Professional Documents

Culture Documents

Pavement Desin

Pavement Desin

Uploaded by

Nikesh Dahal0 ratings0% found this document useful (0 votes)

8 views13 pagesOriginal Title

pavement desin

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

8 views13 pagesPavement Desin

Pavement Desin

Uploaded by

Nikesh DahalCopyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You are on page 1of 13

Introduction to pavement design

Lecture notes in Transportation Systems

Engineering

3 August 2009

Overview

A highway pavement is a structure consisting of

superimposed layers of processed materials above

the natural soil sub-grade, whose primary function

is to distribute the applied vehicle loads to the sub-

grade. The pavement structure should be able to

provide a surface of acceptable riding quality,

adequate skid resistance, favorable light reflecting

characteristics, and low noise pollution. The

ultimate aim is to ensure that the transmitted

stresses due to wheel load are sufficiently reduced,

so that they will not exceed bearing capacity of the

sub-grade. Two types of pavements are generally

recognized as serving this purpose, namely flexible

pavements and rigid pavements. This chapter

gives an overview of pavement types, layers, and

their functions, and pavement failures. Improper

design of pavements leads to early failure of

pavements affecting the riding quality.

Requirements of a pavement

An ideal pavement should meet the following

requirements:

Sufficient thickness to distribute the wheel load

stresses to a safe value on the sub-grade soil,

Structurally strong to withstand all types of

stresses imposed upon it,

Adequate coefficient of friction to prevent

skidding of vehicles,

Smooth surface to provide comfort to road

users even at high speed,

Produce least noise from moving vehicles,

Dust proof surface so that traffic safety is not

impaired by reducing visibility,

Impervious surface, so that sub-grade soil is

well protected, and

Long design life with low maintenance cost.

Types of pavements

The pavements can be classified based on the

structural performance into two, flexible

pavements and rigid pavements. In flexible

pavements, wheel loads are transferred by grain-

to-grain contact of the aggregate through the

granular structure. The flexible pavement, having

less flexural strength, acts like a flexible sheet

(e.g. bituminous road). On the contrary, in rigid

pavements, wheel loads are transferred to sub-

grade soil by flexural strength of the pavement and

the pavement acts like a rigid plate (e.g. cement

concrete roads). In addition to these, composite

pavements are also available. A thin layer of

flexible pavement over rigid pavement is an ideal

pavement with most desirable characteristics.

However, such pavements are rarely used in new

construction because of high cost and complex

analysis required.

Flexible pavements

Flexible pavements will transmit wheel load

stresses to the lower layers by grain-to-grain

transfer through the points of contact in the

granular structure (see Figure 1).

Figure 1: Load transfer in granular structure

Deflection on flexible pavement

The wheel load acting on the pavement will be

distributed to a wider area, and the stress

decreases with the depth. Taking advantage of this

stress distribution characteristic, flexible

pavements normally has many layers. Hence, the

design of flexible pavement uses the concept of

layered system. Based on this, flexible pavement

may be constructed in a number of layers and the

top layer has to be of best quality to sustain

maximum compressive stress, in addition to wear

and tear. The lower layers will experience lesser

magnitude of stress and low quality material can

be used. Flexible pavements are constructed using

bituminous materials. These can be either in the

form of surface treatments (such as bituminous

surface treatments generally found on low volume

roads) or, asphalt concrete surface courses

(generally used on high volume roads such as

national highways). Flexible pavement layers

reflect the deformation of the lower layers on to

the surface layer (e.g., if there is any undulation in

sub-grade then it will be transferred to the surface

layer). In the case of flexible pavement, the design

is based on overall performance of flexible

pavement, and the stresses produced should be

kept well below the allowable stresses of each

pavement layer.

Types of Flexible Pavements

The following types of construction have been used

in flexible pavement:

Conventional layered flexible pavement,

Full - depth asphalt pavement, and

Contained rock asphalt mat (CRAM).

Conventional flexible pavements are layered

systems with high quality expensive materials are

placed in the top where stresses are high, and low

quality cheap materials are placed in lower layers.

Full - depth asphalt pavements are constructed

by placing bituminous layers directly on the soil

sub-grade. This is more suitable when there is high

traffic and local materials are not available.

