Professional Documents

Culture Documents

Towards Sustainability of Protected Agriculture: Automatic Control and Structural Technologies Integration of An Intelligent Greenhouse

Towards Sustainability of Protected Agriculture: Automatic Control and Structural Technologies Integration of An Intelligent Greenhouse

Uploaded by

BACHIRI WahibaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Towards Sustainability of Protected Agriculture: Automatic Control and Structural Technologies Integration of An Intelligent Greenhouse

Towards Sustainability of Protected Agriculture: Automatic Control and Structural Technologies Integration of An Intelligent Greenhouse

Uploaded by

BACHIRI WahibaCopyright:

Available Formats

11th IFAC Workshop on Intelligent Manufacturing Systems ThFT2.

4

The International Federation of Automatic Control

May 22-24, 2013. São Paulo, Brazil

Towards Sustainability of Protected Agriculture:

Automatic Control and Structural Technologies Integration of an

Intelligent Greenhouse

Paul Cepeda. Pedro Ponce. Arturo Molina. Esther Lugo

Tecnológico de Monterrey Campus Ciudad de México

(e-mails: paul.cepeda.rode@gmail.com, pedro.ponce@itesm.mx,

armolina@itesm.mx, estherlg7705@yahoo.com.mx).

Abstract: Nowadays, protected agriculture has continually lagged because of the scarce and slow

technological advances and unskilled labor. The implementation of intelligent greenhouses to improve

the quality and quantity of crops allows a precise regulation of the environmental conditions inside the

greenhouse considering the lifecycle of the crop within the control rules. The main objective of the

present is to describe the stages of analysis, design and implementation of an intelligent greenhouse

developed in the Tecnológico de Monterrey Campus Ciudad de México. The focus of this is based on the

sustainable development approach considering a robust design that integrates reliable, simple, efficient,

ecologic and low cost materials and systems with the aim of achieving the automation and control of the

microenvironment. The reason of using artificial intelligence techniques over conventional methods,

resides in the fact that the greenhouse model is highly nonlinear at many operating points.

Keywords: Technological advances, intelligent greenhouses, precise regulation, environmental

conditions, sustainable development, low cost, automation, control, artificial intelligence, nonlinear.

1. INTRODUCTION

The greenhouse effect, proposed by Jean Baptiste Joseph

Fourier in 1824, comes from the old gardening glass

buildings, its meaning is linked to the overheating of the

planets surfaces due to atmospheres, Balas [2008]. Therefore,

in agreement with the greenhouse effect, a building designed

for the protection of growing plants (protected agriculture)

out of season against excessive cold or heat was called

greenhouse or glasshouse.

The greenhouse structure protects the crops from the rain and

wind allowing solar radiation passes through the walls

making possible the heat exchange with the exterior

environment.

By the middle of 19th century, all the techniques needed for

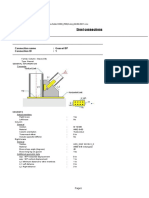

Fig. 1. Typical Diagram of an Automated Greenhouse

successful greenhouse gardening were developed; the

greenhouse went from being a mere refuge from a hostile Greenhouses provided with the appropriate equipment the

climate into a controlled environment, adapted to the needs of environmental conditions can be further improved by means

particular plants, Greenhouses [2011]. of climate and irrigation control, Javadikia et al. [2009].

These improvements have become in recent years a mean to

By the late 1970s, it was possible to build a small greenhouse achieve controlled production obtaining higher quality and

with automatic controls for less than one third the cost of a economic benefits, Trabelsi et al. [2007].

small car. Today a variety of greenhouses are available, many

of them built with glass or plastic enclosed framed structure Greenhouse technologies with controllable environments will

in modular form to permit easy expansion. Automated trigger the following achievements:

greenhouses, as shown in Fig. 1, are commonly used for the

production of fruits, vegetables, flowers and any other plants x To ensure production quality ± commercial objectives

that require special environmental conditions, Tiwari [2003]. by setting quality standards.

x To achieve highest productivity.

