Professional Documents

Culture Documents

RK0S RK0SPB - 25CrMo4 Nr.1.7218 25CrMoS4 Nr.1.7213 ENG PDF

Uploaded by

tosse atanasovOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

RK0S RK0SPB - 25CrMo4 Nr.1.7218 25CrMoS4 Nr.1.7213 ENG PDF

Uploaded by

tosse atanasovCopyright:

Available Formats

25CrMo4 - Nr. 1.

7218 QUENCHING

25CrMoS4 - Nr. 1.7213 AND TEMPERING

STANDARD REFERENCE:

EN ISO 683-2: 2018 (Hot-rolled products) | EN 10277: 2018 (Bright products)

RODACCIAI REFERENCES AND COMPARABLE STANDARDS

EUROPE ITALY GERMANY FRANCE UK USA

EN 10083-3: 2006

(UNI 7845-78) (DIN 17200-86) (NF A 35-552-86) (BS 970 pt.3-96) ASTM A 29

EN 10277-5: 2008

Grade N° Werkstoff N°

25CrMo4 1.7218 25CrMo4 1.7218

25CrMo4 25 CD 4 - -

25CrMoS4 1.7213 25CrMoS4 1.7213

CHEMICAL COMPOSITION (CAST ANALYSIS) (%)

C Si Mn P / max S Cr Mo Cu / max Al Pb

≤ 0,035 -

0,22÷0,29 0,10÷0,40 0,60÷0,90 0,025 0,020÷0,040 0,90÷1,20 0,15÷0,30 0,40 0,020÷0,050 -

0,020÷0,040 0,15÷0,30

MECHANICAL PROPERTIES - AS ROLLED CONDITION

HB max to condition Quenched and tempered (+QT)

Size

mm Treated to improve Soft annealing

Rp0,2 (MPa) min Rm (MPa) A5 (%) min Z (%) min KV (J) min

shearability (+S) (+A)

≤ 16 255 212 700 900÷1100 12 50 -

> 16 ≤ 40 255 212 600 800÷950 14 55 50

> 40 ≤ 100 255 212 450 700÷850 15 60 50

> 100≤ 160 255 212 400 650÷800 16 60 45

MECHANICAL PROPERTIES - BRIGHT PRODUCTS CONDITION

Quenched+Tempered + Cold Drawn

as Rolled + Turned (+A+SH) Quenched+Tempered + Turned (+QT+SH)* as Rolled+Cold Drawn (+A+C)

Size (+QT+C)

mm Hardness HB max

Rp0,2 (MPa)

Rm (MPa) A5 (%) min KV (J) min

Rp0,2 (MPa)

Rm (MPa) A5 (%) min Hardness HB max

min min

≥ 5 ≤ 10 - - - - 700 900÷1100 9 270

> 10 ≤ 16 - - - - 700 900÷1100 9 260

> 16 ≤ 40 212 600 800÷950 14 50 600 800÷1000 10 255

> 40 ≤ 63 212 450 700÷850 15 50 520 700÷900 11 250

> 63 ≤ 100 212 450 700÷850 15 50 450 700÷900 12 250

*This values are valid also for Cold Drawn - Quenched + Tempered Condition (+C +QT)

For size <5 mm the mechanical properties may be agreed at the time of enquiry and order

WORKING TEMPERATURES RECOMMENDED

Hot forgings Quenching

rev. 10/2018

Operation deformation Isothermal annealing Soft annealing in water or oil Tempering

°C 850÷1150 850÷880 650 680÷720 840÷870 550÷650

Mark Rodacciai Download APP

QUENCHING AND TEMPERING

RK0S - RK0SPB

ALLOYED

25CrMo4 - Nr. 1.7218 QUENCHING

25CrMoS4 - Nr. 1.7213 AND TEMPERING

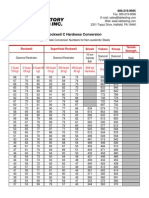

HARDNESS LIMITS (JOMINY TEST)

Limits Hardness HRC at a distance from quenched end of test pieces (mm)

of range 1,5 3 5 7 9 11 13 15 20 25 30 35 40 45 50

Max 52 52 51 50 48 46 43 41 37 35 33 32 31 31 31

+H

Min 44 43 40 37 34 32 29 27 23 21 20 - - - -

Max 52 52 51 50 48 46 43 41 37 35 33 32 31 31 31

+HH

Min 47 46 44 41 39 37 34 32 28 26 24 23 22 22 22

Max 49 49 47 46 43 41 38 36 32 30 29 28 27 27 27

+HL

Min 44 43 40 37 34 32 29 27 23 21 20 - - - -

TTT

TEMPERING CURVE

Temperature °C

Time

CCT

Tempering temperature °C

Temperature °C

rev. 10/2018

Time

Mark Rodacciai Download APP

QUENCHING AND TEMPERING

RK0S - RK0SPB

ALLOYED

You might also like

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- RK1 RK1PB - 42CrMo4 Nr.1.7225 42CrMoS4 Nr.1.7227 ENG PDFDocument2 pagesRK1 RK1PB - 42CrMo4 Nr.1.7225 42CrMoS4 Nr.1.7227 ENG PDFAnonymous yshOO0tEjKNo ratings yet

