Professional Documents

Culture Documents

Us2467764 PDF

Uploaded by

RodrigoPomaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Us2467764 PDF

Uploaded by

RodrigoPomaCopyright:

Available Formats

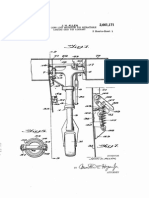

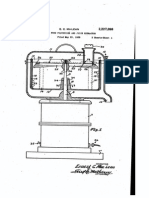

April 19, 1949. .

'

J, MARTIN

2,467,764

APPARATUS FOR TESTING ON THE GROUND EJECTION

SEATS INTENDED FOR USE IN AIRCRAFT

Filed April 9, 1946

7 Sheets-Sheet 1

Inventor

JAMES MART/N

per

Attorney.

April 19, 194.9;

2,467,764

,

J. MARTIN

APPARATUS FOR TESTING ON THE GROUND EJECTION

'SEATS INTENDED FOR USE IN AIRCRAFT

7 Sheets-Sheet 2

Filed April 9, 1946

p8)

JAMES MART/N

fg

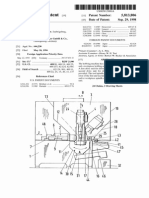

April 19, 1949-

J. MARTIN

APPARATUS FOR TESTING ON THE GROUND EJECTION

SEATS INTENDED FOR USE IN AIRCRAFT

Filed April 9, 1946

2,467,764

7 Sheets-Sheet 3

1/

4Vr14,

Inventor

_

JAMES MART/N

W ?

fg.

AZ army.

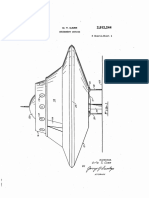

April 19, 1949.

-

J MARTIN

2,467,764 '

APPARATUS FOR TETING ON THE GROUND EJECTION

SEATS INTENDED FOR USE IN'AIRGRAFT

Filed April 9, 1946

7 Sheets-Sheet 4

Inventor '

JAMES MART/N

W

'

'

AZ orney,

April 19, 1949.

Y

J_ MARTIN

2,467,764

APPARATUS FOR TESTING ON THE GROUND EJECTION

SEATS INTENDED FOR USE IN AIRCRAFT

7 Sheets-Sheet 5

Filed April 9, 1946

Inventor

JAMES MART/N

per

1 Attorney.

Aprll 19, 1949.

J. MARTIN

2,467,764

APPARATUS FOR TESTING ON THE GROUND EJECTION

.

SEATS INTENDED FOR USE IN AIRCRAFT

7 Sheets-Sheet 6

Filed April . 9, 1946

Inventor

JAMES MART/N

per M

Attorney.

April 19, 1949.

J. MARTIN

2,467,764

APPARATUS FOR TESTING ON THE GROUND EJECTION

SEATS INTENDED FOR USE IN AIRCRAFT

Filed April 9, 1946

7 Shaets-Sheet_ '7

~45.

46

47

\-

'

\-__-

'

,' _

20

'

49

F'_./_

L10

J

_

Inventor

per

I

JAMES MART/N

"g

A Z?army

>

2,467,764

Patented Apr. 19, 1949

UNITED STATES PATENT OFFICE

2,467,764

APPARATUS FOR TESTING ON THE GROUND

EJECTION SEATS INTENDED FOR USE IN

AIRCRAFT

James Martin, Higher Denham, near Uxbridge,

England

Application April 9, 1946, Serial No. 660,816

In Great Britain February 18, 1946 I

- 5 Claims.

(Cl. 35-10)

The bogie is provided with a hook adapted to

The invention relates to the testing or making

of practical trials in connection with the launch

ing of personnel from aircraft in flight and is

intended to enable pilots or other personnel to

become familiar with the launching apparatus

engage with a shackle on the seat or other device

mounted on the testing rig and this shackle is

interconnected with one or more sprags which

engage with ratchet stops on the guides of the

testing rig so that whilst the weight of the seat

or other device is supported by the shackle, bogie

and winding gear, the sprags will be withdrawn

vention comprises a testing rig adapted to be set

from engagement with the ratchet teeth to en

up on an aerodrome or in a hangar or other suit

able building on which repeated tests or trials 10 able the seat to be lowered along the guides.

