Professional Documents

Culture Documents

Ftalk pp021 - en P PDF

Uploaded by

Maricruz OlivarOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ftalk pp021 - en P PDF

Uploaded by

Maricruz OlivarCopyright:

Available Formats

VantagePoint Energy

Understand and Better Manage your

Energy Consumption with Energy Intelligence

Energy Consumption is

no longer a cost of doing

business. It is a major driver in

determining how best in class

manufacturers are creating a

competitive advantage.

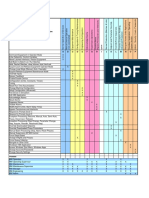

FactoryTalk VantagePoint

Energy can help you:

• Monitor energy usage based on

demand/availability for increased

efficiency and reduced costs

• Identify energy consumption by asset

and correlate energy information

with production information for more

informed decision making

• Relate kWh to product unit produced

to help reduce costs

• Enable comparison of lines, shifts,

machines, and plant energy usage

in order to improve overall energy

consumption

• Utilize pre-configured content and

reports to save time and money

Energy Awareness and Visibility

“With VantagePoint Energy we have

Critical to Operations

a more granular level of energy

Improved awareness and visibility to energy resource data is the foundation

information allowing us to make much for any strategic energy management program – it helps an organization

more detailed adjustments to our understand where, when and how it utilizes energy in order to then establish

process and production.“ the necessary scope of its energy savings efforts, define key metrics, and

put the appropriate measures in place. The depth and granularity by which

Operations Manager organizations visualize energy consumption varies greatly – from facility

level or site level awareness to production and product level awareness.

Large Global Food Manufacturer By integrating energy information with production information you not

only gain better insight to how energy influences the bottom line, but also

how energy improvements can ultimately improve production.

What is Energy Intelligence? The Power of an Integrated Energy Model

Energy Intelligence is an extension of a manufacturing By fully integrating energy information in the Unified

intelligence approach applied to energy use within a Production Model (UPM), it is now possible to fully correlate

company’s manufacturing facilities. An energy intelligence energy data with other manufacturing data available at

system can integrate data from islands of energy usage various levels in the model. Customers can now use the data

information (building management systems, building to make smart decisions based on the energy data, and also

sensors, utilities, etc.) and combine it with other operational use the production data to make smart production decisions

data from your enterprise applications (supply chain, that ultimately will improve their energy consumption.

manufacturing, asset management, etc.) to provide visibility

into usage trends, costs and efficiencies. By bringing this

information together in one place, an Energy Intelligence

system can help company leaders understand their current Energy at the Asset Level

energy usage and provide them with information to make Having energy information available at the asset

informed decisions about what actions will provide level is critical to being able to use energy as

the most return. a controlling input to production. Correlating

energy with production information allows you

Something Different to make more informed decisions regarding your

equipment and production – ultimately resulting

Traditional Energy Management solutions are based on

in lowering energy costs and improving

metering energy across the organization and using this

production results.

information to look at behaviors and areas for optimizing

energy use. Energy Usage is measured by overall facility

consumption and the focus is on using less energy

without a real understanding of where the specific Powerful Energy Dashboards and Reports

“energy hogs” are. Improvement initiatives are often

seen as an expense instead of an investment. To have Utilizing energy metered data from sources such as

an effective Energy Management program, you need to Allen-Bradley Power Monitors, Intelligent Drive Control

establish a baseline by measuring your energy usage over products, IntelliCENTER Motor Control Centers, reporting

time to understand why you are using it and to determine content and dashboards are provided out of the box

how your energy consumption is contributing to your to provide visibility into energy consumption. This also

overall cost (e.g. Peak Demand). provides a framework for building an Enterprise Energy

Management solution based on the Unified Production

To take Energy Management to the next level, you Model provided in FactoryTalk VantagePoint EMI.

would want to correlate energy usage with production

information for true insights into how your production

decisions influence your energy usage.

