Professional Documents

Culture Documents

Us4036274 Safety Cage For Inflation

Uploaded by

Jimmy Cuevas Monsalve0 ratings0% found this document useful (0 votes)

18 views5 pagesSAFETY CAGE FOR INFLATION

Original Title

US4036274 SAFETY CAGE FOR INFLATION

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentSAFETY CAGE FOR INFLATION

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

18 views5 pagesUs4036274 Safety Cage For Inflation

Uploaded by

Jimmy Cuevas MonsalveSAFETY CAGE FOR INFLATION

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 5

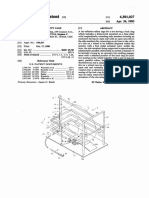

United States Patent 19 11 4,036,274

Peel, Sr. 45 July 19, 1977

54 SAFETY CAGE FORTIRE INFLATION Assistant Examiner-James G. Smith

76 Inventor: Aubrey A. Peel, Sr., Rte. 2, 1505 Attorney, Agent, or Firm-Duckworth, Hobby, Orman,

Allen & Pettis

Nemeth St., Auburndale, Fla. 33823

57 ABSTRACT

21 Appl. No.: 702,719 A safety cage for holding a pneumatic tire during infla

22 Filed: July 6, 1976 tion is provided in which a framework is formed having

51) Int. C.’.............................................. B60C 25/00 a base and a center post protruding therefrom for the

52 U.S. C. ........................................................ 157/1 placement of a pneumatic tire for inflation of the tire.

Side frame members extend from the base member and

58 Field of Search ............................................ 157/1 have top frame members attached thereto which swing

56 References Cited over onto the center post where a locking pin locks the

U.S. PATENT DOCUMENTS top frame members together and to the center post for

holding the pneumatic tire mounted on a wheel within

2,407,049 9/1946 Winarsky et al. ....................... 157/1 the safety cage to prevent injury to a worker during the

2,792,056 5/1957 Ricketts et al. .......................... 157/1 inflation operation.

3,495,647 2/1970 Branick ................................ 157/1 X

Primary Examiner-Al Lawrence Smith 9 Claims, 4 Drawing Figures

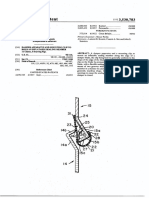

U.S. Patent July 19, 1977 Sheet 1 of 2 4,036,274

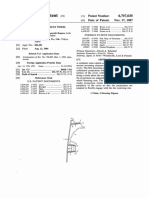

U.S. Patent July 19, 1977 Sheet 2 of 2 4,036,274

4,036,274

1. 2.

tire in the cage to protect an operator during the infla

SAFETY CAGE FORTRE NFLATON tion operation.

BACKGROUND OF THE INVENTION BRIEF DESCRIPTION OF THE DRAWINGS

The present invention relates to a safety device for 5 Other objects, features and advantages of the present

the protection of vehicle tire workers to prevent injury invention will be apparent from the written description

in the event that a tire breaks or disintegrates during the and from the drawings in which:

inflation operation by providing a safety cage for lock FIG. 1 is a perspective view of an operator inflating a

ing the tire during the inflation operation. mounted pneumatic tire located in safety cage in accor

One of the more precarious and risky operations in 10 dance with the present invention.

the servicing of automotive and truck equipment is the FIG. 2 is a perspective view of the assembled safety

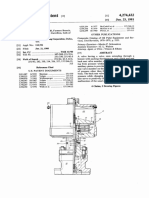

changing and inflation of tires. When a given tire casing cage in accordance with the present invention.

has been damaged or has lived its useful life or for any FIG. 3 is a perspective view of an operator removing

other reason must be removed from the wheel, it is a a pneumatic tire from the safety cage of the present

simple operation to extract the valve stem and permit 15 invention,

the air to exhaust from the inner tube whereupon it is a FIG. 4 is a perspective view of an unlocked and open

relatively simple operation to remove the casing and safety cage in accordance with FIGS. 1 through 3.