- KV45 R45S R45PB - C45E Nr.1.1191 C45R Nr.1.1201 ENGDocument2 pagesKV45 R45S R45PB - C45E Nr.1.1191 C45R Nr.1.1201 ENGNarimane BentyNo ratings yet

- KV45 R45S R45PB - C45E Nr.1.1191 C45R Nr.1.1201 ENGDocument2 pagesKV45 R45S R45PB - C45E Nr.1.1191 C45R Nr.1.1201 ENGBiaizidi Abbou SamirNo ratings yet

- 34CRNIMO6 - 34CrNiMo6-Nr 1 6582-ENGDocument2 pages34CRNIMO6 - 34CrNiMo6-Nr 1 6582-ENGNarimane BentyNo ratings yet

- 50CRMO4_50CrMo4-Nr.1.7228-ENGDocument2 pages50CRMO4_50CrMo4-Nr.1.7228-ENGLuiz Antonio dos AnjosNo ratings yet

- 34CrNiMo6 1.6582 ENGDocument2 pages34CrNiMo6 1.6582 ENGAmarendra PendseNo ratings yet

- Stainless Steels 410: MartensiticDocument2 pagesStainless Steels 410: MartensiticKiranNo ratings yet

- Not Alloyed: Case-Hardening Steels C16EDocument1 pageNot Alloyed: Case-Hardening Steels C16Esafat parNo ratings yet

- Special Steels CB10FF: For Cold Deformation and BearingsDocument1 pageSpecial Steels CB10FF: For Cold Deformation and BearingsRollpass DesignNo ratings yet

- 34 CR Ni Mo 6Document4 pages34 CR Ni Mo 6Jonas AnderssonNo ratings yet

- 42 CR Mo 4Document4 pages42 CR Mo 4Alin ChehadeNo ratings yet

- Special Steels SB4: For Cold Deformation and BearingsDocument1 pageSpecial Steels SB4: For Cold Deformation and BearingsRollpass DesignNo ratings yet

- Alloyed: Case-Hardening Steels Rn3 - Rn3PbDocument2 pagesAlloyed: Case-Hardening Steels Rn3 - Rn3PbSaba AhmedNo ratings yet

- 30crnimo8: Steel GradeDocument2 pages30crnimo8: Steel GradewemersonsrNo ratings yet

- 34 CR Ni Mo 6Document4 pages34 CR Ni Mo 6Krzysztof WrzeszczNo ratings yet

- 42crmo4: Steel GradeDocument5 pages42crmo4: Steel GradeMahmoud KchaouNo ratings yet

- Special steels A320 L7 - L7M American standards ASTMDocument1 pageSpecial steels A320 L7 - L7M American standards ASTMNarimane BentyNo ratings yet

- Material Data Sheet SB482 Steel Grade 38MnVS6Document3 pagesMaterial Data Sheet SB482 Steel Grade 38MnVS6Jaison JacobNo ratings yet

- Steel Grade: Material Data SheetDocument7 pagesSteel Grade: Material Data Sheetispat_jagadeeshNo ratings yet

- 52crmov4: Steel GradeDocument2 pages52crmov4: Steel GradeHEMANTNo ratings yet

- Medium Strength Extrusion Alloy Data SheetDocument1 pageMedium Strength Extrusion Alloy Data Sheetankur panwarNo ratings yet

- 42crmo6 : Steel GradeDocument2 pages42crmo6 : Steel GradeYonas Dwiananta YuwonoNo ratings yet

- Stainless Steels 430F: MartensiticDocument2 pagesStainless Steels 430F: MartensiticRavindra ErabattiNo ratings yet

- Tempering Conditions For 30CrNiMo8Document2 pagesTempering Conditions For 30CrNiMo8madyeNo ratings yet

- CEWELD - 308LSi TIGDocument1 pageCEWELD - 308LSi TIGFilipe CordeiroNo ratings yet

- C4C - Special Steel for Cold Deformation and BearingsDocument1 pageC4C - Special Steel for Cold Deformation and BearingsObaciuIonel100% (1)

- Steel Grade: Material Data SheetDocument4 pagesSteel Grade: Material Data SheetAlin ChehadeNo ratings yet

