept. 3, 1946

UNITED STATES

Searcn noun

2,407,049

PATENT OFFICE

2,407,049

TIRE INFLATION GUARD

Nathan Winarsky and Benjamin Winarsky,

Newark, \N. J., assignors to Belmont Body

Builders, Newark, N.

J.,a partnership

Application August 9, 1945, Serial No. 609,894

5 Claims.

1

‘The present invention deals with a safety de-

vice known as a tire inflation guard. Usually, or-

dinary passenger automobile tires ‘involve little

hazard, during inflation, although there have

been incidents reported wherein tires burst be-

cause of overinflation or defective casings. ‘This

danger in the case of truck and airplane tires is

more prevalent, due to the higher pressures and

larger tires employed. Since such tires cost a

great deal more than passenger tires, there is

also the tendency to try to make them lest long-

er, so that there is a greater possibility of en-

countering defective carcasses. Many instances

have been known in which such tires have ex-

ploded from intemal pressure during inflation,

causing not only injury, but also death to the

operators as well as individuals who happened.

to be in the vicinity at the time, ‘Truck tires also

have locking rings on the rims which lock the tire

and rim in place upon inflation. Tn many in-

stances, this ring has been known to expand and

spring open, even though believed to be in locked,

Position, thus causing bodily injury.

The device of the present invention is not de-

veloped to prevent the bursting of tires, but to

safeguard the personnel and others against possi-

ble injury or death in the event of a failure of a

tire carcass to hold the air pressure which is fed

into it,

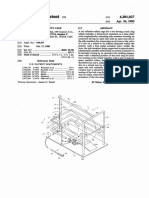

The invention would be best understood by ref-

erence to the drawing which gives a perspective

and diagrammatic view of a type of device which

‘would exemplify the invention involved, In the

figure, all of the metal members, with the excep-

tion of a few (which will be designated) are

made of angle iron stock of sufficiently largo di-

mensions to withstand the driving force of the

tires upon explosion. We find it preferable to

employ 1%" x 144" x ¥e"" angle iron, although

somewhat smaller ‘sizes and also larger stocks

may be used.

Numerals | and 2 represent two angle iron

members wide enough apart to receive the widest

tire to be inflated, For truck tires, we find that

a width of 12 inches is generally satisfactory.

‘Welded to the ends of these are two members $

and 4, thus forming a base for the cage struc-

ture, ‘The latter two members have protruding

ends (protruding, roughly about 7 inches) to

prevent the structure from capsizing upon im-

pact. Members § and 6 are welded to | and 2,

to give, roughly, equidistant spacing between §

and 4, These members § and 6 not only act as

reinforcement, but they also serve as guides or

stops to keep the tire fixed in place while it Is be=

(CL. 109-49.5)

2

ing inflated. ‘The tire is outlined in dotted lines

and is designated by numeral 31.

Welded to the base, preferably at, junctures

with other members, are upright members T, 8,

{3 and (4, while between them, equally spaced

and welded to members | and 2 are uprights 9,

10, (1 and (2, while at right angles to them, and

preferably equally spaced are horizontal mem-

bers 18, 20, 23 and 24. Forming the top of the

structure are members 28 (welded to the ends of

members 1, 8, {1 and 3), and 26 (welded to tops

of 8, 10, 12 and (4), ‘Then end members 7 and

8 are joined at the top by member 27, while end

‘members (3 and 14 are similarly joined by mem-

ber 28, Spaced equidistantly between 27 and 28

‘are members 28 and 30, welded on to top mem-

bers 25 and 26, In a similar manner, the side

members 21 and 22 are welded to corner mem-

bers 13 and 4, The protruding ends of base

members 3 and 4 are reinforced by struts 15, 16,

{T and 18, Base members 3 and 4 may also be

provided with means for fastening them to the

floor or foundation,

‘Between members 1 and 8 are located bar

‘members 83 and 34 for allowing entry of the tire

into the structure, Both bar members are piv-

oted on member 8 at points 35 and 36, and their

free ends are locked in clasps $f and 82 which are

welded on member 7. Knobs 42 and 43 are pro-

vided for lifting members 38 and 34 and swing-

ing them to positions indicated by 33° and 34°.

‘Stops 40 and 41 may be welded on member 8 to

prevent bars 38 and 34 from swinging in the open

positions.

In the operation of the device, bar members

39 and 34 are swung into the open position and

tthe tire or wheel having a tire mounted thereon

is rolled inside the structure. Then the mem-

bers 38 and 34 are locked into closed position

and the tire is inflated, In the event of explo-

sion, not only the tire carcass, but also the rim

are retained within the structure, thereby pre~

venting bodily infury to the operator and those

‘within normal striking distance of the explod-

ing tire.