tube from the wheel, and it is almost as simple to place DETAILED DESCRIPTION OF THE

a new casing and tube on the same wheel. When, how 20 DRAWINGS

ever, air under pressure is forced into the tube to pre Referring now to FIGS. 1 through 4 of the drawings,

pare the tire for the road, a considerable danger arises. a safety cage 10 in accordance with the present inven

If there are defects in the casing, which is especially apt tion has a pneumatic tire 11 mounted to a wheel 12

to occur when a used casing is replaced on a wheel, or located therein, with an operator 13 inflating the tire 11

if the baseband is defective, or if the casing is not prop 25 in FIG.1. The safety cage has a plurality of pairs of base

erly seated on the wheel, when sufficient pressure is or floor members 14, 15, 16 and 17 extending in four

reached, the tire may burst or be blown off of the rim. directions to form both a base for setting the entire

This occurs only after from 20 to 30 pounds of pressure apparatus on the floor and for mounting a center post

have been built up in the tire, and the result is that the 18. Center post 17 may be a cylindrical steel pipe or post

mechanic who is placing the tire is in serious danger of 30 fixedly welded to the interesecting base frame members

severe injury or even death. 14, 15, 16 and 17. The base members 17 has a single

The most dangerous items are the removable ring and vertically

the lock ring. These items under the impulse of 20 to 40 tween the extendingpair of

side frame member 20 pinned be

members 17 by pin 21 and adapted to

pounds air pressure are entirely capable of decapitating swing on the pin 21 while each of the pair of base mem

an operator. The safety cage of the present invention is 35 bers 14, 15 and 16 may have identical pairs of side frame

especially designed to catch these rings if they are dis members 22 with a center reinforcing member 23 for

lodged by air pressure, and prevent injury to the opera fixedly attaching the side frame members 22 and 23 to

tor. Similarly, a long tear in the fabric of the carcass, or the pairs of base members 14, 15 and 16. Each of the

separation of the cords in the carcass, may result in the three pair of side members 22 has a top frame member

dislodgment of a considerable sized fragment of tire 24 pinned therebetween with a bolt 25 and is adapted to

which under pressures of 20 to 40 pounds per square swing on the bolt 25. Vertically extending frame mem

inch may have sufficient impetus to break arms or ribs, ber 20 has a single top frame member 26 connected with

disabling the operator for a considerable time. The a bracket 27 and bolts or pins 28 and 30 for swinging

homework of the present guard structure are designed thereon so that side frame member 20 and top frame

to intercept major fragments or tire casing large enough 45 member 26 may be swung out of the way as illustrated

to injure an operator. in FIGS. 3 and 4. One top frame member 31 located

The safety cage of the present invention consists of a opposite top frame member 26 has a pair of locking

base or floor frame having a center post protruding brackets 32 fixedly attached thereto such as by welding,

therefrom so that a pneumatic tire mounted on a wheel as while each of the top frame members 24 and 33 have

rim can be placed over the center post and enclosed in 50 a locking member 34 extending perpendicular thereto,

a cage to prevent the escape of rings during the inflation and parallel to the locking member 32. In addition, the

of the tire. Advantageously, the device allows for the center post 18 has a pair of locking brackets 35, fixedly

rapid placing and locking of the wheel in the safety cage attached to the top thereof and mounted so that the

for the inflation and for the rapid removal upon the locking brackets 34 on top frame members 34 and 33

completion of the inflation operation. 55 will fall just inside thereof while the locking braces 32

SUMMARY OF THE INVENTION will fall just inside of the locking members 34 and 33 to

form one convenient center section of interconnecting

The present invention provides a safety cage for plac members. Locking members 34 and 32 as well as top

ing a pneumatic tire mounted upon a wheel for the frame member 26 all have identical and aligned holes

inflation of a pneumatic tire. It has a base or floor frame 60 therethrough so that a locking pin 36 attached to a chain

which has a center post member attached thereto and 37 and connected at 38 to the top frame member 24

protruding therefrom. Side frame members are attached which can be easily slid into the openings in the locking

to the base of the frame and have top frame members members 32,34 and top frame member 26 for locking all

attached thereto and mounted to swing over the top of of the top frame members together to the center post 18.

a mounted tire placed over the center post. The top 65 An opening 40 can be seen in top frame member 26 of

frame members are brought together at the top of the FIG. 4 while openings 41 can be seen in the brackets 35

center post and a single locking pin locks the top frame of the center post 18 and openings 42 in the locking

members together for locking the mounted pneumatic members 34 with one opening 43 in each of the pair of

4,036,274 4.