The control of climatic environment and irrigation systems in

x To control calendars of production ± manage the

greenhouses has received considerable attention in these last

years. The main purpose of a greenhouse is to improve the beginning and completion of production.

environmental conditions in which plants are grown. x To save energy ± low cost of operation.

978-3-902823-33-5/13/$20.00 © 2013 IFAC 366

In advanced greenhouse automation systems, the regulation 2.3 Greenhouse Materials

of indoor environment is focus on creating an appropriate

microclimate for the intensification of plant growth and The greenhouses design takes place in such a way that can be

reduction of the final cost, Kolokotsa et al. [2010]. The most YHULILHG WKDW LW GRHVQ¶W H[FHHG WKH ORDG OLPLWV DW DQ\ WLPH

relevant variables considered and controlled in a hydroponic This is determined according to the type of greenhouse and

automated greenhouse are: temperature, relative humidity, the materials used. For an intelligent greenhouse containing

light intensity, CO2 concentration and, electrical conductivity high value equipment and crops, they should not be designed

and pH of the nutrient solution in the irrigation system. for a lifecycle less than 10 years. To avoid structure damages,

The main problem that should be taken into account for the it should be considered the stress limits, which are associated

greenhouse control is the complex interactions between the with a structure collapse endangering human life, Muñoz et

inside and outside parameters. Conventional control systems al. [2013]. The ultimate limit states, which may require

are not suitable for this type of applications because a consideration, are: breakage, shakiness, fatigue, excessive

greenhouse model shows non-linear behavior on many tensions and deformations. The most commonly used

points, Fourati and Chtourou [2007]. It is not possible to materials for the structure, cladding and floor, FAO [2002],

achieve an accurate mathematical model reason why artificial Service [2012], are:

intelligence techniques DUH DSSOLHG 7KHVH WHFKQLTXHV GRQ¶W

need a mathematical model, Oduk and Allahverdi [2011]. Structure Materials: Galvanized Steel, maple Wood, low

One of the most significant difficulties faced by designers of carbon steel (AISI 1010), Aluminum Alloy (Aluminum

greenhouses is the construction of a structure that allows the 6061), high-strength low-alloy steel (HSLA 340).

correct regulation of the environmental conditions. The

structure, automation systems and control should be closely Cladding Materials: Low density polyethylene (PE), glass,

linked; if the structure or automation systems are not properly polyvinyl Chloride (PVC).

installed, the control strategy could be the best but it will

perform as the worst and vice versa. Floor Materials: The materials of greenhouses floor goes

from bare ground to concrete, but the cost and pollution they

The intelligent greenhouse of Tecnológico de Monterrey produced had led to look for others such as eco-materials.

Campus Ciudad de Mexico is a project framed within the

sustainability, understanding that in its design and 2.4 Greenhouse Locations

functionality it responds to social, economic and ecological

aspects, the key pillars of sustainable development. Any greenhouse should be located in places with the

adequate sunlight, adequate soil drainage, easy access for

2. GREENHOUSES: people and materials, access to utilities, and a pleasing blend

GENERAL OVERVIEW with the landscape. Other location considerations include

ensuring that location is even and that the soil drains well.

2.1 Greenhouse Basic Elements Low areas with poor air drainage should be avoided,

especially those surrounded by woods or buildings; cold and

A greenhouse is basically composed by the following basic humid air can remain and increase heating costs.

elements, University of Maryland [2013], AMCI [2008]:

Frame or structure: The principal consideration in selecting 2.5 Greenhouse Structural Loads

the frame is its load-bearing requirement. Each manufacturer

will specify the appropriate bow spacing depending on the The loads affecting the greenhouse structures critically are

strength of the tubing. permanent loads such as wind, snow, permanent or temporary

facilities, crop loads and concentrated vertical loads. The

Cladding: It is expected that the covering material allows biggest enemy of a greenhouse is the wind. Wind loads

heat storage to provide maximum energy savings by means of increase the tensile and shear stresses on covering films and

reducing heat loss. degrade them by abrasion and friction. In particular cases,

End walls: Provide more protection against wind and air sandstorms can be especially destructive, Grafiadellis [1999].

