Professional Documents

Culture Documents

2K 5.0V Automotive Temperature Microwire Serial EEPROM: Features Package Type

Uploaded by

DanielOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

2K 5.0V Automotive Temperature Microwire Serial EEPROM: Features Package Type

Uploaded by

DanielCopyright:

Available Formats

M 2K 5.

0V Automotive Temperature Microwire® Serial EEPROM

93C56A/B

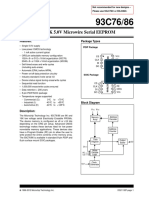

FEATURES PACKAGE TYPE

PDIP

• Single supply 5.0V operation VCC

CS 1 8

• Low power CMOS technology

93C56A/B

- 1 mA active current (typical) CLK 2 7 NC

- 1 µA standby current (maximum)

• 256 x 8 bit organization (93C56A) DI 3 6 NC

• 128 x 16 bit organization (93C56B)

DO 4 5 VSS

• Self-timed ERASE and WRITE cycles (including

auto-erase)

• Automatic ERAL before WRAL SOIC

• Power on/off data protection circuitry

CS 1 8 VCC

• Industry standard 3-wire serial interface

93C56A/B

• Device status signal during ERASE/WRITE 2 7 NC

CLK

cycles

• Sequential READ function DI 3 6 NC

• 100,000 E/W cycles guaranteed 4 5

• Data retention > 200 years DO VSS

• 8-pin PDIP and SOIC packages

• Available for the following temperature ranges:

- Automotive (E): -40°C to +125°C BLOCK DIAGRAM

DESCRIPTION MEMORY ADDRESS

ARRAY DECODER

The Microchip Technology Inc. 93C56A/B is a 2K-bit,

low-voltage serial Electrically Erasable PROM. The

device memory is configured as 256 x 8 bits (93C56A) ADDRESS

or 128 x 16 bits (93C56B). Advanced CMOS technol- COUNTER

ogy makes this device ideal for low-power, nonvolatile

memory applications. The 93C56A/B is available in DATA OUTPUT

REGISTER DO

BUFFER

standard 8-pin DIP and surface mount SOIC packages. DI

This device is only recommeded for 5V automotive

temperature applications. For all commercial and MEMORY

DECODE

industrial applications, the 93LC56A/B is recom- CS LOGIC

mended.

VCC

CLK CLOCK

GENERATOR VSS

Microwire is a registered trademark of National Semiconductor.

1998 Microchip Technology Inc. Preliminary DS21206B-page 1

93C56A/B

1.0 ELECTRICAL TABLE 1-1: PIN FUNCTION TABLE

CHARACTERISTICS Name Function

1.1 Maximum Ratings* CS Chip Select

CLK Serial Data Clock

VCC ...................................................................................7.0V

All inputs and outputs w.r.t. VSS ................ -0.6V to Vcc +1.0V DI Serial Data Input

Storage temperature .....................................-65°C to +150°C DO Serial Data Output

Ambient temp. with power applied.................-65°C to +125°C

VSS Ground

Soldering temperature of leads (10 seconds) ............. +300°C

ESD protection on all pins................................................4 kV NC No Connect

*Notice: Stresses above those listed under “Maximum ratings” may VCC Power Supply

cause permanent damage to the device. This is a stress rating only and

functional operation of the device at those or any other conditions

above those indicated in the operational listings of this specification is

not implied. Exposure to maximum rating conditions for extended peri-

ods may affect device reliability.

TABLE 1-2: DC AND AC ELECTRICAL CHARACTERISTICS

All parameters apply over the Automotive (E)VCC = +4.5V to +5.5VTamb = -40°C to +125°C

specified operating ranges

unless otherwise noted

Parameter Symbol Min. Max. Units Conditions

High level input voltage VIH 2.0 VCC +1 V (Note 2)

Low level input voltage VIL -0.3 0.8 V

Low level output voltage VOL — 0.4 V IOL = 2.1 mA; VCC = 4.5V

High level output voltage VOH 2.4 — V IOH = -400 µA; VCC = 4.5V

Input leakage current ILI -10 10 µA VIN = VSS to VCC

Output leakage current ILO -10 10 µA VOUT = VSS to VCC

Pin capacitance VIN/VOUT = 0 V (Notes 1 & 2)

CIN, COUT — 7 pF

(all inputs/outputs) Tamb = +25°C, FCLK = 1 MHz

ICC write — 1.5 mA

Operating current

ICC read — 1 mA

Standby current ICCS — 1 µA CS = VSS

Clock frequency FCLK — 2 MHz

Clock high time TCKH 250 — ns

Clock low time TCKL 250 — ns

Chip select setup time TCSS 50 — ns Relative to CLK

Chip select hold time TCSH 0 — ns Relative to CLK

Chip select low time TCSL 250 — ns

Data input setup time TDIS 100 — ns Relative to CLK

Data input hold time TDIH 100 — ns Relative to CLK

Data output delay time TPD — 400 ns CL = 100 pF

Data output disable time TCZ — 100 ns CL = 100 pF (Note 2)

Status valid time TSV — 500 ns CL = 100 pF

TWC — 2 ms ERASE/WRITE mode

Program cycle time TEC — 6 ms ERAL mode

TWL — 15 ms WRAL mode

Endurance — 100K — cycles 25°C, VCC = 5.0V, Block Mode (Note 3)

Note 1: This parameter is tested at Tamb = 25°C and FCLK = 1 MHz.