If however the hook should become disengaged

may be carried out either for testing the launch

or the winding gear should fail, then the sprags

ing apparatus or for rendering pilots or others

would automatically engage with the ratchet

familiar with the apparatus and its manner of

teeth and will support the seat or other device

use so as to give them con?dence in the effec

tlveness of the apparatus and to enable them to 15 so that it cannot fall or descend precipitately

down the guides thus providing an automatic

take full and quick advantage of the launching

safety

supporting means for the seat or other

apparatus should the need for its use arise when

device.

.

in ?ight in an aircraft ?tted with such ap

A practical embodiment of the invention will

paratus. The invention is particularly intended

now be described with reference to the attached

for use in connection with the launching appa

drawings in which:

ratus described in co-pending patent applica

and its method of use in a simple and safe man

ner on the ground. For this purpose the in

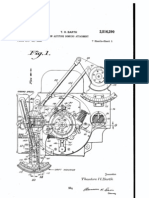

Fig. l is a side elevation of a suitable testing

tion Serial No. 638,762 ?led January 3, 1946.

rig of a type to which the present invention may

This invention comprises improvements in and

be applied.

_

additions to the'testing apparatus described and

claimed in the speci?cation ofco-pending patent 25 Fig. 2 is a front elevation of the testing rig

shown in Fig. 1.

_

application Serial No. 606,356 ?led July 21,

Fig. 3 is a front elevation of a bogie for slidably

1945, which comprises an apparatus for testing

mounting in the guides of the testing rig shown

on the ground, personnel ejection seats intended

in Figs. 1 and 2 and the shackle on the seat

for use in the launching of personnel from air

30

back

for engagement therewith.

craft, the apparatus comprising upwardly di

Fig. 4 is a part sectional side elevation on the

rected guides, a supporting frame for such guides,

centre line of Fig. 3.

a personnel seat slidably mounted in the guides,

Fig. 4A is a front elevation of the seat shackle.

and a winding gear for lowering the seat; how

ever it is necessary for the occupant of the seat

to manually fasten the winding gear to the seat.

The present invention has for its object to pro

vide means for lowering the seat after each test

and enables this to be done without the need for

any action by thev occupant of the seat and it

further enables tests to be made without any

human occupant in the seat. This invention

also provides for the automatic support of the

seat in the event of failure of the lowering ap

paratus or breakage of the supporting cable,

thus providing an additional means of preventing

an accident and ensuring the safety of those

engaged in making or observing the trials.

According to this invention the testing rig is

provided with a bogie mounted to slide in the

guides on the testing rig and suspended therein

by suitable winding gear-adapted to raise and

lower the bogie which is normally'located near

the top of the guides above the seat or other

device which is impelled upwardly along the

guides. forv testing or demonstration purposes.

Fig. 5 is a part sectional side elevation show

35 ing the sliding seat and the bogie mounted in

the testing rig in the relative positions they will

occupy just before the suspension hook on the

bogie engages with the shackle on the back of

the sliding seat.

Fig. 6 is an enlarged sectional detail of the

upper and lower portions of Fig. 5 but showing

the suspension .hook engaged with the seat

shackle.

Fig. 7 is a similar view to Fig. 6 but shows

45 the weight of the seat supported by the suspen

sion hook of the bogie and the sprags on the

seat disengaged from the ratchet teeth on the

guides of the testing rig, and

40

Fig. 8 is a cross section through the lower

50 part of the sliding seat and the testing rig guides.

Referring to the drawings Figs. 1 and 2 illus

trate the type of testing rig covered by co-pend

ing patent application Serial No. 606,356 ?led

July 21st, 1945, and to which is applied the em

bodiment of the present invention which is de

2,467,764

scribed hereafter by way of example. As de

scribed in my co-pending application Serial No.

606,356 the testing rig comprises a pair of chan

rig and extends downwardly to winding gear 21

located near the ground level and by which the

bogie 30 may be lowered and raised along the

nel section guides I mounted parallel to each

other and spaced apart a suitable distance by the

guides of the testing rig. The end of the cable

28 is anchored to the bolt 32 in the bracket 33

transverse V-shaped connecting members 2

whose inner face is covered by panels 3 of sheet

of the bogie 30. The bogie 30 which is shown in

greater detail in Figs. 3 and 4 is normally re

metal or other suitable material to form a re

tained near the top of the testing rig guides.