3

locking members 32. In a typical safety cage the entire 2. The apparatus in accordance with claim 1 in which

framework can be made of steel channels, a cylindrical each said top frame member is swingably attached to at

steel pipe 18, and steel brackets and locking members least one said side frame member allowing said top

even though it should be clear that other metals or frame member to swing away from said center post

materials can be used to make the safety cage without member when mounting a tire on said center post.

departing from the spirit and scope of the invention. 3. The apparatus in accordance with claim 1 in which

Steel reinforcing bars 39 are welded to the bottom side said locking brackets attached to said center post and

of top frame members 24, 31, 33 and 26 to accept the said locking members attached to said top frame men

bers each have openings therein for sliding a lockingpin

blow of an exploding tire ring to prevent further dam O for locking said members together and to said center

age to the frame.

In operation the open cage 10 as illustrated in FIG. 4 post brackets.

4. The apparatus in accordance with claim 3 in which

has a tire mounted on a wheel placed over the center said lockingpin is attached to a flexible holding member

post 18 and each of the top frame members 24, 31 and 33 at one end which flexible holding member is attached to

folded together with the side frame member 20 folded 15 one said top member.

to a vertical position so that the top frame member 26 5. The apparatus in accordance with claim 4 in which

can be folded onto the center post 18 so that all top one said side member is swingably mounted to one said

frame members fall into alignment onto the center post base frame member for swinging said side member and

with the locking bracket 41 and the locking pin 36 slid its attached top frame member out of the way during

through the openings for locking the mounted tire 11 in 20 the placing of a mounted tire on said center post.

the cage. The operator 13 can then inflate the tire while 6. The apparatus in accordance with claim 5 in which

the removal ring and lock ring are safely held within the said base frame includes four pairs of steel frame mem

locking cage in the event the pneumatic tire burst from bers with a cylindrical center pipe welded to the inter

the wheel. It will of course be clear that different shapes section of said pairs of base frame members.

and sizes can be used for the face members, side mem 25 7. The apparatus in accordance with claim 6 in which

bers, top members, as well as center posts without de two said top frame members have perpendicular lock

parting from the scope of the invention and that differ ing members extending therefrom having an opening

ent locking and connecting members can be utilized. therethrough and one said top frame member has a pair

Accordingly, the present invention is not be be con 30 of locking members extending therefrom having an

opening therethrough which aligns with the openings in

strued as limited to the particular forms shown herein said pair of perpendicular extending locking members

which are to be considered illustrative rather than re

strictive. on said pair of top frame members and said locking

I claim: brackets attached to said center post member having

openings

1. Safety cage for placing a pneumatic tire during 35 frame members therein which align with openings on said top

locking members whereby said remov

inflation comprising in combination: able locking pin can extend through said locking brack

a base frame; ets and locking members for locking said top frame

a center post member attached to said base frame and members together.

protruding therefrom, said center post member 8. The apparatus in accordance with claim 7 in which

having a locking bracket fixedly attached thereto; one said top frame member has an opening there

side frame members attached to said base frame in a through which aligns over said center post member

spaced relationship to said center post member; with the openings in said locking brackets attached to

top frame members attached to said side frame mem said center post and said other locking members at

bers and movable toward said center post member tached to said other top frame members for locking said

in one position and movable to a second position to 45 top frame members together with said locking pin.