Contained rock asphalt mats are constructed by

placing dense/open graded aggregate layers in

between two asphalt layers. Modified dense graded

asphalt concrete is placed above the sub-grade will

significantly reduce the vertical compressive strain

on soil sub-grade and protect from surface water.

Typical layers of a flexible pavement

Typical layers of a conventional flexible pavement

includes seal coat, surface course, tack coat,

binder course, prime coat, base course, sub-base

course, compacted sub-grade, and natural sub-

grade (Figure 2).

Seal Coat:

Seal coat is a thin surface treatment used to

water-proof the surface and to provide skid

resistance.

Tack Coat:

Tack coat is a very light application of asphalt,

usually asphalt emulsion diluted with water. It

provides proper bonding between two layer of

binder course and must be thin, uniformly cover

the entire surface, and set very fast.

Prime Coat:

Prime coat is an application of low viscous cutback

bitumen to an absorbent surface like granular

bases on which binder layer is placed. It provides

bonding between two layers. Unlike tack coat,

prime coat penetrates into the layer below, plugs

the voids, and forms a water tight surface.

Figure 2: Typical cross section of a flexible pavement

Surface course

Surface course is the layer directly in contact with

traffic loads and generally contains superior quality

materials. They are usually constructed with dense

graded asphalt concrete(AC). The functions and

requirements of this layer are:

It provides characteristics such as friction,

smoothness, drainage, etc. Also it will prevent

the entrance of excessive quantities of surface

water into the underlying base, sub-base and

sub-grade,

It must be tough to resist the distortion under

traffic and provide a smooth and skid- resistant

riding surface,

It must be water proof to protect the entire

base and sub-grade from the weakening effect

of water.

Binder course

This layer provides the bulk of the asphalt concrete

structure. It's chief purpose is to distribute load to

the base course The binder course generally

consists of aggregates having less asphalt and

doesn't require quality as high as the surface

course, so replacing a part of the surface course by

the binder course results in more economical

design.

Base course

The base course is the layer of material

immediately beneath the surface of binder course

and it provides additional load distribution and

contributes to the sub-surface drainage It may be

composed of crushed stone, crushed slag, and

other untreated or stabilized materials.

Sub-Base course

The sub-base course is the layer of material

beneath the base course and the primary functions

are to provide structural support, improve

drainage, and reduce the intrusion of fines from

the sub-grade in the pavement structure If the

base course is open graded, then the sub-base

course with more fines can serve as a filler

between sub-grade and the base course A sub-

base course is not always needed or used. For

example, a pavement constructed over a high

quality, stiff sub-grade may not need the additional

features offered by a sub-base course. In such

situations, sub-base course may not be provided.

Sub-grade

The top soil or sub-grade is a layer of natural soil

prepared to receive the stresses from the layers

above. It is essential that at no time soil sub-grade

is overstressed. It should be compacted to the

desirable density, near the optimum moisture

content.

Failure of flexible pavements

The major flexible pavement failures are fatigue

cracking, rutting, and thermal cracking. The

fatigue cracking of flexible pavement is due to

horizontal tensile strain at the bottom of the

asphaltic concrete. The failure criterion relates

allowable number of load repetitions to tensile

strain and this relation can be determined in the

laboratory fatigue test on asphaltic concrete

specimens. Rutting occurs only on flexible

pavements as indicated by permanent deformation

or rut depth along wheel load path. Two design

methods have been used to control rutting: one to

limit the vertical compressive strain on the top of

subgrade and other to limit rutting to a tolerable

amount (12 mm normally). Thermal cracking

includes both low-temperature cracking and

thermal fatigue cracking.

Rigid pavements

Rigid pavements have sufficient flexural strength

to transmit the wheel load stresses to a wider area

below. A typical cross section of the rigid

pavement is shown in Figure 3. Compared to

flexible pavement, rigid pavements are placed

either directly on the prepared sub-grade or on a

single layer of granular or stabilized material. Since

there is only one layer of material between the

concrete and the sub-grade, this layer can be

called as base or sub-base course.