infiltration, and better insulation. The way the film is installed (e.g., with wire supports or

clipping) can also cause mechanical stress leading to the

Cooling and ventilation systems: Greenhouses need vent rupture of film, Briassoulis et al. [2004].

systems as passive ventilation for air exchange and in order

to equalize temperatures within the greenhouse. In case of 2.6 Eco-materials

poor airflows active ventilation is needed, such as exhaust

fans, to perform the same functions. Some of the materials used for building a greenhouse could

not be environment friendly due to their long period of

2.2 Greenhouse Structure Types degradation. Eco-materials appear to handle this situation;

these are the materials which give less environmental impact

The structure type selection is based on factors such as soil with high recyclability and efficient utilization of material.

type, topography, winds, bio-climatological requirements of

the crop, the climatic characteristics of the area, labor and The eco-materials can be classified into four main categories:

cost. Based on the above mentioned considerations, different nonlinear source materials, materials for ecology and

types of structures have been developed such as parral or environmental protection, materials for society and human

classic, post and rafter, asymmetrical, chapel, double chapel health, materials for energy. Some examples for eco-

and tunnel or semicircular, Pacheco [2006]. materials are showed in Table 1, Nowosielski [2007].

978-3-902823-33-5/13/$20.00 © 2013 IFAC 367

Table 1. Examples of Eco-materials Applications 4. INTELLIGENT GREENHOUSE:

PRODUCT DESIGN

Categories Examples

Eco-cement, coal ash concrete, The mechanical, electrical, electronic and control systems of

Recycled the intelligent greenhouse contemplate the physical structure,

marine block.

Wood based materials, ventilation, humidification, and hydroponic system. The

Renewable biodegradable plastic made of a sensors, actuators and a controller form the control loop for

vegetable base. regulating the variables which seeks to provide the adequate

Wear resistant metals and alloys, microclimate within the greenhouse. The material, the

Material for structure and the automation systems are selected, designed

pre-paint steels, corrosion resistant

efficiency and described below; the control is explained later.

steel and alloy

Biodegradable plastics, functionally 4.1 Materials Selection

Material for easy

graded material, colorbetos which

disposal or recycle

replaces asbestos. The selected material for the structure is galvanized steel.

Hazardous free Chromium-free steel, heavy metals This material is widely used in the construction of

materials free polyesters. greenhouses because of its mechanical properties of high

Materials for resistance to stress and ensures structural integrity for natural

Vibration damping steel sheet, disasters as high winds.

reducing human

sound proof panels.

health impacts The cladding chosen is treated plastic (polyethylene) with

Ultra-light steel, high magnetic UV II stabilizer 720 calibers because of its low cost,

Materials for

induction steel sheets, highly versatility, malleability, substantial mechanical properties and

energy efficiency

endothermic steel. it is a lightweight material, thus no heavy loads are generated

Selective transparent glass, highly on the greenhouse structure.

Materials for

durable sealing sheets for solar

green energy The hydroponic and water fogging system is mostly

batteries.

composed by PVC (polyvinyl chloride). Finally, the

Some combination of these eco-materials may serve for the greenhouse floor is pure concrete in order to provide stability

greenhouse structure, cladding and floor in future to the structure and not allow the growth of harmful plants

developments. inside the greenhouse.

3. INTELLIGENT GREENHOUSE: 4.2 Structural and Automation Systems Design

PRODUCT SPECIFICATIONS

In the development of greenhouses is essential to make a The physical structure designed is based on a modular

specifications list where the points of what designers expect architecture that allows easy assembly/disassembly and

at the end are exposed. The most relevant are described below: scalability with the aim of achieving a quick installation and

increase the surface if necessary.

Functionality: Maintain the optimal conditions for crops, The design of the structure has two side vents and a zenith

ability to operate in different places, rational use of energy, assisting air exchange and a passive temperature regulation; it

easy mounting and dismantling of the structure. is also considered two exhaust fans that will be started in case

Dimensions: Optimum height for proper ventilation, wide that the passive system could not respond to control needs.

and long enough for a proper distribution of crops, correct The intelligent greenhouse also features a shading system

curvature of the top (roof) to prevent condensation and with the intention of protecting the crop against solar

subsequent drip on crops causing the damages, enough radiation regulating the light intensity.

amount of space for production.