allow a pneumatic tire around said center post 9. The apparatus in accordance with claim 8 in which

member, each said top frame member having a three of said side frame members are mounted in pairs to

locking member mounted thereon for locking to said base frame and each have a top frame member held

said locking bracket fixedly attached to said center therebetween with ak bolt. for .

swinging

. .

thereon.

post member. s 50

55

65

You might also like

- 06.damper Apparatus and Mounting Clip ToDocument4 pages06.damper Apparatus and Mounting Clip ToRohit BirajdarNo ratings yet

- Us4380197 PDFDocument8 pagesUs4380197 PDFsoNo ratings yet

- US460Document5 pagesUS460bbNo ratings yet

- US4219241Document7 pagesUS4219241aungkyawzoreNo ratings yet

- Ullltbd States Patent (19) (11) Patent Number: 5,143,154: Mody Et Al. (45) Date of Patent: Sep. 1, 1992Document7 pagesUllltbd States Patent (19) (11) Patent Number: 5,143,154: Mody Et Al. (45) Date of Patent: Sep. 1, 1992mohammadreza91No ratings yet

- US4707035Document5 pagesUS4707035aungkyawzoreNo ratings yet

- US5303813Document7 pagesUS5303813AdailsonNo ratings yet

- Farris 3800 ManualDocument12 pagesFarris 3800 ManualNelson AlvarezNo ratings yet

- US patent for positive back seat valve closure systemDocument5 pagesUS patent for positive back seat valve closure systemTaufik Budi WibowoNo ratings yet

- Taylorcraft Service Manual BB12Document48 pagesTaylorcraft Service Manual BB12Jessie BechaydaNo ratings yet

- Traction device for motor vehiclesDocument5 pagesTraction device for motor vehiclesxeron7126No ratings yet

- Division: of Counsel (Patents) 1176 Howell StreetaDocument13 pagesDivision: of Counsel (Patents) 1176 Howell StreetaIsrar Ul HaqNo ratings yet

- 4.5 Inch Rocket ManualDocument30 pages4.5 Inch Rocket ManualGasMaskBobNo ratings yet

- Installation Guide C175-C172 All Models Appendix C 242 Rev BDocument52 pagesInstallation Guide C175-C172 All Models Appendix C 242 Rev BJonathan Miguel Gómez MogollónNo ratings yet

- United States Patent: Millerman (45) Date of Patent: Dec. 12, 2006Document9 pagesUnited States Patent: Millerman (45) Date of Patent: Dec. 12, 2006Ayush MaliNo ratings yet

- United States Patent (19) : WalkerDocument8 pagesUnited States Patent (19) : Walker155No ratings yet

- Rotating Breech Gun MechanismDocument5 pagesRotating Breech Gun MechanismminiselNo ratings yet

- Installation, Operation and Maintenance of Airflex@ CM Marine ClutchDocument12 pagesInstallation, Operation and Maintenance of Airflex@ CM Marine Clutchaiyubi2No ratings yet

- Us6772548 PDFDocument8 pagesUs6772548 PDFJin SongNo ratings yet

- US4893426Document7 pagesUS4893426Jean DelaronciereNo ratings yet

- United States Patent: Sultan Et Al. (45) Date of Patent: Apr. 29, 2008Document7 pagesUnited States Patent: Sultan Et Al. (45) Date of Patent: Apr. 29, 2008aqil_shamsiNo ratings yet

- Discus T Manual enDocument42 pagesDiscus T Manual enCosmin BuhuNo ratings yet

- United States Patent (19) : Felix-DalichowDocument5 pagesUnited States Patent (19) : Felix-DalichowBarmak CheraghiNo ratings yet

- Windproof Umbrella Having An Improved Rib Linkage SystemDocument9 pagesWindproof Umbrella Having An Improved Rib Linkage SystemAyoub El kadaouiNo ratings yet

- WPT - Spring Set Brake Air ReleaseDocument5 pagesWPT - Spring Set Brake Air ReleaseSilver AngelNo ratings yet