Figure 3: Typical Cross section of Rigid pavement

In rigid pavement, load is distributed by the slab

action, and the pavement behaves like an elastic

plate resting on a viscous medium (Figure 4). Rigid

pavements are constructed by Portland cement

concrete (PCC) and should be analyzed by plate

theory instead of layer theory, assuming an elastic

plate resting on viscous foundation. Plate theory is

a simplified version of layer theory that assumes

the concrete slab as a medium thick plate which is

plane before loading and to remain plane after

loading. Bending of the slab due to wheel load and

temperature variation and the resulting tensile and

flexural stress.

Elastic plate resting on viscous foundation

Deflection on concrete pavement

Types of Rigid Pavements

Rigid pavements can be classified into four types:

Jointed plain concrete pavement (JPCP),

Jointed reinforced concrete pavement (JRCP),

Continuous reinforced concrete pavement

(CRCP), and

Pre-stressed concrete pavement (PCP).

Jointed Plain Concrete Pavement:

are plain cement concrete pavements constructed

with closely spaced contraction joints. Dowel bars

or aggregate interlocks are normally used for load

transfer across joints. They normally has a joint

spacing of 5 to 10m.

Jointed Reinforced Concrete Pavement:

Although reinforcements do not improve the

structural capacity significantly, they can

drastically increase the joint spacing to 10 to 30m.

Dowel bars are required for load transfer.

Reinforcements help to keep the slab together

even after cracks.

Continuous Reinforced Concrete Pavement:

Complete elimination of joints are achieved by

reinforcement.

Failure criteria of rigid pavements

Traditionally fatigue cracking has been considered

as the major, or only criterion for rigid pavement

design. The allowable number of load repetitions to

cause fatigue cracking depends on the stress ratio

between flexural tensile stress and concrete

modulus of rupture. Of late, pumping is identified

as an important failure criterion. Pumping is the

ejection of soil slurry through the joints and cracks

of cement concrete pavement, caused during the

downward movement of slab under the heavy

wheel loads. Other major types of distress in rigid

pavements include faulting, spalling, and

deterioration.

Summary

Pavements form the basic supporting structure in

highway transportation. Each layer of pavement

has a multitude of functions to perform which has

to be duly considered during the design process.

Different types of pavements can be adopted

depending upon the traffic requirements. Improper

design of pavements leads to early failure of

pavements affecting the riding quality also.

Problems

1. The thin layer of bitumen coating between

an existing bituminous layer and a new

bituminous layer is:

1. Seal coat

2. Intermediate coat

3. Tack coat

4. Prime coat

2. Rigid pavements are designed by

1. Rigid plate theory

2. Elastic plate theory

3. Infinite layer theory

4. Interlocking of aggregates

Solutions

1. The thin layer of bitumen coating between

an existing bituminous layer and a new

bituminous layer is:

1. Seal coat

2. Intermediate coat

3. Tack coat

4. Prime coat

2. Rigid pavements are designed by

1. Rigid plate theory

2. Elastic plate theory

3. Infinite layer theory

4. Interlocking of aggregates

You might also like

- Overview of Road Construction and MaintenanceDocument14 pagesOverview of Road Construction and MaintenanceOribuyaku DamiNo ratings yet

- Crack Width Calc BS 8110Document1 pageCrack Width Calc BS 8110mvap2856No ratings yet

- Operational Writup of Stacker and ReclaimerDocument10 pagesOperational Writup of Stacker and ReclaimerZahoor AhmedNo ratings yet

- Labour Manifesto PDFDocument29 pagesLabour Manifesto PDFNewshub100% (1)

- Introduction To Pavement DesignDocument23 pagesIntroduction To Pavement DesignDaniel Berhane100% (1)

- Introduction To Pavement Design Lecture Notes in Transportation Systems Engineering 3 August 2009Document12 pagesIntroduction To Pavement Design Lecture Notes in Transportation Systems Engineering 3 August 2009Shreenidhi HariharanNo ratings yet

- Introduction To Pavement DesignDocument1 pageIntroduction To Pavement DesignZharif ZubirNo ratings yet

- Introduction To Pavement DesignDocument11 pagesIntroduction To Pavement DesignChris EminentNo ratings yet

