Professional Documents

Culture Documents

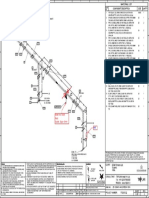

Pesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1

Uploaded by

Valesh MonisOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Pesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1

Uploaded by

Valesh MonisCopyright:

Available Formats

1 2 3 4 5 6 7 8

PART MATERIAL DESCRIPTION SIZE ITEM CODE QTY. SPEC

No

FABRICATION MATERIALS

N

1 Tee, Female threaded end, 50X50 MDJAWBUAEAAGABQZZUS 1 B10

Galvanized,ASME-B16.11, A105, 45

CL 3000

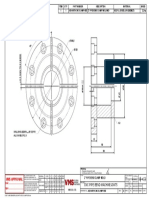

A 2 Threaded flange, CL150, 50 FACAHABZZAADABQZZUS 5 B10 5 A

Raised-face flanged end,

ASME-B16.5, A105, Galvanised CONN TO

45 22

PIPE SUPPORTS 4 Accumulator/n2

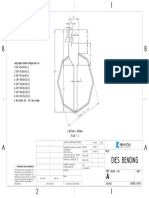

3 Design Pipe Assembly 50 DesignPipeH_5 3 B10 50 mm RFFE 150

<6 E 261959

ERECTION MATERIALS >

4 99 N 224975

4 Pipe, MTE, Galvanized, 50 PAAZZBNAEABAABOAAZZUS 4.1 M 7 EL +235

382

ASME-B36.10M, A53-B, Seamless, 33 15

7 0

S-40 S3 10

337

5

5 90 degree elbow, Female 50 MCKAWBUAEAAGABQZZUS 4 B10 10GCF10BQ040 9

<7> 4

178

threaded end, STEM UP

10GCF10AA003 45

Galvanized,ASME-B16.11, A105,

F2 G6 B7

CL 3000

16

6 Spiral wound, CL150, 4.5mm, 50 GMAHAOAABFMUS 5 B10 SEE ISO 1 <1> 4 5

ASME-B16.20, SS316 (Asbestos 10GCF10BR002 50DN

E 260801 F2 G6 B7 <5 45

Free) > 45 F2 G6 B7

B N 225819 4 B

7 Stud Bolt, ASME-B18.2.1, ASTM 5/8 BAZZZZZZAAYBFZZZUS 20 B10 EL +280 F2 G6 B7 4

A193-B7, hot dip galvanized, < 2>

50X50DN 1

With 2heavy Hex nuts A194 50X50DN F2 G6 B7 1 45

36

Gr.2H and 2 washers - 95 mm EL +662

Length 67

6 58

8 Gate valve, CL600, Raised face 50 VAAAPBUAEAAFABQZZZZUSF 1 B10 45 11

flanged end, ASME-B16.10, A105

9 Gate valve, CL600, Raised face 50 VAAAPBUAEAAFABQZZZZUSF 1 B10

5

flanged end, ASME-B16.10, A105 R0

S3 27 178

<4> 4

10GCF10BQ041 8

STEM UP

10GCF10AA001

337

427

4

> 13

C <3 92 C

7

24 S3 62

10GCF10BQ037 6

<8

>

4

45

45

5

45

45

D D

388

<9> 4

50DN

SEE ISO

10GCF10BR001 SHT 02

E 260801

N 223430

EL +228

E 9 388 50 SCREWED SCREWED PAAZZBNAEABAABOAAZZUS E

8 1302 50 SCREWED SCREWED PAAZZBNAEABAABOAAZZUS

7 337 50 SCREWED SCREWED PAAZZBNAEABAABOAAZZUS

6 555 50 SCREWED SCREWED PAAZZBNAEABAABOAAZZUS OWNER

5 155 50 SCREWED SCREWED PAAZZBNAEABAABOAAZZUS

4 337 50 SCREWED SCREWED PAAZZBNAEABAABOAAZZUS DISTRIBUTION W/C

3 516 50 SCREWED SCREWED PAAZZBNAEABAABOAAZZUS MATRIX

2 355 50 SCREWED SCREWED PAAZZBNAEABAABOAAZZUS

1 98 50 SCREWED SCREWED PAAZZBNAEABAABOAAZZUS NOTES:- EPC

PIECE

NO

LENGTH

MM

SIZE

MM

END PREP END PREP ITEM CODE

1. ALL DIMENSIONS AND ELEVATIONS ARE IN MILLIMETERS

2. FINISHED GROUND LEVEL (FGL) OF PLANT IS (-)0.300 WHICH

CORRESPONDS TO MSL (+)8.50M

PESCO

3. FOR PAINTING & SURFACE PREPARATION DETAILS REFER "TECHNICAL

