Professional Documents

Culture Documents

Mcrf250: 125 KHZ Microid Passive Rfid Device With Anti-Collision

Uploaded by

Panagiotis PanagosOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Mcrf250: 125 KHZ Microid Passive Rfid Device With Anti-Collision

Uploaded by

Panagiotis PanagosCopyright:

Available Formats

MCRF250

125 kHz microID™ Passive RFID Device with Anti-Collision

Features Package Type

Factory programming and memory serialization PDIP/SOIC

VA 1 8 VB

(SQTPSM)

• Anti-collision feature to read multiple tags in the NC 2 7 NC

same RF field. I/O 3 6 VSS

• One-time contactless programmable (developer

Reset 4 5 VCC

kit only)

• Read-only data transmission after programming Note: Pins 3, 4, 5 and 6 are for device test purposes only.

Pins 1 and 8 are for antenna connection.

• 96 or 128 bits of One-Time Programmable (OTP)

user memory (also supports 48- and 64-bit

protocols) Description

• Typical operation frequency: 100 kHz-400 kHz The MCRF250 is equipped with an anti-collision

• Ultra low-power operation (5 µA @ VCC = 2V) feature that allows multiple tags in the same field to be

• Modulation options: read simultaneously. This revolutionary feature

- ASK, FSK, PSK eliminates the issue of data corruption due to

• Data Encoding options: simultaneous transmissions from multiple tags.

- NRZ Direct, Differential Biphase, Manchester The MCRF250 is a passive Radio Frequency Identifi-

Biphase cation (RFID) device for low frequency applications

• Die, wafer, COB or SOIC package options (100 kHz-400 kHz). The device is powered by

rectifying an incoming RF signal from a reader

• Factory programming options

interrogator. The device requires an external LC

resonant circuit to receive the incoming energizing

Applications signal and to send data. The device develops a

• Access control and time attendance sufficient DC voltage for operation when it’s external

coil voltage reaches approximately 10 VPP.

• Security systems

• Animal tagging This device has a total of 128 bits of user programma-

ble memory and an additional 12 bits in its configuration

• Product identification

register. The user can manually program the 128 bits of

• Industrial tagging user memory by using a contactless programmer in a

• Inventory control microID developer kit such as DV103001 or

• Multiple item tagging PG103001. However, in production volume the

MCRF250 is programmed at the factory (Microchip

RF SQTP - see Technical Bulletin TB023).The device is a

Signal

One-Time Programmable (OTP) integrated circuit and

Reader operates as a read-only device after programming.

MCRF250

Data

2003 Microchip Technology Inc. DS21267F-page 1

MCRF250

Block Diagram

Modulation and Data

Anti-Collision

Control

Clock

Generator Row Memory

Coil Decode Array

Connections Load

VCC

Rectifier

VSS

Counter Column

Decode

The configuration register includes options for commu-

nication protocol (ASK, FSK, PSK), data encoding

method, data rate and data length.These options are

specified by customer and are factory programmed

during production.

The device has a modulation transistor between the

two antenna connections (VA and VB). The modulation

transistor damps or undamps the coil voltage when it

sends data. The variation of coil voltage controlled by

the modulation transistor results in a perturbation of

voltage in reader antenna coil. By monitoring the

changes in reader coil voltage, the data transmitted

from the device can be reconstructed.

The device is available in die, wafer, Chip-on-Board

(COB) modules, PDIP or SOIC packages. Factory

programming and memory serialization (SQTP) are

also available upon request. See TB023 for more

information on contact programming support.

The DV103002 Developer’s Kit includes Contactless

Programmer, MCRF250 Anti-Collision FSK reference

reader, and reference design guide. The reference

design guide includes schematics for readers and

contactless programmer as well as in-depth

documentation for antenna circuit designs.

DS21267F-page 2 2003 Microchip Technology Inc.

MCRF250

1.0 ELECTRICAL CHARACTERISTICS

Absolute Maximum Ratings(†)

Storage temperature ..............................................................................................................................- 65°C to +150°C

Ambient temperature with power applied................................................................................................-40°C to +125°C

Maximum current into coil pads ..............................................................................................................................50 mA

† NOTICE: Stresses above those listed under "Absolute Maximum Ratings" may cause permanent damage to the

device. This is a stress rating only and functional operation of the device at those or any other conditions above those

indicated in the operation listings of this specification is not implied. Exposure to maximum rating conditions for

extended periods may affect device reliability.

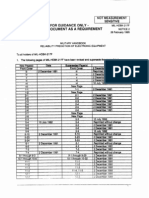

TABLE 1-1: AC AND DC CHARACTERISTICS

All parameters apply across the

specified operating ranges Industrial (I): TA = -40°C to +85°C

unless otherwise noted.

Parameter Sym Min Typ Max Units Conditions

Clock frequency FCLK 100 — 400 kHz

Contactless programming time TWC — 2 — sec For all 128-bit array

Data retention 200 — — Years at 25°C

Coil current (Dynamic) ICD — 50 µA

Operating current IDD — 5 µA VCC = 2V

Turn-on-voltage (Dynamic) for VAVB 10 — — VPP

modulation VCC 2 — — VDC

Input Capacitance CIN — 2 — pF Between VA and VB

2003 Microchip Technology Inc. DS21267F-page 3

MCRF250

2.0 FUNCTIONAL DESCRIPTION 2.1.3 CLOCK GENERATOR

The device contains three major building blocks. They This circuit generates a clock based on the carrier

are RF front-end, configuration and control logic, and frequency from the reader. This clock is used to derive

memory sections. The Block Diagram is shown on all timing in the device, including the baud rate and

page 1. modulation rate.

2.1.4 IRQ DETECTOR

2.1 RF Front-End

This circuitry detects an interrupt in the continuous

The RF front-end of the device includes circuits for electromagnetic field of the interrogator. An IRQ

rectification of the carrier, VDD (operating voltage), and (interrupt request) is defined as the absence of the

high-voltage clamping to prevent excessive voltage electromagnetic field for a specific number of clock

from being applied to the device. This section also cycles. Detection of an IRQ will trigger the device to

generates a system clock from the incoming carrier enter the Anti-collision mode. This mode is discussed

signal and modulates the carrier signal to transmit data in detail in Section 5.0 “Anti-Collision”.

to the reader.

2.1.5 MODULATION CIRCUIT

2.1.1 RECTIFIER – AC CLAMP

The device sends the encoded data to the reader by

The rectifier circuit rectifies RF voltage on the external AM-modulating the coil voltage across the tuned LC

LC antenna circuit. Any excessive voltage on the tuned circuit. A modulation transistor is placed between the

circuit is clamped by the internal circuitry to a safe level two antenna coil pads (VA and VB). The transistor turns

to prevent damage to the IC. on and off based on the modulation signal. As a result,

the amplitude of the antenna coil voltage varies with the

2.1.2 POWER-ON RESET modulation signal. See Figure 2-1 for details.

This circuit generates a Power-on Reset when the tag

first enters the reader field. The Reset releases when

sufficient power has developed on the VDD regulator to

allow correct operation.

FIGURE 2-1: MODULATION SIGNAL AND MODULATED SIGNAL

MCRF250

VA Modulation

Signal

L C

Modulation

Transistor

VB

Amplitude

Modulation Signal

Modulated RF Signal t

(across VA and VB)

DS21267F-page 4 2003 Microchip Technology Inc.

MCRF250

2.2 Configuration Register and 2.2.3 MODULATION OPTION

Control Logic CB8 and CB9 determine the modulation protocol of the

encoded data. The available choices are:

The configuration register determines the operational

parameters of the device. The configuration register • ASK

can not be programmed contactlessly; it is • FSK

programmed during wafer probe at the Microchip fac- • PSK_1

tory. CB11 is always a one; CB12 is set when success-

• PSK_2

ful contact or contactless programming of the data

array has been completed. Once CB12 is set, device When ASK (direct) option is chosen, the encoded data

programming and erasing is disabled. Table 2-1 is fed into the modulation transistor without change.

contains a description of the bit functions of the control When FSK option is chosen, the encoded data is

register. represented by:

2.2.1 BAUD RATE TIMING OPTION a) Sets of 10 RF carrier cycles (first 5 cycles →

higher amplitude, the last 5 cycles → lower

The chip will access data at a baud rate determined by amplitude) for logic “high” level.

bits CB2, CB3, and CB4 of the configuration register.

b) Sets of 8 RF carrier cycles (first 4 cycles →

For example, MOD32 (CB2 = 0, CB3 = 1, CB4 = 1) has

higher amplitude, the last 4 cycles → lower

32 RF cycles per bit. This gives the data rate of 4 kHz

amplitude) for logic “low” level.

for the RF carrier frequency of 128 kHz.