cessed space between them. These parallel

Supported in the bogie is a suspension hook 34

guides I are connected by pin joints 4 to the in 10 which is adapted to engage with a shackle 40

verted channel cross-bar 5 extending across the

on the top of the back of the seat 20, slidably

front corner of the triangular base made of

mounted in the testing rig guides. This suspen

channel steel girders 6. At the junction of each

sion hook 34 is pivoted at 35 to the ?tting 36 se

two girders 6, that is at each corner of the tri

cured in the frame of the bogie 30 and is spring

angular base, is provided an upright boss I in 15 loaded by the enclosed spring 31 to act as a latch

which is adjustably supported a pad 8 the base

for automatic engagement with the seat shackle

of which provides a substantial area to rest on

40. The suspension hook 34 is provided with

the ground. The shank to each pad 8 may be

a cross-bar or ?nger piece 38 for manual manipu

screw threaded into its boss 'I so as to constitute

lation through an opening 39 in the bogie frame.

a means of adjustment for levelling up the base 20

The seat shackle 40 is mounted on the top of

frame 6.

The upper ends of the guides I are

the seat back and is located in an upward ex

supported by a pair of tubular struts 9 pin jointed

to the guides I at I0 and extending downwardly

tension thereon. The shackle 40 is mounted

to provide limited sliding movement between it

and the tubular extension H of the seat back 20

and outwardly to pin joints I I near the rear cor

ners of the triangular frame 6. The triangulated

by means of the shank 42 which is connected to a

structure is stiifened by means of tubular mem

stop collar 43 slidable in the cap 44 on the exten

bers I2 pin jointed to brackets I3 on the guides

sion H. The shackle 42 is interconnected with

I and sleeves I4 on the struts 9. Further in

the spring loaded sprags 23 so that when the

clined tubes I5 and I6 are pin jointed at their

weight of the seat is supported by the suspension

upper ends to the brackets I3 and I4 and at their 80 hook 34 on the bogie 32 and the cable 28 and

lower ends to brackets I! on the base frame

winding gear 21 then the spring loaded sprags 23

channels 6.

will be withdrawn from engagement with the

The present invention is intended for testing

ratchet stops 22 provided along the testing rig

on the ground the launching gear intended for

guides Ia. For this purpose, the lower end of the

use in propelling a pilot and his seat from a high 35 shank 42 of the shackle 40 is connected to the end

speed ?ghter type of aeroplane and the seat and

propelling gear is represented diagrammatically

at 20 in Figs. 1 and 5. Examples of a suitable

launching gear are fully described in the speci

?cation and illustrated in the drawings of co 40

pending patent application Serial No. 638,762

?led January 3, 1946. The guides I are pro

vided with front and rear facing strips Ia which

overhang the inner edges of the guides I to form

channels to receive the rollers 2 I on the seat and

launching gear 20, see Fig. 8. The front facing

strip Ia is provided with a multiplicity of wedge

shaped stops 22 arranged to form a ratchet face

to the two guides I and spring actuated sprags

23 of the seat ride freely over the ratchet stops

22 when the seat is travelling upwardly along the

guides but engage with the ratchet stops 22 to

prevent the seat returning downwardly along the

guides I. The seat will thus be automatically

supported at the highest point to which it is pro

pelled by the launching apparatus. It is to be

understood that in the present testing apparatus

the seat is not actually ejected from the support

ing guides but always remains captive within the

limits of the guides, therefore, the present ap

paratus is merely for testing on the ground a

seat which is intended for later use in an air

of a lever 45 pivoted to the seat back extension 4!

and the outer end of which is connected to the

top of a push rod or tube 45, the lower end of

which is connected to a lever 41 on a cross-tube

or shaft 48 mounted in bearings 48 in the seat

frame 20 and carrying the sprags 23, see Figs.

5, 6, 7 and 8. A portion 50 of the push rod or

tube 46 is telescopic and is spring loaded by the

spring 5i so that the initial relative movement

" of the shackle 40 in its mounting in the tubular

extension M of the seat back 20 merely come

presses the spring 5] in the telescopic portion

50 of the push rod or tube 46 so that when the

seat has been slightly raised by operating the

winding gear, its weight will no longer rest on

the sprags 23 and the energy stored in the spring

5| compressed in the telescopic portion 50 of the

push rod or tube 46, will turn the shaft 48 car

rying the sprags 23 so as to disengage them from

the ratchet teeth 22. The amount of telescopic

movement between the parts of the push rod

or tube 46 is limited by suitable stops. A pair

of levers 52 on the cross-shaft 48 are each con

nected by enclosed springs 53 to brackets 54 on

the seat frame 20 and normally act to keep the

zrzirags 23 in engagement with the ratchet stops

craft. Located above the seat 20 is the bogie 30

In operation the bogie 3D is normally retained

which also slides in the guides Ia, suitable rollers

near the top of the guides of the testing rig.