SPECIFICATION FOR PAITING" DOC NO. TCE.11191A-SP-3903 MAIN PLANT EQUIPMENT SUPPLIER

4. FOR INSULATION DETAILS REFER "TECHNICAL SPECIFICATION FOR

INSULATION" DOC NO. TCE.11191A-SP-3902

5. ALL ELEVATIONS INDICATED ARE CENTER LINE OF PIPES UNLESS

OTHERWISE NOTED. PROJECT NAME

6. SMALL BORE PIPING (DN 50 & BELOW) ARE FIELD RUN. ISOMETRICS

ISSUED FOR THE SAME IS INDICATIVE AND MAY BE ADJUSTED TO SUIT ADEN POWER PLANT - PHASE 1

F SITE CONDITIONS. F

7. FOR SUPPORT ARRANGEMENT, REFER TYPICAL STANDARD SKETCH

DRAWING - TCE.11191A-D-4909 DRAWING TITLE ISOMETRICS FOR RAW WATER AND SERVICE

8. VICTAULIC PIPE FITTINGS SHALL NOT REST ON SUPPORTS AND SHALL

R0

WATER DISTRIBUTION SYSTEM

HAVE AMPLE CLEARANCE FROM SUPPORT.

10GCF10BR001 01 of 04

P&ID NO. ENGINEERING JOB No. DRAWING NUMBER REV

PIPING LAYOUT DRAWING NO. No. DATE REVISION DESCRIPTION BY CHK APPR Civil Mech Elect I/C PIP HSE PROS

11191A TCE.11191A-D-4916 R0

FILE NAME 10GCF10BR001.SHA DATE : DESIGNED : DRAWN : CHEF ENGR : TATA CONSULTING ENGINEERS LIMITED

1 2 3 4 5 6 7 8

You might also like

- Dutfield & Suthersanen 2008 Global Intellectual Property LawDocument380 pagesDutfield & Suthersanen 2008 Global Intellectual Property LawCristóbal AstorgaNo ratings yet

- ResearchDocument22 pagesResearchRANRIANo ratings yet

- Pesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Document1 pagePesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Valesh MonisNo ratings yet

- Pesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Document1 pagePesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Valesh MonisNo ratings yet

- Pesco: E 394705 N 265622 EL +917 Screwed End To Gt#11 AreaDocument1 pagePesco: E 394705 N 265622 EL +917 Screwed End To Gt#11 AreaValesh MonisNo ratings yet

- Pesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Document1 pagePesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Valesh MonisNo ratings yet

- 066504u58271 004 004-ADocument1 page066504u58271 004 004-ADINESH VNo ratings yet

- E32 P R340 2136Document5 pagesE32 P R340 2136Ranish P. KurianNo ratings yet

- Pesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Document1 pagePesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Valesh MonisNo ratings yet

- Fabrication Materials ListDocument1 pageFabrication Materials ListSaptarshi MandalNo ratings yet

- Pesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Document1 pagePesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Valesh MonisNo ratings yet

- FABRICATION MATERIALS LISTDocument1 pageFABRICATION MATERIALS LISTSaptarshi MandalNo ratings yet

- 50 10xaa1 He40 21RDCH 1016Document1 page50 10xaa1 He40 21RDCH 1016uma raneNo ratings yet

- Pesco: Isometrics For Light Crude Oil System Aden Power Plant - Phase 1Document1 pagePesco: Isometrics For Light Crude Oil System Aden Power Plant - Phase 1Valesh MonisNo ratings yet