For example, FSK signal for MOD40 is represented:

The default timing is MOD 128 (FCLK/128), and this

mode is used for contact and contactless program- a) 4 sets of 10 RF carrier cycles for data ‘1’.

ming. Once the array is successfully programmed, the b) 5 sets of 8 RF carrier cycles for data ‘0’.

lock bit CB12 is set. When the lock bit is set, program- Refer to Figure 2-2 for the FSK signal with MOD40

ming and erasing the device becomes permanently option.

disabled. The configuration register has no effect on

device timing until the EEPROM data array is The PSK_1 represents change in the phase of the

programmed (CB12 = 1). modulation signal at the change of the encoded data.

For example, the phase changes when the encoded

2.2.2 DATA ENCODING OPTION data is changed from ‘1’ to ‘0’, or from ‘0’ to ‘1’.

This logic acts upon the serial data being read from the The PSK_2 represents change in the phase at the

EEPROM. The logic encodes the data according to the change on ‘1’. For example, the phase changes when

configuration bits CB6 and CB7. CB6 and CB7 the encoded data is changed from ‘0’ to ‘1’, or from ‘1’

determine the data encoding method. The available to ‘1’.

choices are:

• Non-return to zero-level (NRZ_L)

• Biphase_S (Differential)

• Biphase_L (Manchester)

• Inverted Manchester

FIGURE 2-2: ENCODED DATA AND FSK OUTPUT SIGNAL FOR MOD40 OPTION

Encoded Data ‘1’ Encoded Data ‘0’

5 cycles (HI) 4 cycles (HI)

5 cycles (LO) 4 cycles (LO)

40 RF cycles 40 RF cycles

2003 Microchip Technology Inc. DS21267F-page 5

MCRF250

FIGURE 2-3: PSK DATA MODULATION

‘1’ ‘0’ ‘0’ ‘1’ ‘1’

Encoded Data

(NRZ_L)

PSK_ 1

PP PP Change on Data

PP

P PP PSK _2

Change on ‘1’

P PP

2.2.4 MEMORY ARRAY LOCK BIT (CB12) 2.4 Examples of Configuration

The CB12 must be ‘0’ for contactless programming Settings

(Blank). The bit (CB12) is automatically set to ‘1’ itself

as soon as the device is programmed contactlessly. EXAMPLE 2-1: “48D” CONFIGURATION

The “48D” (hex) configuration is interpreted as

2.3 Memory Section follows:

The device has 128 bits of one-time programmable CB12 CB1

(OTP) memory. The user can choose 96 or 128 bits by “48D” → 0100-1000-1101

selecting the CB1 bit in the configuration register. See

Table 2-1 for more details. Referring to Table 2-1, the “48D” configuration

represents:

2.3.1 COLUMN AND ROW DECODER

LOGIC AND BIT COUNTER Blank (not programmed) Device

Anti-Collision

The column and row decoders address the EEPROM Modulation = PSK_1

array at the clock rate and generate a serial data PSK rate = rf/2

stream for modulation. This data stream can be up to Data encoding = NRZ_L (direct)

128 bits in length. The size of the data stream is user Baud rate = rf/32 = MOD32

programmable with CB1 and can be set to 96 or 128 Memory size: 128 bits

bits. Data lengths of 48 and 64 bits are available by

programming the data twice in the array, end-to-end.

The column and row decoders route the proper voltage EXAMPLE 2-2: “40A” CONFIGURATION

to the array for programming and reading. In the The “40A” (hex) configuration is interpreted as

programming modes, each individual bit is addressed follows:

serially from bit 1 to bit 128. CB12 CB1

“40A” → 0100-0000-1010

The MSB corresponds to CB12 and the LSB

corresponds to CB1 of the configuration register.

Therefore, we have:

CB12=0 CB11=1 CB10=0 CB9=0

CB8=0 CB7=0 CB6=0 CB5=0

CB4=1 CB3=0 CB2=1 CB1=0

Referring to Table 2-1, the “40A” configuration

represents:

Not programmed device (blank), anticollision,

FSK protocol, NRZ_L (direct) encoding, MOD50

(baud rate = rf/50), 96 bits.

Note: The sample cards in the DV103002 kit

are configured to “40A”.

DS21267F-page 6 2003 Microchip Technology Inc.

MCRF250

TABLE 2-1: CONFIGURATION REGISTER

CB12 CB11 CB10 CB9 CB8 CB7 CB6 CB5 CB4 CB3 CB2 CB1

MEMORY SIZE

CB1 = 1 128-bit user memory array

CB1 = 0 96-bit user memory array

BAUD RATE

CB2 CB3 CB4 Rate

0 0 0 MOD128

0 0 1 MOD100

0 1 0 MOD80

0 1 1 MOD32

1 0 0 MOD64

1 0 1 MOD50

1 1 0 MOD40

1 1 1 MOD16

SYNC WORD

CB5 = 0 (Always)

DATA ENCODING

CB6 = 0; CB7 = 0 NRZ_L (Direct)

CB6 = 0; CB7 = 1 Biphase_S (Differential)

CB6 = 1; CB7 = 0 Biphase_L (Manchester)

CB6 = 1; CB7 = 1 (Inverted Manchester)

MODULATION OPTIONS

CB8 = 0; CB9 = 0 FSK 0 = Fc/8, 1 = Fc/10

CB8 = 0; CB9 = 1 Direct (ASK)

CB8 = 1; CB9 = 0 PSK_1

(phase change on change of data)

CB8 = 1; CB9 = 1 PSK_2

(phase change at beginning of a one)

PSK RATE OPTION

CB10 = 1 Carrier/4

CB10 = 0 Carrier/2

(ANTI-COLLISION OPTION (Read only)

CB11 = 1 (Always)

MEMORY ARRAY LOCK BIT (Read only)

CB12 = 0 User memory array not locked (Blank)

CB12 = 1 User memory array is locked

(Programmed)

2003 Microchip Technology Inc. DS21267F-page 7

MCRF250

3.0 MODES OF OPERATION 3.2 Read Mode

The device has two basic modes of operation: Native After the device is programmed (CB12 = 1), the device

Mode and Read Mode. is operated in the Read-only mode. The device

transmits its data according to the protocol in the

3.1 Native Mode configuration register.

Every unprogrammed blank device (CB12 = 0)

operates in Native mode, regardless of configuration

register settings:

Baud rate = FCLK/128, FSK, NRZ_L (direct)

Once the user memory is programmed, the lock bit is

set (CB12 = 1) which causes the MCRF250 to switch

from Native mode to Communication mode defined by

the configuration register.

Refer to Figure 4-1 for contactless programming

sequence. Also see the microID™ 125 kHz RFID

System Design Guide (DS51115) for more information.

FIGURE 3-1: TYPICAL APPLICATION CIRCUIT

IAC 390 pF Input capacitance: 2 pF

From 4.05 mH

RF Signal

Reader

125 kHz

Pad VA

L

Pad VB

To Reader

MCRF250

amplifier/filter Data

C

1

f res = ------------------- = 125 kHz

2π LC

DS21267F-page 8 2003 Microchip Technology Inc.

MCRF250

4.0 CONTACTLESS

PROGRAMMING

The contactless programming of the device is possible

for a blank device (CB12 = 0) only, and is

recommended for only low-volume, manual operation

during development. In volume production, the

MCRF250 is normally used as a factory programmed

device only. The contactless programming timing

sequence consists of:

a) RF Power-up signal.

b) Short gap (absence of RF field).

c) Verify signal (continuous RF signal).

d) Programming signal.

e) Device response with programmed data.