3i thereon being provided to engage with the

The seat launching gear is brought into operguides for this purpose. The bogie 30 is of ap

ation to impel the seat 20 upwardly along the

proximately rectangular form consisting of a

guides I and when it has reached the top of its

suitable metal casting or pressing or a hollow

upward movement the sprags 23 will engage the

sheet metal structure with guide wheels 3| at 70 ratchet stops 22 and retain the seat 20 against

each side to engage with the guides Ia of the

downward movement. This position is illus

testing rig. The bogie is suspended from the

trated in Fig. 5. The winding gear 21 may now

cable 28 of the winding gear 21 and this cable

be operated from the ground to lower the bogie

28 passes round one or more pulleys supported

30 along the testing rig guides until the suspen

by the cross-bar 26 near the top of the testing

sion hook 34 snaps into engagement with the

2,467,764

shackle 40 on the seat back 20. This disposition

of the parts is illustrated in Fig. 6. The winding

in which said guides are provided with ratchet

stops and said seat is provided with sprags for

engagement with said ratchet stops.

gear 21 is now operated to slightly raise the bogie

4. Apparatus for testing, on the ground, an

30 and with it the seat 20. As soon as the weight

of the seat 20 is lifted from the sprags 23 the Ci ejection seat intended for use in launching per

sonnel from aircraft comprising upwardly di

rected guides, a supporting frame for the upward

ly directed guides, a bogie slidably mounted in

said guides, a seat slidably mounted below said

spring 5| compressed in the telescopic portion of

the push rod or tube 46 Will turn the sprags 23

away from and maintain them disengaged from

the ratchet stops 22 and the bogie 30 and seat

20 may be lowered by operating the winding gear

21 in the required manner. This may all be

_ bogie and within said guides, winding gear for

accomplished without requiring any co-operation

from the person in the seat or in fact without

any person in the seat if desired. The arrange

ment also provides a safeguard against accident I

due to breakage of the cable or faulty operation

of any part of the winding gear. When the

weight of the seat and any occupant is not sup

ported by the shackle 40 and 1cable 28, the spring

5| will extend the tube 46 to its maximum extent

and the springs 5| will not affect the sprags 23

which will be ?rmly urged toward the ratchet

stops 22.

I claim:

lowering and raising the bogie in the guides and

ratchet stops on said guides, sprags on said seat

for engagement with the ratchet stops, a suspen

sion hook on said bogie, a shackle on the seat

for engagement by the suspension hook on the

bogie and automatic-ally releasing means con

necting the shackle with the sprags.

5. A testing apparatus as recited in claim 4 in

which the automatic releasing means between

the shacle and the sprags comprises a spring

loaded telescopic connection between said shackle

and said sprags.

JAMES MARTIN.

1. Apparatus for testing, on the ground, an 25

ejection seat intended for use in launching per

REFERENCES CITED

The following references are of record in the

sonnel from aircraft comprising upwardly di

?le of this patent:

rected guides, a, supporting frame for the upward

1y directed guides, a bogie slidably mounted in said

UNITED STATES PATENTS

guides, a seat slidably mounted below said bogie )0 Number

Name

Date

and within said guides, winding gear for low

290,297

Weymouth ______ __ Dec. 18, 1883

ering and raising the bogie in the guides and

means on the bogie for automatically engaging

and connecting it to said seat.

2. A testing apparatus as recited in claim 1 35

in which the engaging and connecting means

comprises a resiliently mounted suspension hook

659,197

1,321,780

1,615,657

Allen ____________ __ Oct. 2, 1900

Anderson ________ __ Nov. 11, 1919

Schwafel ________ __ Jan. 25, 1927

2,357,293

Strong ____________ Sept. 5, 1944

2,376,886

Smith ___________ __ May 29, 1945

on said bogie and a shackle ?xed to said seat,

said hook engaging said shackle when the body

10 Number

is lowered into contact with said seat.

