Professional Documents

Culture Documents

Innovation Corner 040811

Uploaded by

popushellyCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Innovation Corner 040811

Uploaded by

popushellyCopyright:

Available Formats

I N N O VA T I O N C O R N E R P R O C E S S I N N OVAT I O N

WOOD WORTH

Young innovator from

B

amboo is everywhere in India—it holds up

scaffoldings, wedding tents, roofs and welcome

the North East develops arches. Bamboo furniture adorns urban homes

as well as corporate waiting rooms. Its pulp

affordable machine that makes paper and rayon, while bamboo chips,

processes bamboo at glued into boards, make for excellent building material.

Bamboo grows to an average height of 35 feet but all of it is

25 times the speed of not used. At least five feet are snipped off from the tip and

manual processing. the base. But that is not all, once harvested, each bamboo

pole must be processed. It involves removing the hard

PHOTO BY PHOTOS.COM

BY VIKRAM SINGH nodes or rings every few inches along the length of the pole.

This is a must to smoothen the surface of the pole. The sur-

face of bamboo is naturally coated with protective silica, giv-

ing it its sheen. The silica must also be filed away in order

40 APRIL-MAY 2011 www.ibef.org

P R O C E S S I N N OVAT I O N I N N O VA T I O N C O R N E R

to prepare its surface for texturing and the government’s National Bamboo but he says he has business enquiries

for receiving paint. Mission (NBM), India’s share of this from nearly seven states including far-

Processing bamboo is a tedious, man- market is a billion dollars, but by 2030, away Andhra Pradesh.

ual task. Using a short local machete, it can grow ten-fold. Apart from the “The highlight of the machine lies in

called the dow, workers in the North most obvious use as scaffolding, bam- using a single versatile wood process-

East hack away the protruding nodes boo is used for making paper, rayon ing platform for seamlessly processing

of the bamboo, and rub the silica away and bamboo boards. bamboo. The precision in work is

with rough hand tools. However, their Imli, 30, has been making machines achieved by deploying the dedicated

imprecise and irregular methods are and devising solutions for as long as he control centre and a user friendly four

crude and extremely time-consuming. can remember. His innovative spirit has way joystick”, says Prof Anil K Gupta,

For years, Imli Toshi Namo, a resident earned him the moniker ‘serial innovator’. Chairman of the National Innovation

of Nagaland had observed the workers Although he had made the first pro- Foundation. The electrically operated

process the bamboo. In the best of cir- totype in 2006 and improved it a year machine weighs 75 kg.

cumstances, they can process about 100 later, Imli has so far been able to sell NIF was among the first to help Imli

feet of bamboo per working day. That’s only one such machine. And that too, through its Micro Venture Investment

about five or six poles a day. to a local government body. “It is not Fund. It has also taken Imli’s innova-

Imli grew up in Nagaland, roaming that the machine is not good enough tion to various forums, showcasing

the sprawling bamboo plantations and or doesn’t do the needful. I have not yet him and his work. “NIF has really

observing the grass being harvested been able to find an industrial house helped me take Arulepsa from an idea

and processed, before it was shaped that will manufacture my machine for in my head to a working machine on

into furniture or items of handicraft. the market,” says a thoughtful Imli. the ground. I have also been exposed to

He was always struck by the enormity The prototype and its improvement new opportunities through the fund,”

of the human labour that went into cost him a total of INR 300,000 (US$ acknowledges Imli.

cutting away its nodes, filing away its 6,725). He had funding from the Nation- In the four years since having made

surface and removing the silica. After al Innovation Foundation (NIF) and the Arulepsa, Imli hasn’t been resting.