- Dokumen - Tips SR en 10088 1 2005 Oteluri Inoxidabile Partea 1 Lista Otelurilor InoxidabilepdfDocument2 pagesDokumen - Tips SR en 10088 1 2005 Oteluri Inoxidabile Partea 1 Lista Otelurilor InoxidabilepdfraduonoNo ratings yet

- 52crmov4: Steel GradeDocument3 pages52crmov4: Steel GradeemregnesNo ratings yet

- 304 - X5CrNi18 10 Nr.1.4301 ENG PDFDocument2 pages304 - X5CrNi18 10 Nr.1.4301 ENG PDFGaurav AggarwalNo ratings yet

- 41 CR 4Document3 pages41 CR 4AHMED FATHINo ratings yet

- Principal Application Fields General Application SteelDocument1 pagePrincipal Application Fields General Application SteelBhuvnesh VermaNo ratings yet

- Tehnicke Karakteristike Asistal Alu OkapnicaDocument2 pagesTehnicke Karakteristike Asistal Alu OkapnicaDARKO RADICEVICNo ratings yet

- Nedal Aluminium BV Alloy Data Sheet for EN-AW 6060 Extrusion AlloyDocument1 pageNedal Aluminium BV Alloy Data Sheet for EN-AW 6060 Extrusion Alloyankur panwarNo ratings yet

- 41 CR 4Document2 pages41 CR 4Jhon ChitNo ratings yet

- 42 CR Mo 4Document3 pages42 CR Mo 4lucasNo ratings yet

- 34 CR Ni Mo 6Document4 pages34 CR Ni Mo 6InaamNo ratings yet

- Alloy Data Sheet En-Aw 6063 (Almg0.7Si) : Type: General Extrusion Alloy)Document1 pageAlloy Data Sheet En-Aw 6063 (Almg0.7Si) : Type: General Extrusion Alloy)CocoNo ratings yet

- 56 Si 7Document2 pages56 Si 7Bhuvanesh ShanmugamNo ratings yet

- 38 MN VS6Document2 pages38 MN VS6Pramod NautiyalNo ratings yet

- CR Mo 4Document2 pagesCR Mo 4Mohsen ParpinchiNo ratings yet

- 25crmo4: Steel GradeDocument3 pages25crmo4: Steel GradeCristian Stiven Martinez GonzalezNo ratings yet

- 1 5736Document2 pages1 5736solidwormNo ratings yet

- Direct-Hardening: Free-Cutting Steels 35S20Document1 pageDirect-Hardening: Free-Cutting Steels 35S20Biaizidi Abbou SamirNo ratings yet

- 34crnimo6: Steel GradeDocument4 pages34crnimo6: Steel GradeAndrea FerrerNo ratings yet

- 40crmov4-6: Steel GradeDocument3 pages40crmov4-6: Steel GradeMahsaNo ratings yet

- TG S50 PDFDocument1 pageTG S50 PDFIvan RocoNo ratings yet

- Catalago Pistones TikDocument304 pagesCatalago Pistones TikNeiser Muñoz DiazNo ratings yet

- 42 CR Mo 4Document2 pages42 CR Mo 4ElMacheteDelHuesoNo ratings yet

- CDA 84400 phosphor bronze alloy propertiesDocument4 pagesCDA 84400 phosphor bronze alloy propertiesShariq KhanNo ratings yet

- 20Mncr5: Steel GradeDocument4 pages20Mncr5: Steel GradeAhmad ShujaNo ratings yet

- 46S20PB - 46SPb20-Nr 1 0757-ENGDocument1 page46S20PB - 46SPb20-Nr 1 0757-ENGVipul SharmaNo ratings yet

- 42 CR Mo 4Document4 pages42 CR Mo 4eduardomanar1224No ratings yet

- Steel Grade: Material Data SheetDocument7 pagesSteel Grade: Material Data SheetRohit VanapalliNo ratings yet

- Sandvik 254 SMO Datasheet for Seamless Tube and PipeDocument9 pagesSandvik 254 SMO Datasheet for Seamless Tube and PipeReadersmoNo ratings yet

- Quality S275J2: Structural SteelDocument1 pageQuality S275J2: Structural Steeloussama somraniNo ratings yet

- 25CrMo4 (EN 10083 3)Document2 pages25CrMo4 (EN 10083 3)mohsen_267No ratings yet

- Matecconf Fatigue2018 06006Document6 pagesMatecconf Fatigue2018 06006tosse atanasovNo ratings yet

- Tool Steels: Højerslev, CDocument27 pagesTool Steels: Højerslev, Ctosse atanasovNo ratings yet