839,729

3. A testing apparatus as recited in claim 1

FOREIGN PATENTS

Country

Date

France ___________________ -..1939

You might also like

- Rig-E???': Gill!Document6 pagesRig-E???': Gill!luiscremaschiNo ratings yet

- L'il Wu" MM: Jan. 30, 1951 R, E - Ljungkull 2,539,545Document12 pagesL'il Wu" MM: Jan. 30, 1951 R, E - Ljungkull 2,539,545lfilippiniNo ratings yet

- Airman Knowledge Testing Supplement for Sport Pilot, Recreational Pilot, Remote Pilot, and Private Pilot (FAA-CT-8080-2H)From EverandAirman Knowledge Testing Supplement for Sport Pilot, Recreational Pilot, Remote Pilot, and Private Pilot (FAA-CT-8080-2H)Rating: 4 out of 5 stars4/5 (1)

- Illlllllllllilllllllllilllllllllli: United States Patent (191Document3 pagesIlllllllllllilllllllllilllllllllli: United States Patent (191dgfsduuwioNo ratings yet

- Us1955360 PDFDocument8 pagesUs1955360 PDFRodrigoPomaNo ratings yet

- United States Patent (191: Cél 296/97 /2/70g Primary Exammer - Margaret A. FocannoDocument7 pagesUnited States Patent (191: Cél 296/97 /2/70g Primary Exammer - Margaret A. FocannoDanister GladwinNo ratings yet

- Anti-Aircraft Fire Control Device (1937)Document10 pagesAnti-Aircraft Fire Control Device (1937)CAP History LibraryNo ratings yet

- Braiding MachineDocument7 pagesBraiding Machinejojaberi100% (1)

- United States "Patents PDFDocument17 pagesUnited States "Patents PDFTien Nguyen VanNo ratings yet

- Cheshire: Composing Room Machine Filed June 1927 3 Sheets-SheetDocument7 pagesCheshire: Composing Room Machine Filed June 1927 3 Sheets-SheetmephitNo ratings yet

- Aerial Tow Target (1943)Document4 pagesAerial Tow Target (1943)CAP History LibraryNo ratings yet

- Target Kite (1944)Document7 pagesTarget Kite (1944)CAP History LibraryNo ratings yet

- Aug-15, 1967 I P. R. Southall 3,336,042: Filed Aug. 17, 19.64 2 Sheets-Sheet 1Document4 pagesAug-15, 1967 I P. R. Southall 3,336,042: Filed Aug. 17, 19.64 2 Sheets-Sheet 1raseks1No ratings yet

- Hutchinson Mfg. Co. v. Mayrath, 192 F.2d 110, 10th Cir. (1951)Document6 pagesHutchinson Mfg. Co. v. Mayrath, 192 F.2d 110, 10th Cir. (1951)Scribd Government Docs100% (1)

- J. H. Wilson: Inventor.Document6 pagesJ. H. Wilson: Inventor.lfilippiniNo ratings yet

- Jose/0H Schu/Man.:, Sept-7, 1937 - J. Schulman 2,092,476Document3 pagesJose/0H Schu/Man.:, Sept-7, 1937 - J. Schulman 2,092,476akomocarNo ratings yet

- US2128620 - Bending MachineDocument5 pagesUS2128620 - Bending MachinedevheadbotNo ratings yet

- Us2765819 PDFDocument8 pagesUs2765819 PDFAzri LunduNo ratings yet

- 3/ Z7 VZMZM/ZZ : V. Holek 2,216,412Document3 pages3/ Z7 VZMZM/ZZ : V. Holek 2,216,412wererNo ratings yet

- Tow Target Cable Drag Mechanism (1941)Document4 pagesTow Target Cable Drag Mechanism (1941)CAP History LibraryNo ratings yet

- Us4036274 Safety Cage For InflationDocument5 pagesUs4036274 Safety Cage For InflationJimmy Cuevas MonsalveNo ratings yet

- Military Searchlight Truck (1937)Document8 pagesMilitary Searchlight Truck (1937)CAP History LibraryNo ratings yet

- United States Patent 1191Document13 pagesUnited States Patent 1191ddeeff715No ratings yet

- Nun M.: BC BM 0000Document12 pagesNun M.: BC BM 0000shdhsjkNo ratings yet

- Apron MechanismDocument7 pagesApron Mechanismgopalpaul0% (2)

- US2645344 AyamDocument6 pagesUS2645344 AyamOm FaNo ratings yet

- Us 4023499Document4 pagesUs 4023499ererNo ratings yet

- Pantente Primer DollyDocument6 pagesPantente Primer DollyJorge SotoNo ratings yet