The blank device (CB12 = 0) understands the RF

power-up followed by a gap as a blank checking

command, and outputs 128 bits of FSK data with all ‘1’s

after the short gap. To see this blank data (verify), the

reader/programmer must provide a continuous RF

signal for 128 bit-time. (The blank (unprogrammed)

device has all ‘F’s in its memory array. Therefore, the

blank data should be all ‘1’s in FSK format). Since the

blank device operates at Default mode (MOD128),

there are 128 RF cycles for each bit. Therefore, the

time requirement to complete this verify is 128 bits x

128 RF cycles/bit x 8 use/cycles = 131.1 msec for

125 kHz signal.

As soon as the device completes the verify, it enters the

programming mode. The reader/programmer must

provide RF programming data right after the verify. In

this programming mode, each bit lasts for 128 RF

cycles. Refer to Figure 4-1 for the contactless

programming sequence.

Customer must provide the following specific voltage

for the programming:

1. Power-up and verify signal = 13.5 VPP ±1 VPP

2. Programming voltage:

- To program bit to ‘1’: 13.5 VPP ±1 VPP

- To program bit to ‘0’: 30 VPP ±2 VPP

After the programming cycle, the device outputs

programmed data (response). The reader/programmer

can send the programming data repeatedly after the

device response until the programming is successfully

completed. The device locks the CB12 as soon as the

programming mode (out of field) is exited and becomes

a read-only device.

Once the device is programmed (CB12 = 1), the device

outputs its data according to the configuration register.

The PG103001 (Contactless Programmer) is used for

the programming of the device. The voltage level

shown in Figure 4-1 is adjusted by R5 and R7 in the

contactless programmer. Refer to the MicroID™

125 kHz RFID System Design Guide (DS51115) for

more information.

2003 Microchip Technology Inc. DS21267F-page 9

Contactless Programming Protocol

f = 125 kHz

t = 8 µs

FIGURE 4-1:

DS21267F-page 10

POWER-UP GAP

MCRF250

VERIFY PROGRAM

FSK Signal

Bit 1 Bit 2 Bit 3…

Low-Power High-Power

Signal Signal

13.5 ±1 VPP

80 - 180 µs ~ 50 - 100 µs

CONTACTLESS PROGRAMMING SEQUENCE

13.5 ± 1 VPP 30 ± 2 VPP

128 bits x 128 cycles/bit x 8 µs/cycle = 131.1 ms

13.5 ± 1 VPP (R5) (R7)

(R5) 0V

128 bits

1 bit = 128 cycles x 8 µs/cycle = 1.024 ms

∆t = Guard Band

Default programming protocol = FSK, Fc/8/10, 128 bits

For 96-bit programming, bits 33-64 are ‘don’t care’, but all Note: Low-power signal: leaves bit = 1

128-bit cycles must be in the sequence. High-power signal: programs bit = 0

2003 Microchip Technology Inc.

MCRF250

5.0 ANTI-COLLISION FIGURE 5-1: ANTI-COLLISION

FLOWCHART

The anti-collision feature is enabled after the array lock

bit (CB12) is set. This feature relies on internal random

number oscillator/counter and special gap pulses

(= turn off RF field) provided by a reader. Figure 5-1 Begin

shows the anti-collision flowchart.

The MCRF250 works with the following anti-collision

features:

1. The device does not output data until it sees the Provide Gap*

first gap. (no RF field for about 60 µsec.)

2. When the device sees the first gap, the internal

random number oscillator starts clocking

immediately after the gap.

3. At the same time, the internal random number Wait 5-bit times

counter starts counting the random number

clocks.

4. The device waits for 5 bit times (about 5 msec.

for MOD128 configuration). Is

modulation No

Example: 1 bit time=RF/128=1 msec for 128 kHz present?

for MOD128

5. After the 5 bit times, the device sends data. Yes

6. At this time, the random number counter is still Is

running. If multiple tags in the field send data at only one tag No

the same time, the reader will see a data modulating?

collision.

7. When the reader sees the data collision, it sends Yes

the second gap pulse. (no RF field for about

60 µsec.)

8. After the second gap pulse, there is a chance Read Tag

that the random number counter of each tag

may have a different value due to a random

variation in the oscillator’s starting time, etc.

Provide gap in the

9. After the second gap, the random number first half of the first

oscillator stops and the random number counter bit time to make

will decrement at each subsequent gap. tag stop

10. The device will transmit data when its random transmitting

number counter reaches ‘0’.

11. The device repeats this sequence (as shown in

the flowchart in Figure 5-1) according to the Note: *Gap = lack of RF carrier signal

proper gap pulses provided by the reader. = 60 µs ± 20%.

Note: Each device will output data in

different time frames since each

random number counter will arrive at

‘0’ at different times. As a result, the

reader can receive clean data from a

different tag in each time frame.

2003 Microchip Technology Inc. DS21267F-page 11

MCRF250

6.0 MECHANICAL TABLE 6-1: PAD COORDINATES (µm)

SPECIFICATIONS FOR DIE Passivation

AND WAFER Openings

Pad Pad

FIGURE 6-1: DIE PLOT Pad Pad Pad

Center Center

Device Test Only Name Width Height

X Y

VA 90.0 90.0 427.50 -734.17

Vss Vcc Reset I/O

VB 90.0 90.0 -408.60 -734.17

Note 1: All coordinates are referenced from the

center of the die.

2: Die size: 1.1215 mm x 1.7384 mm.

44.15 mils x 68.44 mils

TABLE 6-2: PAD FUNCTION TABLE

Name Function

VA

Antenna Coil connections

VB

VSS

VCC For device test only

Reset Do Not Connect to Antenna

I/O

VB VA

DS21267F-page 12 2003 Microchip Technology Inc.

MCRF250

TABLE 6-3: DIE MECHANICAL DIMENSIONS

Specifications Min Typ Max Unit Comments

Bond pad opening — 3.5 x 3.5 — mil Note 1, Note 2

— 89 x 89 — µm

Die backgrind thickness — 7 — mil Sawed 6” wafer on frame

— 177.8 — µm (option = WF) Note 3

— 11 — mil Unsawed wafer

— 279.4 — µm (option = W) Note 3

Die backgrind thickness tolerance — — ±1 mil

— — ±25.4 µm

Die passivation thickness (multilayer) — 0.9050 — µm Note 4

Die Size:

Die size X*Y before saw (step size) — 44.15 x 68.44 — mil —

Die size X*Y after saw — 42.58 x 66.87 — mil —

Note 1: The bond pad size is that of the passivation opening. The metal overlaps the bond pad passivation by at

least 0.1 mil.

2: Metal Pad Composition is 98.5% Aluminum with 1% Si and 0.5% Cu.

3: As the die thickness decreases, susceptibility to cracking increases. It is recommended that the die be as

thick as the application will allow..

4: The Die Passivation thickness can vary by device depending on the mask set used:

-Layer 1: Oxide (undopped oxide, 0.135 µm)

-Layer 2: PSG (dopped oxide, 0.43 µm)

-Layer 3: Oxynitride (top layer, 0.34 µm)

5: The conversion rate is 25.4 µm/mil.

Notice: Extreme care is urged in the handling and assembly of die products since they are susceptible to

mechanical and electrostatic damage.

TABLE 6-4: WAFER MECHANICAL SPECIFICATIONS

Specifications Min Typ Max Unit Comments

Wafer Diameter — 8 — inch 150 mm

Die separation line width — 80 — µm

Dice per wafer — 14,000 — die

Batch size — 24 — wafer

2003 Microchip Technology Inc. DS21267F-page 13

MCRF250

7.0 FAILED DIE IDENTIFICATION 9.0 NOTICE ON DIE AND WAFER

Every die on the wafer is electrically tested according HANDLING

to the data sheet specifications and visually inspected The device is very susceptible to Electrostatic

to detect any mechanical damage such as mechanical Discharge (ESD). ESD can cause critical damage to

cracks and scratches. the device. Special attention is needed during the

Any failed die in the test or visual inspection is identified handling process.

by black colored inking. Therefore, any die covered Any ultraviolet (UV) light can erase the memory cell

with black ink should not be used. contents of an unpackaged device. Fluorescent lights

The ink dot specification: and sun light can also erase the memory cell although

it takes more time than UV lamps. Therefore, keep any

• Ink dot size: minimum 20 µm x 20 µm

unpackaged devices out of UV light and also avoid

• Position: central third of die direct exposure from strong fluorescent lights and sun

• Color: black light.