2: This parameter is periodically sampled and not 100% tested.

3: This application is not tested but guaranteed by characterization. For endurance estimates in a specific

application, please consult the Total Endurance Model which may be obtained on Microchip’s BBS or web-

site.

DS21206B-page 2 Preliminary 1998 Microchip Technology Inc.

93C56A/B

2.0 PIN DESCRIPTION CLK cycles are not required during the self-timed

WRITE (i.e., auto ERASE/WRITE) cycle.

2.1 Chip Select (CS) After detecting a START condition, the specified num-

ber of clock cycles (respectively low to high transitions

A high level selects the device. A low level deselects

of CLK) must be provided. These clock cycles are

the device and forces it into standby mode. However, a

required to clock in all required opcode, address, and

programming cycle which is already in progress will be

data bits before an instruction is executed (Table 2-1

completed, regardless of the CS input signal. If CS is

and Table 2-2). CLK and DI then become don't care

brought low during a program cycle, the device will go

inputs waiting for a new START condition to be

into standby mode as soon as the programming cycle

detected.

is completed.

CS must be low for 250 ns minimum (TCSL) between Note: CS must go low between consecutive

consecutive instructions. If CS is low, the internal con- instructions.

trol logic is held in a RESET status.

2.3 Data In (DI)

2.2 Serial Clock (CLK)

Data In is used to clock in a START bit, opcode,

The Serial Clock is used to synchronize the communi- address, and data synchronously with the CLK input.

cation between a master device and the 93C56A/B.

2.4 Data Out (DO)

Opcode, address, and data bits are clocked in on the

positive edge of CLK. Data bits are also clocked out on Data Out is used in the READ mode to output data syn-

the positive edge of CLK. chronously with the CLK input (TPD after the positive

CLK can be stopped anywhere in the transmission edge of CLK).

sequence (at high or low level) and can be continued This pin also provides READY/BUSY status informa-

anytime with respect to clock high time (TCKH) and tion during ERASE and WRITE cycles. READY/BUSY

clock low time (TCKL). This gives the controlling master status information is available on the DO pin if CS is

freedom in preparing opcode, address, and data. brought high after being low for minimum chip select

CLK is a “Don't Care” if CS is low (device deselected). low time (TCSL) and an ERASE or WRITE operation

If CS is high, but the START condition has not been has been initiated. The status signal is not available on

detected, any number of clock cycles can be received DO, if CS is held low during the entire ERASE or

by the device without changing its status (i.e., waiting WRITE cycle. In this case, DO is in the HIGH-Z mode.

for a START condition). If status is checked after the ERASE/WRITE cycle, the

data line will be high to indicate the device is ready.

.

TABLE 2-1: INSTRUCTION SET FOR 93C56A

Instruction SB Opcode Address Data In Data Out Req. CLK Cycles

ERASE 1 11 X A7 A6 A5 A4 A3 A2 A1 A0 — (RDY/BSY) 12

ERAL 1 00 1 0 X X X X X X X — (RDY/BSY) 12

EWDS 1 00 0 0 X X X X X X X — HIGH-Z 12

EWEN 1 00 1 1 X X X X X X X — HIGH-Z 12

READ 1 10 X A7 A6 A5 A4 A3 A2 A1 A0 — D7 - D0 20

WRITE 1 01 X A7 A6 A5 A4 A3 A2 A1 A0 D7 - D0 (RDY/BSY) 20

WRAL 1 00 0 1 X X X X X X X D7 - D0 (RDY/BSY) 20

TABLE 2-2: INSTRUCTION SET FOR 93C56B

Instruction SB Opcode Address Data In Data Out Req. CLK Cycles

ERASE 1 11 X A6 A5 A4 A3 A2 A1 A0 — (RDY/BSY) 11

ERAL 1 00 1 0 X X X X X X — (RDY/BSY) 11

EWDS 1 00 0 0 X X X X X X — HIGH-Z 11

EWEN 1 00 1 1 X X X X X X — HIGH-Z 11

READ 1 10 X A6 A5 A4 A3 A2 A1 A0 — D15 - D0 27

WRITE 1 01 X A6 A5 A4 A3 A2 A1 A0 D15 - D0 (RDY/BSY) 27

WRAL 1 00 0 1 X X X X X X D15 - D0 (RDY/BSY) 27

1998 Microchip Technology Inc. Preliminary DS21206B-page 4-3

93C56A/B

3.0 FUNCTIONAL DESCRIPTION 3.2 Data IN (DI) and Data Out (DO)

Instructions, addresses, and write data are clocked into It is possible to connect the Data In (DI) and Data Out

the DI pin on the rising edge of the clock (CLK). The DO (DO) pins together. However, with this configuration, if

pin is normally held in a HIGH-Z state except when A0 is a logic-high level, it is possible for a “bus conflict”

reading data from the device, or when checking the to occur during the “dummy zero” that precedes the