- H31 SW F34 2475Document4 pagesH31 SW F34 2475Bini RanishNo ratings yet

- Abo Cow 4 14Document1 pageAbo Cow 4 14AdewaleNo ratings yet

- Fabrication materials listDocument1 pageFabrication materials listthe.avishekkNo ratings yet

- Pesco: Isometrics For Light Crude Oil System Aden Power Plant - Phase 1Document1 pagePesco: Isometrics For Light Crude Oil System Aden Power Plant - Phase 1Valesh MonisNo ratings yet

- Fabrication and Erection Materials Bill of MaterialsDocument1 pageFabrication and Erection Materials Bill of MaterialsValesh MonisNo ratings yet

- Pesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Document1 pagePesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Valesh MonisNo ratings yet

- Fabrication Materials PT Description N.S QTY Client Code: Yna-ACDocument1 pageFabrication Materials PT Description N.S QTY Client Code: Yna-ACMarcellino YohanesNo ratings yet

- 25 10xaa1 H40 22RDCH 1014Document1 page25 10xaa1 H40 22RDCH 1014uma raneNo ratings yet

- Pesco: Isometrics For Light Crude Oil System Aden Power Plant - Phase 1Document1 pagePesco: Isometrics For Light Crude Oil System Aden Power Plant - Phase 1Valesh MonisNo ratings yet

- Pesco: Isometrics For Light Crude Oil System Aden Power Plant - Phase 1Document1 pagePesco: Isometrics For Light Crude Oil System Aden Power Plant - Phase 1Valesh MonisNo ratings yet

- 00GBB01BR005SH1Document1 page00GBB01BR005SH1AhmedNo ratings yet

- Chwr-1015-Cs-250-Ic-45 - Sheet (5 of 6)Document1 pageChwr-1015-Cs-250-Ic-45 - Sheet (5 of 6)vishwas salunkheNo ratings yet

- 9100 Series - CD220628Document6 pages9100 Series - CD220628Eduardo TapiaNo ratings yet

- MUL ACS880 01 R4 R5 Quick Start GuideDocument88 pagesMUL ACS880 01 R4 R5 Quick Start GuideMinh Trieu NguyenNo ratings yet

- 25 10xaa1 H40 21RDCH 1014Document1 page25 10xaa1 H40 21RDCH 1014uma raneNo ratings yet

- Lab1 PDFDocument1 pageLab1 PDFYOSSEF ROJAS TAPARANo ratings yet

- 1u01 WW 9002 01Document1 page1u01 WW 9002 01syslor.kimNo ratings yet

- Pipe Support Fabrication and Erection Materials ListDocument1 pagePipe Support Fabrication and Erection Materials ListValesh MonisNo ratings yet

- Roller Bracket AssemblyDocument1 pageRoller Bracket AssemblyRishikesh GunjalNo ratings yet

- Piping Isometric - 4Document1 pagePiping Isometric - 4CosminMarianNo ratings yet

- HPE FM 2 Pump 0820 P UCPDocument1 pageHPE FM 2 Pump 0820 P UCPbondsivamaniNo ratings yet

- 150 10xaa1 H50 21RDCH 1004 1Document1 page150 10xaa1 H50 21RDCH 1004 1uma raneNo ratings yet

- Material List - Fabrication: - / - A1ZA-1 2 PMDocument2 pagesMaterial List - Fabrication: - / - A1ZA-1 2 PMMallela Sampath KumarNo ratings yet

- VR2D 245-4000 + 1xCD 101 - C25036ECDC09 - C PDFDocument6 pagesVR2D 245-4000 + 1xCD 101 - C25036ECDC09 - C PDFAhmed Nasr (By NAZRi)No ratings yet

- Chwr-1021-Cs-100-Ic-40 - Sheet (1 of 1)Document1 pageChwr-1021-Cs-100-Ic-40 - Sheet (1 of 1)vishwas salunkheNo ratings yet

- Fabrication Materials ListDocument7 pagesFabrication Materials ListCLS AKNo ratings yet

- Jabel- Substructure DetailDocument1 pageJabel- Substructure Detailjamesbeth162No ratings yet

- PIPE AND FLANGE PART DETAILSDocument1 pagePIPE AND FLANGE PART DETAILSfaviikaujaNo ratings yet