- Properties of MaterialsDocument3 pagesProperties of MaterialsSimas ServutasNo ratings yet

- Chart Hardness CDocument2 pagesChart Hardness CJanaka MangalaNo ratings yet

- ENG302 Part 2Document7 pagesENG302 Part 2Oğuzhan DalkılıçNo ratings yet

- Review of Train Wheel Fatigue LifeDocument15 pagesReview of Train Wheel Fatigue Lifeabdurhman suleimanNo ratings yet

- Using Sunspots To Measure Solar Rotation: Astronomy 104 Observing Laboratory Spring 2009Document6 pagesUsing Sunspots To Measure Solar Rotation: Astronomy 104 Observing Laboratory Spring 2009Jeko Betguen PalangiNo ratings yet

- Aristotle's virtue theory - Become virtuous through habitDocument4 pagesAristotle's virtue theory - Become virtuous through habitWiljan Jay AbellonNo ratings yet

- Costallocationvideolectureslides 000XADocument12 pagesCostallocationvideolectureslides 000XAWOw Wong100% (1)

- DIK 18A Intan Suhariani 218112100 CJR Research MethodologyDocument9 pagesDIK 18A Intan Suhariani 218112100 CJR Research MethodologyFadli RafiNo ratings yet

- Drone Hexacopter IjisrtDocument4 pagesDrone Hexacopter IjisrtDEPARTEMEN RUDALNo ratings yet

- M-2 AIS Installation Manual ContentDocument57 pagesM-2 AIS Installation Manual ContentAdi PrasetyoNo ratings yet

- Baghouse Compressed AirDocument17 pagesBaghouse Compressed Airmanh hung leNo ratings yet

- FOXPAK Control Valve System SpecificationsDocument0 pagesFOXPAK Control Valve System Specificationscico_ctNo ratings yet

- Shimano 105 Gear Change ManualDocument1 pageShimano 105 Gear Change Manual1heUndertakerNo ratings yet

- Basic Vacuum Theory PDFDocument17 pagesBasic Vacuum Theory PDFada guevarraNo ratings yet

- Nature and Scope of History as a Social ScienceDocument14 pagesNature and Scope of History as a Social SciencejustadorkyyyNo ratings yet

- AR Ageing FinalDocument13 pagesAR Ageing FinalHAbbunoNo ratings yet

- BERGSTROM, Karl Jones. Playing For Togetherness (Tese)Document127 pagesBERGSTROM, Karl Jones. Playing For Togetherness (Tese)Goshai DaianNo ratings yet

- Activity No.1 in GED 103Document2 pagesActivity No.1 in GED 103Kenneth HerreraNo ratings yet

- Glover 5e SI - Chapter 05Document30 pagesGlover 5e SI - Chapter 05novakiNo ratings yet

- Synopsis On Training & DevelopmentDocument6 pagesSynopsis On Training & DevelopmentArchi gupta86% (14)

- Narrative Report On Catch Up Friday ReadingDocument2 pagesNarrative Report On Catch Up Friday ReadingNova Mae AgraviadorNo ratings yet

- REHAU 20UFH InstallationDocument84 pagesREHAU 20UFH InstallationngrigoreNo ratings yet

- Sample Interview Questions – Promoting Diversity and InclusionDocument3 pagesSample Interview Questions – Promoting Diversity and InclusionLiah Piano-Beast UchihaNo ratings yet

- Stat and Prob Q1 M3Document15 pagesStat and Prob Q1 M3Samantha Kyle E. PedrigozaNo ratings yet

- Mass TransportationDocument20 pagesMass Transportationyoyo_8998No ratings yet

- Kathryn Stanley ResumeDocument2 pagesKathryn Stanley Resumeapi-503476564No ratings yet

- SRFP 2015 Web List PDFDocument1 pageSRFP 2015 Web List PDFabhishekNo ratings yet

- Latihan Soal ADS Bab 14-16Document1 pageLatihan Soal ADS Bab 14-16nadea06_20679973No ratings yet

- Driven by Passion. Eager To Grow. If That'S You, Join Bearingpoint!Document15 pagesDriven by Passion. Eager To Grow. If That'S You, Join Bearingpoint!Ana Maria PetreNo ratings yet

- Time May Not Exist - Tim Folger in DiscoverDocument3 pagesTime May Not Exist - Tim Folger in DiscoverTrevor Allen100% (5)

- Green Building by Superadobe TechnologyDocument22 pagesGreen Building by Superadobe TechnologySivaramakrishnaNalluri67% (3)

- Basic Instructions: A Load (Contact) SymbolDocument3 pagesBasic Instructions: A Load (Contact) SymbolBaijayanti DasNo ratings yet