- Nose Landing Gear - Maintenance Practices 1. General: Page 1 of 14 Print Date: Mon Sep 25 02:29:33 CDT 2023Document14 pagesNose Landing Gear - Maintenance Practices 1. General: Page 1 of 14 Print Date: Mon Sep 25 02:29:33 CDT 2023lahiru0615No ratings yet

- United States Patent (191: Patent Number: Date of Patent: (11) 145) GrimesDocument3 pagesUnited States Patent (191: Patent Number: Date of Patent: (11) 145) GrimesDanister GladwinNo ratings yet

- 1967 Chevrolet Chevelle Camaro Chevyii Corvette Overhaul ManualDocument325 pages1967 Chevrolet Chevelle Camaro Chevyii Corvette Overhaul Manualfernan blanco100% (1)

- Us 3960084Document3 pagesUs 3960084rte678No ratings yet

- United States "Patents PDFDocument17 pagesUnited States "Patents PDFTien Nguyen VanNo ratings yet

- Propeller RemovalDocument10 pagesPropeller RemovalMedha Jog Katdare100% (1)

- United States Patent (191: Cél 296/97 /2/70g Primary Exammer - Margaret A. FocannoDocument7 pagesUnited States Patent (191: Cél 296/97 /2/70g Primary Exammer - Margaret A. FocannoDanister GladwinNo ratings yet

- Cessna Corvalis Models Empennage Failures from Extreme BrakingDocument47 pagesCessna Corvalis Models Empennage Failures from Extreme BrakingNuttapol Fuangfoodamrongchai100% (1)

- United States Patent (19) : Dec. 10, 1991 (45) Date of PatentDocument4 pagesUnited States Patent (19) : Dec. 10, 1991 (45) Date of PatentKeval KamaniNo ratings yet

- United States Patent (19) : 11 Patent Number: 45) Date of Patent: Jan. 7, 1997Document9 pagesUnited States Patent (19) : 11 Patent Number: 45) Date of Patent: Jan. 7, 1997Kaustubh PanchalNo ratings yet

- Type A31A High PerformanceDocument24 pagesType A31A High PerformanceJesus BolivarNo ratings yet

- 70000905clinker Crusher (Peyvand)Document32 pages70000905clinker Crusher (Peyvand)hamid hoorshadNo ratings yet

- US5513743Document6 pagesUS5513743AdailsonNo ratings yet

- US20120056033A1Document8 pagesUS20120056033A1雷黎明No ratings yet

- Copt ManualDocument79 pagesCopt ManualPradeep Shukla94% (17)

- Patent Application Publication (10) Pub. No.: US 2002/0153034 A1Document25 pagesPatent Application Publication (10) Pub. No.: US 2002/0153034 A1Paballo MontleNo ratings yet

- Removable Francis Turbine SealsDocument4 pagesRemovable Francis Turbine SealsmachevelNo ratings yet

- US3200917Document5 pagesUS3200917张淼No ratings yet

- United States Patent: Chang Et AlDocument9 pagesUnited States Patent: Chang Et AlEric Manuel Mercedes AbreuNo ratings yet

- US4827759Document7 pagesUS4827759jonyNo ratings yet

- Tip Brake Mechanism Slows Wind Turbine Blade RotationDocument11 pagesTip Brake Mechanism Slows Wind Turbine Blade RotationRubén Gutiérrez AmoNo ratings yet

- Segmented Sealing Lips Reduce Cracking in Turbine Disk SealsDocument4 pagesSegmented Sealing Lips Reduce Cracking in Turbine Disk SealsshamsNo ratings yet

- United States PatentDocument7 pagesUnited States PatentBrilliant DavidsonNo ratings yet

- Us2467764 PDFDocument10 pagesUs2467764 PDFRodrigoPomaNo ratings yet

- Us 4676137Document6 pagesUs 4676137fghdfjerNo ratings yet

- Operating Instructions: VKS 80 Pneumatic DrifterDocument15 pagesOperating Instructions: VKS 80 Pneumatic DrifterДмитрий ОвчинниковNo ratings yet

- Cloth Tow Target Sleeve (1992)Document26 pagesCloth Tow Target Sleeve (1992)CAP History LibraryNo ratings yet