READY/BUSY status during a programming operation. READ operation. Under such a condition, the voltage

The READY/BUSY status can be verified during an level seen at DO is undefined and will depend upon the

ERASE/WRITE operation by polling the DO pin; DO relative impedances of DO and the signal source driv-

low indicates that programming is still in progress, while ing A0. The higher the current sourcing capability of A0,

DO high indicates the device is ready. The DO will enter the higher the voltage at the DO pin.

the HIGH-Z state on the falling edge of the CS.

3.3 Data Protection

3.1 START Condition

During power-up, all programming modes of operation

The START bit is detected by the device if CS and DI are inhibited until Vcc has reached a level greater than

are both high with respect to the positive edge of CLK 3.8V. During power-down, the source data protection

for the first time. circuitry acts to inhibit all programming modes when

Before a START condition is detected, CS, CLK, and DI Vcc has fallen below 3.8V at nominal conditions.

may change in any combination (except to that of a The ERASE/WRITE Disable (EWDS) and ERASE

START condition), without resulting in any device oper- WRTE Enable (EWEN) commands give additional pro-

ation (READ, WRITE, ERASE, EWEN, EWDS, ERAL, tection against accidentally programming during nor-

and WRAL). As soon as CS is high, the device is no mal operation.

longer in the standby mode.

After power-up, the device is automatically in the

An instruction following a START condition will only be EWDS mode. Therefore, an EWEN instruction must be

executed if the required amount of opcode, address performed before any ERASE or WRITE instruction

and data bits for any particular instruction is clocked in. can be executed.

After execution of an instruction (i.e., clock in or out of

the last required address or data bit) CLK and DI

become don't care bits until a new START condition is

detected.

FIGURE 3-1: SYNCHRONOUS DATA TIMING

VIH

CS

VIL TCSS TCKH TCKL

TCSH

VIH

CLK

VIL

TDIS TDIH

VIH

DI

VIL

TCZ

TPD

TPD

VOH

DO

(READ) TCZ

VOL

TSV

DO VOH

(PROGRAM) STATUS VALID

VOL

Note: AC Test Conditions: VIL = 0.4V, VIH = 2.4V.

DS21206B-page 4 Preliminary 1998 Microchip Technology Inc.

93C56A/B

3.4 ERASE 3.5 Erase All (ERAL)

The ERASE instruction forces all data bits of the spec- The ERAL instruction will erase the entire memory

ified address to the logical “1” state. This cycle begins array to the logical “1” state. The ERAL cycle is identical

on the rising clock edge of the last address bit. to the ERASE cycle, except for the different opcode.

The DO pin indicates the READY/BUSY status of the The ERAL cycle is completely self-timed and com-

device if CS is brought high after a minimum of 250 ns mences at the rising clock edge of the last address bit.

low (TCSL). DO at logical “0” indicates that program- Clocking of the CLK pin is not necessary after the

ming is still in progress. DO at logical “1” indicates that device has entered the ERAL cycle.

the register at the specified address has been erased The DO pin indicates the READY/BUSY status of the

and the device is ready for another instruction. device, if CS is brought high after a minimum of 250 ns

low (TCSL) and before the entire ERAL cycle is com-

plete.

FIGURE 3-2: ERASE TIMING

TCSL

CS

CHECK STATUS

CLK

DI 1 1 1 AN AN-1 AN-2 ••• A0

TSV TCZ

HIGH-Z

DO BUSY READY

HIGH-Z

TWC

FIGURE 3-3: ERAL TIMING

TCSL

CS

CHECK STATUS

CLK

DI 1 0 0 1 0 X ••• X

TSV TCZ

HIGH-Z

DO BUSY READY

HIGH-Z

TEC

1998 Microchip Technology Inc. Preliminary DS21206B-page 5

93C56A/B

3.6 ERASE/WRITE Disable and Enable 3.7 READ

(EWDS/EWEN)

The READ instruction outputs the serial data of the

The device powers up in the ERASE/WRITE Disable addressed memory location on the DO pin. A dummy

(EWDS) state. All programming modes must be pre- zero bit precedes the 8-bit (93C56A) or 16-bit

ceded by an ERASE/WRITE Enable (EWEN) instruc- (93C56B) output string. The output data bits will toggle

tion. Once the EWEN instruction is executed, on the rising edge of the CLK and are stable after the

programming remains enabled until an EWDS instruc- specified time delay (TPD). Sequential read is possible

tion is executed or VCC is removed from the device. To when CS is held high. The memory data will automati-

protect against accidental data disturbance, the EWDS cally cycle to the next register and output sequentially.

instruction can be used to disable all ERASE/WRITE

functions and should follow all programming opera-

tions. Execution of a READ instruction is independent

of both the EWEN and EWDS instructions.