In order to adequately take care of inflation of

tires mounted on disk-type wheels, upright bar

member 39 is welded to members 1, 19 and 28,

equidistant between members 9 and {1 and ex-

tending from the base to member 28, Hole 38 is,

cut out in member 99 to accommodate a stud

which is inserted through opening 38 into the

isk wheel hub, ‘This is to further anchor such

‘55 wheels which Welgh considerably more than tire

0

35

30

35

40

5

2,407,049

3

and rim assemblies and thus offer greater safety

hazards,

For general truck tire use, we find the follow-

ing linear dimensions most’ satisfactory: Mem

bers | and 2, 46-48 inches long, 3 and 4 about 29

inches, and members 1, 8, 8, 10, 11, 12, 13 and 14

may be about 46-48 inches.

Instead of members 33 and 84, it is also pos-

sible to employ a solid steel plate door having the

width and length of the space between members

38 and 34, hinged on member 8 and locked in

closed position by a latch or lock on member 7.

Tt will be observed that structural iron mem-

bers are employed. These may be bar stock,

angle, T, channel, and the like, the strongest

directional strain-resisting portion being on the

inside of the structure, preference, however, be-

ing in maintaining a smooth interior to prevent

interference while rolling the tire into the cage:

Although a circular shape is possible for this

structure, we have described the simplest, cheap-

est, and most readily constructed design. Other

metals, laminated plasties and even plywood may

be employed to reduce the weight and effect other

advantages. The device is portable and may be

‘mounted on a service truck, if desired,

Although the inflation guard shown in the

drawing Is fixed to hold 2 tire vertically (which

is the preferred position since it occupies the

least floor space and enables the tire to be rolled

in), the assembly may be employed with the

smaller dimension in the vertical position.

‘We claim:

1. A tire inflation guard for preventing acci-

dents during truck tire inflation, comprising a

base for positioning a truck wheel holding a tire,

at least four rigid heavy metal upright supports

circumseribing the space occupied by the tire and

fixed solidly to the base, a top section fastened to

the supports, rigid heavy metal cross members

fastened securely between the supports to prevent

sudden escape of the tire rim, at least one mov-

able member serving as a closure between the sup-

10

6

30

35

40

4

Ports to allow entry of the tire into the guard,

protruding members extending from the base at

right angles to the plane of the main axis of

the tire-cireumseribing space and of such dimen-

sions as to prevent capsizing of the guard, and

‘means for locking said member in closed position

after the wheel is placed in the guard.

2. A tire inflation guard according to claim 1

in which the base is provided with stops disposed

substantially perpendicularly to the plane of the

‘wheel to position the wheel.

3. A truck tire inflation guard for inflating a

tire mounted on a disk wheel comprising a base

for positioning the wheel, at least four rigid heavy

metal upright supports fastened to the base and

forming a rectangular space circumseribing the

tire, the long side of the rectangle being adjacent,

to the side of the wheel, a rigid heavy metal top

section fastened to the supports, rigid heavy metal

‘cross members fastened securely between the sup-

ports to prevent sudden escape of the tire rim, at

east one movable rigid heavy metal member

serving as a closure between the supports to allow

entry of the wheel into the guard, an upright

member positioned about in the middle of a long

side of the rectangle, fastened securely to the base

and at least one cross member, and means for

locking said movable member in closed position,

after the wheel is placed in the guard.

4, A tire inflation guard according to claim 3

in which the upright member positioned about in

the middle of a long side is provided with means

for securing the disk whee! to said upright mem-

er.

5. A tire inflation guard according to claim 3

in which the upright member positioned about in

the middle of a long side is provided with an

opening of such dimensions and elevation to en-

able securing of the disk wheel to said upright

member by passing a stud through said opening

and engaging it with the hub of the disk wheel

NATHAN WINARSKY,

BENJAMIN WINARSEY,

You might also like

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- Safe Use of Cryogenic MaterialsDocument28 pagesSafe Use of Cryogenic MaterialsJimmy Cuevas MonsalveNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5810)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (346)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Mini-Tutorial - Regulación OSHA 1910.177Document1 pageMini-Tutorial - Regulación OSHA 1910.177Jimmy Cuevas MonsalveNo ratings yet

- Us4381027 Tire Inflation Safety CageDocument9 pagesUs4381027 Tire Inflation Safety CageJimmy Cuevas MonsalveNo ratings yet

- Us4036274 Safety Cage For InflationDocument5 pagesUs4036274 Safety Cage For InflationJimmy Cuevas MonsalveNo ratings yet

- Taylor Wharton XT Series User ManualDocument2 pagesTaylor Wharton XT Series User ManualJimmy Cuevas MonsalveNo ratings yet

- Cryopreservación AccesoriosDocument48 pagesCryopreservación AccesoriosJimmy Cuevas MonsalveNo ratings yet