- United States Patent (19) : PreticDocument5 pagesUnited States Patent (19) : Pretic63No ratings yet

- Us 4234275Document6 pagesUs 4234275MahnooshNo ratings yet

- Vizion Autopilot Installation for Cessna 172Document50 pagesVizion Autopilot Installation for Cessna 172sandyNo ratings yet

- US Patent 7090236 Land SailingDocument8 pagesUS Patent 7090236 Land SailingDimas MaulanaNo ratings yet

- A 1020Document16 pagesA 1020Pong KrubNo ratings yet

- Us4252504 PDFDocument7 pagesUs4252504 PDFAhmed EltemsahNo ratings yet

- US5180284Document7 pagesUS5180284vishal pandeyNo ratings yet

- Big Tyre: Case StudyDocument3 pagesBig Tyre: Case StudyJimmy Cuevas MonsalveNo ratings yet

- Big Tyre: Case StudyDocument3 pagesBig Tyre: Case StudyJimmy Cuevas MonsalveNo ratings yet

- Tire Inflating Station and Method For Inflating TiresDocument6 pagesTire Inflating Station and Method For Inflating TiresJimmy Cuevas MonsalveNo ratings yet

- Preventing Tire Blowout AccidentsDocument14 pagesPreventing Tire Blowout AccidentsJimmy Cuevas MonsalveNo ratings yet

- Us8333228 Tire Changer With Attached Inflation CageDocument9 pagesUs8333228 Tire Changer With Attached Inflation CageJimmy Cuevas MonsalveNo ratings yet

- Tire Modelling Blow-OutDocument10 pagesTire Modelling Blow-OutkeanshengNo ratings yet

- Operating Manual For Cryogenics ThermoflasksDocument6 pagesOperating Manual For Cryogenics ThermoflasksJimmy Cuevas MonsalveNo ratings yet

- Taylor Wharton XT Series User ManualDocument2 pagesTaylor Wharton XT Series User ManualJimmy Cuevas MonsalveNo ratings yet

- Us4381027 Tire Inflation Safety CageDocument9 pagesUs4381027 Tire Inflation Safety CageJimmy Cuevas MonsalveNo ratings yet

- Safe Use of Cryogenic MaterialsDocument28 pagesSafe Use of Cryogenic MaterialsJimmy Cuevas MonsalveNo ratings yet

- Meet Frank PDFDocument2 pagesMeet Frank PDFJimmy Cuevas MonsalveNo ratings yet

- Cryopreservación AccesoriosDocument48 pagesCryopreservación AccesoriosJimmy Cuevas MonsalveNo ratings yet

- 0000007913.6039 en 1212Document64 pages0000007913.6039 en 1212Jesus N RodriguezNo ratings yet

- Printable Fastener Tools PDFDocument32 pagesPrintable Fastener Tools PDFColumbia Gomez0% (1)

- Design Guides For PlasticsDocument67 pagesDesign Guides For Plasticsselvap77No ratings yet

- Big Kaiser2019 PDFDocument624 pagesBig Kaiser2019 PDFGoto SamNo ratings yet

- HSS DimensionsDocument28 pagesHSS DimensionsRichard StratulakNo ratings yet

- Vietnam - Introduce Tekla Open APIDocument34 pagesVietnam - Introduce Tekla Open API김성곤No ratings yet

- USB Flash Drive Price ListDocument1 pageUSB Flash Drive Price Listrick990No ratings yet

- 231C Air Impact Wrench - Exploded View: (Dwg. TPA567-11)Document2 pages231C Air Impact Wrench - Exploded View: (Dwg. TPA567-11)julio bolivarNo ratings yet

- Alluminio TeoriaDocument91 pagesAlluminio TeoriaxypangioNo ratings yet

- MONLEON, REI JULIAN KYLE T. - Module 3 - Assignment 3 - MT NPBST 11 A1Document5 pagesMONLEON, REI JULIAN KYLE T. - Module 3 - Assignment 3 - MT NPBST 11 A1Christian Felix GuevarraNo ratings yet