FIGURE 3-4: READ TIMING

CS

CLK

DI 1 1 0 An ••• A0

HIGH-Z

DO 0 Dx ••• D0 Dx ••• D0 Dx ••• D0

FIGURE 3-5: EWDS TIMING

TCSL

CS

CLK

DI 1 0 0 0 0 X ••• X

FIGURE 3-6: EWEN TIMING

TCSL

CS

CLK

1 0 0 1 1 X ••• X

DI

DS21206B-page 6 Preliminary 1998 Microchip Technology Inc.

93C56A/B

3.8 WRITE 3.9 Write All (WRAL)

The WRITE instruction is followed by 8-bits (93C56A) The Write All (WRAL) instruction will write the entire

16-bits (93C56B) of data which are written into the memory array with the data specified in the command.

specified address. After the last data bit is clocked into The WRAL cycle is completely self-timed and com-

the DI pin, the self-timed auto-erase and programming mences at the rising clock edge of the last data bit.

cycle begins. Clocking of the CLK pin is not necessary after the

The DO pin indicates the READY/BUSY status of the device has entered the WRAL cycle. The WRAL com-

device, if CS is brought high after a minimum of 250 ns mand does include an automatic ERAL cycle for the

low (TCSL) and before the entire write cycle is complete. device. Therefore, the WRAL instruction does not

DO at logical “0” indicates that programming is still in require an ERAL instruction but the chip must be in the

progress. DO at logical “1” indicates that the register at EWEN status.

the specified address has been written with the data The DO pin indicates the READY/BUSY status of the

specified and the device is ready for another instruc- device if CS is brought high after a minimum of 250 ns

tion. low (TCSL).

FIGURE 3-7: WRITE TIMING

TCSL

CS

CLK

DI 1 0 1 An ••• A0 Dx ••• D0

TSV TCZ

HIGH-Z

DO BUSY READY

HIGH-Z

Twc

FIGURE 3-8: WRAL TIMING

TCSL

CS

CLK

DI 1 0 0 0 1 X ••• X Dx ••• D0

TSV TCZ

HIGH-Z

DO BUSY READY

HIGH-Z

TWL

1998 Microchip Technology Inc. Preliminary DS21206B-page 7

93C56A/B

NOTES:

DS21206B-page 8 Preliminary 1998 Microchip Technology Inc.

93C56A/B

NOTES:

1998 Microchip Technology Inc. Preliminary DS21206B-page 9

93C56A/B

NOTES:

DS21206B-page 10 Preliminary 1998 Microchip Technology Inc.

93C56A/B

93C56A/B PRODUCT IDENTIFICATION SYSTEM

To order or obtain information, e.g., on pricing or delivery, refer to the factory or the listed sales office.

93C56A/B /P

P = Plastic DIP (300 mil Body), 8-lead

Package:

SN = Plastic SOIC (150 mil Body), 8-lead

Temperature E = -40°C to +125°C

Range:

93C56A 2K Microwire Serial EEPROM (x8)

93C56AT 2K Microwire Serial EEPROM (x8) Tape and Reel

Device:

93C56B 2K Microwire Serial EEPROM (x16)

93C56BT 2K Microwire Serial EEPROM (x16) Tape and Reel

Sales and Support

Data Sheets

Products supported by a preliminary Data Sheet may have an errata sheet describing minor operational differences and recom-

mended workarounds. To determine if an errata sheet exists for a particular device, please contact one of the following:

1. Your local Microchip sales office.

2. The Microchip Corporate Literature Center U.S. FAX: (602) 786-7277.

3. The Microchip’s Bulletin Board, via your local CompuServe number (CompuServe membership NOT required).

1998 Microchip Technology Inc. Preliminary DS21206B-page 11

M

WORLDWIDE SALES AND SERVICE

AMERICAS ASIA/PACIFIC EUROPE

Corporate Office Hong Kong United Kingdom

Microchip Technology Inc. Microchip Asia Pacific Arizona Microchip Technology Ltd.

2355 West Chandler Blvd. RM 3801B, Tower Two 505 Eskdale Road

Chandler, AZ 85224-6199 Metroplaza Winnersh Triangle

Tel: 602-786-7200 Fax: 602-786-7277 223 Hing Fong Road Wokingham

Technical Support: 602 786-7627 Kwai Fong, N.T., Hong Kong Berkshire, England RG41 5TU

Web: http://www.microchip.com Tel: 852-2-401-1200 Fax: 852-2-401-3431 Tel: 44-1189-21-5858 Fax: 44-1189-21-5835

Atlanta India France

Microchip Technology Inc. Microchip Technology Inc. Arizona Microchip Technology SARL