To adjust the relative humidity a water fogging system was

Automation: Correct instrumentation for the greenhouse selected. This system, besides increasing the humidity, also

operation; temperature, relative humidity, light intensity, helps regulating the temperature together with the ventilation

electrical conductivity and pH control. system; thermodynamically, increasing relative humidity the

Materials: Use of high resistance and noncorrosive materials, temperature decreases and vice versa.

implementation of low cost materials, shading mesh with UV The irrigation is based on a hydroponic technique called NFT

protection. (Nutrient Film Technique) which consists in recirculating a

Lifecycle and maintenance: Easy access to the components nutrient solution through the pipes feeding the crop. Attached

for maintenance, periodic equipment review to avoid failures, to the hydroponic system there is a nutrient supply system.

XVHU¶V PDQXDO GHYHORSPHQW This consists of three tanks that store the necessary solutions

for every stage of crop growth. The number of tanks varies

Cost: Cost reduction without affecting the greenhouse according to the requirements of nutrition stages of crop.

efficiency, use high-tech looking for an optimal relationship

between cost and benefit. The complete assembly of the intelligent greenhouse

including the above explained structure and automation

To meet the specifications, the design of the intelligent systems is shown in Fig. 2 in CAD (Computer Aided

greenhouse is composed by the integration of different Design). The shading and ventilation systems, humidification

technologies which are: modular structure, hydroponic and irrigation and, nutrient supply are driven by electric gear-

irrigation system, automation systems, and control strategies. motors, pumps and control valves, respectively.

978-3-902823-33-5/13/$20.00 © 2013 IFAC 368

activated by a power control module. This stage allows the

energy conduction through the single phase or three phase

lines as the case of the actuators.

The Green Tech Control and Supervisor is being developed

in stages, a first one, as already mentioned, only take into

account the weather conditions regulating variables such as

temperature and relative humidity; a second phase of

development of the Green Tech Control and Supervisor will

include an external module for handling irrigation systems, in

this case hydroponic.

The automatic control techniques were developed based on

the knowledge of skilled operators in greenhouses, reason

why it was not necessary to set the greenhouse model.

Linked to the intelligent control strategies that control the

climatic conditions within the greenhouse, the Green Tech

Control and Supervisor also ensures minimum energy

consumption and protects the entire greenhouse structure

against abrupt climate changes, specifically against rain and

wind. No matter what automatic control is selected or

running the controller is constantly checking for extreme

conditions which may affect the structure, these are:

x If the wind speed is equal or above the limit of strong

wind, for protection to the physical structure, the

controller will close all the vents.

x If the wind speed is strong, the controller checks the

wind direction in order to close only the affected

vents. This allows cooling of the greenhouse through

the non-exposed vents.

x Any finding of rain, the vents will close preventing

structural damages due to water accumulations or

floods inside the greenhouse.

Manual Control

This mode is used to control all the actuators movement

manually; this means that using the keyboard the user can

turn on/off the systems without any parameters or prior

programming.

Fig. 2. Intelligent Greenhouse ± CAD a. Assembly b. Structure c. Time Control

Vent System d. Exhaust Fan e. Shading Mesh System f. Water

Fogging System g. Hydroponics and Nutrient Supply System This control selection is in the automatic menu where the

controller will maintain or regulate the temperature reference

5. INTELLIGENT GREENHOUSE CONTROL that you assign. The time control name comes from the fact

The Tecnológico de Monterrey Campus Ciudad de México that the controller waits for a change in the temperature

developed a climate control module for greenhouses called ranges to make a decision of action.