Certain integrated circuit (IC) manufacturing, chip-on-

8.0 WAFER DELIVERY board (COB) and tag assembly operations may use UV

DOCUMENTATION light. Operations such as backgrind, de-tape, certain

cleaning operations, epoxy or glue cure should be done

Each wafer container is marked with the following without exposing the die surface to UV light.

information:

Using x-ray for die inspection will not harm the die, nor

• Microchip Technology Inc. MP Code erase memory cell contents.

• Lot Number

• Total number of wafer in the container

• Total number of good dice in the container

• Average die per wafer (DPW)

• Scribe number of wafer with number of good dice.

DS21267F-page 14 2003 Microchip Technology Inc.

MCRF250

10.0 PACKAGING INFORMATION

10.1 Package Marking Information

8-Lead PDIP (300 mil) Example:

XXXXXXXX MCRF250

XXXXXNNN XXXXXNNN

YYWW 0025

8-Lead SOIC (150 mil) Example:

XXXXXXXX MCRF250

XXXXYYWW XXX0025

NNN NNN

Legend: XX...X Customer specific information*

Y Year code (last digit of calendar year)

YY Year code (last 2 digits of calendar year)

WW Week code (week of January 1 is week ‘01’)

NNN Alphanumeric traceability code

Note: In the event the full Microchip part number cannot be marked on one line, it will

be carried over to the next line thus limiting the number of available characters

for customer specific information.

* Standard device marking consists of Microchip part number, year code, week code, and traceability

code.

2003 Microchip Technology Inc. DS21267F-page 15

MCRF250

8-Lead Plastic Dual In-line (P) – 300 mil (PDIP)

E1

n 1

A A2

L

c

A1

β B1

p

eB B

UNITS INCHES* MILLIMETERS

DIMENSION LIMITS MIN NOM MAX MIN NOM MAX

Number of Pins n 8 8

Pitch p .100 2.54

Top to Seating Plane A .140 .155 .170 3.56 3.94 4.32

Molded Package Thickness A2 .115 .130 .145 2.92 3.30 3.68

Base to Seating Plane A1 .015 0.38

Shoulder to Shoulder Width E .300 .313 .325 7.62 7.94 8.26

Molded Package Width E1 .240 .250 .260 6.10 6.35 6.60

Overall Length D .360 .373 .385 9.14 9.46 9.78

Tip to Seating Plane L .125 .130 .135 3.18 3.30 3.43

Lead Thickness c .008 .012 .015 0.20 0.29 0.38

Upper Lead Width B1 .045 .058 .070 1.14 1.46 1.78

Lower Lead Width B .014 .018 .022 0.36 0.46 0.56

Overall Row Spacing § eB .310 .370 .430 7.87 9.40 10.92

Mold Draft Angle Top α 5 10 15 5 10 15

Mold Draft Angle Bottom β 5 10 15 5 10 15

* Controlling Parameter

§ Significant Characteristic

Notes:

Dimensions D and E1 do not include mold flash or protrusions. Mold flash or protrusions shall not exceed

.010” (0.254mm) per side.

JEDEC Equivalent: MS-001

Drawing No. C04-018

DS21267F-page 16 2003 Microchip Technology Inc.

MCRF250

8-Lead Plastic Small Outline (SN) – Narrow, 150 mil (SOIC)

E1

D

2

B n 1

h α

45°

c

A A2

φ

β L A1

UNITS INCHES* MILLIMETERS

DIMENSION LIMITS MIN NOM MAX MIN NOM MAX

Number of Pins n 8 8

Pitch p .050 1.27

Overall Height A .053 .061 .069 1.35 1.55 1.75

Molded Package Thickness A2 .052 .056 .061 1.32 1.42 1.55

Standoff § A1 .004 .007 .010 .10 .18 .25

Overall Width E .228 .237 .244 5.79 6.02 6.20

Molded Package Width E1 .146 .154 .157 3.71 3.91 3.99

Overall Length D .189 .193 .197 4.80 4.90 5.00

Chamfer Distance h .010 .015 .020 .25 .38 .51

Foot Length L .019 .025 .030 .48 .62 .76

Foot Angle φ 0 4 8 0 4 8

Lead Thickness c .008 .009 .010 .20 .23 .25

Lead Width B .013 .017 .020 .33 .42 .51

Mold Draft Angle Top α 0 12 15 0 12 15

Mold Draft Angle Bottom β 0 12 15 0 12 15

* Controlling Parameter

§ Significant Characteristic

Notes:

Dimensions D and E1 do not include mold flash or protrusions. Mold flash or protrusions shall not exceed

.010” (0.254mm) per side.

JEDEC Equivalent: MS-012

Drawing No. C04-057

2003 Microchip Technology Inc. DS21267F-page 17

MCRF250

1M/3M COB (IOA2)

MCRF250 COB

5 mm

Antenna Coil Connection

8 mm

Thickness = 0.4 mm

DS21267F-page 18 2003 Microchip Technology Inc.

MCRF250

ON-LINE SUPPORT SYSTEMS INFORMATION AND

Microchip provides on-line support on the Microchip UPGRADE HOT LINE

World Wide Web site. The Systems Information and Upgrade Line provides

The web site is used by Microchip as a means to make system users a listing of the latest versions of all of

files and information easily available to customers. To Microchip's development systems software products.

view the site, the user must have access to the Internet Plus, this line provides information on how customers

and a web browser, such as Netscape® or Microsoft® can receive the most current upgrade kits. The Hot Line

Internet Explorer. Files are also available for FTP Numbers are:

download from our FTP site. 1-800-755-2345 for U.S. and most of Canada, and

1-480-792-7302 for the rest of the world.

Connecting to the Microchip Internet

Web Site 042003

The Microchip web site is available at the following

URL:

www.microchip.com

The file transfer site is available by using an FTP

service to connect to:

ftp://ftp.microchip.com

The web site and file transfer site provide a variety of

services. Users may download files for the latest

Development Tools, Data Sheets, Application Notes,

User's Guides, Articles and Sample Programs. A

variety of Microchip specific business information is

also available, including listings of Microchip sales

offices, distributors and factory representatives. Other

data available for consideration is:

• Latest Microchip Press Releases

• Technical Support Section with Frequently Asked

Questions

• Design Tips

• Device Errata

• Job Postings

• Microchip Consultant Program Member Listing

• Links to other useful web sites related to

Microchip Products

• Conferences for products, Development Systems,

technical information and more

• Listing of seminars and events

2003 Microchip Technology Inc. DS21267F-page 19

MCRF250

READER RESPONSE

It is our intention to provide you with the best documentation possible to ensure successful use of your Microchip prod-

uct. If you wish to provide your comments on organization, clarity, subject matter, and ways in which our documentation

can better serve you, please FAX your comments to the Technical Publications Manager at (480) 792-4150.

Please list the following information, and use this outline to provide us with your comments about this document.

To: Technical Publications Manager Total Pages Sent ________

RE: Reader Response

From: Name

Company

Address

City / State / ZIP / Country

Telephone: (_______) _________ - _________ FAX: (______) _________ - _________

Application (optional):

Would you like a reply? Y N

Device: MCRF250 Literature Number: DS21267F

Questions:

1. What are the best features of this document?

2. How does this document meet your hardware and software development needs?

3. Do you find the organization of this document easy to follow? If not, why?

4. What additions to the document do you think would enhance the structure and subject?

5. What deletions from the document could be made without affecting the overall usefulness?

6. Is there any incorrect or misleading information (what and where)?

7. How would you improve this document?

DS21267F-page 20 2003 Microchip Technology Inc.

MCRF250

PRODUCT IDENTIFICATION SYSTEM

To order or obtain information, e.g., on pricing or delivery, refer to the factory or the listed sales office.

PART NO. -X /XXX XXX Examples:

Device Temperature Package Configuration/SQTP Code a) MCRF250-I/W40A = 125 kHz, industrial

Range temperature, wafer package, contactlessly

programmable, 96 bit, FSK Fc/8 Fc/10,

direct encoded, Fc/50 data return rate tag.