500 Sugar Mill Road, Suite 200B India Liaison Office Zone Industrielle de la Bonde

Atlanta, GA 30350 No. 6, Legacy, Convent Road 2 Rue du Buisson aux Fraises

Tel: 770-640-0034 Fax: 770-640-0307 Bangalore 560 025, India 91300 Massy, France

Boston Tel: 91-80-229-0061 Fax: 91-80-229-0062 Tel: 33-1-69-53-63-20 Fax: 33-1-69-30-90-79

Microchip Technology Inc. Korea Germany

5 Mount Royal Avenue Microchip Technology Korea Arizona Microchip Technology GmbH

Marlborough, MA 01752 168-1, Youngbo Bldg. 3 Floor Gustav-Heinemann-Ring 125

Tel: 508-480-9990 Fax: 508-480-8575 Samsung-Dong, Kangnam-Ku D-81739 Müchen, Germany

Chicago Seoul, Korea Tel: 49-89-627-144 0 Fax: 49-89-627-144-44

Tel: 82-2-554-7200 Fax: 82-2-558-5934 Italy

Microchip Technology Inc.

333 Pierce Road, Suite 180 Shanghai Arizona Microchip Technology SRL

Itasca, IL 60143 Microchip Technology Centro Direzionale Colleoni

Tel: 630-285-0071 Fax: 630-285-0075 RM 406 Shanghai Golden Bridge Bldg. Palazzo Taurus 1 V. Le Colleoni 1

Dallas 2077 Yan’an Road West, Hong Qiao District 20041 Agrate Brianza

Shanghai, PRC 200335 Milan, Italy

Microchip Technology Inc.

Tel: 86-21-6275-5700 Tel: 39-39-6899939 Fax: 39-39-6899883

14651 Dallas Parkway, Suite 816

Fax: 86 21-6275-5060

Dallas, TX 75240-8809

Tel: 972-991-7177 Fax: 972-991-8588 Singapore

Microchip Technology Taiwan

JAPAN

Dayton Microchip Technology Intl. Inc.

Singapore Branch

Microchip Technology Inc. Benex S-1 6F

200 Middle Road

Two Prestige Place, Suite 150 3-18-20, Shinyokohama

#07-02 Prime Centre

Miamisburg, OH 45342 Kohoku-Ku, Yokohama-shi

Singapore 188980

Tel: 937-291-1654 Fax: 937-291-9175 Kanagawa 222 Japan

Tel: 65-334-8870 Fax: 65-334-8850

Los Angeles Taiwan, R.O.C

Tel: 81-45-471- 6166 Fax: 81-45-471-6122

Microchip Technology Inc.

Microchip Technology Taiwan 12/30/97

18201 Von Karman, Suite 1090

10F-1C 207

Irvine, CA 92612

Tung Hua North Road

Tel: 714-263-1888 Fax: 714-263-1338

Taipei, Taiwan, ROC

New York Tel: 886-2-2717-7175 Fax: 886-2-2545-0139

Microchip Technology Inc.

150 Motor Parkway, Suite 202

Hauppauge, NY 11788

Tel: 516-273-5305 Fax: 516-273-5335

San Jose

Microchip Technology Inc.

2107 North First Street, Suite 590

San Jose, CA 95131

Tel: 408-436-7950 Fax: 408-436-7955

Toronto

Microchip Technology Inc.

5925 Airport Road, Suite 200

Mississauga, Ontario L4V 1W1, Canada

Tel: 905-405-6279 Fax: 905-405-6253

All rights reserved. © 1998, Microchip Technology Incorporated, USA. 1/98 Printed on recycled paper.

Information contained in this publication regarding device applications and the like is intended for suggestion only and may be superseded by updates. No representation or warranty is given and no

liability is assumed by Microchip Technology Incorporated with respect to the accuracy or use of such information, or infringement of patents or other intellectual property rights arising from such use

or otherwise. Use of Microchip’s products as critical components in life support systems is not authorized except with express written approval by Microchip. No licenses are conveyed, implicitly or

otherwise, under any intellectual property rights. The Microchip logo and name are registered trademarks of Microchip Technology Inc. in the U.S.A. and other countries. All rights reserved. All other

trademarks mentioned herein are the property of their respective companies.

DS21206B-page 12 Preliminary 1998 Microchip Technology Inc.

You might also like

- 8051 Microcontroller: An Applications Based IntroductionFrom Everand8051 Microcontroller: An Applications Based IntroductionRating: 5 out of 5 stars5/5 (6)

- 93C66Document12 pages93C66Alex AlvarezNo ratings yet

- 8K/16K 5.0V Microwire Serial EEPROM: Features: Package TypesDocument20 pages8K/16K 5.0V Microwire Serial EEPROM: Features: Package Typesfarhood ranjbarkhanghahNo ratings yet

- 256 Bit/1K 5.0V CMOS Serial EEPROM: Features Package TypeDocument8 pages256 Bit/1K 5.0V CMOS Serial EEPROM: Features Package TypeAgustin AndrokaitesNo ratings yet

- 8K/16K 5.0V Microwire Serial EEPROM: FeaturesDocument12 pages8K/16K 5.0V Microwire Serial EEPROM: FeaturesStephensonNo ratings yet