Green Tech Control and Supervisor (patent). This controller There are three important set points for this control mode: a

has the task of managing and monitoring the weather desired temperature with a certain allowed band, a high

conditions inside the greenhouse, temperature and relative critical temperature and low critical temperature. If the

humidity, making decisions autonomously (without an temperature is in desired range, the actuators remain off; if

operator) of what to do considering the optimal conditions the temperature is out of the band without exceeding the high

programmed. These decisions are obtained from monitoring or low critical values, the actuators are started to meet the

the internal and external sensors. needs; if the temperature exceeded the critic levels, the

The control system provides a high degree of autonomy to actuators are activated as the case and also the alarm.

the greenhouse; it is only required that the user, operator or Decision Trees Control

farmer make occasional visits to check the levels of water

and nutrients in the storage tanks. The Green Tech Control Its operation is based on following a series of decisions

and Supervisor has four modes of operation which are preprogrammed based on the set points assigned by the user.

flexible and adaptable to the requirements of the end user, a This control strategy combines the readings received from the

manual control (user) and three automated. The autonomous sensors and depending on the references consigned the

decisions are taken based on three types of intelligent controller makes a decision from a decision network that

controllers: time control, decision tree and fuzzy logic. Once could trigger the actuators simultaneously.

the control decides the action to follow the actuators are

978-3-902823-33-5/13/$20.00 © 2013 IFAC 369

Fuzzy Logic Control Due to the mechanical features, durability, economy and

versatility of materials presented above, it was chosen

In this scheme, a PD (Proportional - Derivative) Takagi ± galvanized steel for the structure, polyethylene for the

Sugeno fuzzy control is implemented. This controller keeps cladding and PVC for hydroponics and the fog system.

the temperature inside the greenhouse at a programmed

reference by an intelligent activation of the actuators. The On the other hand, there is the Green Tech Control and

degree of activation depends on how far is the current to the Supervisor which is in charge of giving protection to the

desired temperature. This controller avoids sudden changes greenhouse structure and automation systems against extreme

with proportional openings. For example if the actual weather conditions such as strong winds, torrential rains, and

temperature barely exceeds the desired point, the vents will high temperatures, among others, without leaving aside its

rise slightly proportionally or when the temperature is main task, regulation of the micro-climate within the

excessive, the opening is total. greenhouse ensuring high production and crop quality.

The added value of the Green Tech Control and Supervisor is

6. RESULTS that it gathers different control techniques in order to satisfy

Greenhouses structures must meet the following conditions: the market needs, at this time four different modes. A special

lightweight and strong, economic material, easy to care, feature it offers is the possibility to be reprogrammed which

expandable, adaptable and modifiable to cover materials. In brings versatility to include new controllers. Table 4 brings a

this order, Table 2 and Table 3 present a brief comparison comparison between different control techniques which can

between greenhouse structure types and materials, respectively. be found in literature or in the market, including the current

methods. The comparison takes into account their complexity

Table 2. Greenhouse Structure Types Comparison and the need of a mathematical model to be designed.

Types Table 4. Controllers Type Comparison

1 2 3 4 5 6 7

Mathematical

Price Low Med. Med. Low Med. High High Controller Complexity

Model

Volume Low Med. High High High High Low Bang-bang No Low

Construct. Diff. Med. Med. Easy Med. Easy Diff. PID Yes Low

Ventilation Poor Good Exc. Good Exc. Good Exc. Auto-Tuning PID Yes Medium

Durability Low Med. Med. High High High High Time Control No Low

Zenith No Yes Yes Yes Yes Yes Yes Robust H2 Yes High

Model Predictive Yes High

Table 3. Greenhouse Structure Materials Comparison Decision Trees No Low

Structure Fuzzy Logic No Medium

Mechanical properties of high resistance to Neural Networks No High

GV

stresses. Ensures structural integrity against

Steel The three modes of automatic control of the Green Tech

climate and natural disasters as high speed winds.

Control and Supervisor GRQ¶W QHHG WR EH GHYHORSHG WKURXJK D

Low cost and versatility. Steel and wood structures mathematical model and its complexity goes from low to

Wood possess concrete foundation to ensure structural medium which demonstrate their simplicity. The proposed

integrity against natural disasters. methods can handle system nonlinearities. Finally, the

Mechanical properties very similar to those of following pictures demonstrate the completion of the project.

AISI

galvanized steel. It is cheaper and it has less

1010

environmental impact than galvanized steel.

ALU It is very light. Not used to build structures due to

M its poor resistance to stresses. It is advisable to use

6061 near places where food is produced.