Device: MCRF250 = 125 kHz Anticollision MicroID tag, 96/128-bit b) MCRF250-I/WFQ23 = 125 kHz, industrial

temperature, wafer sawn and mounted on

frame, factory programmed.

Temperature Range: I = -40°C to +85°C

The configuration register is:

CB12 CB11 CB10 CB9 CB8 CB7 CB6 CB5 CB4 CB3 CB2 CB1

Package: WF = Sawed wafer on frame (7 mil backgrind) 0 1 0 0 0 0 0 0 1 0 1 0

W = Wafer (11 mil backgrind)

S = Dice in waffle pack

P = Plastic PDIP (300 mil Body) 8-lead

SN = Plastic SOIC (150 mil Body) 8-lead

Configuration: Three-digit hex value to be programmed into the configura-

tion register. Three hex characters correspond to 12 binary

bits. These bits are programmed into the configuration

register MSB first (CB12, CB11...CB1). Refer to example.

SQTP Code: An assigned, customer 3-digit code used for tracking and

controlling production and customer data files for factory

programming. In this case the configuration code is not

shown in the part number, but is captured in the SQTP

documention.

Sales and Support

Data Sheets

Products supported by a preliminary Data Sheet may have an errata sheet describing minor operational differences and recom-

mended workarounds. To determine if an errata sheet exists for a particular device, please contact one of the following:

1. Your local Microchip sales office

2. The Microchip Corporate Literature Center U.S. FAX: (480) 792-7277

3. The Microchip Worldwide Site (www.microchip.com)

Please specify which device, revision of silicon and Data Sheet (include Literature #) you are using.

New Customer Notification System

Register on our web site (www.microchip.com/cn) to receive the most current information on our products.

2003 Microchip Technology Inc. DS21267F-page21

MCRF250

NOTES:

DS21267F-page22 2003 Microchip Technology Inc.

Note the following details of the code protection feature on Microchip devices:

• Microchip products meet the specification contained in their particular Microchip Data Sheet.

• Microchip believes that its family of products is one of the most secure families of its kind on the market today, when used in the

intended manner and under normal conditions.

• There are dishonest and possibly illegal methods used to breach the code protection feature. All of these methods, to our

knowledge, require using the Microchip products in a manner outside the operating specifications contained in Microchip's Data

Sheets. Most likely, the person doing so is engaged in theft of intellectual property.

• Microchip is willing to work with the customer who is concerned about the integrity of their code.

• Neither Microchip nor any other semiconductor manufacturer can guarantee the security of their code. Code protection does not

mean that we are guaranteeing the product as “unbreakable.”

Code protection is constantly evolving. We at Microchip are committed to continuously improving the code protection features of our

products. Attempts to break microchip’s code protection feature may be a violation of the Digital Millennium Copyright Act. If such acts

allow unauthorized access to your software or other copyrighted work, you may have a right to sue for relief under that Act.

Information contained in this publication regarding device Trademarks

applications and the like is intended through suggestion only

The Microchip name and logo, the Microchip logo, Accuron,

and may be superseded by updates. It is your responsibility to

dsPIC, KEELOQ, MPLAB, PIC, PICmicro, PICSTART,

ensure that your application meets with your specifications.

PRO MATE and PowerSmart are registered trademarks of

No representation or warranty is given and no liability is

Microchip Technology Incorporated in the U.S.A. and other

assumed by Microchip Technology Incorporated with respect

countries.

to the accuracy or use of such information, or infringement of

patents or other intellectual property rights arising from such AmpLab, FilterLab, microID, MXDEV, MXLAB, PICMASTER,

use or otherwise. Use of Microchip’s products as critical com- SEEVAL, SmartShunt and The Embedded Control Solutions

ponents in life support systems is not authorized except with Company are registered trademarks of Microchip Technology

express written approval by Microchip. No licenses are con- Incorporated in the U.S.A.

veyed, implicitly or otherwise, under any intellectual property Application Maestro, dsPICDEM, dsPICDEM.net,

rights. dsPICworks, ECAN, ECONOMONITOR, FanSense,

FlexROM, fuzzyLAB, In-Circuit Serial Programming, ICSP,

ICEPIC, microPort, Migratable Memory, MPASM, MPLIB,

MPLINK, MPSIM, PICkit, PICDEM, PICDEM.net, PICtail,

PowerCal, PowerInfo, PowerMate, PowerTool, rfLAB, rfPIC,

Select Mode, SmartSensor, SmartTel and Total Endurance

are trademarks of Microchip Technology Incorporated in the

U.S.A. and other countries.

Serialized Quick Turn Programming (SQTP) is a service mark

of Microchip Technology Incorporated in the U.S.A.

All other trademarks mentioned herein are property of their

respective companies.

© 2003, Microchip Technology Incorporated, Printed in the

U.S.A., All Rights Reserved.

Printed on recycled paper.

Microchip received ISO/TS-16949:2002 quality system certification for

its worldwide headquarters, design and wafer fabrication facilities in

Chandler and Tempe, Arizona and Mountain View, California in October

2003 . The Company’s quality system processes and procedures are

for its PICmicro® 8-bit MCUs, KEELOQ® code hopping devices, Serial

EEPROMs, microperipherals, non-volatile memory and analog

products. In addition, Microchip’s quality system for the design and

manufacture of development systems is ISO 9001:2000 certified.

2003 Microchip Technology Inc. DS21267F-page 23

WORLDWIDE SALES AND SERVICE

AMERICAS ASIA/PACIFIC Korea

168-1, Youngbo Bldg. 3 Floor

Corporate Office Australia

Samsung-Dong, Kangnam-Ku

2355 West Chandler Blvd. Suite 22, 41 Rawson Street

Seoul, Korea 135-882

Chandler, AZ 85224-6199 Epping 2121, NSW

Tel: 82-2-554-7200 Fax: 82-2-558-5932 or

Tel: 480-792-7200 Australia

82-2-558-5934

Fax: 480-792-7277 Tel: 61-2-9868-6733

Technical Support: 480-792-7627 Fax: 61-2-9868-6755 Singapore

Web Address: http://www.microchip.com 200 Middle Road

China - Beijing

#07-02 Prime Centre

Atlanta Unit 706B

Singapore, 188980

3780 Mansell Road, Suite 130 Wan Tai Bei Hai Bldg.

Tel: 65-6334-8870 Fax: 65-6334-8850

Alpharetta, GA 30022 No. 6 Chaoyangmen Bei Str.