- M © JG) - B) John Garlic/9r.: Sept-3, 1959 J. Gallo, SR 2,902,815Document3 pagesM © JG) - B) John Garlic/9r.: Sept-3, 1959 J. Gallo, SR 2,902,815James LindonNo ratings yet

- July 26, 1966 R. Mowatt-Larssen Etal 3,262,402 IDocument13 pagesJuly 26, 1966 R. Mowatt-Larssen Etal 3,262,402 IKrozeNo ratings yet

- Dec. 1, 1953 J. H. Allen: Filed Oct. 11, 1951Document8 pagesDec. 1, 1953 J. H. Allen: Filed Oct. 11, 1951Rezicky ImamNo ratings yet

- Wagner Iron Works v. Koehring Company, A Wisconsin Corporation, Wagner Iron Works v. Henry Manufacturing Company, Inc., 282 F.2d 317, 10th Cir. (1960)Document10 pagesWagner Iron Works v. Koehring Company, A Wisconsin Corporation, Wagner Iron Works v. Henry Manufacturing Company, Inc., 282 F.2d 317, 10th Cir. (1960)Scribd Government DocsNo ratings yet

- United States Patent (19) : Miiller (45) Date of PatentDocument8 pagesUnited States Patent (19) : Miiller (45) Date of PatentRodrigoPomaNo ratings yet

- 23mm", @722 GOZ067g: Automobile Side Bumper Filed Nov. 9. 1923Document3 pages23mm", @722 GOZ067g: Automobile Side Bumper Filed Nov. 9. 1923akomocarNo ratings yet

- United States Patent (19) : Brown (45) Date of PatentDocument9 pagesUnited States Patent (19) : Brown (45) Date of Patentapsint12No ratings yet

- Us 2912244Document9 pagesUs 2912244alexhkiNo ratings yet

- 1,138,232. Patented May 4, 1915,: 0, J, McgannDocument3 pages1,138,232. Patented May 4, 1915,: 0, J, McgannVyacheslavNo ratings yet

- Us1434007 PDFDocument5 pagesUs1434007 PDFsebastian escobarNo ratings yet

- Dec. 18, 1945. A. M. Carter 2,391,224 - .: Filed Aug. 10, 1944 3 Sheets-Sheet 1Document6 pagesDec. 18, 1945. A. M. Carter 2,391,224 - .: Filed Aug. 10, 1944 3 Sheets-Sheet 1varun mNo ratings yet

- Barth 1939 US2516290Document16 pagesBarth 1939 US2516290Dreamk990No ratings yet

- @341 A É'Wqkammm: Filed July 28-, 1944Document3 pages@341 A É'Wqkammm: Filed July 28-, 1944devheadbotNo ratings yet

- Us 4407085Document5 pagesUs 4407085rte678No ratings yet

- May 12, 1942-, 'J. D Spaldlng 2,282,615: Brake For DrawworksDocument10 pagesMay 12, 1942-, 'J. D Spaldlng 2,282,615: Brake For DrawworkslfilippiniNo ratings yet

- US4827759Document7 pagesUS4827759jonyNo ratings yet

- Post 6 38604 Reifgraber AutoDocument14 pagesPost 6 38604 Reifgraber AutoAoolf ManNo ratings yet

- RR PatentsDocument7 pagesRR PatentsAlan SmartNo ratings yet

- United States Patent: CarverDocument4 pagesUnited States Patent: CarverwewewewNo ratings yet

- Us1517483 PDFDocument10 pagesUs1517483 PDFJin SongNo ratings yet

- United States: (12) Patent Application Publication (10) Pub. No.: US 2014/0021016 A1Document14 pagesUnited States: (12) Patent Application Publication (10) Pub. No.: US 2014/0021016 A1Kalai SelvanNo ratings yet

- W, B. Kidder. : Tree Climbing MotorDocument4 pagesW, B. Kidder. : Tree Climbing Motormonem2014No ratings yet

- Tm. VC: May 13, 1969 E. F. CielaszykDocument3 pagesTm. VC: May 13, 1969 E. F. CielaszykjoycebaylonNo ratings yet

- LL-LLL'LL-FLL: 31, 1940. E. C. MmleanDocument7 pagesLL-LLL'LL-FLL: 31, 1940. E. C. MmleanKrozeNo ratings yet