- 1610546775introduction To Pavement Structure DesignDocument12 pages1610546775introduction To Pavement Structure DesignSasultan UltansasNo ratings yet

- Introduction To Pavement DesignDocument12 pagesIntroduction To Pavement DesignVijay KumarNo ratings yet

- Introduction To Pavement DesignDocument7 pagesIntroduction To Pavement DesignPrabhakar Kumar BarnwalNo ratings yet

- Pavement DesignDocument18 pagesPavement DesignTjandra LiemNo ratings yet

- Pavement DesignDocument18 pagesPavement DesignTjandra LiemNo ratings yet

- Pavement Design (15cv833)Document90 pagesPavement Design (15cv833)Pavan kashappagoudarNo ratings yet

- 15cv833-Pavement DesignDocument90 pages15cv833-Pavement DesignMEHRAN KAPRANo ratings yet

- Pavement DesignDocument20 pagesPavement DesignHanamant HunashikattiNo ratings yet

- Lec 8 Pavement DesignDocument87 pagesLec 8 Pavement DesignBernard de VeraNo ratings yet

- Lec 8 Pavement DesignDocument87 pagesLec 8 Pavement DesignMay de Vera100% (1)

- Lecture 1 Cce 2424 Pavement Design and ConstructionDocument18 pagesLecture 1 Cce 2424 Pavement Design and Constructionmotanyadebra11No ratings yet

- Civil Pavement Design ReportDocument13 pagesCivil Pavement Design ReportChandu BandelaNo ratings yet

- Desirable Characteristics: Module 1: Introduction Introduction To Pavement DesignDocument21 pagesDesirable Characteristics: Module 1: Introduction Introduction To Pavement DesignBharath SpidyNo ratings yet

- Structural Design of HighwayDocument19 pagesStructural Design of Highwayبلسم محمود شاكرNo ratings yet

- Document Siri 2Document65 pagesDocument Siri 2Hema Chandra Reddy KarimireddyNo ratings yet

- Pavement Design (Document45 pagesPavement Design (nawinarasaNo ratings yet

- Pavement DesignDocument12 pagesPavement DesignTarun KumarNo ratings yet

- Different Types of Highway PavementsDocument8 pagesDifferent Types of Highway PavementsAmith SharmaNo ratings yet

- General IntroductionDocument12 pagesGeneral IntroductionKanimozhi SNo ratings yet

- Unit2 - Lecture1 CIV241Document64 pagesUnit2 - Lecture1 CIV241Soumya MishraNo ratings yet

- Unit 3 RIGID AND FLEXIBLE PAVEMENTSDocument33 pagesUnit 3 RIGID AND FLEXIBLE PAVEMENTSAnonymous SEDun6PWNo ratings yet

- Transport Assignment 2Document37 pagesTransport Assignment 2Animesh MishraNo ratings yet

- Introduction To Pavement DesignDocument12 pagesIntroduction To Pavement DesignSANDI SAI TEJA NBKRISTNo ratings yet

- Unit III - Design of Flexible and Rigid PavementsDocument13 pagesUnit III - Design of Flexible and Rigid PavementsKandasamy AsohanNo ratings yet

- Highway Pavement Materials and DesignDocument16 pagesHighway Pavement Materials and DesignWarner Leano100% (1)

- Topic:-Flexible Pavement: By: AMIT KumarDocument10 pagesTopic:-Flexible Pavement: By: AMIT Kumarpkgoyal1983No ratings yet

- High Way - Ass.1docxDocument11 pagesHigh Way - Ass.1docxMekuannint DemekeNo ratings yet

- Module-1 Types of Pavements & Load Distribution UpdatedDocument12 pagesModule-1 Types of Pavements & Load Distribution UpdatedHuzaifa ZafarNo ratings yet

- Pavement DesignDocument13 pagesPavement Designsamrat sahaNo ratings yet

- Types of PavementsDocument17 pagesTypes of PavementsPereira KastroNo ratings yet

- Chapter OneDocument17 pagesChapter OneAlemayehu MitekuNo ratings yet

- IntroductionDocument55 pagesIntroductionketanbaghel66No ratings yet

- HWAYDocument2 pagesHWAYMarc Anthony de Villa100% (1)