Beijing, 100027, China Taiwan

Tel: 770-640-0034

Tel: 86-10-85282100 Kaohsiung Branch

Fax: 770-640-0307

Fax: 86-10-85282104 30F - 1 No. 8

Boston Min Chuan 2nd Road

China - Chengdu

2 Lan Drive, Suite 120 Kaohsiung 806, Taiwan

Westford, MA 01886 Rm. 2401-2402, 24th Floor, Tel: 886-7-536-4818

Tel: 978-692-3848 Ming Xing Financial Tower Fax: 886-7-536-4803

Fax: 978-692-3821 No. 88 TIDU Street

Chengdu 610016, China Taiwan

Chicago Tel: 86-28-86766200 Taiwan Branch

333 Pierce Road, Suite 180 Fax: 86-28-86766599 11F-3, No. 207

Itasca, IL 60143 Tung Hua North Road

China - Fuzhou Taipei, 105, Taiwan

Tel: 630-285-0071

Unit 28F, World Trade Plaza Tel: 886-2-2717-7175 Fax: 886-2-2545-0139

Fax: 630-285-0075

No. 71 Wusi Road

Dallas Fuzhou 350001, China EUROPE

4570 Westgrove Drive, Suite 160 Tel: 86-591-7503506

Austria

Addison, TX 75001 Fax: 86-591-7503521

Tel: 972-818-7423 Durisolstrasse 2

China - Hong Kong SAR A-4600 Wels

Fax: 972-818-2924 Unit 901-6, Tower 2, Metroplaza Austria

Detroit 223 Hing Fong Road Tel: 43-7242-2244-399

Tri-Atria Office Building Kwai Fong, N.T., Hong Kong Fax: 43-7242-2244-393

32255 Northwestern Highway, Suite 190 Tel: 852-2401-1200 Denmark

Farmington Hills, MI 48334 Fax: 852-2401-3431 Regus Business Centre

Tel: 248-538-2250 China - Shanghai Lautrup hoj 1-3

Fax: 248-538-2260 Room 701, Bldg. B Ballerup DK-2750 Denmark

Kokomo Far East International Plaza Tel: 45-4420-9895 Fax: 45-4420-9910

2767 S. Albright Road No. 317 Xian Xia Road France

Kokomo, IN 46902 Shanghai, 200051 Parc d’Activite du Moulin de Massy

Tel: 765-864-8360 Tel: 86-21-6275-5700 43 Rue du Saule Trapu

Fax: 765-864-8387 Fax: 86-21-6275-5060 Batiment A - ler Etage

China - Shenzhen 91300 Massy, France

Los Angeles

Rm. 1812, 18/F, Building A, United Plaza Tel: 33-1-69-53-63-20

18201 Von Karman, Suite 1090 No. 5022 Binhe Road, Futian District Fax: 33-1-69-30-90-79

Irvine, CA 92612 Shenzhen 518033, China

Tel: 949-263-1888 Germany

Tel: 86-755-82901380 Steinheilstrasse 10

Fax: 949-263-1338 Fax: 86-755-8295-1393 D-85737 Ismaning, Germany

Phoenix China - Shunde Tel: 49-89-627-144-0

2355 West Chandler Blvd. Room 401, Hongjian Building Fax: 49-89-627-144-44

Chandler, AZ 85224-6199 No. 2 Fengxiangnan Road, Ronggui Town Italy

Tel: 480-792-7966 Shunde City, Guangdong 528303, China Via Quasimodo, 12

Fax: 480-792-4338 Tel: 86-765-8395507 Fax: 86-765-8395571 20025 Legnano (MI)

San Jose China - Qingdao Milan, Italy

1300 Terra Bella Avenue Rm. B505A, Fullhope Plaza, Tel: 39-0331-742611

Mountain View, CA 94043 No. 12 Hong Kong Central Rd. Fax: 39-0331-466781

Tel: 650-215-1444 Qingdao 266071, China Netherlands

Tel: 86-532-5027355 Fax: 86-532-5027205 P. A. De Biesbosch 14

Toronto

India NL-5152 SC Drunen, Netherlands

6285 Northam Drive, Suite 108

Divyasree Chambers Tel: 31-416-690399

Mississauga, Ontario L4V 1X5, Canada

1 Floor, Wing A (A3/A4) Fax: 31-416-690340

Tel: 905-673-0699

Fax: 905-673-6509 No. 11, O’Shaugnessey Road United Kingdom

Bangalore, 560 025, India 505 Eskdale Road

Tel: 91-80-2290061 Fax: 91-80-2290062 Winnersh Triangle

Japan Wokingham

Benex S-1 6F Berkshire, England RG41 5TU

3-18-20, Shinyokohama Tel: 44-118-921-5869

Kohoku-Ku, Yokohama-shi Fax: 44-118-921-5820

Kanagawa, 222-0033, Japan

Tel: 81-45-471- 6166 Fax: 81-45-471-6122 11/24/03

DS21267F-page 24 2003 Microchip Technology Inc.

You might also like

- Embedded system battery life calculatorDocument60 pagesEmbedded system battery life calculatorCyphFalconNo ratings yet

- MCP79410/MCP79411/MCP79412: I C™ Real-Time Clock/Calendar With EEPROM, SRAM, Unique ID and Battery SwitchoverDocument38 pagesMCP79410/MCP79411/MCP79412: I C™ Real-Time Clock/Calendar With EEPROM, SRAM, Unique ID and Battery SwitchoverDaniel CortelettiNo ratings yet

- Bus Serial EEPROMDocument12 pagesBus Serial EEPROMMatiasNo ratings yet

- 24AA52/24LCS52: 2K 2.2V I C Serial EEPROM With Software Write-ProtectDocument24 pages24AA52/24LCS52: 2K 2.2V I C Serial EEPROM With Software Write-Protecta4rfanNo ratings yet

- 93C66Document12 pages93C66Alex AlvarezNo ratings yet

- CMT2156A Datasheet-EN-V1.3-20210824-LDocument23 pagesCMT2156A Datasheet-EN-V1.3-20210824-LMichel GrigautNo ratings yet

- 24C320-EP MicrochipTechnologyDocument12 pages24C320-EP MicrochipTechnologyMateus CorrêaNo ratings yet

- 2K 5.0V Automotive Temperature Microwire Serial EEPROM: Features Package TypeDocument12 pages2K 5.0V Automotive Temperature Microwire Serial EEPROM: Features Package TypeDanielNo ratings yet

- 25AA640/25LC640/25C640: 64K Spi Bus Serial EEPROMDocument11 pages25AA640/25LC640/25C640: 64K Spi Bus Serial EEPROMAndrey OliveiraNo ratings yet

- 8K/16K 5.0V Microwire Serial EEPROM: Features: Package TypesDocument20 pages8K/16K 5.0V Microwire Serial EEPROM: Features: Package Typesfarhood ranjbarkhanghahNo ratings yet

- 24AA64/24LC64/24FC64: 64K I C™ Serial EEPROMDocument45 pages24AA64/24LC64/24FC64: 64K I C™ Serial EEPROMJuan Carlos CrespoNo ratings yet

- Infrared Encoder/Decoder: Features Package TypesDocument34 pagesInfrared Encoder/Decoder: Features Package TypesmmunzvilNo ratings yet

- Micrf114: Low-Power Integrated Sub-Ghz Wireless RF TransmitterDocument34 pagesMicrf114: Low-Power Integrated Sub-Ghz Wireless RF TransmitterAnselmo LimaNo ratings yet

- Spansion S25FL256S - 32MB SPI FlashromDocument149 pagesSpansion S25FL256S - 32MB SPI FlashromcockNo ratings yet

- MSP430F22x2 Automotive Mixed-Signal Microcontrollers: 1 FeaturesDocument78 pagesMSP430F22x2 Automotive Mixed-Signal Microcontrollers: 1 FeaturesMiljenko PolićNo ratings yet

- DS89C430 DS89C450Document46 pagesDS89C430 DS89C450sivanathanbNo ratings yet

- Mc9s08de60 V2 0 9 2007Document408 pagesMc9s08de60 V2 0 9 2007LuchazoNo ratings yet

- MCP 79410Document34 pagesMCP 79410Krishna SinghNo ratings yet

- 32K 5.0V I C Smart Serial EEPROM: Features Package TypesDocument12 pages32K 5.0V I C Smart Serial EEPROM: Features Package TypesRamon LopezNo ratings yet

- Spc570s40e1, Spc570s40e3, Spc570s50e1, Spc570s50e3Document75 pagesSpc570s40e1, Spc570s40e3, Spc570s50e1, Spc570s50e3Dan danNo ratings yet

- 25CSM04 4 Mbit SPI Serial EEPROM With 128 Bit Seri-2944121Document56 pages25CSM04 4 Mbit SPI Serial EEPROM With 128 Bit Seri-2944121ManunoghiNo ratings yet

- Infineon S70GL02GS 2Gbit256Mbytes3 0V Flash Memory-3363879Document25 pagesInfineon S70GL02GS 2Gbit256Mbytes3 0V Flash Memory-3363879accessmodyfierNo ratings yet

- 16-Bit, RISC, Microcontroller-Based, Ultrasonic Distance-Measuring SystemDocument41 pages16-Bit, RISC, Microcontroller-Based, Ultrasonic Distance-Measuring SystemMarcus Principe CostaNo ratings yet

- 25AA160/25LC160/25C160: 16K Spi Bus Serial EEPROMDocument23 pages25AA160/25LC160/25C160: 16K Spi Bus Serial EEPROMЕвгенийNo ratings yet

- SN74LVC2G125 Dual Bus Buffer Gate With 3-State Outputs: 1 Features 3 DescriptionDocument27 pagesSN74LVC2G125 Dual Bus Buffer Gate With 3-State Outputs: 1 Features 3 Descriptionviatr0nicNo ratings yet

