Professional Documents

Culture Documents

32K 2.5V I C Serial EEPROM: Features Package Types

Uploaded by

insomnium86Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

32K 2.5V I C Serial EEPROM: Features Package Types

Uploaded by

insomnium86Copyright:

Available Formats

24LC32A

32K 2.5V I2C™ Serial EEPROM

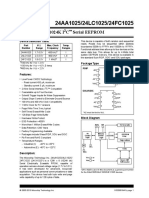

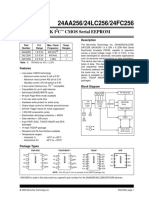

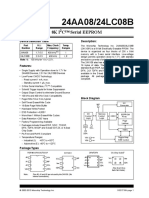

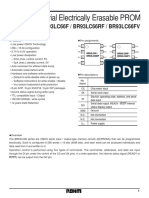

FEATURES PACKAGE TYPES

• Single supply with operation down to 2.5V PDIP

- Maximum write current 3 mA at 6.0V

- Standby current 1 µA max at 2.5V A0 1 8 Vcc

• 2-wire serial interface bus, I2C compatible

24LC32A

• 100 kHz (2.5V) and 400 kHz (5V) compatibility A1 2 7 WP

• Self-timed ERASE and WRITE cycles

• Power on/off data protection circuitry A2 3 6 SCL

• Hardware write protect

• 1,000,000 Erase/Write cycles guaranteed

Vss 4 5 SDA

• 32 byte page or byte write modes available

• Schmitt trigger filtered inputs for noise suppres-

sion

• Output slope control to eliminate ground bounce

SOIC

• 2 ms typical write cycle time, byte or page

• Up to eight devices may be connected to the

same bus for up to 256K bits total memory

A0 1 8 Vcc

• Electrostatic discharge protection > 4000V

• Data retention > 200 years

24LC32A

A1 2 7 WP

• 8-pin PDIP and SOIC packages

• Temperature ranges

A2 3 6 SCL

- Commercial (C): 0°C to +75°C

- Industrial (I): -40°C to +85°C

Vss 4 5 SDA

DESCRIPTION

The Microchip Technology Inc. 24LC32A is a 4K x 8

(32K bit) Serial Electrically Erasable PROM capable of

operation across a broad voltage range (2.5V to 6.0V). BLOCK DIAGRAM

It has been developed for advanced, low power appli-

cations such as personal communications or data A0 A1 A2 WP HV GENERATOR

acquisition. The 24LC32A also has a page-write capa-

bility of up to 32 bytes of data. The 24LC32A is capable

of both random and sequential reads up to the 32K

I/O MEMORY

boundary. Functional address lines allow up to eight CONTROL CONTROL XDEC

EEPROM

ARRAY

24LC32A devices on the same bus, for up to 256K bits LOGIC LOGIC

address space. Advanced CMOS technology and PAGE LATCHES

broad voltage range make this device ideal for low-

power/low-voltage, nonvolatile code and data applica- I/O

SCL

tions. The 24LC32A is available in the standard 8-pin YDEC

plastic DIP and both 150 mil and 200 mil SOIC packag-

SDA

ing.

VCC

VSS SENSE AMP

R/W CONTROL

I2C is a trakemark of Philips Corporation.

1999 Microchip Technology Inc. DS21144D-page 1

24LC32A

1.0 ELECTRICAL TABLE 1-1: PIN FUNCTION TABLE

CHARACTERISTICS Name Function

1.1 Maximum Ratings* A0,A1,A2 User Configurable Chip Selects

VSS Ground

VCC...................................................................................7.0V

All inputs and outputs w.r.t. VSS ............... -0.6V to VCC +1.0V SDA Serial Address/Data I/O

Storage temperature .....................................-65°C to +150°C SCL Serial Clock

Ambient temp. with power applied ................-65°C to +125°C WP Write Protect Input

Soldering temperature of leads (10 seconds) ............. +300°C

ESD protection on all pins ..................................................≥ 4 kV VCC +2.5V to 6.0V Power Supply

*Notice: Stresses above those listed under “Maximum Ratings”

may cause permanent damage to the device. This is a stress rat-

ing only and functional operation of the device at those or any

other conditions above those indicated in the operational listings

of this specification is not implied. Exposure to maximum rating

conditions for extended periods may affect device reliability.

TABLE 1-2: DC CHARACTERISTICS

VCC = +2.5V to 6.0V

Commercial (C): Tamb = 0°C to +70°C

Industrial (I): Tamb = -40°C to +85°C

Parameter Symbol Min Typ Max Units Conditions

A0, A1, A2, SCL , SDA and WP

pins:

High level input voltage VIH .7 VCC — V

Low level input voltage VIL — .3 Vcc V

Hysteresis of Schmitt Trigger VHYS .05 — V (Note)

inputs VCC

Low level output voltage VOL — .40 V IOL = 3.0 mA

Input leakage current ILI -10 10 µA VIN = .1V to VCC

Output leakage current ILO -10 10 µA VOUT = .1V to VCC

Pin capacitance CIN,COUT — 10 pF VCC = 5.0V (Note)

(all inputs/outputs) Tamb = 25°C, Fc = 1 MHz

Operating current ICC Write — 3 mA VCC = 6.0V

ICC Read — 0.5 mA VCC = 6.0V, SCL = 400 KHz

Standby current ICCS — 1 5 µA SCL = SDA = VCC = 5.5V

ICCS 1 µA VCC = 2.5V (Note)

WP = VSS, A0, A1, A2 = VSS

Note: This parameter is periodically sampled and not 100% tested.

FIGURE 1-1: BUS TIMING START/STOP

VHYS

SCL

THD:STA

TSU:STA TSU:STO

SDA

START STOP

DS21144D-page 2 1999 Microchip Technology Inc.