graduating in Geology, he spent years National Bamboo Mission (NBM). When Among his many innovations is one

thinking of a way to reduce the drudg- I met him at the Rashtrapati Bhawan in that is currently keeping him extremely

ery of the bamboo workers and helping New Delhi recently, Imli was poring over busy. It is called the Solar Farm Produce

them multiply their yield. By 2006, he machinery catalogues. He told me he Dehydrator and has really caught the

had designed Arulepsa, the prototype was ordering a range of machines to set fancy of officials and villagers alike. In

of an integrated, precision-controlled, up his own unit for producing Arulepsa. the high moisture North Eastern states

bamboo processing machine. Arulepsa Imli was in New Delhi, participating in of India, keeping farm produce dry is

processes five feet of highly finished an innovation exhibition organised by an arduous task. Most people dry their

bamboo per minute. That translates the NIF and at the invitation of President ginger, chilli and fish either in a smoke

to 300 feet an hour, or 2,400 feet per Pratibha Patil. stack or out in the

working day of eight hours. That’s Since then, he has fer- ARULEPSA sun. Imli’s Solar Farm

nearly 25 times the output of manual ried the machines to his Produce Dehydrator is a

processing. “Even then, the finished workshop in Dimapur, simple contraption that

bamboo that Arulepsa produces is far Nagaland. Imli says the

Weight: 75-kg uses specially treated

more uniform, better finished, well- first of the new machines polyurethane sheets in

planed and surfaced,” says Imli. should roll out by August Development an innovative design.

India is the second richest bamboo this year. He is thinking Cost: US$ 6,725 In spite of his strug-

resource country in the world, next of pricing them at INR gles and challenges,

only to China. According to the For- 80,000 (US$ 1,800) each. Unit Price: Imli’s spirit is indomi-

est Survey of India, the North Eastern “That’s not much, con- US$ 1,800 table and his mind

states of India have bountiful bamboo sidering the substantial relentlessly innovative.

reserves. Although they cover only savings a company will While he waits for his

eight per cent of the country’s land make using Arulepsa”, says Imli. Accord- prototype to turn into an entire line of

area, the states together hold two-thirds ing to him, the buyers of his machine are machines for sale, he spends his time

of its bamboo that grows over more potentially all furniture manufactures working on new ideas. For sure, mak-

than three million acres. Currently, the and producers of handicraft products. In ing furniture and items of handicraft

global market size of bamboo products the North East itself, he should be able to from bamboo will soon become a lot

is worth US$ 10 billion. According to sell a sizeable number of his machines, easier, thanks to Imli Toshi.

www.ibef.org APRIL-MAY 2011

41

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (120)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Handbook David Austin RosesDocument64 pagesHandbook David Austin RosesDragan Radojcin100% (2)

- Return On Investment and Return On EquityDocument8 pagesReturn On Investment and Return On EquitypopushellyNo ratings yet

- Introduction To Accounting: Earning BjectivesDocument22 pagesIntroduction To Accounting: Earning Bjectiveslalu morwalNo ratings yet

- Introduction To Accounting: Earning BjectivesDocument22 pagesIntroduction To Accounting: Earning Bjectiveslalu morwalNo ratings yet

- Credit DerivativesDocument23 pagesCredit DerivativesMakarand LonkarNo ratings yet

- Bill of Exchange: Earning BjectivesDocument42 pagesBill of Exchange: Earning BjectivespopushellyNo ratings yet

- Pedalling A Green CauseDocument3 pagesPedalling A Green CauseZigZag NetworksNo ratings yet

- Appendixc PDFDocument9 pagesAppendixc PDFomer1299No ratings yet

- Appendixc PDFDocument9 pagesAppendixc PDFomer1299No ratings yet

- 320 L - 2 Accounting Concepts PDFDocument15 pages320 L - 2 Accounting Concepts PDFpopushellyNo ratings yet

- 320 L - 2 Accounting Concepts PDFDocument15 pages320 L - 2 Accounting Concepts PDFpopushellyNo ratings yet

- 320 L - 2 Accounting Concepts PDFDocument15 pages320 L - 2 Accounting Concepts PDFpopushellyNo ratings yet