- 24LC21 1K 2.5V Dual Mode I2C Serial EEPROMDocument12 pages24LC21 1K 2.5V Dual Mode I2C Serial EEPROMVictor TruccoNo ratings yet

- dsPIC33CK256MP508-Family-Data-Sheet-DS70005349Document646 pagesdsPIC33CK256MP508-Family-Data-Sheet-DS70005349testtestNo ratings yet

- 8/10/12-Bit Dual Voltage Output Digital-to-Analog Converter With Internal V and SPI InterfaceDocument50 pages8/10/12-Bit Dual Voltage Output Digital-to-Analog Converter With Internal V and SPI InterfaceGustavo YbañezNo ratings yet

- 8K/16K 5.0V Microwire Serial EEPROM: FeaturesDocument12 pages8K/16K 5.0V Microwire Serial EEPROM: FeaturesStephensonNo ratings yet

- 8K/16K 5.0V SPI Bus Serial EEPROM: Features Package TypesDocument12 pages8K/16K 5.0V SPI Bus Serial EEPROM: Features Package Typesrıdvan71No ratings yet

- MPC5748G NXPDocument76 pagesMPC5748G NXPCammy KohNo ratings yet

- MCP4802Document46 pagesMCP4802KarbonNo ratings yet

- Remote Access Identification Device With Integrated 3D Wakeup Receiver and Immobilizer InterfaceDocument10 pagesRemote Access Identification Device With Integrated 3D Wakeup Receiver and Immobilizer InterfacecaptainNo ratings yet

- 24CW16X 24CW32X 24CW64X 24CW128X Data Sheet 200057-1397638Document51 pages24CW16X 24CW32X 24CW64X 24CW128X Data Sheet 200057-1397638ManunoghiNo ratings yet

- Flash S29GL128NDocument108 pagesFlash S29GL128NDaniel Norberto DemariaNo ratings yet

- 25AA640/25LC640: 64K Spi Bus Serial EEPROMDocument12 pages25AA640/25LC640: 64K Spi Bus Serial EEPROMinsomnium86No ratings yet

- No3109 Datasheet TS8-32GEMC210 Formal Version V10Document22 pagesNo3109 Datasheet TS8-32GEMC210 Formal Version V10Jhon Geimar Ortiz RodriguezNo ratings yet

- BIG-INNO EMCP MX100 Series Datasheet PDFDocument109 pagesBIG-INNO EMCP MX100 Series Datasheet PDFSteven ChowNo ratings yet

- 24AA64/24LC64/24FC64: 64K I C Serial EEPROMDocument28 pages24AA64/24LC64/24FC64: 64K I C Serial EEPROMJuan Luis Pineda GonzálezNo ratings yet

- MX25L8005 MxicDocument41 pagesMX25L8005 Mxicdanehcan graNo ratings yet

- ds89c430-ds89c450Document46 pagesds89c430-ds89c450freddyNo ratings yet

- BDocument54 pagesBVasikaran PrabaharanNo ratings yet

- SKEA64PB, Product Brief - Product BriefDocument14 pagesSKEA64PB, Product Brief - Product BriefMayank VyasNo ratings yet

- SG2042Document4 pagesSG2042Hinduja IcchapuramNo ratings yet

- Features: or Modifications Due To Changes in Technical Specifications. Rev. C, Issue Date: 2009/10/13Document48 pagesFeatures: or Modifications Due To Changes in Technical Specifications. Rev. C, Issue Date: 2009/10/13Namaku rokibNo ratings yet

- 5-V Can Transceiver With I/O Level Shifting and Low-Power Mode Supply OptimizationDocument22 pages5-V Can Transceiver With I/O Level Shifting and Low-Power Mode Supply OptimizationMurilo MarquesNo ratings yet

- SST26VF080A: 2.5V/3.0V 8-Mbit Serial Quad I/O™ (SQI™) Flash MemoryDocument72 pagesSST26VF080A: 2.5V/3.0V 8-Mbit Serial Quad I/O™ (SQI™) Flash MemoryManunoghiNo ratings yet

- MPC5643LDocument136 pagesMPC5643LNavya SreeNo ratings yet

- RM25C32DS 32-Kbit 1.65V Minimum Non-Volatile Serial EEPROM Spi BusDocument36 pagesRM25C32DS 32-Kbit 1.65V Minimum Non-Volatile Serial EEPROM Spi BusX'mix ĐreamerNo ratings yet

- C8051F336Document226 pagesC8051F336padrititaNo ratings yet

- 24AA02/24LC02B: 2KI C Serial EEPROMDocument32 pages24AA02/24LC02B: 2KI C Serial EEPROMhanifNo ratings yet

- 2.0 V, 32/16 KB Flash, Smartclock, 12-Bit Adc: Analog Peripherals Digital I/ODocument270 pages2.0 V, 32/16 KB Flash, Smartclock, 12-Bit Adc: Analog Peripherals Digital I/Owalo91No ratings yet

- En25qh64a EonDocument75 pagesEn25qh64a EonMarcelituz RojasNo ratings yet

- Infineon S27KL0643 S27KS0643 3 0 V 1 8 V 64 MB 8 - 3107371Document58 pagesInfineon S27KL0643 S27KS0643 3 0 V 1 8 V 64 MB 8 - 3107371ManunoghiNo ratings yet

- 24AA1025 24LC1025 24FC1025 1024 Kbit I2C Serial EE-2853738Document32 pages24AA1025 24LC1025 24FC1025 1024 Kbit I2C Serial EE-2853738İbrahim DemircioğluNo ratings yet

- Datasheet PDFDocument26 pagesDatasheet PDFNicoli LourençoNo ratings yet

- 93C86Document20 pages93C86cgmannerheimNo ratings yet

- Compactblock I/O For Devicenet: Technical DataDocument36 pagesCompactblock I/O For Devicenet: Technical DataRodrigo Antonio TomazeliNo ratings yet

- LMK61E2 Ultra-Low Jitter Programmable Oscillator With Internal EEPROMDocument55 pagesLMK61E2 Ultra-Low Jitter Programmable Oscillator With Internal EEPROMAymane FahmiNo ratings yet

- Drop Leaf Dining Table by Arne Vodder: All Seating Lighting Tables Storage Various Webshops Shops Trade ShowsDocument6 pagesDrop Leaf Dining Table by Arne Vodder: All Seating Lighting Tables Storage Various Webshops Shops Trade ShowsPanagiotis PanagosNo ratings yet

- What Are You Looking For?: Join IKEA Family Today. It's Quick, Easy and Free. A Safe, Warm Welcome Back To Our Stores!Document5 pagesWhat Are You Looking For?: Join IKEA Family Today. It's Quick, Easy and Free. A Safe, Warm Welcome Back To Our Stores!Panagiotis PanagosNo ratings yet

- Get The SC: Sign Up For Email Updates On New Products, Outlet Deals and Ways To Save!Document1 pageGet The SC: Sign Up For Email Updates On New Products, Outlet Deals and Ways To Save!Panagiotis PanagosNo ratings yet

- Triple Level Side Table Walnut: More InformationDocument2 pagesTriple Level Side Table Walnut: More InformationPanagiotis PanagosNo ratings yet

- U - Frame Pine Wood Dining Table / Black Frame U - Frame Pine Wood Dining Table / Black Frame by Strachel A.F. by Strachel A.FDocument2 pagesU - Frame Pine Wood Dining Table / Black Frame U - Frame Pine Wood Dining Table / Black Frame by Strachel A.F. by Strachel A.FPanagiotis PanagosNo ratings yet

- Coffee Table-Espresso: What Are You Looking For?Document6 pagesCoffee Table-Espresso: What Are You Looking For?Panagiotis PanagosNo ratings yet

- Wfhome (HTTPS://WWW - Wakefit.Co/Sale/Terms/Sale-Coupon)Document6 pagesWfhome (HTTPS://WWW - Wakefit.Co/Sale/Terms/Sale-Coupon)Panagiotis PanagosNo ratings yet

- Lexington Nes NG Table: Product CodeDocument5 pagesLexington Nes NG Table: Product CodePanagiotis PanagosNo ratings yet

- Search: Free Click & Collect On Orders Over $20Document40 pagesSearch: Free Click & Collect On Orders Over $20Panagiotis PanagosNo ratings yet