It has mechanical properties that favor the

HSLA greenhouse structural integrity. It is used in some

340 tubes, bases and joints. Not suggested for use in

agricultural production areas. Low durability.

Cladding

Low cost. Resistant to extreme weather conditions,

PE molding ability and lightweight. Not readily

degradable so its use must be measured.

+LJK FRVW ,W LVQ¶W DV PDOOHDEOH DQG DGMXVWDEOH DV

Glass PE. It is heavier so the structure would be subject

to greater stresses. It is fragile.

The most economical and used choice. Widely

used due to its versatility, malleability and

PVC mechanical properties. It is lightweight so it

GRHVQ¶W JHQHUDWH ODUJH VWUHVVHV LQ WKH VWUXFWXUH 1RW

Fig. 3. Greenhouse and Automation Systems

environmentally friendly, slow to degrade.

978-3-902823-33-5/13/$20.00 © 2013 IFAC 370

REFERENCES

FAO. (2002). ³El Cultivo Protegido en Clima Mediterráneo´.

Retrieved from http://www.fao.org/DOCREP/005/S8630S/s8

630s00.htm#Contents

Balas, M.M.; Balas, V.E. (2008). ³0RGHOLQJ 3DVVLYH

Greenhouses. 7KH 6XQ V ,QIOXHQFH´ 2008 International

Conference on Intelligent Engineering Systems (INES),

pp.71-75, 25-29

Briassoulis, D.; Aristopoulou, A.; Bonora, M.; Verlodt, I.

(2004). Degradation Characterization of Agricultural Low-

density Polyethylene Films. Biosystems Engineering, 88, no.

2, pp. 131-143.

)RXUDWL ) &KWRXURX 0 ³$ *UHHQKRXVH &RQWURO ZLWK

Feed-IRUZDUG DQG 5HFXUUHQW 1HXUDO 1HWZRUNV ´

Simulation Modeling Practice and Theory, pp. 1016-1028

Grafiadellis, M. (1999). The Greenhouse Structures in

Mediterranean Regions - Problems and Trends. Cahiers

Options Mediterraneennes, 31, pp. 17-27

Fig. 4. Green Tech Control and Supervisor Greenhouse. (2011). In Encyclopaedia Britannica. Retrieved

from http://www.britannica.com/EBchecked/topic/24522

7. CONCLUSIONS /greenhouse

Protected agriculture has become very important in Javadikia, P.; Tabatabaeefar, A.; Omid, M.; Alimardani, R.;

agricultural industry, both local and national governments Fathi, M. (2009). ³(YDOXDWLRQ RI ,QWHOOLJHQW *UHHQKRXVH

Climate Control System Based Fuzzy Logic in Relation to

have increased the idea to build greenhouses to increase the

&RQYHQWLRQDO 6\VWHPV´ ,QWHUQDWLRQDO &RQference

production of fruits, vegetables, legumes and flowers. The on Artificial Intelligence and Computational Intelligence

private sector is the one that has captured the massive (AICI), pp. 146-150

construction of greenhouses in areas strategically productive Kolokotsa, D.; Saridakis, G.; Dalamagkidis, K.; Dolianitis, S.;

and also being the driving force behind its technification and .DOLDNDWVRV , ³'HYHORSPHQW RI DQ ,QWHOOLJHQW ,QGRRU

modernization. Today a greenhouse has at least lateral or Environment and Energy Management System for the

zenith ventilation with manual override. *UHHQKRXVHV´ (QHUJ\ &RQYHUVLRQ DQG 0DQDJHPHQW

pp. 155-168.

A product design methodology was followed from Muñoz, P.; Antón, A.; Montero, J. (2013). Tendencias en la

specifications until the construction of the functional Construcción de Invernaderos: normas CEN y UNE.

prototype of an intelligent greenhouse. The selection of the Sistemas de Control Ambiental y Posibilidades de

greenhouse materials was based on the so-called Mecanización de Operaciones de Cultivo y Riego.

conventional. These present strong mechanical properties but 1HOVRQ 3 9 ³*UHHQKRXVH 2SHUDWLRQ DQG 0DQDJHPHQW´

cost and pollution have led to seek others such as eco- 5ta Ed., Upper Saddle River, United States: Prentice Hall.