With FactoryTalk VantagePoint Energy the focus is on

driving the measured energy usage at the main and

sub-station level and distributing it as energy

consumption across the enterprise.

FactoryTalk VantagePoint Energy is a model extension

for Energy for FactoryTalk VantagePoint EMI. The Energy

component includes an ISA-95 organizational model

extension for energy, as well as energy metering and

energy consumption. The Energy model components

include predefined content, such as energy reporting

and dashboards, as well as production energy reporting

and dashboards. With this capability, users can aggregate

metered energy/consumption data with production

assets throughout the organization to start monitoring

energy utilization. Daily View

Energy data resides all over

your plant. With FactoryTalk

VantagePoint Energy, you

can access that energy data

from its source in relation

to your production

information in a single,

logical model to create

useful reports and KPIs for

more informed decisions

See how energy information from your operation becomes part of a smart energy and sustainable solution

with informative dashboards and reports.

Standardized Framework to Trending and Plotting

Build Powerful Solutions FactoryTalk VantagePoint EMI incorporates two of the

most versatile and powerful trending and plotting

FactoryTalk VantagePoint EMI includes some of the most applications in the world. With drag-and-drop simplicity,

powerful reporting components in the industry. You may you can drop simple tags or complete objects onto the

begin by creating an ad hoc report, then when you have it plot. Change time periods, stack traces, switch between

set up the way you want, you can publish it with a simple historian and real-time data.

click of the mouse. The objects are immediately a part of

the model and are accessible from the reports list by

anyone with a web browser and user permission. You

may view the reports directly or via the FactoryTalk

VantagePoint EMI Portal.

Microsoft Excel® Add-In

You can leverage all the capabilities in Excel and have the

means to pull information from the Unified Production

Model in FactoryTalk VantagePoint EMI to build highly

effective reports. Touch it up, format cells and regions to

your liking, even create some graphs and charts from the

data. Once you have published the report, you no longer

need the spreadsheet. It is perfectly preserved for you in

the model. And it is not necessary to have Excel installed

on any client to be able to view the report.

Support of Energy Management Systems

FactoryTalk VantagePoint Energy is the perfect tool Case Study

to support implementing Energy Management systems

(such as ISO 50001 and SEP: Superior Energy Performance). Energy Savings is the Driving Force for

Combining energy consumption information with

Change for a Large Confectionery Plant

other relevant variables from production allows you to The rising energy costs were driving up

create energy performance indicators and baselines and production costs for a confectionery company

display those in dashboards and reports thereby making that produces 18,200 tons of products in Europe,

the progress of energy savings transparent within an so Rockwell Automation offered a solution using

organization as well as allow employees and operators to Power Monitors (PM 1000 and PM 3000) and

potentially be able to understand how their actions help FactoryTalk EnergyMetrix.

improve energy savings and ultimately help contributing to “In the first step, we looked especially to the

the organizations objectives and goals. quality of our electrical power supply, because

we had some issues with our electricity provider,”

Provide Visibility into Energy Consumption explains the Technical Team Leader. “In the

following steps, over the next year, we would

at the Unit, Machine and Load Level like to investigate the energy consumption for

By looking at energy down at the asset level, you are able each production line with a PM1000 from

to much better evaluate energy savings based on your Rockwell Automation.”

objectives, targets and action plans put in place over time.

By adding FactoryTalk VantagePoint Energy

You are able to see how an improvement in a specific

with a connector to FactoryTalk EnergyMetrix,

process area or piece of equipment has an impact on the

this customer can now measure their energy

energy use and/or production for that area. consumption in direct correlation to various

In addition, with the capabilities of FactoryTalk VantagePoint production parameters. (i.e. Energy use by line,

EMI of connecting to all of your operations disparate shift or product) The logging and trending

data sources, you can use this system as the main energy of energy data can be done with FactoryTalk

management system across the facility. Then, your energy EnergyMetrix, while useful reports, dashboards

and KPIs from FactoryTalk VantagePoint Energy,

information is correlated with production information,

can now provide information for energy and

as well as other relevant variables such as weather data,

cost savings throughout the plant.

product and raw material characteristics, transportation

costs, etc. to provide a broader picture of possible energy

and business cost reductions.