24LC32A

TABLE 1-3: AC CHARACTERISTICS

Vcc = 2.5-6.0V Vcc = 4.5-6.0V

Parameter Symbol Standard Mode Fast Mode Units Remarks

Min Max Min Max

Clock frequency FCLK — 100 — 400 kHz

Clock high time THIGH 4000 — 600 — ns

Clock low time TLOW 4700 — 1300 — ns

SDA and SCL rise time TR — 1000 — 300 ns (Note 1)

SDA and SCL fall time TF — 300 — 300 ns (Note 1)

START condition hold time THD:STA 4000 — 600 — ns After this period the first

clock pulse is generated

START condition setup TSU:STA 4700 — 600 — ns Only relevant for repeated

time START condition

Data input hold time THD:DAT 0 — 0 — ns

Data input setup time TSU:DAT 250 — 100 — ns

STOP condition setup time TSU:STO 4000 — 600 — ns

Output valid from clock TAA — 3500 — 900 ns (Note 2)

Bus free time TBUF 4700 — 1300 — ns Time the bus must be free

before a new transmission

can start

Output fall time from VIH TOF — 250 20 250 ns (Note 1), CB ≤ 100 pF

min to VIL max +0.1CB

Input filter spike suppres- TSP — 50 — 50 ns (Note 3)

sion (SDA and SCL pins)

Write cycle time TWR — 5 — 5 ms Byte or Page mode

Endurance — 1M — 1M — cycles 25°C, Vcc = 5.0V, Block

Mode Cycle (Note 4)

Note 1: Not 100% tested. CB = Total capacitance of one bus line in pF.

2: As a transmitter, the device must provide an internal minimum delay time to bridge the undefined region

(minimum 300 ns) of the falling edge of SCL to avoid unintended generation of START or STOP conditions.

3: The combined TSP and VHYS specifications are due to Schmitt trigger inputs which provide improved noise

and spike suppression. This eliminates the need for a Ti specification for standard operation.

4: This parameter is not tested but guaranteed by characterization. For endurance estimates in a specific appli-

cation, please consult the Total Endurance Model which can be obtained on our website.

FIGURE 1-2: BUS TIMING DATA

TF TR

THIGH

TLOW

SCL

TSU:STA

THD:DAT TSU:DAT TSU:STO

THD:STA

SDA

IN TSP

TAA THD:STA

TAA TBUF

SDA

OUT

1999 Microchip Technology Inc. DS21144D-page 3

24LC32A

2.0 FUNCTIONAL DESCRIPTION 3.4 Data Valid (D)

The 24LC32A supports a Bi-directional 2-wire bus and The state of the data line represents valid data when,

data transmission protocol. A device that sends data after a START condition, the data line is stable for the

onto the bus is defined as transmitter, and a device duration of the HIGH period of the clock signal.

receiving data as receiver. The bus must be controlled

The data on the line must be changed during the LOW

by a master device which generates the Serial Clock

period of the clock signal. There is one clock pulse per

(SCL), controls the bus access, and generates the

bit of data.

START and STOP conditions, while the 24LC32A

works as slave. Both master and slave can operate as Each data transfer is initiated with a START condition

transmitter or receiver but the master device deter- and terminated with a STOP condition. The number of

mines which mode is activated. the data bytes transferred between the START and

STOP conditions is determined by the master device.

3.0 BUS CHARACTERISTICS

The following bus protocol has been defined: 3.5 Acknowledge

• Data transfer may be initiated only when the bus Each receiving device, when addressed, is obliged to

is not busy. generate an acknowledge signal after the reception of

• During data transfer, the data line must remain each byte. The master device must generate an extra

stable whenever the clock line is HIGH. Changes clock pulse which is associated with this acknowledge

in the data line while the clock line is HIGH will be bit.

interpreted as a START or STOP condition.

Note: The 24LC32A does not generate any

Accordingly, the following bus conditions have been acknowledge bits if an internal program-

defined (Figure 3-1). ming cycle is in progress.

3.1 Bus not Busy (A) A device that acknowledges must pull down the SDA

line during the acknowledge clock pulse in such a way

Both data and clock lines remain HIGH. that the SDA line is stable LOW during the HIGH period

of the acknowledge related clock pulse. Of course,

3.2 Start Data Transfer (B) setup and hold times must be taken into account. Dur-

ing reads, a master must signal an end of data to the

A HIGH to LOW transition of the SDA line while the slave by NOT generating an acknowledge bit on the last

clock (SCL) is HIGH determines a START condition. All byte that has been clocked out of the slave. In this case,

commands must be preceded by a START condition. the slave (24LC32A) will leave the data line HIGH to

enable the master to generate the STOP condition.

3.3 Stop Data Transfer (C)

A LOW to HIGH transition of the SDA line while the

clock (SCL) is HIGH determines a STOP condition. All

operations must be ended with a STOP condition.

FIGURE 3-1: DATA TRANSFER SEQUENCE ON THE SERIAL BUS

(A) (B) (D) (D) (C) (A)

SCL

SDA

START ADDRESS OR DATA STOP

CONDITION ACKNOWLEDGE ALLOWED CONDITION

VALID TO CHANGE

DS21144D-page 4 1999 Microchip Technology Inc.

24LC32A

3.6 Device Addressing Following the start condition, the 24LC32A monitors

the SDA bus checking the device type identifier being

A control byte is the first byte received following the transmitted. Upon receiving a 1010 code and appropri-

start condition from the master device. The control byte ate device select bits, the slave device outputs an

consists of a 4-bit control code; for the 24LC32A this is acknowledge signal on the SDA line. Depending on the

set as 1010 binary for read and write (R/W) operations. state of the R/W bit, the 24LC32A will select a read or

The next three bits of the control byte are the device write operation.

select bits (A2, A1, A0). They are used by the master

device to select which of the eight devices are to be Control

Operation Device Select R/W

accessed. These bits are in effect the three most signif- Code

icant bits of the word address. The last bit of the control Read 1010 Device Address 1

byte defines the operation to be performed. When set

Write 1010 Device Address 0

to a one a read operation is selected, and when set to

a zero a write operation is selected. The next two bytes

received define the address of the first data byte

(Figure 3-3). Because only A11...A0 are used, the

upper four address bits must be zeros. The most signif-

icant bit of the most significant byte of the address is

transferred first.