- Heat Resistant Rust Preventive CoatingDocument2 pagesHeat Resistant Rust Preventive CoatingMar EngineerNo ratings yet

- Huawei DBS3900 Spare Parts CatalogueDocument102 pagesHuawei DBS3900 Spare Parts CatalogueKhalidox SolitaireNo ratings yet

- SM JCB 3CX 4CX 328739808-9803-3280-9 PDFDocument1,212 pagesSM JCB 3CX 4CX 328739808-9803-3280-9 PDFСергей Ганкевич97% (30)

- Oracle Apps Technical ConsultantDocument5 pagesOracle Apps Technical ConsultantRamesh Babu KadiyamNo ratings yet

- Polymer IntroDocument15 pagesPolymer IntroYUG PRATAP SINGHNo ratings yet

- CT VTDocument56 pagesCT VTRK K100% (1)

- Design Example For Beams With Web Openings: Ue ToDocument9 pagesDesign Example For Beams With Web Openings: Ue ToalbertoxinaNo ratings yet

- WPS GTAW pipe welding procedureDocument2 pagesWPS GTAW pipe welding procedureRichard PeriyanayagamNo ratings yet

- MB Manual Ga-f2a58m-Ds2h v.3.0 eDocument36 pagesMB Manual Ga-f2a58m-Ds2h v.3.0 eSAN100% (1)

- Gran Turismo 4 Complete Used Car CycleDocument745 pagesGran Turismo 4 Complete Used Car CycleMaicom Elio PereiraNo ratings yet

- GT-i8190 Galaxy S III Mini 08 Level 3 - Block-, PCB DiagramsDocument43 pagesGT-i8190 Galaxy S III Mini 08 Level 3 - Block-, PCB DiagramsJose GomezNo ratings yet

- ViewingDocument49 pagesViewingnishasaiyed2304No ratings yet

- Range UO - BD 049 Bulbs - 2017-08-26Document4 pagesRange UO - BD 049 Bulbs - 2017-08-26johnNo ratings yet

- Phu Luc - Huong Dan Cau Hinh VPN L2 B0404Document14 pagesPhu Luc - Huong Dan Cau Hinh VPN L2 B0404luisNo ratings yet

- Ficha Tecnica Ciac Hi Wall 60 HZ R-22Document1 pageFicha Tecnica Ciac Hi Wall 60 HZ R-22Eduardo GarcíaNo ratings yet

- SS TBC6Document3 pagesSS TBC6GERENCIA COMERCIALNo ratings yet

- CA VD4-R (EN) - CatalogDocument72 pagesCA VD4-R (EN) - Catalogdorin serbanNo ratings yet

- (CHEVROLET) Manual de Taller Chevrolet Sail 2010Document120 pages(CHEVROLET) Manual de Taller Chevrolet Sail 2010Nader Jimenez79% (14)

- Luxury 5-Bedroom Villa with Ocean Views in Sri LankaDocument3 pagesLuxury 5-Bedroom Villa with Ocean Views in Sri LankaMr. Firdaus NurulNo ratings yet

- Tandemloc Aj12a00Document2 pagesTandemloc Aj12a00baloo122No ratings yet

- Yi Smart LaMP-EnDocument3 pagesYi Smart LaMP-EnCiprian GeorgeNo ratings yet

- ENGSCI 442 Petroleum Engineering LecturesDocument77 pagesENGSCI 442 Petroleum Engineering LecturessereptNo ratings yet

- Multileaf Data VCDDocument4 pagesMultileaf Data VCDalexa_liviaNo ratings yet

- Flake Ice MachineDocument2 pagesFlake Ice MachineWisermenNo ratings yet

- Physics 486: "A Treatise On The Arc Length of Projectiles Under Natural Mechanical Influences"Document21 pagesPhysics 486: "A Treatise On The Arc Length of Projectiles Under Natural Mechanical Influences"Josh GoochNo ratings yet