- 93C86Document20 pages93C86cgmannerheimNo ratings yet

- 93LC66A/B: 4K 2.5V Microwire Serial EEPROMDocument12 pages93LC66A/B: 4K 2.5V Microwire Serial EEPROMinsomnium86No ratings yet

- 24C320-EP MicrochipTechnologyDocument12 pages24C320-EP MicrochipTechnologyMateus CorrêaNo ratings yet

- 1K 5.0V Microwire Serial EEPROM: Features Block DiagramDocument12 pages1K 5.0V Microwire Serial EEPROM: Features Block Diagraminsomnium86No ratings yet

- 93 LC 46 BDocument12 pages93 LC 46 Bwabp_23No ratings yet

- Data SheetDocument12 pagesData SheetPrasetyo Muhammad SaktiNo ratings yet

- 1K/2K/4K 2.5V Microwire Serial EEPROM: Features: Package TypesDocument20 pages1K/2K/4K 2.5V Microwire Serial EEPROM: Features: Package TypesJoão PauloNo ratings yet

- 32K 5.0V I C Smart Serial EEPROM: Features Package TypesDocument12 pages32K 5.0V I C Smart Serial EEPROM: Features Package TypesRamon LopezNo ratings yet

- Bus Serial EEPROMDocument12 pagesBus Serial EEPROMMatiasNo ratings yet

- 32K 5.0V I C Serial EEPROM: Features Package TypesDocument12 pages32K 5.0V I C Serial EEPROM: Features Package TypesChrono GtzNo ratings yet

- 24LC21 1K 2.5V Dual Mode I2C Serial EEPROMDocument12 pages24LC21 1K 2.5V Dual Mode I2C Serial EEPROMVictor TruccoNo ratings yet

- Datasheet PDFDocument26 pagesDatasheet PDFNicoli LourençoNo ratings yet

- 24AA02/24LC02B: 2KI C Serial EEPROMDocument32 pages24AA02/24LC02B: 2KI C Serial EEPROMhanifNo ratings yet

- 24AA52/24LCS52: 2K 2.2V I C Serial EEPROM With Software Write-ProtectDocument24 pages24AA52/24LCS52: 2K 2.2V I C Serial EEPROM With Software Write-Protecta4rfanNo ratings yet

- 24AA64/24LC64/24FC64: 64K I C Serial EEPROMDocument28 pages24AA64/24LC64/24FC64: 64K I C Serial EEPROMJuan Luis Pineda GonzálezNo ratings yet

- 21073K PDFDocument24 pages21073K PDFadfumegaNo ratings yet

- 32K 5.0V I C Serial EEPROM: Features Package TypesDocument12 pages32K 5.0V I C Serial EEPROM: Features Package Typesinsomnium86No ratings yet

- 25AA160/25LC160/25C160: 16K Spi Bus Serial EEPROMDocument23 pages25AA160/25LC160/25C160: 16K Spi Bus Serial EEPROMЕвгенийNo ratings yet

- 24C32Document12 pages24C32SilviuCocoloșNo ratings yet

- 24FC1025 EepromDocument28 pages24FC1025 EepromAnirudh ReddyNo ratings yet

- 24AA1025/24LC1025/24FC1025: 1024K I C Serial EEPROMDocument29 pages24AA1025/24LC1025/24FC1025: 1024K I C Serial EEPROMSudhagarSubbiyanNo ratings yet

- Mcrf250: 125 KHZ Microid Passive Rfid Device With Anti-CollisionDocument24 pagesMcrf250: 125 KHZ Microid Passive Rfid Device With Anti-CollisionPanagiotis PanagosNo ratings yet

- 24AA1025 24LC1025 24FC1025 1024 Kbit I2C Serial EE-2853738Document32 pages24AA1025 24LC1025 24FC1025 1024 Kbit I2C Serial EE-2853738İbrahim DemircioğluNo ratings yet

- 24AA256/24LC256: 256K I C Cmos Serial EepromDocument12 pages24AA256/24LC256: 256K I C Cmos Serial EepromWelleyNo ratings yet

- mcp4725 PDFDocument50 pagesmcp4725 PDFGessa BulaongNo ratings yet

- 25AA640/25LC640/25C640: 64K Spi Bus Serial EEPROMDocument11 pages25AA640/25LC640/25C640: 64K Spi Bus Serial EEPROMAndrey OliveiraNo ratings yet

- Three-Wire Serial EEPROM: 1. FeaturesDocument17 pagesThree-Wire Serial EEPROM: 1. FeatureskppsadiNo ratings yet

- 24l1026i Memoria EEPROM 1024kDocument28 pages24l1026i Memoria EEPROM 1024kMarta_d_eNo ratings yet

- DS12885 Ds12c887aDocument22 pagesDS12885 Ds12c887aRohan RayakarNo ratings yet

- TMC93LC46Document15 pagesTMC93LC46Agustin AndrokaitesNo ratings yet

- Data Sheet EN25QDocument50 pagesData Sheet EN25Qsvetislav_vuksanovicNo ratings yet