FIGURE 3-2: CONTROL BYTE

ALLOCATION

START READ/WRITE

SLAVE ADDRESS R/W A

1 0 1 0 A2 A1 A0

FIGURE 3-3: ADDRESS SEQUENCE BIT ASSIGNMENTS

CONTROL BYTE ADDRESS BYTE 1 ADDRESS BYTE 0

A A A A A A A A A

1 0 1 0 2 1 0 R/W 0 0 0 0 11 10 9 8 7 • • • • • • 0

SLAVE DEVICE

ADDRESS SELECT

BUS

1999 Microchip Technology Inc. DS21144D-page 5

24LC32A

4.0 WRITE OPERATION 4.2 Page Write

4.1 Byte Write The write control byte, word address and the first data

byte are transmitted to the 24LC32A in the same way

Following the start condition from the master, the con- as in a byte write. But instead of generating a stop con-

trol code (four bits), the device select (three bits), and dition, the master transmits up to 32 bytes which are

the R/W bit which is a logic low are clocked onto the bus temporarily stored in the on-chip page buffer and will be

by the master transmitter. This indicates to the written into memory after the master has transmitted a

addressed slave receiver that a byte with a word stop condition. After receipt of each word, the five lower

address will follow after it has generated an acknowl- address pointer bits are internally incremented by one.

edge bit during the ninth clock cycle. Therefore, the If the master should transmit more than 32 bytes prior

next byte transmitted by the master is the high-order to generating the stop condition, the address counter

byte of the word address and will be written into the will roll over and the previously received data will be

address pointer of the 24LC32A. The next byte is the overwritten. As with the byte write operation, once the

least significant address byte. After receiving another stop condition is received, an internal write cycle will

acknowledge signal from the 24LC32A the master begin. (Figure 4-2).

device will transmit the data word to be written into the

addressed memory location. Note: Page write operations are limited to writing

bytes within a single physical page, regard-

The 24LC32A acknowledges again and the master

less of the number of bytes actually being

generates a stop condition. This initiates the internal

written. Physical page boundaries start at

write cycle, and during this time the 24LC32A will not

addresses that are integer multiples of the

generate acknowledge signals (Figure 4-1).

page buffer size (or ‘page size’) and end at

addresses that are integer multiples of

[page size - 1]. If a page write command

attempts to write across a physical page

boundary, the result is that the data wraps

around to the beginning of the current page

(overwriting data previously stored there),

instead of being written to the next page as

might be expected. It is therefore neces-

sary for the application software to prevent

page write operations that would attempt to

cross a page boundary.

FIGURE 4-1: BYTE WRITE

S

BUS ACTIVITY T S

A CONTROL ADDRESS ADDRESS T

MASTER LOW BYTE DATA

R BYTE HIGH BYTE O

T P

SDA LINE S 0 0 0 0 P

A A A A

BUS ACTIVITY C C C C

K K K K

FIGURE 4-2: PAGE WRITE

S

BUS ACTIVITY T S

MASTER A CONTROL ADDRESS ADDRESS T

R BYTE HIGH BYTE LOW BYTE O

T DATA BYTE 0 DATA BYTE 31 P

SDA LINE S 0 0 0 0 P

A A A A

BUS ACTIVITY C C C C

K K K K

DS21144D-page 6 1999 Microchip Technology Inc.

24LC32A

5.0 ACKNOWLEDGE POLLING 6.0 READ OPERATION

Since the device will not acknowledge during a write Read operations are initiated in the same way as write

cycle, this can be used to determine when the cycle is operations with the exception that the R/W bit of the

complete (this feature can be used to maximize bus slave address is set to one. There are three basic types

throughput). Once the stop condition for a write com- of read operations: current address read, random read,

mand has been issued from the master, the device ini- and sequential read.

tiates the internally timed write cycle. Acknowledge

Polling (ACK) can be initiated immediately. This 6.1 Current Address Read

involves the master sending a start condition followed

The 24LC32A contains an address counter that main-

by the control byte for a write command (R/W = 0). If the

tains the address of the last word accessed, internally

device is still busy with the write cycle, then NO ACK

incremented by one. Therefore, if the previous access

will be returned. If the cycle is complete, then the

(either a read or write operation) was to address n (n is

device will return the ACK and the master can then pro-

any legal address), the next current address read oper-

ceed with the next read or write command. See

ation would access data from address n + 1. Upon

Figure 5-1 for flow diagram.

receipt of the slave address with R/W bit set to one, the

FIGURE 5-1: ACKNOWLEDGE POLLING 24LC32A issues an acknowledge and transmits the

FLOW eight bit data word. The master will not acknowledge

the transfer but does generate a stop condition and the

Send 24LC32A discontinues transmission (Figure 6-1).

Write Command

6.2 Random Read

Send Stop Random read operations allow the master to access

Condition to any memory location in a random manner. To perform

Initiate Write Cycle this type of read operation, first the word address must

be set. This is done by sending the word address to the

24LC32A as part of a write operation (R/W bit set to

Send Start zero). After the word address is sent, the master gen-

erates a start condition following the acknowledge. This

terminates the write operation, but not before the inter-

nal address pointer is set. Then the master issues the

Send Control Byte control byte again but with the R/W bit set to a one. The

with R/W = 0 24LC32A will then issue an acknowledge and transmit

the 8-bit data word. The master will not acknowledge

the transfer but does generate a stop condition which

causes the 24LC32A to discontinue transmission

Did Device NO

Acknowledge (Figure 6-2).

(ACK = 0)?

6.3 Contiguous Addressing Across

YES Multiple Devices

Next The device select bits A2, A1, A0 can be used to

Operation

expand the contiguous address space for up to 256K

bits by adding up to eight 24LC32A’s on the same bus.

In this case, software can use A0 of the control byte as

address bit A12, A1 as address bit A13, and A2 as

address bit A14.

1999 Microchip Technology Inc. DS21144D-page 7

24LC32A

6.4 Sequential Read To provide sequential reads the 24LC32A contains an

internal address pointer which is incremented by one at

Sequential reads are initiated in the same way as a ran- the completion of each operation. This address pointer

dom read except that after the 24LC32A transmits the allows the entire memory contents to be serially read

first data byte, the master issues an acknowledge as during one operation. The internal address pointer will

opposed to the stop condition used in a random read. automatically roll over from address 0FFF to address

This acknowledge directs the 24LC32A to transmit the 000 if the master acknowledges the byte received from

next sequentially addressed 8-bit word (Figure 6-3). the array address 0FFF.