materials. An important thing to keep in mind is the strictly AMCI. (2008) Norma Mexicana para el Diseño y Construcción

connection between the structure, automation systems and de Invernaderos. (NMX-E-255-CNCP-2008). Retrieved from

control; if the structure or automation systems are not www.amci.org.mx

properly fitted the controlOHU ZRQ¶W have its best performance. Nowosielsky, R.; Kania, A.; Spilka, M. ³'HYHORSPHQW RI

Ecomaterials and Materials THFKQRORJLHV´ -RXUQDO RI

Having a climate control module, Green Tech Control and Achievements in Materials and Manufacturing Engineering.

Supervisor, regulating temperature and humidity with four Vol 21, issue 1.PP 27-30

different control modes, ensures a high quality crop; if also Oduk, 0 $OODKYHUGL 1 ³7KH $GYDQWDJHV RI )X]]\

controls the irrigation, production maximizes profits in terms Logic over Traditional Control System in Greenhouse

of time and economic retribution. The control modes allow a $XWRPDWLRQ´ ICGST AIML-11, Dubai.

smooth weather regulation without leaving aside the entire 3DFKHFR $ ´)XQGDPHQWRV Técnicos para el Diseño y

greenhouse protection against extreme weather conditions, Construcción de IQYHUQDGHURV´ Curso de producción de

increasing the materials durability. horWDOL]DV EDMR LQYHUQDGHURV´ )XQGDFLyQ SURGXFH 6LQDORD

A.C.

Finally, the level of technology will determine how excellent Service, W. V. (2012). Planning and Building a Greenhouse.

or poor the production will be; according to the climatic Retrieved from http://www.wvu.edu/~agexten/hortcult/

conditions of the greenhouse, suitable for crop growth, a greenhou/building.htm#Structural

better harvest and growth in less time will be achieved. Tecnológico de Monterrey Campus Ciudad de México. (2011).

³&RQWURODGRU &OLPiWLFR SDUD ,QYHUQDGHURV FRQ &RQWUROHV

The future work will be focus on creating a framework of $GDSWDEOHV \ 0RGXOR GH 3RWHQFLD ([WHUQD´ ([S

some of the ecological materials presented in this paper to MX/a/2011/009101, Folio: MX/e/2011/060799, 30 Agosto

show which of them, due to their mechanical properties, may 2011

be candidates for future greenhouse structures. On the other 7LZDUL * 1 ³*UHHQKRXVH 7HFKQRORJ\ IRU &RQWUROOHG

hand, improve the Green Tech Control and Supervisor with (QYLURQPHQW´ 3DQJERXUQH (QJODQG $OSKD 6FLHQFH

other control techniques merging artificial intelligence such Trabelsi, A.; Lafont, F.; Kamoun, M.; Enea, G. (2007). ³)X]]\

as fuzzy logic, neural networks and genetic algorithms, with ,GHQWLILFDWLRQ RI D *UHHQKRXVH´ $SSOLHG 6RIW

nonlinear control methods like sliding mode; and, finally, Computing, pp. 1092-1101

develop an irrigation and nutrient supply control as an 8QLYHUVLW\ RI 0DU\ODQG & ³*UHHQKRXVH FRQVWUXFWLRQ´

external module of the Green Tech Control and Supervisor. Greenhouse & Nursery Resource.

978-3-902823-33-5/13/$20.00 © 2013 IFAC 371

You might also like

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5813)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- 9.dimensionless Parameters in Free and Forced Convective Heat TransferDocument5 pages9.dimensionless Parameters in Free and Forced Convective Heat Transferkkk100% (2)

- 17-2 PT Indesso - NikenDocument4 pages17-2 PT Indesso - Nikenmonica deboraNo ratings yet

- Flooring: Sikafloor®-3240 A Versatile Flooring ProductDocument4 pagesFlooring: Sikafloor®-3240 A Versatile Flooring ProductGeorge EnescuNo ratings yet

- Con-Stab Id Seal Fittings: Gas Distribution Products ®Document7 pagesCon-Stab Id Seal Fittings: Gas Distribution Products ®Adam KnottNo ratings yet