- Vms Approval: CNC Pipe Bend Machine-Dw75Document1 pageVms Approval: CNC Pipe Bend Machine-Dw75Luong LeNo ratings yet

- D-000731-2-SCLP-C21BT-02049 SHT.4 Rev 1 - Line No. SCLP-C21BT-02049 ISODocument1 pageD-000731-2-SCLP-C21BT-02049 SHT.4 Rev 1 - Line No. SCLP-C21BT-02049 ISOneil horwoodNo ratings yet

- Final Sheet-Model - PDF 1Document1 pageFinal Sheet-Model - PDF 1Prateek SharmaNo ratings yet

- 13L00501A - 7P-A: General NotesDocument7 pages13L00501A - 7P-A: General NotesCLS AKNo ratings yet

- 13L00501A - 7P-A: General NotesDocument7 pages13L00501A - 7P-A: General NotesCLS AKNo ratings yet

- Fabrication Materials ListDocument6 pagesFabrication Materials ListcelonevesNo ratings yet

- Nandhimangalam Sb-Plinth Beam DetailDocument1 pageNandhimangalam Sb-Plinth Beam DetailWillip Desert KingNo ratings yet

- Fuse CutoutDocument1 pageFuse CutoutSameer KmNo ratings yet

- Detail 2Document1 pageDetail 2Widad RusdiNo ratings yet

- Dies Custom 4Document1 pageDies Custom 4Irfan FebrianNo ratings yet

- CCM-196-19-CK68 DETAIL UDocument15 pagesCCM-196-19-CK68 DETAIL UNguyen Anh TuanNo ratings yet

- Regal Beloit America, Inc.: Rev Date/ © Date Revision by Request Number Drawing Revision Drawn by Date Approved byDocument1 pageRegal Beloit America, Inc.: Rev Date/ © Date Revision by Request Number Drawing Revision Drawn by Date Approved byDANIEL'S SERVICIOS INTEGRALES EN SOLDADURANo ratings yet

- TC0-Dual Plate Wafer Type Check Valve-A395 65 45 15 DI-150LBDocument1 pageTC0-Dual Plate Wafer Type Check Valve-A395 65 45 15 DI-150LBCV Carlitos Maju PratamaNo ratings yet

- KSKC-CWR24127 - Sample of Isometric (To Relaease HOLD and Uprev R1)Document7 pagesKSKC-CWR24127 - Sample of Isometric (To Relaease HOLD and Uprev R1)Ahmad AqilNo ratings yet

- Bridge Attachment Hanger Material ListDocument5 pagesBridge Attachment Hanger Material Listthaw kaung mawNo ratings yet

- 2220 PW 12168 - SPOOL2 ModelDocument1 page2220 PW 12168 - SPOOL2 Modelmiguel angel reynaga acevedoNo ratings yet

- 5592F - Válvula de Bola (Roscada)Document1 page5592F - Válvula de Bola (Roscada)Rafael SalazarNo ratings yet

- Drawing1 ModelDocument1 pageDrawing1 Modelmiguel angel reynaga acevedoNo ratings yet

- Golar GimiTemperature Junction BoxDocument1 pageGolar GimiTemperature Junction Boxauto etrustNo ratings yet

- The Rough Guide to Beijing (Travel Guide eBook)From EverandThe Rough Guide to Beijing (Travel Guide eBook)Rating: 2 out of 5 stars2/5 (1)

- Pesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Document1 pagePesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Valesh MonisNo ratings yet

- Pesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Document1 pagePesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Valesh MonisNo ratings yet

- Pesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Document1 pagePesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Valesh MonisNo ratings yet

- Pesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Document1 pagePesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Valesh MonisNo ratings yet

- Pesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Document1 pagePesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Valesh MonisNo ratings yet

- Pipe Support Fabrication and Erection Materials ListDocument1 pagePipe Support Fabrication and Erection Materials ListValesh MonisNo ratings yet

- Petro Masila Company: Tata Consulting Engineers Limited - Phase 1Document1 pagePetro Masila Company: Tata Consulting Engineers Limited - Phase 1Valesh MonisNo ratings yet