- MCP79410/MCP79411/MCP79412: I C™ Real-Time Clock/Calendar With EEPROM, SRAM, Unique ID and Battery SwitchoverDocument38 pagesMCP79410/MCP79411/MCP79412: I C™ Real-Time Clock/Calendar With EEPROM, SRAM, Unique ID and Battery SwitchoverDaniel CortelettiNo ratings yet

- Spansion S25FL256S - 32MB SPI FlashromDocument149 pagesSpansion S25FL256S - 32MB SPI FlashromcockNo ratings yet

- 32K 2.5V I C Serial EEPROM: Features Package TypesDocument12 pages32K 2.5V I C Serial EEPROM: Features Package Typesinsomnium86No ratings yet

- 24LC04B PDFDocument22 pages24LC04B PDFEddy RosarioNo ratings yet

- IDT_7164S15TPDocument9 pagesIDT_7164S15TPRuslanNo ratings yet

- 24 LC 256Document38 pages24 LC 256johnNo ratings yet

- EN25Q32A 32 Megabit Serial Flash Memory With 4kbyte Uniform SectorDocument52 pagesEN25Q32A 32 Megabit Serial Flash Memory With 4kbyte Uniform SectorDavid Zuccarini BarroetaNo ratings yet

- 24AA02/24LC02B: 2KI C Serial EEPROMDocument24 pages24AA02/24LC02B: 2KI C Serial EEPROMMayk OzNo ratings yet

- 24AA16/24LC16B: 16K I C Serial EEPROMDocument25 pages24AA16/24LC16B: 16K I C Serial EEPROMDaniel VásquezNo ratings yet

- Ic PDFDocument36 pagesIc PDFdharamNo ratings yet

- 24AA00/24LC00/24C00: 128-Bit I C Bus Serial EEPROMDocument34 pages24AA00/24LC00/24C00: 128-Bit I C Bus Serial EEPROMKhalid BenaribaNo ratings yet

- 25AA640/25LC640: 64K Spi Bus Serial EEPROMDocument12 pages25AA640/25LC640: 64K Spi Bus Serial EEPROMinsomnium86No ratings yet

- CAT24WC256: 256K-Bit I C Serial Cmos EepromDocument10 pagesCAT24WC256: 256K-Bit I C Serial Cmos EepromAntonio ManuelNo ratings yet

- EEPROM 24LC256 - Microchip PDFDocument28 pagesEEPROM 24LC256 - Microchip PDFValdir DerlannNo ratings yet

- 24aa515, 24LC515, 24FC515Document20 pages24aa515, 24LC515, 24FC515dorudNo ratings yet

- 8K/16K 5.0V SPI Bus Serial EEPROM: Features Package TypesDocument12 pages8K/16K 5.0V SPI Bus Serial EEPROM: Features Package Typesrıdvan71No ratings yet

- SN74LVC2G125 Dual Bus Buffer Gate With 3-State Outputs: 1 Features 3 DescriptionDocument27 pagesSN74LVC2G125 Dual Bus Buffer Gate With 3-State Outputs: 1 Features 3 Descriptionviatr0nicNo ratings yet

- 24aa08 - 24lc08 Eeprom PDFDocument40 pages24aa08 - 24lc08 Eeprom PDFEdgar DauzonNo ratings yet

- EN25Q32C 32 Megabit Serial Flash Memory With 4kbyte Uniform SectorDocument62 pagesEN25Q32C 32 Megabit Serial Flash Memory With 4kbyte Uniform Sectoramir baroughNo ratings yet

- EEPROM 24WC256 - CatalystDocument8 pagesEEPROM 24WC256 - CatalystValdir DerlannNo ratings yet

- Features: or Modifications Due To Changes in Technical Specifications. Rev. C, Issue Date: 2009/10/13Document48 pagesFeatures: or Modifications Due To Changes in Technical Specifications. Rev. C, Issue Date: 2009/10/13Namaku rokibNo ratings yet

- 25 LC 1024Document28 pages25 LC 1024hyd27No ratings yet

- 78M6618 Octal Power and Energy Measurement IC: Description FeaturesDocument32 pages78M6618 Octal Power and Energy Measurement IC: Description FeaturesDanielNo ratings yet

- Saw Filters For Mobile Communication SystemDocument1 pageSaw Filters For Mobile Communication SystemDanielNo ratings yet

- 74VHC4046 CMOS Phase Lock Loop: General DescriptionDocument16 pages74VHC4046 CMOS Phase Lock Loop: General DescriptionDanielNo ratings yet

- 74LVC1G74: 1. General DescriptionDocument21 pages74LVC1G74: 1. General DescriptionDanielNo ratings yet

- Data Sheet: 74HC/HCT688Document7 pagesData Sheet: 74HC/HCT688DanielNo ratings yet

- CD74HC7046A, CD74HCT7046A: Features DescriptionDocument22 pagesCD74HC7046A, CD74HCT7046A: Features DescriptionDanielNo ratings yet