Following the final byte transmitted to the master, the

master will NOT generate an acknowledge but will gen-

erate a stop condition.

FIGURE 6-1: CURRENT ADDRESS READ

S

BUS ACTIVITY T S

MASTER A T

R CONTROL BYTE DATA BYTE O

T P

SDA LINE S P

A N

BUS ACTIVITY C O

K

A

C

K

FIGURE 6-2: RANDOM READ

S S

T T S

BUS ACTIVITY A CONTROL ADDRESS A

MASTER ADDRESS CONTROL DATA T

R BYTE HIGH BYTE LOW BYTE R BYTE BYTE O

T T P

SDA LINE S 0 0 0 0 S P

A A A A N

BUS ACTIVITY C C C C O

K K K K

A

C

K

FIGURE 6-3: SEQUENTIAL READ

S

BUS ACTIVITY T

MASTER CONTROL DATA n DATA n + 1 DATA n + 2 DATA n + x O

BYTE P

P

SDA LINE

A A A A N

C C C C O

BUS ACTIVITY K K K K

A

C

K

DS21144D-page 8 1999 Microchip Technology Inc.

24LC32A

7.0 PIN DESCRIPTIONS 8.0 NOISE PROTECTION

The SCL and SDA inputs have filter circuits which sup-

7.1 A0, A1, A2 Chip Address Inputs

press noise spikes to ensure proper device operation

The A0..A2 inputs are used by the 24LC32A for multi- even on a noisy bus. All I/O lines incorporate Schmitt

ple device operation and conform to the 2-wire bus triggers for 400 kHz (Fast Mode) compatibility.

standard. The levels applied to these pins define the 9.0 POWER MANAGEMENT

address block occupied by the device in the address

map. A particular device is selected by transmitting the This design incorporates a power standby mode when

corresponding bits (A2, A1, A0) in the control byte the device is not in use and automatically powers off

(Figure 3-3). after the normal termination of any operation when a

stop bit is received and all internal functions are com-

7.2 SDA Serial Address/Data Input/Output plete. This includes any error conditions, i.e., not

receiving an acknowledge or stop condition per the 2-

This is a Bi-directional pin used to transfer addresses wire bus specification. The device also incorporates

and data into and data out of the device. It is an open VDD monitor circuitry to prevent inadvertent writes

drain terminal, therefore the SDA bus requires a pullup (data corruption) during low-voltage conditions. The

resistor to VCC (typical 10KΩ for 100 kHz, 2 KΩ for VDD monitor circuitry is powered off when the device is

400 kHz) in standby mode in order to further reduce power con-

For normal data transfer SDA is allowed to change only sumption.

during SCL low. Changes during SCL HIGH are

reserved for indicating the START and STOP condi-

tions.

7.3 SCL Serial Clock

This input is used to synchronize the data transfer from

and to the device.

7.4 WP

This pin must be connected to either VSS or VCC.

If tied to VSS, normal memory operation is enabled

(read/write the entire memory 000-FFF).

If tied to VCC, WRITE operations are inhibited. The

entire memory will be write-protected. Read operations

are not affected.

1999 Microchip Technology Inc. DS21144D-page 9

24LC32A

NOTES:

DS21144D-page 10 1999 Microchip Technology Inc.

24LC32A

24LC32A Product Identification System

To order or to obtain information, e.g., on pricing or delivery, please use the listed part numbers, and refer to the factory or the listed

sales offices.

24LC32A - /P

P = Plastic DIP (300 mil Body), 8-lead

Package: SN = Plastic SOIC (150 mil Body, EIAJ standard), 8-lead

SM = Plastic SOIC (207 mil Body, EIAJ standard), 8-lead

Temperature Blank = 0°C to +70°C

Range: I = -40°C to +85°C

Device: 24LC32A 32K I2C Serial EEPROM (100 kHz, 400 kHz)

24LC32AT 32K I2C Serial EEPROM (Tape and Reel)

Sales and Support

Data Sheets

Products supported by a preliminary Data Sheet may have an errata sheet describing minor operational differences and recom-

mended workarounds. To determine if an errata sheet exists for a particular device, please contact one of the following:

1. Your local Microchip sales office

2. The Microchip Corporate Literature Center U.S. FAX: (602) 786-7277

3. The Microchip Worldwide Site (www.microchip.com)

Please specify which device, revision of silicon and Data Sheet (include Literature #) you are using.

New Customer Notification System

Register on our web site (www.microchip.com/cn) to receive the most current information on our products.

1999 Microchip Technology Inc. DS21144D-page 11

WORLDWIDE SALES AND SERVICE

AMERICAS AMERICAS (continued) ASIA/PACIFIC (continued)

Corporate Office Toronto Singapore

Microchip Technology Inc. Microchip Technology Inc. Microchip Technology Singapore Pte Ltd.

2355 West Chandler Blvd. 5925 Airport Road, Suite 200 200 Middle Road

Chandler, AZ 85224-6199 Mississauga, Ontario L4V 1W1, Canada #07-02 Prime Centre

Tel: 480-786-7200 Fax: 480-786-7277 Tel: 905-405-6279 Fax: 905-405-6253 Singapore 188980

Technical Support: 480-786-7627 ASIA/PACIFIC Tel: 65-334-8870 Fax: 65-334-8850

Web Address: http://www.microchip.com Taiwan, R.O.C

Hong Kong Microchip Technology Taiwan

Atlanta Microchip Asia Pacific 10F-1C 207

Microchip Technology Inc. Unit 2101, Tower 2 Tung Hua North Road

500 Sugar Mill Road, Suite 200B Metroplaza Taipei, Taiwan, ROC

Atlanta, GA 30350 223 Hing Fong Road Tel: 886-2-2717-7175 Fax: 886-2-2545-0139

Tel: 770-640-0034 Fax: 770-640-0307 Kwai Fong, N.T., Hong Kong

Boston Tel: 852-2-401-1200 Fax: 852-2-401-3431 EUROPE

Microchip Technology Inc. Beijing United Kingdom

5 Mount Royal Avenue Microchip Technology, Beijing Arizona Microchip Technology Ltd.

Marlborough, MA 01752 Unit 915, 6 Chaoyangmen Bei Dajie 505 Eskdale Road

Tel: 508-480-9990 Fax: 508-480-8575 Dong Erhuan Road, Dongcheng District Winnersh Triangle