- Raw Water & Service Water Distribution System: Isometric Drawing ListDocument1 pageRaw Water & Service Water Distribution System: Isometric Drawing ListValesh MonisNo ratings yet

- 10ENA01BR003 Sheet3-ModelDocument1 page10ENA01BR003 Sheet3-ModelValesh MonisNo ratings yet

- 10ENA01BR004 Sheet5-ModelDocument1 page10ENA01BR004 Sheet5-ModelValesh MonisNo ratings yet

- 10ENA01BR003 Sheet1-ModelDocument1 page10ENA01BR003 Sheet1-ModelValesh MonisNo ratings yet

- Fabrication materials and pipe supports bill of materialsDocument1 pageFabrication materials and pipe supports bill of materialsValesh MonisNo ratings yet

- Fabrication and Erection Materials Bill of MaterialsDocument1 pageFabrication and Erection Materials Bill of MaterialsValesh MonisNo ratings yet

- Fabrication materials and pipe supports bill of materialsDocument1 pageFabrication materials and pipe supports bill of materialsValesh MonisNo ratings yet

- Pesco: Isometrics For Light Crude Oil System Aden Power Plant - Phase 1Document1 pagePesco: Isometrics For Light Crude Oil System Aden Power Plant - Phase 1Valesh MonisNo ratings yet

- 10ENA01BR003 Sheet2-ModelDocument1 page10ENA01BR003 Sheet2-ModelValesh MonisNo ratings yet

- Tce.11191a-D-4213 - Ldo P&id - R4 (Ur)Document2 pagesTce.11191a-D-4213 - Ldo P&id - R4 (Ur)Valesh MonisNo ratings yet

- Pesco: Isometrics For Light Crude Oil System Aden Power Plant - Phase 1Document1 pagePesco: Isometrics For Light Crude Oil System Aden Power Plant - Phase 1Valesh MonisNo ratings yet

- Fabrication materials and pipe supports bill of materialsDocument1 pageFabrication materials and pipe supports bill of materialsValesh MonisNo ratings yet

- Pesco: Isometrics For Light Crude Oil System Aden Power Plant - Phase 1Document1 pagePesco: Isometrics For Light Crude Oil System Aden Power Plant - Phase 1Valesh MonisNo ratings yet

- TCE LDO Isometric Drawings for Aden Power Plant Phase 1Document1 pageTCE LDO Isometric Drawings for Aden Power Plant Phase 1Valesh MonisNo ratings yet

- Pesco: Isometrics For Light Crude Oil System Aden Power Plant - Phase 1Document1 pagePesco: Isometrics For Light Crude Oil System Aden Power Plant - Phase 1Valesh MonisNo ratings yet

- Pesco: Isometrics For Light Crude Oil System Aden Power Plant - Phase 1Document1 pagePesco: Isometrics For Light Crude Oil System Aden Power Plant - Phase 1Valesh MonisNo ratings yet

- Pesco: Isometrics For Light Crude Oil System Aden Power Plant - Phase 1Document1 pagePesco: Isometrics For Light Crude Oil System Aden Power Plant - Phase 1Valesh MonisNo ratings yet

- Green Heart - Data SheetDocument4 pagesGreen Heart - Data SheetIshmael WoolooNo ratings yet

- Latest Technology of Mill DiaphragmsDocument17 pagesLatest Technology of Mill DiaphragmsISLAM I. Fekry100% (5)

- Experiment No-15Document6 pagesExperiment No-15hdgsefseaNo ratings yet

- Proposed Rule: Endangered and Threatened Species: Findings On Petitions, Etc.— California Spotted OwlDocument8 pagesProposed Rule: Endangered and Threatened Species: Findings On Petitions, Etc.— California Spotted OwlJustia.comNo ratings yet

- Food Test Countable Uncountablea An Some Anyfood VocabularyDocument3 pagesFood Test Countable Uncountablea An Some Anyfood Vocabularyapi-304432259100% (2)

- Cedrela Angustifolia and Juglans Australis: Two New Tropical Species Useful in DendrochronologyDocument12 pagesCedrela Angustifolia and Juglans Australis: Two New Tropical Species Useful in Dendrochronologyjose carlos quispe davilaNo ratings yet