- Customers Who Viewed YAMAZEN ESK-751 (B) Casual Kotatsu Japanese Heated TableDocument9 pagesCustomers Who Viewed YAMAZEN ESK-751 (B) Casual Kotatsu Japanese Heated TablePanagiotis PanagosNo ratings yet

- Search 600,000 Products For Your Home: More Deals You May LikeDocument3 pagesSearch 600,000 Products For Your Home: More Deals You May LikePanagiotis PanagosNo ratings yet

- Select Your Store Now To View Price and Product AvailabilityDocument4 pagesSelect Your Store Now To View Price and Product AvailabilityPanagiotis PanagosNo ratings yet

- Search: Offer Price: 2464Document11 pagesSearch: Offer Price: 2464Panagiotis PanagosNo ratings yet

- Starburst Nest of Coffee Tables: Enquire NowDocument6 pagesStarburst Nest of Coffee Tables: Enquire NowPanagiotis PanagosNo ratings yet

- Skogsta: Cookies PolicyDocument2 pagesSkogsta: Cookies PolicyPanagiotis PanagosNo ratings yet

- Solid Wood Kuber Writing / Study: SKU: SCK-25-WDocument9 pagesSolid Wood Kuber Writing / Study: SKU: SCK-25-WPanagiotis PanagosNo ratings yet

- More Cart: Crystal Furnitech Sigma Engineered Wood Coffee Table (Finish Color - Wal + Wenge)Document4 pagesMore Cart: Crystal Furnitech Sigma Engineered Wood Coffee Table (Finish Color - Wal + Wenge)Panagiotis PanagosNo ratings yet

- Fairhope Storage Coffee Table: Apply For Credit Pay My Bill in Store AdsDocument6 pagesFairhope Storage Coffee Table: Apply For Credit Pay My Bill in Store AdsPanagiotis PanagosNo ratings yet

- Beavip: $250 Egift CardDocument5 pagesBeavip: $250 Egift CardPanagiotis PanagosNo ratings yet

- Office Banquet Table White Color (120 CM X 60 CM X 76 CM) : Search in LazadaDocument4 pagesOffice Banquet Table White Color (120 CM X 60 CM X 76 CM) : Search in LazadaPanagiotis PanagosNo ratings yet

- Our Home Event Has Been Extended Until 6 October 2020! Don't Miss Out On Up To 50% o !Document5 pagesOur Home Event Has Been Extended Until 6 October 2020! Don't Miss Out On Up To 50% o !Panagiotis PanagosNo ratings yet

- Rentals: TA HADocument17 pagesRentals: TA HAPanagiotis PanagosNo ratings yet

- Armadillo Co Ee/dining TableDocument4 pagesArmadillo Co Ee/dining TablePanagiotis PanagosNo ratings yet

- 1Document6 pages1Panagiotis PanagosNo ratings yet

- Knight Coffee Table, Mahogany: What Can We Help You Find Today?Document3 pagesKnight Coffee Table, Mahogany: What Can We Help You Find Today?Panagiotis PanagosNo ratings yet

- Triple Level Side Table Walnut: More InformationDocument2 pagesTriple Level Side Table Walnut: More InformationPanagiotis PanagosNo ratings yet

- Beavip: $250 Egift CardDocument4 pagesBeavip: $250 Egift CardPanagiotis PanagosNo ratings yet

- Customers Who Viewed This Also ViewedDocument4 pagesCustomers Who Viewed This Also ViewedPanagiotis PanagosNo ratings yet

- Search: Free Click & Collect On Orders Over $20Document30 pagesSearch: Free Click & Collect On Orders Over $20Panagiotis PanagosNo ratings yet

- Customers Who Viewed YAMAZEN ESK-751 (B) Casual Kotatsu Japanese Heated TableDocument8 pagesCustomers Who Viewed YAMAZEN ESK-751 (B) Casual Kotatsu Japanese Heated TablePanagiotis PanagosNo ratings yet

- Embedded System of Shibu K VDocument10 pagesEmbedded System of Shibu K Vshahebgoudahalladamani0% (1)

- Unit 5: Memory OrganizationsDocument14 pagesUnit 5: Memory OrganizationsAbdullahel ShafiNo ratings yet

- IT Tools and Business System Module on Computer OrganizationDocument72 pagesIT Tools and Business System Module on Computer OrganizationAlexNo ratings yet

- DS350 Operators Link Belt HC248HDocument71 pagesDS350 Operators Link Belt HC248HMarcus ChuaNo ratings yet

- Plum+ Service ManualDocument211 pagesPlum+ Service ManualkmsamarioNo ratings yet

- Semiconducter MemoryDocument13 pagesSemiconducter MemorySayed AsifNo ratings yet

- Embedded System Industrial Trainng ReportDocument102 pagesEmbedded System Industrial Trainng ReportSurinder Singh Bindra50% (4)

- Introduction To Motorola 68HC11: 1.1 ObjectivesDocument36 pagesIntroduction To Motorola 68HC11: 1.1 ObjectivesRaoul ToludNo ratings yet

- ComputerDocument5 pagesComputerLindsay RamosNo ratings yet

- Embedded Systems - WikibookDocument117 pagesEmbedded Systems - WikibookAman AroraNo ratings yet

- Problem Sloving Through C ProgrammingDocument51 pagesProblem Sloving Through C Programmingmanoj hmNo ratings yet

- Mil HDBK 217FDocument80 pagesMil HDBK 217FSivapriya SamyNo ratings yet

- Reconfigurable Computing Es Zg554 / Mel ZG 554 Session 2: BITS PilaniDocument35 pagesReconfigurable Computing Es Zg554 / Mel ZG 554 Session 2: BITS PilaniRahamtulla MohammadNo ratings yet

- Memory DevicesDocument60 pagesMemory DevicesShahin ShuvoNo ratings yet

- Smt. CHM College, Ulhasnagar - 3: Prof. Y. P. JadhavDocument40 pagesSmt. CHM College, Ulhasnagar - 3: Prof. Y. P. JadhavProf. Yashavant p. JadhavNo ratings yet

- Pixeles Bca & Mca (Ignou) : ClassesDocument15 pagesPixeles Bca & Mca (Ignou) : ClassesslayrNo ratings yet

- Programmable Logic DevicesDocument50 pagesProgrammable Logic Devicesanon_463330020No ratings yet

- Unit3 CRRDocument29 pagesUnit3 CRRadddataNo ratings yet

- Unit I Embedded Computing: 2 Marks QuestionsDocument28 pagesUnit I Embedded Computing: 2 Marks Questionslogu87No ratings yet

- Defination of ROMDocument4 pagesDefination of ROMshubham shakyaNo ratings yet

- 5.6 Basic Computer Structure: Basic Maintenance Training Manual Module 5 Digital Technology / EISDocument26 pages5.6 Basic Computer Structure: Basic Maintenance Training Manual Module 5 Digital Technology / EISIvomadnessNo ratings yet

- Mektek2 Manual Jan 08 PDFDocument45 pagesMektek2 Manual Jan 08 PDFzokiNo ratings yet

- Programmable Asics 4: The AntifuseDocument12 pagesProgrammable Asics 4: The AntifuseVivek100% (2)

- Memory Design and Layout OptimizationDocument21 pagesMemory Design and Layout OptimizationmohammedNo ratings yet

- Digital Electronics NotesDocument29 pagesDigital Electronics NotesHimanshu KhanduriNo ratings yet

- Assignment # 2 Introduction To Computer Bscs-1A: Name: Roll No.: Instructor: Q.1)Document3 pagesAssignment # 2 Introduction To Computer Bscs-1A: Name: Roll No.: Instructor: Q.1)Obaidullah MansoorNo ratings yet

- Unit 4 - L Notes - Introduction To MicrocontrollerDocument53 pagesUnit 4 - L Notes - Introduction To MicrocontrollerAKSHANSH MATHUR100% (1)

- MMI PAL Handbook 3ed 1983Document660 pagesMMI PAL Handbook 3ed 1983yewie561No ratings yet

- The 8088/8086 Microprocessors and Their Memory and Input/Output InterfaceDocument37 pagesThe 8088/8086 Microprocessors and Their Memory and Input/Output InterfaceKanaan JalalNo ratings yet