- Oct. 19, 1943. W, E. Humphrey 2,331,931: / 61,4847, M M/MaaxDocument14 pagesOct. 19, 1943. W, E. Humphrey 2,331,931: / 61,4847, M M/MaaxAulia Haq AqobyNo ratings yet

- Us 4676137Document6 pagesUs 4676137fghdfjerNo ratings yet

- Ajuste QuiropraticoDocument5 pagesAjuste QuiropraticoCesar Odilon PereiraNo ratings yet

- Erection Procedure SCRDocument23 pagesErection Procedure SCRvskreddy90% (10)

- US4678202Document8 pagesUS4678202basarNo ratings yet

- 1 ChuquisacaDocument6 pages1 ChuquisacaRodrigoPomaNo ratings yet

- Nov. 25, v1941. J, R, Mcmahon Eral 2,264,048: Apparatus For Applying Protective Coatings T0 SuspendedDocument7 pagesNov. 25, v1941. J, R, Mcmahon Eral 2,264,048: Apparatus For Applying Protective Coatings T0 SuspendedRodrigoPomaNo ratings yet

- Diagrama Bases 1Document1 pageDiagrama Bases 1RodrigoPomaNo ratings yet

- Large Batch Hard Candy and LollipopsDocument2 pagesLarge Batch Hard Candy and LollipopsRodrigoPomaNo ratings yet

- LM 7805 RegulatorDocument12 pagesLM 7805 RegulatorFadel BairuniNo ratings yet

- Us 4106436Document10 pagesUs 4106436RodrigoPomaNo ratings yet

- United States Patent: Dreve, Jr. (45) May 16, 1972Document6 pagesUnited States Patent: Dreve, Jr. (45) May 16, 1972RodrigoPomaNo ratings yet

- WWW VMQ, I07: Feb. 12, 1963 v. C. BOWMANDocument6 pagesWWW VMQ, I07: Feb. 12, 1963 v. C. BOWMANRodrigoPomaNo ratings yet

- United States Patent: Dreve, Jr. (45) May 16, 1972Document6 pagesUnited States Patent: Dreve, Jr. (45) May 16, 1972RodrigoPomaNo ratings yet

- M. Schwafel: Derrick Safety CageDocument4 pagesM. Schwafel: Derrick Safety CageRodrigoPomaNo ratings yet

- Us 2296645Document4 pagesUs 2296645RodrigoPomaNo ratings yet

- Us1223254 PDFDocument7 pagesUs1223254 PDFRodrigoPomaNo ratings yet

- Us659197 PDFDocument3 pagesUs659197 PDFRodrigoPomaNo ratings yet

- June 16, 1964: C. R. Steele Disintegrator Having Downwardly Inclined Baffles Filed Nov. 17, 1960Document6 pagesJune 16, 1964: C. R. Steele Disintegrator Having Downwardly Inclined Baffles Filed Nov. 17, 1960RodrigoPomaNo ratings yet

- Datasheet UA741CPDocument19 pagesDatasheet UA741CPlcruz_86No ratings yet

- United States Patent (19) : Grote Et A1Document9 pagesUnited States Patent (19) : Grote Et A1RodrigoPomaNo ratings yet

- Us2678614 PDFDocument6 pagesUs2678614 PDFRodrigoPomaNo ratings yet

- United States Patent - (191: Mayeux Et AlDocument4 pagesUnited States Patent - (191: Mayeux Et AlRodrigoPomaNo ratings yet

- Us4589264 PDFDocument6 pagesUs4589264 PDFRodrigoPomaNo ratings yet

- Jan. 1, 1952 F, J, Uprighete 2,580,864: Ea 6-) "?? (0 JUPE/GHTDocument5 pagesJan. 1, 1952 F, J, Uprighete 2,580,864: Ea 6-) "?? (0 JUPE/GHTRodrigoPomaNo ratings yet

- United States Patent (19) : Miiller (45) Date of PatentDocument8 pagesUnited States Patent (19) : Miiller (45) Date of PatentRodrigoPomaNo ratings yet

- Cba The GPSDocument7 pagesCba The GPSRodrigoPomaNo ratings yet

- MikroDocument5 pagesMikroAmir Si KetengNo ratings yet

- Musical Intelligence: Let's Cut It Off! I Guess You Are Out of TuneDocument1 pageMusical Intelligence: Let's Cut It Off! I Guess You Are Out of TuneHenry GutierrezNo ratings yet