Get More Information

For information about ordering FactoryTalk

VantagePoint Energy, contact your local Rockwell Automation

sales office or Allen-Bradley distributor. Or learn more

by visiting http://discover.rockwellautomation.com/energy

Allen-Bradley, Rockwell Software, FactoryTalk, SLC and Integrated Architecture are trademarks or registered trademarks of Rockwell Automation, Inc.

Microsoft, Excel and SharePoint are trademarks of Microsoft Corporation. Trademarks not belonging to Rockwell Automation are property of their respective companies.

Publication FTALK-PP021-EN-P – February 2013 Copyright © 2013 Rockwell Automation, Inc. All Rights Reserved. Printed in USA.

Supersedes FTALK-PP028E-EN-P – February 2012

You might also like

- A210-30-11 220-230V 50Hz / 230-240V 60Hz Contactor: Product-DetailsDocument5 pagesA210-30-11 220-230V 50Hz / 230-240V 60Hz Contactor: Product-DetailsMaricruz OlivarNo ratings yet

- AF400-30-11 250-500V 50/60Hz / 250-500V DC Contactor: Product-DetailsDocument5 pagesAF400-30-11 250-500V 50/60Hz / 250-500V DC Contactor: Product-DetailsMaricruz OlivarNo ratings yet

- PlantPAx Process Library Security ConfigurationDocument1 pagePlantPAx Process Library Security ConfigurationMaricruz OlivarNo ratings yet

- PR04 PDFDocument234 pagesPR04 PDFMaricruz OlivarNo ratings yet

- PlantPAX Guia PDFDocument48 pagesPlantPAX Guia PDFMaricruz OlivarNo ratings yet

- 1305 Adjustable Frequency AC Drive: User ManualDocument162 pages1305 Adjustable Frequency AC Drive: User ManualMaricruz OlivarNo ratings yet

- First Step Next Step Play All Steps Rewind All Steps Previous Step Last StepDocument1 pageFirst Step Next Step Play All Steps Rewind All Steps Previous Step Last StepMaricruz OlivarNo ratings yet

- ActiveXTrendConfig Rev1Document14 pagesActiveXTrendConfig Rev1Maricruz OlivarNo ratings yet

- ActiveXTrendConfig Rev1Document14 pagesActiveXTrendConfig Rev1Maricruz OlivarNo ratings yet

- OPC Consideration For Network Security: Corporate, Information Technology... Engineering, Operations, Maintenance..Document3 pagesOPC Consideration For Network Security: Corporate, Information Technology... Engineering, Operations, Maintenance..Maricruz OlivarNo ratings yet

- MatrikonOPC Desktop Historian Quick StartDocument4 pagesMatrikonOPC Desktop Historian Quick StartMaricruz OlivarNo ratings yet

- 0059101-D2L3 RevJ (HHS Tarjeta Level 3) Diagrama Eléctrico PDFDocument1 page0059101-D2L3 RevJ (HHS Tarjeta Level 3) Diagrama Eléctrico PDFMaricruz OlivarNo ratings yet

- 1756 Controllogix I/O Specifications: Technical DataDocument274 pages1756 Controllogix I/O Specifications: Technical DataMaricruz OlivarNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5796)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (589)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Project On Brand Awareness of TulipDocument46 pagesProject On Brand Awareness of TulipBappaditya Bhowal100% (5)

- Bookmap MasterclassDocument378 pagesBookmap MasterclassThierry100% (4)

- MF History: First Phase - 1964-1987Document3 pagesMF History: First Phase - 1964-1987vmktptNo ratings yet