Chicago New China Hong Kong Manhattan Building Wokingham

Microchip Technology Inc. Beijing 100027 PRC Berkshire, England RG41 5TU

333 Pierce Road, Suite 180 Tel: 86-10-85282100 Fax: 86-10-85282104 Tel: 44 118 921 5858 Fax: 44-118 921-5835

Itasca, IL 60143 India Denmark

Tel: 630-285-0071 Fax: 630-285-0075 Microchip Technology Inc. Microchip Technology Denmark ApS

Dallas India Liaison Office Regus Business Centre

Microchip Technology Inc. No. 6, Legacy, Convent Road Lautrup hoj 1-3

4570 Westgrove Drive, Suite 160 Bangalore 560 025, India Ballerup DK-2750 Denmark

Addison, TX 75248 Tel: 91-80-229-0061 Fax: 91-80-229-0062 Tel: 45 4420 9895 Fax: 45 4420 9910

Tel: 972-818-7423 Fax: 972-818-2924 Japan France

Dayton Microchip Technology Intl. Inc. Arizona Microchip Technology SARL

Microchip Technology Inc. Benex S-1 6F Parc d’Activite du Moulin de Massy

Two Prestige Place, Suite 150 3-18-20, Shinyokohama 43 Rue du Saule Trapu

Miamisburg, OH 45342 Kohoku-Ku, Yokohama-shi Batiment A - ler Etage

Tel: 937-291-1654 Fax: 937-291-9175 Kanagawa 222-0033 Japan 91300 Massy, France

Detroit Tel: 81-45-471- 6166 Fax: 81-45-471-6122 Tel: 33-1-69-53-63-20 Fax: 33-1-69-30-90-79

Microchip Technology Inc. Korea Germany

Tri-Atria Office Building Microchip Technology Korea Arizona Microchip Technology GmbH

32255 Northwestern Highway, Suite 190 168-1, Youngbo Bldg. 3 Floor Gustav-Heinemann-Ring 125

Farmington Hills, MI 48334 Samsung-Dong, Kangnam-Ku D-81739 München, Germany

Tel: 248-538-2250 Fax: 248-538-2260 Seoul, Korea Tel: 49-89-627-144 0 Fax: 49-89-627-144-44

Los Angeles Tel: 82-2-554-7200 Fax: 82-2-558-5934 Italy

Microchip Technology Inc. Shanghai Arizona Microchip Technology SRL

18201 Von Karman, Suite 1090 Microchip Technology Centro Direzionale Colleoni

Irvine, CA 92612 RM 406 Shanghai Golden Bridge Bldg. Palazzo Taurus 1 V. Le Colleoni 1

Tel: 949-263-1888 Fax: 949-263-1338 2077 Yan’an Road West, Hong Qiao District 20041 Agrate Brianza

New York Shanghai, PRC 200335 Milan, Italy

Microchip Technology Inc. Tel: 86-21-6275-5700 Fax: 86 21-6275-5060 Tel: 39-039-65791-1 Fax: 39-039-6899883

150 Motor Parkway, Suite 202

11/15/99

Hauppauge, NY 11788

Tel: 631-273-5305 Fax: 631-273-5335

San Jose Microchip received QS-9000 quality system

Microchip Technology Inc. certification for its worldwide headquarters,

2107 North First Street, Suite 590 design and wafer fabrication facilities in

San Jose, CA 95131 Chandler and Tempe, Arizona in July 1999. The

Tel: 408-436-7950 Fax: 408-436-7955 Company’s quality system processes and

procedures are QS-9000 compliant for its

PICmicro® 8-bit MCUs, KEELOQ® code hopping

devices, Serial EEPROMs and microperipheral

products. In addition, Microchip’s quality

system for the design and manufacture of

development systems is ISO 9001 certified.

All rights reserved. © 1999 Microchip Technology Incorporated. Printed in the USA. 11/99 Printed on recycled paper.

Information contained in this publication regarding device applications and the like is intended for suggestion only and may be superseded by updates. No representation or warranty is given and no liability is assumed

by Microchip Technology Incorporated with respect to the accuracy or use of such information, or infringement of patents or other intellectual property rights arising from such use or otherwise. Use of Microchip’s products

as critical components in life support systems is not authorized except with express written approval by Microchip. No licenses are conveyed, implicitly or otherwise, under any intellectual property rights. The Microchip

logo and name are registered trademarks of Microchip Technology Inc. in the U.S.A. and other countries. All rights reserved. All other trademarks mentioned herein are the property of their respective companies.

1999 Microchip Technology Inc.

You might also like

- 32K 5.0V I C Serial EEPROM: Features Package TypesDocument12 pages32K 5.0V I C Serial EEPROM: Features Package Typesinsomnium86No ratings yet

- 24C32Document12 pages24C32SilviuCocoloșNo ratings yet

- 32K 5.0V I C Serial EEPROM: Features Package TypesDocument12 pages32K 5.0V I C Serial EEPROM: Features Package TypesChrono GtzNo ratings yet

- 24AA64/24LC64/24FC64: 64K I C Serial EEPROMDocument28 pages24AA64/24LC64/24FC64: 64K I C Serial EEPROMJuan Luis Pineda GonzálezNo ratings yet

- 24AA02/24LC02B: 2KI C Serial EEPROMDocument24 pages24AA02/24LC02B: 2KI C Serial EEPROMMayk OzNo ratings yet

- 24l1026i Memoria EEPROM 1024kDocument28 pages24l1026i Memoria EEPROM 1024kMarta_d_eNo ratings yet

- 24LC04B PDFDocument22 pages24LC04B PDFEddy RosarioNo ratings yet

- 24AA1025/24LC1025/24FC1025: 1024K I C Serial EEPROMDocument29 pages24AA1025/24LC1025/24FC1025: 1024K I C Serial EEPROMSudhagarSubbiyanNo ratings yet

- 24aa515, 24LC515, 24FC515Document20 pages24aa515, 24LC515, 24FC515dorudNo ratings yet

- 24AA02/24LC02B: 2KI C Serial EEPROMDocument32 pages24AA02/24LC02B: 2KI C Serial EEPROMhanifNo ratings yet