- Flexible PavementsDocument13 pagesFlexible PavementsAhmad NajiNo ratings yet

- Highway ConstructionDocument80 pagesHighway Constructionsarat100% (1)

- Design of Pavement Structure-Odd 2015 - Print 01Document11 pagesDesign of Pavement Structure-Odd 2015 - Print 01BISUNo ratings yet

- Pavement Design Seminar ReportDocument27 pagesPavement Design Seminar ReportRenuka Talwar100% (2)

- Unit V Pavement DesignDocument21 pagesUnit V Pavement DesignSiva PrasadNo ratings yet

- Pavement Design & Highway ConstructionDocument40 pagesPavement Design & Highway ConstructionAjay Patel100% (3)

- Chapter 1 Principles of Pavement DesignDocument28 pagesChapter 1 Principles of Pavement DesignGetu Neberu100% (1)

- Design of Flexible PavementDocument81 pagesDesign of Flexible PavementAnonymous UncXDPRy100% (1)

- Assignment - 1 - Flexible and Rigid Pavment ComparissionDocument2 pagesAssignment - 1 - Flexible and Rigid Pavment ComparissionYAHAMPATH ARACHCHIGE PASAN MADURA YahampathNo ratings yet

- Design of Surfaces & Guide Ways: PavementDocument20 pagesDesign of Surfaces & Guide Ways: PavementSam BarotillaNo ratings yet

- Highway Engineering Lab Assignment#03Document73 pagesHighway Engineering Lab Assignment#03tayyabNo ratings yet

- Report On ENGINEERING COMPARISON BETWEEN FLEXIBLE AND RIGID PAVEMENTDocument35 pagesReport On ENGINEERING COMPARISON BETWEEN FLEXIBLE AND RIGID PAVEMENTTahmidul Islam FarabiNo ratings yet

- Types of PavementsDocument20 pagesTypes of PavementsPrameshwar SutharNo ratings yet

- Road StructureDocument10 pagesRoad StructureMohammed NawzanNo ratings yet

- Unit I VDocument19 pagesUnit I VRubel RanaNo ratings yet

- Pavement Design SeminarDocument12 pagesPavement Design SeminarWayaya2009100% (3)

- Cc302 Highway Engineering: Razif Fitri Bin Radzwan 06DKA12F1097Document44 pagesCc302 Highway Engineering: Razif Fitri Bin Radzwan 06DKA12F1097Ruzengulalebih ZEta's-Listik100% (1)

- Chapter 1Document10 pagesChapter 1Nalina Amith VijayanandNo ratings yet

- Reinforced Concrete Grade Beams, Piles & Caissons: A Practical Guide for Hillside ConstructionFrom EverandReinforced Concrete Grade Beams, Piles & Caissons: A Practical Guide for Hillside ConstructionNo ratings yet

- Sewage Disposal Works: Their Design and ConstructionFrom EverandSewage Disposal Works: Their Design and ConstructionNo ratings yet

- DMM Foundation Design Design of Strip Footing: Project: Air Compressor Shed Client: ONGC Rev: R1 Date: 15/07/06Document7 pagesDMM Foundation Design Design of Strip Footing: Project: Air Compressor Shed Client: ONGC Rev: R1 Date: 15/07/06mvap2856No ratings yet

- Check For Crack Width:-: As Per IS 3370 - 2009 (Part 2), ANNEX - A, Page - 6Document2 pagesCheck For Crack Width:-: As Per IS 3370 - 2009 (Part 2), ANNEX - A, Page - 6mvap2856No ratings yet

- Introduction To Pavement DesignDocument17 pagesIntroduction To Pavement Designmvap2856No ratings yet

- Sheet 2 - Roof Beam Car Wash Plant - 30.03.12Document1 pageSheet 2 - Roof Beam Car Wash Plant - 30.03.12mvap2856No ratings yet

- Sheet 2 - Roof Beam Car Wash Plant - 30.03.12Document1 pageSheet 2 - Roof Beam Car Wash Plant - 30.03.12mvap2856No ratings yet

- 7.10 M High Wall - Valecha Engg - 3-3-14Document11 pages7.10 M High Wall - Valecha Engg - 3-3-14mvap2856No ratings yet