- 320 L - 2 Accounting Concepts PDFDocument15 pages320 L - 2 Accounting Concepts PDFpopushellyNo ratings yet

- Appendixc PDFDocument9 pagesAppendixc PDFomer1299No ratings yet

- Appendixc PDFDocument9 pagesAppendixc PDFomer1299No ratings yet

- DerivativesDocument15 pagesDerivativespopushellyNo ratings yet

- Alpha Beta Calculations PDFDocument3 pagesAlpha Beta Calculations PDFpopushellyNo ratings yet

- 320 L - 2 Accounting Concepts PDFDocument15 pages320 L - 2 Accounting Concepts PDFpopushellyNo ratings yet

- 1471609638850Document254 pages1471609638850popushellyNo ratings yet

- Pedalling A Green Cause 130913 PDFDocument3 pagesPedalling A Green Cause 130913 PDFpopushellyNo ratings yet

- 1465 1 1444 1 10 20150216Document9 pages1465 1 1444 1 10 20150216popushellyNo ratings yet

- 320 L - 2 Accounting Concepts PDFDocument15 pages320 L - 2 Accounting Concepts PDFpopushellyNo ratings yet

- 1496999122269Document253 pages1496999122269popushellyNo ratings yet

- UntitledDocument39 pagesUntitledpopushellyNo ratings yet

- Sub Section I Issues by Indian Companies in India: WWW - Sebi.gov - inDocument32 pagesSub Section I Issues by Indian Companies in India: WWW - Sebi.gov - inKevin PaulNo ratings yet

- CigarDocument16 pagesCigardr_tripathineerajNo ratings yet

- UntitledDocument39 pagesUntitledpopushellyNo ratings yet

- UntitledDocument15 pagesUntitledpopushellyNo ratings yet

- Complete ActDocument73 pagesComplete ActScarletalmeidaNo ratings yet

- CPA86Document8 pagesCPA86popushellyNo ratings yet

- Overcoming Dragon Fruit Diseases in The FarmDocument5 pagesOvercoming Dragon Fruit Diseases in The FarmZainudin Meon80% (5)

- GPP 2023 ReportDocument27 pagesGPP 2023 ReportJHERIC ROMERO100% (1)

- Using Growing Degree Days To Predict Plant Stages: MT200103 AG 7/2001Document8 pagesUsing Growing Degree Days To Predict Plant Stages: MT200103 AG 7/2001RA TumacayNo ratings yet

- Guide To Maize Production in Northern Nigeria: A.Y. Kamara, N. Kamai, L.O. Omoigui, A. Togola, F. Ekeleme, J.E. OnyibeDocument26 pagesGuide To Maize Production in Northern Nigeria: A.Y. Kamara, N. Kamai, L.O. Omoigui, A. Togola, F. Ekeleme, J.E. OnyibeOlutuaseNo ratings yet

- Sometimes: All Poems Published in Devotions by Mary Oliver, Penguin Books, 2017Document15 pagesSometimes: All Poems Published in Devotions by Mary Oliver, Penguin Books, 2017Yhonais100% (1)

- Garden Tools and Equipment: NtroductionDocument10 pagesGarden Tools and Equipment: Ntroductionarunkumar nayakNo ratings yet

- Mridha-Soilless media-IJBSv8n2iDocument12 pagesMridha-Soilless media-IJBSv8n2iNilimesh MridhaNo ratings yet

- Growing Vegetable For Home and MarketDocument102 pagesGrowing Vegetable For Home and MarketAkhtar Ali100% (1)

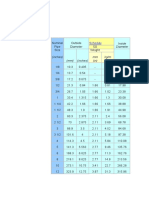

- Sabiley Farm Machineries: Sales Summary JanuaryDocument15 pagesSabiley Farm Machineries: Sales Summary JanuaryElla MariscalNo ratings yet