- IV - Audit of The Investing and Financing CycleDocument8 pagesIV - Audit of The Investing and Financing CycleVan MateoNo ratings yet

- Introduction of EmigallDocument2 pagesIntroduction of EmigallJetNo ratings yet

- #5 Workforce FocusDocument8 pages#5 Workforce FocusNeyka YinNo ratings yet

- New Anti-Merger Theories - A CritiqueDocument21 pagesNew Anti-Merger Theories - A CritiqueKashif Munir IdreesiNo ratings yet

- Our Lady of The Pillar College Cauayan: Prelim Examination Accounting 1 &2Document8 pagesOur Lady of The Pillar College Cauayan: Prelim Examination Accounting 1 &2John Lloyd LlananNo ratings yet

- NPNPNPDocument13 pagesNPNPNPTeuku M. Zachari AlamsyahNo ratings yet

- Class Exercise Final Accounts and End of Year AdjusmentsDocument1 pageClass Exercise Final Accounts and End of Year AdjusmentsJoshua OtienoNo ratings yet

- 1.7-Blue Ocean StrategyDocument27 pages1.7-Blue Ocean StrategyGaurav AthalekarNo ratings yet

- History of AccountingDocument17 pagesHistory of AccountingJasmine Garcia57% (7)

- 1101 Kas 1103 Piutang Usaha 1106 Biaya Dibayar Dimuka: Account No Account Name Account TypeDocument3 pages1101 Kas 1103 Piutang Usaha 1106 Biaya Dibayar Dimuka: Account No Account Name Account TypeAmelia LarasatiNo ratings yet

- Fraud Risk Factors ChecklistDocument5 pagesFraud Risk Factors ChecklistmatrneosonNo ratings yet

- Ipasa Nyo Po Kami Sa LawDocument79 pagesIpasa Nyo Po Kami Sa LawAnne Thea AtienzaNo ratings yet

- Internship Report On GSK. Nabila Alam 09104121Document63 pagesInternship Report On GSK. Nabila Alam 09104121prospereducationNo ratings yet

- Sri Sadananda Foods PVTDocument6 pagesSri Sadananda Foods PVTLakshmi SaraswathiNo ratings yet

- Ob Case IncidentsDocument20 pagesOb Case Incidentsalexandramihaelaciob64% (11)

- Alzou Bi 2016Document22 pagesAlzou Bi 2016Denny PutriNo ratings yet

- IBIS WORLD INDUSTRY REPORT: Sandwich & Sub Store FranchisesDocument33 pagesIBIS WORLD INDUSTRY REPORT: Sandwich & Sub Store FranchisesFortuneNo ratings yet

- Business and Management SL P2 PDFDocument8 pagesBusiness and Management SL P2 PDFLodewijk BajarinNo ratings yet

- Kumar Mangalam Birla: Committee Report On Corporate GovernanceDocument16 pagesKumar Mangalam Birla: Committee Report On Corporate GovernanceSiddharth SinghNo ratings yet

- Waleed QureshiDocument2 pagesWaleed QureshiWaleed Bin KhaliqNo ratings yet

- Bread Is The Staff of Life : Krendel' BakeryDocument19 pagesBread Is The Staff of Life : Krendel' BakeryMehboob AhmedNo ratings yet

- Sn53sup 20170228 001 2200147134Document3 pagesSn53sup 20170228 001 2200147134Henry Low100% (1)

- Um Scenario NDocument3 pagesUm Scenario Nmansha99No ratings yet

- HR-Practical Guideline PDFDocument152 pagesHR-Practical Guideline PDFRo RathaNo ratings yet

- Workforce ManagementDocument5 pagesWorkforce ManagementSplatttttttNo ratings yet

- Marketing of Financial ServicesDocument86 pagesMarketing of Financial Servicesprashantsagar26No ratings yet

- Payroll TablesDocument9 pagesPayroll TableshardanuNo ratings yet