- MXTVXVW PDFDocument3 pagesMXTVXVW PDFRodrigoPomaNo ratings yet

- H. J. Smith: Potato Cutting Machine 28 Filed 00Document3 pagesH. J. Smith: Potato Cutting Machine 28 Filed 00RodrigoPomaNo ratings yet

- A9 PDFDocument25 pagesA9 PDFRodrigoPomaNo ratings yet

- Us116842 PDFDocument6 pagesUs116842 PDFRodrigoPomaNo ratings yet

- 2022 Course Catalog FAADocument20 pages2022 Course Catalog FAANerd Help.meNo ratings yet

- Tifco PDFDocument3 pagesTifco PDFsuna06m6403No ratings yet

- Final DWG ListDocument17 pagesFinal DWG ListCezary0% (1)

- Airfreight BrochureDocument16 pagesAirfreight BrochuredapdanielNo ratings yet

- Fluid QuestionDocument20 pagesFluid Questionsaini_sainiNo ratings yet

- Fluid Mechanics and Hydraulic MachinesDocument3 pagesFluid Mechanics and Hydraulic Machinesvp0209198860% (5)

- Wind EnergyDocument12 pagesWind EnergyManjunathNo ratings yet

- Rolling Threads DetailsDocument0 pagesRolling Threads DetailsfastenersworldNo ratings yet

- US4377052 - Paper PlaneDocument6 pagesUS4377052 - Paper PlaneZeljko LekovicNo ratings yet

- Reverse Seam Bowling ScienceDocument12 pagesReverse Seam Bowling ScienceRajvindRathiNo ratings yet

- KHD KHD: Ltcp/Adf Adiyaman, TurkeyDocument5 pagesKHD KHD: Ltcp/Adf Adiyaman, TurkeyYigit Omer CiftciNo ratings yet

- A350 Technical Training Manual T1+T2 Mechanical and Avionics A350 RR TRENT XWB Airframe (Level1)Document218 pagesA350 Technical Training Manual T1+T2 Mechanical and Avionics A350 RR TRENT XWB Airframe (Level1)Egor Rogulkin100% (2)

- Manevra Navei. Cautare Si SalvareDocument135 pagesManevra Navei. Cautare Si SalvareAndrei RadulescuNo ratings yet

- Antena 20mhz - 6ghzDocument6 pagesAntena 20mhz - 6ghzCris VMNo ratings yet

- Calculation of Eccentricities in Load Bearing Walls-Engineers File NoteDocument8 pagesCalculation of Eccentricities in Load Bearing Walls-Engineers File NoteMbleekNo ratings yet

- A Project Report On "Training and Development of HAL"Document60 pagesA Project Report On "Training and Development of HAL"snehaldoddamaniNo ratings yet

- 1Document2 pages1Dragoș Dragnea0% (1)

- Blower Technologies Loera 061712Document32 pagesBlower Technologies Loera 061712mahdiNo ratings yet

- Cessna Latitude SDDocument47 pagesCessna Latitude SDVincent Lefeuvre100% (1)

- Aero 483 - Space System DesignDocument2 pagesAero 483 - Space System DesignhmtuanbkNo ratings yet

- Space Tourism ProjectDocument72 pagesSpace Tourism Projectpheonix5100% (1)

- Beyond Type Certification A400m CQCDocument20 pagesBeyond Type Certification A400m CQCJDee DeskNo ratings yet

- Advel ChobertDocument8 pagesAdvel Chobertccorp0089No ratings yet

- Blast Load On StructuresDocument30 pagesBlast Load On StructuresrshyamsNo ratings yet

- Jeppview For Windows: List of Pages in This Trip KitDocument19 pagesJeppview For Windows: List of Pages in This Trip KitMiodi Meeow HauganNo ratings yet

- Camber (Aerodynamics) - Wikipedia, The Free EncyclopediaDocument3 pagesCamber (Aerodynamics) - Wikipedia, The Free EncyclopediaPallav AnandNo ratings yet

- Lecture 5 SPACE FRAMING PDFDocument109 pagesLecture 5 SPACE FRAMING PDFRaya VillafloresNo ratings yet

- The Nimble Lancair Legacy: Zu-FcyDocument4 pagesThe Nimble Lancair Legacy: Zu-Fcyaerogem618No ratings yet

- Cyanate Ester Resin5Document26 pagesCyanate Ester Resin5rkkumarcpriNo ratings yet

- Mechanism MechanicsDocument5 pagesMechanism MechanicsEzmel KazimNo ratings yet