- DescriptiveDocument13 pagesDescriptiveLuigi Venezuelo100% (3)

- Plant Project Lab ReportDocument8 pagesPlant Project Lab Reportapi-330050817No ratings yet

- Castor Oil A Vital Industrial Raw MaterialDocument6 pagesCastor Oil A Vital Industrial Raw MaterialVictor LopezNo ratings yet

- Principles of XeriscapingDocument3 pagesPrinciples of XeriscapingprashanthNo ratings yet

- FOX Solutions - Project Reference List PDFDocument16 pagesFOX Solutions - Project Reference List PDFOuseppachan AmbookenNo ratings yet

- Bangalore Market - Traders Profile: S.No Traders Name Address Commodity C0Ntact Number 1Document7 pagesBangalore Market - Traders Profile: S.No Traders Name Address Commodity C0Ntact Number 1Rajan BLNo ratings yet

- Supreme Court: Basilio Aromin For Appellant. Office of The Solicitor-General Paredes For AppelleeDocument4 pagesSupreme Court: Basilio Aromin For Appellant. Office of The Solicitor-General Paredes For AppelleeBrenPeñarandaNo ratings yet

- Public School EVS Classwork on Homes, Families and CommunitiesDocument3 pagesPublic School EVS Classwork on Homes, Families and Communitiessubratdash90No ratings yet

- Detection of Bearing Fault Using Vibration Analysis and Controlling The VibrationsDocument13 pagesDetection of Bearing Fault Using Vibration Analysis and Controlling The VibrationsEswin Paico de la CruzNo ratings yet

- Morphology of Flowering Plants - Shobhit NirwanDocument23 pagesMorphology of Flowering Plants - Shobhit NirwanVraj M Barot100% (1)

- The Trichogramma Manual PDFDocument44 pagesThe Trichogramma Manual PDFanon_378715000No ratings yet

- [Advances in Biochemical Engineering_Biotechnology 32] N. Kosaric, A. Wieczorek, G. P. Cosentino (Auth.) - Agricultural Feedstock and Waste Treatment and Engineering (1985, Springer-Verlag Berlin Heidelberg)Document261 pages[Advances in Biochemical Engineering_Biotechnology 32] N. Kosaric, A. Wieczorek, G. P. Cosentino (Auth.) - Agricultural Feedstock and Waste Treatment and Engineering (1985, Springer-Verlag Berlin Heidelberg)aynuddin87No ratings yet

- The Story of The MonkeyDocument1 pageThe Story of The MonkeypurseonNo ratings yet

- Taste of MangoDocument2 pagesTaste of Mangokaru320No ratings yet

- 1 Digit2Document2 pages1 Digit2Dheyos Edu CentreNo ratings yet

- Fecka & Cisowski 2002 TLC Tannin & FlavonoidDocument1 pageFecka & Cisowski 2002 TLC Tannin & FlavonoidNormaidah ImansyahNo ratings yet

- Aggresand 2Document9 pagesAggresand 2ekrem0867No ratings yet

- Uleiuri Esentiale - Afectiuni CREIERDocument2 pagesUleiuri Esentiale - Afectiuni CREIERGeorgiana VeleaNo ratings yet

- Monarch Butterfly-TestDocument2 pagesMonarch Butterfly-TestJoanna-champlainNo ratings yet

- Chetverikov 2019Document26 pagesChetverikov 2019RGNo ratings yet

- High-quality silage from Patanjali ForagesDocument26 pagesHigh-quality silage from Patanjali ForagesShravankumar GaddiNo ratings yet

- Basic Survival SkillsDocument6 pagesBasic Survival SkillsMihaela LupascuNo ratings yet

![[Advances in Biochemical Engineering_Biotechnology 32] N. Kosaric, A. Wieczorek, G. P. Cosentino (Auth.) - Agricultural Feedstock and Waste Treatment and Engineering (1985, Springer-Verlag Berlin Heidelberg)](https://imgv2-2-f.scribdassets.com/img/document/428720016/149x198/793a4476d2/1570180142?v=1)