- 32K 5.0V I C Smart Serial EEPROM: Features Package TypesDocument12 pages32K 5.0V I C Smart Serial EEPROM: Features Package TypesRamon LopezNo ratings yet

- 24FC1025 EepromDocument28 pages24FC1025 EepromAnirudh ReddyNo ratings yet

- 16K I C Serial EEPROM Extended (M) Operating Temperatures: Number V Range Max. Clock Frequency Temp. RangesDocument22 pages16K I C Serial EEPROM Extended (M) Operating Temperatures: Number V Range Max. Clock Frequency Temp. RangeshcarcaroNo ratings yet

- 24AA16/24LC16B: 16K I C Serial EEPROMDocument25 pages24AA16/24LC16B: 16K I C Serial EEPROMDaniel VásquezNo ratings yet

- 21711c PDFDocument24 pages21711c PDFAbdessamad EladakNo ratings yet

- Datasheet PDFDocument26 pagesDatasheet PDFNicoli LourençoNo ratings yet

- 24AA256/24LC256: 256K I C Cmos Serial EepromDocument12 pages24AA256/24LC256: 256K I C Cmos Serial EepromWelleyNo ratings yet

- 24AA52/24LCS52: 2K 2.2V I C Serial EEPROM With Software Write-ProtectDocument24 pages24AA52/24LCS52: 2K 2.2V I C Serial EEPROM With Software Write-Protecta4rfanNo ratings yet

- 1K 2.5V Dual Mode I C Serial EEPROM: Features Package TypesDocument12 pages1K 2.5V Dual Mode I C Serial EEPROM: Features Package TypesVictor TruccoNo ratings yet

- 24Lc08B/16B Modules: 8K/16K I C Serial Eeproms in Iso MicromodulesDocument12 pages24Lc08B/16B Modules: 8K/16K I C Serial Eeproms in Iso MicromodulesarminNo ratings yet

- 24AA1025 24LC1025 24FC1025 1024 Kbit I2C Serial EE-2853738Document32 pages24AA1025 24LC1025 24FC1025 1024 Kbit I2C Serial EE-2853738İbrahim DemircioğluNo ratings yet

- Atmel 24c02 PDFDocument30 pagesAtmel 24c02 PDFMAX GNo ratings yet

- 1K 5.0V I C™ Serial EEPROM: Features: DescriptionDocument36 pages1K 5.0V I C™ Serial EEPROM: Features: DescriptionDanna PerezNo ratings yet

- 24AA16 24LC16B 24FC16 16K I2C Serial EEPROM 20001703PDocument49 pages24AA16 24LC16B 24FC16 16K I2C Serial EEPROM 20001703Pmarko.jojicoo777No ratings yet

- 24AA02H 24LC02BH 2K I2C Serial EEPROM With Half Array Write Protect 20002105BDocument40 pages24AA02H 24LC02BH 2K I2C Serial EEPROM With Half Array Write Protect 20002105BAlhassan Ahmed OmranNo ratings yet

- 24 LC 256Document38 pages24 LC 256johnNo ratings yet

- EEPROM 24LC256 - Microchip PDFDocument28 pagesEEPROM 24LC256 - Microchip PDFValdir DerlannNo ratings yet

- 24AA00/24LC00/24C00: 128-Bit I C Bus Serial EEPROMDocument34 pages24AA00/24LC00/24C00: 128-Bit I C Bus Serial EEPROMKhalid BenaribaNo ratings yet

- 24aa08 - 24lc08 Eeprom PDFDocument40 pages24aa08 - 24lc08 Eeprom PDFEdgar DauzonNo ratings yet

- I2c EEPROM 24xx256 DsDocument28 pagesI2c EEPROM 24xx256 DsRizwan AmirNo ratings yet

- 11aa02iud 1wire MicrochipDocument32 pages11aa02iud 1wire MicrochipManutenção eletrônicaNo ratings yet

- 24aa512 Mic PDFDocument28 pages24aa512 Mic PDFkt2018No ratings yet

- 21073K PDFDocument24 pages21073K PDFadfumegaNo ratings yet

- 24aa256uid 256k I2c Serial Eeprom With Eui48 Eui64 20005215dDocument28 pages24aa256uid 256k I2c Serial Eeprom With Eui48 Eui64 20005215dAbhishek BhattacharjeeNo ratings yet

- 8K/16K 5.0V SPI Bus Serial EEPROM: Features Package TypesDocument12 pages8K/16K 5.0V SPI Bus Serial EEPROM: Features Package Typesrıdvan71No ratings yet

- 24AA64/24LC64/24FC64: 64K I C™ Serial EEPROMDocument45 pages24AA64/24LC64/24FC64: 64K I C™ Serial EEPROMJuan Carlos CrespoNo ratings yet

- CAT24C32: 32-Kb I C Cmos Serial Eeprom Features Device DescriptionDocument18 pagesCAT24C32: 32-Kb I C Cmos Serial Eeprom Features Device DescriptionPierpaolo GustinNo ratings yet

- 25AA160/25LC160/25C160: 16K Spi Bus Serial EEPROMDocument23 pages25AA160/25LC160/25C160: 16K Spi Bus Serial EEPROMЕвгенийNo ratings yet

- 24C320-EP MicrochipTechnologyDocument12 pages24C320-EP MicrochipTechnologyMateus CorrêaNo ratings yet

- 24C64 - EepromDocument20 pages24C64 - Eepromropay61705No ratings yet

- 24LC08 PDFDocument30 pages24LC08 PDFJaime BarrancoNo ratings yet

- 24AA08/24LC08B: 8KI C Serial EEPROMDocument30 pages24AA08/24LC08B: 8KI C Serial EEPROMjoseNo ratings yet

- 24AA00/24LC00/24C00: 128 Bit I C™ Bus Serial EEPROMDocument12 pages24AA00/24LC00/24C00: 128 Bit I C™ Bus Serial EEPROMmacepaNo ratings yet

- 22122a.book - 11AA02E48T-I-TT-MicrochipDocument2 pages22122a.book - 11AA02E48T-I-TT-MicrochipIori CharaNo ratings yet