- Space Gamer 05 PDFDocument16 pagesSpace Gamer 05 PDFsam mckenzieNo ratings yet

- Chapter 16. Negative-Pressure VentilationDocument25 pagesChapter 16. Negative-Pressure VentilationNeurofisiología INCMNSZNo ratings yet

- Carrot Cake PDFDocument4 pagesCarrot Cake PDFLulu Nana NyagaNo ratings yet

- Self Assessment ParasitologyDocument257 pagesSelf Assessment ParasitologyM Elmanaviean100% (3)

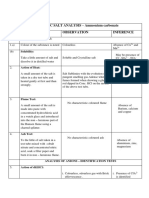

- INORGANIC SALT ANALYSIS - Ammonium Carbonate S.No Experiment Observation InferenceDocument24 pagesINORGANIC SALT ANALYSIS - Ammonium Carbonate S.No Experiment Observation InferenceRyoshiNo ratings yet

- Pollution Control BoardsDocument6 pagesPollution Control Boardsapi-27499979100% (1)

- 278 CMS PDFDocument266 pages278 CMS PDFRecordTrac - City of OaklandNo ratings yet

- Vegetable Nutrition FactsDocument2 pagesVegetable Nutrition FactskboadNo ratings yet

- S04 BoomDocument66 pagesS04 BoomRaul Adrián Quiñonez MadrigalNo ratings yet

- Integration Mapping ERP BW BPC FMDocument11 pagesIntegration Mapping ERP BW BPC FMOluwaseyi ObabiyiNo ratings yet

- Best British Inventions EverDocument4 pagesBest British Inventions EverMaya PmNo ratings yet

- Learning Module DihybridDocument36 pagesLearning Module DihybridPAUL BENEDICT MORENO MENDOZANo ratings yet

- Biocidal Potential of Three Plant Extracts On Rhizopus Stolonifer, Causal Organism of Irish Potato (Solanum Tuberosum L.) Tuber RotDocument6 pagesBiocidal Potential of Three Plant Extracts On Rhizopus Stolonifer, Causal Organism of Irish Potato (Solanum Tuberosum L.) Tuber RotInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Galva Stop Data SheetDocument8 pagesGalva Stop Data Sheetenry gunadiNo ratings yet

- Sprinter 7G Tronic TransmissionDocument7 pagesSprinter 7G Tronic TransmissionRicardo Santo AntonioNo ratings yet

- Relative Strangers by Paula Garner Chapter SamplerDocument39 pagesRelative Strangers by Paula Garner Chapter SamplerCandlewick PressNo ratings yet

- Concept Book Ent Working FileDocument801 pagesConcept Book Ent Working FileDrAssadullah HamzaNo ratings yet

- Distribution Substation Manual IntroductionDocument18 pagesDistribution Substation Manual Introductionharisanju123No ratings yet

- 2 Quarter: Understanding OverexertionDocument15 pages2 Quarter: Understanding OverexertionJhon Keneth NamiasNo ratings yet

- Soil Testing ReportDocument25 pagesSoil Testing Reportanoopgupta52No ratings yet

- Monolithics - Beimdiek 2015.Ppt (Kompatibilitätsmodus)Document59 pagesMonolithics - Beimdiek 2015.Ppt (Kompatibilitätsmodus)Moud Sakly100% (1)

- Research Paper On Minor Project123 FINALDocument7 pagesResearch Paper On Minor Project123 FINALSiddharth kumar ChoudharyNo ratings yet

- DX GX System Guide ISS 5Document22 pagesDX GX System Guide ISS 5Rafael JazzNo ratings yet

- Drought Preparedness and MitigationDocument45 pagesDrought Preparedness and MitigationTinashe KambaramiNo ratings yet

- CasesDocument29 pagesCasesGretchen Delos ReyesNo ratings yet

- Pharma Company ProfileDocument548 pagesPharma Company Profilelavate amol bhimraoNo ratings yet

- Rothe Erde Calculation For Slewing BearingDocument2 pagesRothe Erde Calculation For Slewing Bearingankesh_ghoghariNo ratings yet

- Methodology BioethanolDocument7 pagesMethodology BioethanolShellaNo ratings yet