- Integrated Weed Management 22.11.2021Document8 pagesIntegrated Weed Management 22.11.2021Izukanji KayoraNo ratings yet

- Project Proposal "Brigada Pagbasa Sa Brigada Eskwela 2021": Pandacaqui Resettlement Elementary SchoolDocument4 pagesProject Proposal "Brigada Pagbasa Sa Brigada Eskwela 2021": Pandacaqui Resettlement Elementary SchoolMaris CarvajalNo ratings yet

- Hindustan Petroleum Corporation Limited Chain Link Corporation Limited Chain Link Fencing (Typical)Document1 pageHindustan Petroleum Corporation Limited Chain Link Corporation Limited Chain Link Fencing (Typical)MMNo ratings yet

- Senior Retirement Village Space RequirementsDocument4 pagesSenior Retirement Village Space RequirementsAriane M. Tiongco100% (1)

- 10 Day Fruit Program Extra Options PDFDocument44 pages10 Day Fruit Program Extra Options PDFГантулга Болор-ЭрдэнэNo ratings yet

- Aplikasi Pupuk Kandang Sapi Dan Ayam Terhadap Pertumbuhan DAN HASIL TANAMAN JAHE (Zingiber Officinale Rosc.) DI MEDIA GAMBUTDocument8 pagesAplikasi Pupuk Kandang Sapi Dan Ayam Terhadap Pertumbuhan DAN HASIL TANAMAN JAHE (Zingiber Officinale Rosc.) DI MEDIA GAMBUTMerlyana boangmanaluNo ratings yet

- TLE7 Mod1-2 AGRICROP-PRODDocument6 pagesTLE7 Mod1-2 AGRICROP-PRODMICHAEL ANORANo ratings yet

- Plant Worksheet A. Vascular Plant B. Nonvascular Plant C. Xylem D. Phloem E. Photosynthesis F. Spores G. Dicot H. Monocot I. Embryo J. SeedsDocument1 pagePlant Worksheet A. Vascular Plant B. Nonvascular Plant C. Xylem D. Phloem E. Photosynthesis F. Spores G. Dicot H. Monocot I. Embryo J. Seedsstephanie hufanaNo ratings yet

- VYR Agriculture Irrigation 2Document6 pagesVYR Agriculture Irrigation 2Ahmed HussienNo ratings yet

- What I Need To Know: Lesson 1Document8 pagesWhat I Need To Know: Lesson 1Mayaman UsmanNo ratings yet

- ANSI B36.10 Steel PipesDocument8 pagesANSI B36.10 Steel Pipesphoneme79No ratings yet

- PLANTDocument23 pagesPLANTAngelito HalmainNo ratings yet

- Ms. Motipur Zamindary Co. (Private) Ltd. v. State of Bihar - 52Document1 pageMs. Motipur Zamindary Co. (Private) Ltd. v. State of Bihar - 52knkmuraliNo ratings yet

- Bjarke Ingels Group (BIG)Document5 pagesBjarke Ingels Group (BIG)Patricia Ann DavidNo ratings yet

- Agr122 Lab Report 2Document11 pagesAgr122 Lab Report 2Nur AthirahNo ratings yet

- Agrovigor Volume 5 No. 1 Maret 2012 Issn 1979 5777Document14 pagesAgrovigor Volume 5 No. 1 Maret 2012 Issn 1979 5777Maulana Edith IndrastataNo ratings yet

- Crop ProductionDocument66 pagesCrop ProductionTrixie Maxine Marie CedeñoNo ratings yet

- Strategies For Maintaining Soil Fertility in Ginger ProductionDocument11 pagesStrategies For Maintaining Soil Fertility in Ginger ProductionArif MaulanaNo ratings yet

- Aeroponics Thesis - Docx 2Document83 pagesAeroponics Thesis - Docx 2Kobe YambiNo ratings yet

- Baffa ReportDocument30 pagesBaffa Reportmuazu muhammadNo ratings yet