- 4 PDFDocument31 pages4 PDFAgus OrtizNo ratings yet

- 24AA128/24LC128/24FC128: 128K I C Cmos Serial EepromDocument26 pages24AA128/24LC128/24FC128: 128K I C Cmos Serial EepromcraponzelNo ratings yet

- 25AA160A/B, 25LC160A/B: 16K SPI Bus Serial EEPROMDocument26 pages25AA160A/B, 25LC160A/B: 16K SPI Bus Serial EEPROMmuglanNo ratings yet

- 2-Wire Serial EEPROM: FeaturesDocument19 pages2-Wire Serial EEPROM: FeaturesAgustin AndrokaitesNo ratings yet

- 24C1 Memoria Eeprom SankeyDocument11 pages24C1 Memoria Eeprom Sankeyjavier venturaNo ratings yet

- 25AA1024Document30 pages25AA1024Bình MaiNo ratings yet

- Bus Serial EEPROMDocument12 pagesBus Serial EEPROMMatiasNo ratings yet

- 24lc512 DatasheetDocument27 pages24lc512 DatasheetLeonardo QuevedoNo ratings yet

- 25AA640/25LC640/25C640: 64K Spi Bus Serial EEPROMDocument11 pages25AA640/25LC640/25C640: 64K Spi Bus Serial EEPROMAndrey OliveiraNo ratings yet

- 24C256Document14 pages24C256Việt Thảo TrầnNo ratings yet

- Two-Wire Serial EEPROM 2K: Wuhan Eshine Technology Co., LTDDocument20 pagesTwo-Wire Serial EEPROM 2K: Wuhan Eshine Technology Co., LTDgrufNo ratings yet

- 25 LC 1024Document28 pages25 LC 1024hyd27No ratings yet

- CAT24WC256: 256K-Bit I C Serial Cmos EepromDocument10 pagesCAT24WC256: 256K-Bit I C Serial Cmos EepromAntonio ManuelNo ratings yet

- AT24C01A/02/04/08/16: FeaturesDocument14 pagesAT24C01A/02/04/08/16: FeaturesVeronica GonzalezNo ratings yet

- NM93C66 4096-Bit Serial CMOS EEPROM (MICROWIRE™ Synchronous Bus)Document13 pagesNM93C66 4096-Bit Serial CMOS EEPROM (MICROWIRE™ Synchronous Bus)insomnium86No ratings yet

- FM93C66A 4K-Bit Serial CMOS EEPROM (MICROWIRE™ Synchronous Bus)Document13 pagesFM93C66A 4K-Bit Serial CMOS EEPROM (MICROWIRE™ Synchronous Bus)insomnium86No ratings yet

- HT93LC56: 2K 3-Wire CMOS Serial EEPROMDocument10 pagesHT93LC56: 2K 3-Wire CMOS Serial EEPROMinsomnium86No ratings yet

- NM93C66A 4K-Bit Serial CMOS EEPROM (MICROWIRE™ Synchronous Bus)Document13 pagesNM93C66A 4K-Bit Serial CMOS EEPROM (MICROWIRE™ Synchronous Bus)insomnium86No ratings yet

- FM93C86A 16K-Bit Serial CMOS EEPROM (MICROWIRE™ Synchronous Bus)Document13 pagesFM93C86A 16K-Bit Serial CMOS EEPROM (MICROWIRE™ Synchronous Bus)insomnium86No ratings yet

- NM93CS66 (MICROWIRE™ Bus Interface) 4096-Bit Serial EEPROM With Data Protect and Sequential ReadDocument16 pagesNM93CS66 (MICROWIRE™ Bus Interface) 4096-Bit Serial EEPROM With Data Protect and Sequential Readinsomnium86No ratings yet

- Nonvolatile Memory 8-Kbit E Prom With C Bus Interface SDA 2586-5Document12 pagesNonvolatile Memory 8-Kbit E Prom With C Bus Interface SDA 2586-5insomnium86No ratings yet

- HT93LC56: 2K 3-Wire CMOS Serial EEPROMDocument10 pagesHT93LC56: 2K 3-Wire CMOS Serial EEPROMinsomnium86No ratings yet

- 93LC66A/B: 4K 2.5V Microwire Serial EEPROMDocument12 pages93LC66A/B: 4K 2.5V Microwire Serial EEPROMinsomnium86No ratings yet

- 1K 5.0V Microwire Serial EEPROM: Features Block DiagramDocument12 pages1K 5.0V Microwire Serial EEPROM: Features Block Diagraminsomnium86No ratings yet

- 2,048-Bit Serial Electrically Erasable PROM: BR93LC56 / BR93LC56F / BR93LC56RF / BR93LC56FVDocument12 pages2,048-Bit Serial Electrically Erasable PROM: BR93LC56 / BR93LC56F / BR93LC56RF / BR93LC56FVinsomnium86No ratings yet

- 4,096-Bit Serial Electrically Erasable PROM: BR93LC66 / BR93LC66F / BR93LC66RF / BR93LC66FVDocument12 pages4,096-Bit Serial Electrically Erasable PROM: BR93LC66 / BR93LC66F / BR93LC66RF / BR93LC66FVinsomnium86No ratings yet

- 93c56 DatasheetDocument15 pages93c56 DatasheetsakerhetfreakNo ratings yet

- SPI Serial Eeproms: FeaturesDocument16 pagesSPI Serial Eeproms: FeaturesBachi403No ratings yet

- FM93C66 4096-Bit Serial CMOS EEPROM (MICROWIRE™ Synchronous Bus)Document13 pagesFM93C66 4096-Bit Serial CMOS EEPROM (MICROWIRE™ Synchronous Bus)insomnium86No ratings yet

- 2-Wire Serial Eeprom: FeaturesDocument2 pages2-Wire Serial Eeprom: Featuresinsomnium86No ratings yet

- 25AA080/25LC080/25C080: 8K Spi Bus Serial EEPROMDocument16 pages25AA080/25LC080/25C080: 8K Spi Bus Serial EEPROMinsomnium86No ratings yet

- FM Tranceiver DataDocument9 pagesFM Tranceiver Datainsomnium86No ratings yet

- Interfacing The X24C44-45Document4 pagesInterfacing The X24C44-45insomnium86No ratings yet