- 74HC Hct4046a CNVDocument34 pages74HC Hct4046a CNVmagicecstaticNo ratings yet

- CD54/74HC4059: High-Speed CMOS Logic CMOS Programmable Divide-by-N CounterDocument7 pagesCD54/74HC4059: High-Speed CMOS Logic CMOS Programmable Divide-by-N CounterDanielNo ratings yet

- 74HCT9046A: 1. General DescriptionDocument43 pages74HCT9046A: 1. General DescriptionDanielNo ratings yet

- SN54HC684, SN74HC684 8-Bit Magnitude Comparators: DescriptionDocument7 pagesSN54HC684, SN74HC684 8-Bit Magnitude Comparators: DescriptionDanielNo ratings yet

- 311Document2 pages311Anonymous cS9UMvhBq100% (2)

- Renr9318 11 00 All - MANUALS SERVICE MODULESDocument160 pagesRenr9318 11 00 All - MANUALS SERVICE MODULESait mimouneNo ratings yet

- 401985Document82 pages401985Julio Cesar Garcia ReyesNo ratings yet

- Asme Section Ii A Sa-388 Sa-388m PDFDocument10 pagesAsme Section Ii A Sa-388 Sa-388m PDFdavid perezNo ratings yet

- Antenna Design Concepts Explained with Multiple Choice QuestionsDocument26 pagesAntenna Design Concepts Explained with Multiple Choice QuestionskolisettyvsureshNo ratings yet

- Design and Implementation of Air Mouse Using Accelerometer SensorDocument3 pagesDesign and Implementation of Air Mouse Using Accelerometer SensorKesthara VNo ratings yet

- Comparison of Analog and Digital InstrumentsDocument3 pagesComparison of Analog and Digital Instrumentsgeerwahid100% (3)

- Frequency ResponseDocument28 pagesFrequency ResponseJalu PrasetyoNo ratings yet

- LG L80 Dual - Schematic Diagarm PDFDocument97 pagesLG L80 Dual - Schematic Diagarm PDFzombie z0% (1)

- Sony Str-De915, Ta-V909, Ve910 Service Manual Ver 1.2 2003.07 (9-920-940-13)Document56 pagesSony Str-De915, Ta-V909, Ve910 Service Manual Ver 1.2 2003.07 (9-920-940-13)Alvaro Santos100% (1)

- ACO 3901manual EditionEDocument104 pagesACO 3901manual EditionEs1234tNo ratings yet

- Control 8x8 LED MatrixDocument1 pageControl 8x8 LED Matrixwhynot05No ratings yet

- EitaDocument3 pagesEitaMasanaNo ratings yet

- Bs 7671 2018 Corrigendum Dec 2018 PDFDocument11 pagesBs 7671 2018 Corrigendum Dec 2018 PDFSimon Rae100% (2)

- Comp Dealer PDFDocument4 pagesComp Dealer PDFmanishaNo ratings yet

- Catalog CerberusPRO 2009 2010Document246 pagesCatalog CerberusPRO 2009 2010Liviu MunteanuNo ratings yet

- AN-MR400 Manual PDFDocument5 pagesAN-MR400 Manual PDFmanyak871No ratings yet

- Basic Electronics, Volumes 1-5, (1955) - Text PDFDocument570 pagesBasic Electronics, Volumes 1-5, (1955) - Text PDFfrankNo ratings yet

- PNR 500Document4 pagesPNR 500Frederic Dionor100% (1)

- Shop directly for VE5-2 Block Contactor Accessories and related productsDocument4 pagesShop directly for VE5-2 Block Contactor Accessories and related productsLuciano PereiraNo ratings yet

- Ecp455 - Lab 7 - Spe-1000-13 Tests Part IDocument4 pagesEcp455 - Lab 7 - Spe-1000-13 Tests Part IKyran WonNo ratings yet

- 3-Pole Contactors (40 - 60hp @ 575V) Selection GuideDocument1 page3-Pole Contactors (40 - 60hp @ 575V) Selection GuideGerman J'IngNo ratings yet

- RGMO Operation PDFDocument133 pagesRGMO Operation PDFKumaraswamyNo ratings yet

- Transformer Failures, Causes and ImpactDocument4 pagesTransformer Failures, Causes and ImpactveraNo ratings yet

- DBS3900 PDFDocument24 pagesDBS3900 PDFKaue LinkNo ratings yet

- Thermostat W3230: Function Description of W3230Document4 pagesThermostat W3230: Function Description of W3230p_venture100% (1)

- Types of Compressor: Reciprocating, Rotary, Flow & Their ApplicationsDocument25 pagesTypes of Compressor: Reciprocating, Rotary, Flow & Their ApplicationsvinayakNo ratings yet

- TR-810 VFDocument4 pagesTR-810 VFamir11601No ratings yet

- 8DJH Produktblatt EN Screen PDFDocument2 pages8DJH Produktblatt EN Screen PDFHung Cuong PhamNo ratings yet