- Hammer Unions Fig deDocument7 pagesHammer Unions Fig deSakthivel MurthyNo ratings yet

- As 1289.6.5.1-1999 Methods of Testing Soils For Engineering Purposes Soil Strength and Consolidation TestsDocument2 pagesAs 1289.6.5.1-1999 Methods of Testing Soils For Engineering Purposes Soil Strength and Consolidation TestsSAI Global - APACNo ratings yet

- Typical Civil BOQDocument11 pagesTypical Civil BOQMuhammad Wazim AkramNo ratings yet

- BOF Steelmaking ProcessDocument94 pagesBOF Steelmaking Processradynasr100% (1)

- Carbon Equivalent EquationDocument6 pagesCarbon Equivalent Equationrasnowmah2012No ratings yet

- Dens GlassDocument12 pagesDens GlassTavigno GonzalezNo ratings yet

- Structure of Bridge. No. 3Document1 pageStructure of Bridge. No. 3Ravpreet SinghNo ratings yet

- Steel Connections: Detailed ReportDocument7 pagesSteel Connections: Detailed Reportgv Sathishkumar KumarNo ratings yet

- PM4505 - P2 - Pot Ale Pump No.1Document2 pagesPM4505 - P2 - Pot Ale Pump No.1david_814279227No ratings yet

- Proposed Aquaculture Infrastructure Plumbing WorksDocument29 pagesProposed Aquaculture Infrastructure Plumbing WorksJysar ReubalNo ratings yet

- Pages From Concrete Tall BuildingsDocument1 pagePages From Concrete Tall BuildingsDan MaceNo ratings yet

- Factories and Machinery (Steam Boiler and Unfired Pressure Vessel) Regulations, 1970 Ve - Pua5 - 1970Document46 pagesFactories and Machinery (Steam Boiler and Unfired Pressure Vessel) Regulations, 1970 Ve - Pua5 - 1970Exsan OthmanNo ratings yet

- WP 003Document12 pagesWP 003Suthi Sae DanNo ratings yet

- F + 8 Mpa: C25/30 Means First, The Cylinder Strength of 25 N/MMDocument28 pagesF + 8 Mpa: C25/30 Means First, The Cylinder Strength of 25 N/MMMubin Al-ManafNo ratings yet

- American Wide Flange Steel Beams W Beam Letter PDFDocument7 pagesAmerican Wide Flange Steel Beams W Beam Letter PDFNathaniel Gutierez MangubatNo ratings yet

- Discussion For Shear Force and Bending MomentDocument2 pagesDiscussion For Shear Force and Bending MomentKang Lee76% (25)

- Gs-1300 Design and Construction of PipingDocument42 pagesGs-1300 Design and Construction of PipingGustavo Balarezo InumaNo ratings yet

- Pipe HangerDocument105 pagesPipe HangerYvan Nuñez EscobedoNo ratings yet

- Underpinning of Foundations: Foundation EngineeringDocument115 pagesUnderpinning of Foundations: Foundation EngineeringkKhalid Yousaf100% (1)

- Experiment 4 PDFDocument3 pagesExperiment 4 PDFKartik BhararaNo ratings yet

- ANSI PTC 19.3 TW Prefomance Test Code PDFDocument0 pagesANSI PTC 19.3 TW Prefomance Test Code PDFJairo Wilches0% (1)

- Etd 2mechDocument2 pagesEtd 2mechgsudhanta1604No ratings yet

- Ultramid BASF BrochureDocument68 pagesUltramid BASF BrochureLutfi ArdiansyahNo ratings yet

- Design Model For The Fatigue Behaviour of Normal-Strength, High-Strength and Ultra-High-Strength ConcreteDocument11 pagesDesign Model For The Fatigue Behaviour of Normal-Strength, High-Strength and Ultra-High-Strength Concreteming_zhu10No ratings yet

- Cuando Usar Slip CriticalDocument1 pageCuando Usar Slip CriticalJaime CoronellNo ratings yet

- Flow in Pipe: Characteristic LengthDocument9 pagesFlow in Pipe: Characteristic Lengthguapo93No ratings yet