- 2-Wire Serial Eeproms: FeaturesDocument16 pages2-Wire Serial Eeproms: FeaturesTuan Pham AnhNo ratings yet

- 93LC66A/B: 4K 2.5V Microwire Serial EEPROMDocument12 pages93LC66A/B: 4K 2.5V Microwire Serial EEPROMinsomnium86No ratings yet

- 25AA640/25LC640: 64K Spi Bus Serial EEPROMDocument12 pages25AA640/25LC640: 64K Spi Bus Serial EEPROMinsomnium86No ratings yet

- Application Note An-00100: RF 101 Information For The RF ChallengedDocument5 pagesApplication Note An-00100: RF 101 Information For The RF Challengedinsomnium86No ratings yet

- Product Technical Data: 418Mhz Am Miniature Transmitter Module (Micro TX) Nv08JDocument4 pagesProduct Technical Data: 418Mhz Am Miniature Transmitter Module (Micro TX) Nv08Jinsomnium86No ratings yet

- FMT M - Fmtx1-Xxxx: Ransmitter OdulesDocument6 pagesFMT M - Fmtx1-Xxxx: Ransmitter Odulesinsomnium86No ratings yet

- FM Tranciever AppsDocument7 pagesFM Tranciever Appsinsomnium86No ratings yet

- Application Note An-00160: Considerations For Sending Data With The HP SeriesDocument6 pagesApplication Note An-00160: Considerations For Sending Data With The HP Seriesinsomnium86No ratings yet

- Application Note An-00500: Antennas: Design, Application, PerformanceDocument7 pagesApplication Note An-00500: Antennas: Design, Application, PerformanceAnonymous 0qYv7WpgNo ratings yet

- Informatica Data Quality Data SheetDocument4 pagesInformatica Data Quality Data SheetKuldeep VenatiNo ratings yet

- How To Use Excel Data Model & Relationships Chandoo - Org - Learn Excel, Power BI & Charting OnlineDocument23 pagesHow To Use Excel Data Model & Relationships Chandoo - Org - Learn Excel, Power BI & Charting OnlineAnonymous RQQTvjNo ratings yet

- Data Communication Errors: Networking 2Document24 pagesData Communication Errors: Networking 2Leonelyn Hermosa Gasco - CosidoNo ratings yet

- Cygnus 517Document125 pagesCygnus 517nitin chaurasia0% (2)

- 10ec71 NotesDocument129 pages10ec71 NotesMSAMHOURINo ratings yet

- Getting Started With Distributed SQDocument7 pagesGetting Started With Distributed SQRonaldMartinezNo ratings yet

- Uss 24178253 Spec 76Document77 pagesUss 24178253 Spec 76Raghu RaamanNo ratings yet

- Pci 22 PDFDocument322 pagesPci 22 PDFAnonymous pcNdMpNENo ratings yet

- ECW - ERDAS Compress WaveletsDocument4 pagesECW - ERDAS Compress WaveletsHoi ChongNo ratings yet

- Absence Creation From BackendDocument105 pagesAbsence Creation From BackendkiranNo ratings yet

- 73K224BL V.22bis/V.22/V.21/Bell 212A/103 Single-Chip Modem W/ Integrated HybridDocument33 pages73K224BL V.22bis/V.22/V.21/Bell 212A/103 Single-Chip Modem W/ Integrated HybridNguyễn Văn TrungNo ratings yet

- Realtime C121TADocument1 pageRealtime C121TARayavaram RayavaramNo ratings yet

- Database Security and Integrity Group 3Document52 pagesDatabase Security and Integrity Group 3Jm McCallNo ratings yet

- PDFDocument72 pagesPDFOtman Mauricio Garzon SantiagoNo ratings yet

- Sysadmin's Networking Cheat SheetDocument2 pagesSysadmin's Networking Cheat SheetPriyansh SinghNo ratings yet

- Kubernetes CKAD Weekly Challenge #7 Migrate A ServiceDocument11 pagesKubernetes CKAD Weekly Challenge #7 Migrate A ServiceRpl MarseilleNo ratings yet

- Computer PackagesDocument72 pagesComputer PackagesBildad JoashNo ratings yet

- LRU AlgorithmDocument14 pagesLRU AlgorithmsumikannuNo ratings yet

- FYBCA SemII Slips2Document30 pagesFYBCA SemII Slips2JS vinesNo ratings yet

- Delta Queue QuestionsDocument5 pagesDelta Queue QuestionsSugguna ViswanadthNo ratings yet

- How To Perform A SQL Server Health Check - Brad McGeheeDocument18 pagesHow To Perform A SQL Server Health Check - Brad McGeheeTaoqir KhosaNo ratings yet

- External HDD Error - You Need To Format The Disk Before You Can Use It Solved - Windows 7 Help ForumsDocument3 pagesExternal HDD Error - You Need To Format The Disk Before You Can Use It Solved - Windows 7 Help ForumsVijay KumarNo ratings yet

- Chapter 2 8086 Addressing Modes1Document14 pagesChapter 2 8086 Addressing Modes1Aqeel Ifthkhar100% (1)

- CON9330 Hsu-OOW2015Oct29Document62 pagesCON9330 Hsu-OOW2015Oct29sbabuindNo ratings yet

- Event Table Quick Start GuideDocument10 pagesEvent Table Quick Start GuideDari JohnNo ratings yet

- cdp1802 CosmacDocument27 pagescdp1802 Cosmacrebirth90No ratings yet

- IB Lite 1 11 0 New FeaturesDocument11 pagesIB Lite 1 11 0 New Featuresm.n.malasNo ratings yet

- Devops Interview Questions With Answers 1Document12 pagesDevops Interview Questions With Answers 1Satyam TiwariNo ratings yet

- ID902b06550-1993 Acura Vigor Flasher ManualDocument2 pagesID902b06550-1993 Acura Vigor Flasher ManualMcDonald SeatounNo ratings yet

- Public Class Myclass (Public Static Void Main (String Args) (System - Out.Println ("Hello World") ) ) What Is Java?Document23 pagesPublic Class Myclass (Public Static Void Main (String Args) (System - Out.Println ("Hello World") ) ) What Is Java?Dan Dexter DimalibotNo ratings yet