Professional Documents

Culture Documents

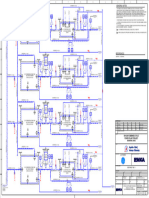

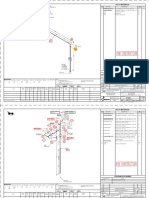

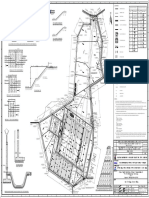

10ENA01BR003 Sheet3-Model

Uploaded by

Valesh MonisOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

10ENA01BR003 Sheet3-Model

Uploaded by

Valesh MonisCopyright:

Available Formats

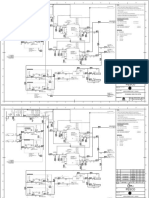

1 2 3 4 5 6 7 8

PART MATERIAL DESCRIPTION SIZE ITEM CODE QTY. SPEC

No

FABRICATION MATERIALS

N

1 Pipe, BE, ASME-B36.10M, 300 PAAZZBOZZABAABSAAZZUS 8.4 M D01

A106-B, Seamless, S-STD

2 Reducing branch tee, , Beveled 300X200 MDRZZBOZZAAEADCZZUS 2 D01

A end, ASME-B16.9, A234-WPB, A

S-STD

3 Threadolet for Thermowell 300X25 MEVAWBUZZABAABQZZUS 1 D01

mouting, Threaded Boss type 13

M33x2, A105, CL 3000

STEM UP

10ENA01AA003

4 Sockolet® Size on Size, 300X20 MEUAWBVZZAEYABQZZUS 2 D01

CL3000, Beveled end, 129

ASME-B36.10M, A105 129 11

5 Weld neck flange, CL300, 300 FAAAMABZZAADABQZZUS 3 D01

0

Raised-face flanged end,

502 20 F5 G9 B10

1

ASME-B16.5, A105, Undefined 8>

2 9 <

PIPE SUPPORTS 4

6 Design Pipe Assembly 300 DesignPipeH_5 1 D01 300X200DN 16

E 343925 129

ERECTION MATERIALS

229 4

7 Pipe, PE, ASME-B36.10M, 20 PAAZZBPZZABAABSAAZZUS 0.6 M 15 1

A106-B, Seamless, S-40 254 > F5 G9 B10

B <7 B

8 90 degree elbow, CL3000, 20 MCKAWBVZZAAGABQZZUS 2 D01 F5 G9 B10

Socket welded end, 146

ASME-B16.11, A105 S6

9 Spiral wound, one ring, CL300, 300 GMAMAQAABFMUS 3 D01

10ENA01BQ023

4.5mm, ASME-B16.20, 316-W, 254

graph-F, CS-CR

10 Stud Bolt, ASME-B18.2.1, ASTM 1.1/8 BAZZZZZZAAYBFZZZUS1 48 D01

A193-B7, hot dip galvanized,

With 2heavy Hex nuts A194

Gr.2H and 2 washers - 180 mm 95

2 14 7

Length SEE ISO

300X200DN 98 10ENA01BR002

11 Blind flange, CL300, Beveled 300 MAAAMBOZZAADABQZZUS 1 D01 E 342430 1

end, ASME-B16.5, A105 <6> E 343925

N 354382

INSTRUMENTS EL +1666

12 TEMPERATURE TRANSMITTER 25 1 D01

229

C TT10ENA01CT001

254

C

13 Gate valve, short pattern, 300 VABAMABZZAAFADAAKZZUS 1 D01

CL300, Raised-face flanged 254

end, ASME-B16.10, A216-WCB, SEE ISO 17

10ENA01BR001 PT10ENA01CP001

Gear operator E 342430

14 Ball valve, full port, CL600, 20 VAIAPBUZZAAFABQZZBFUS 1 D01 N 354382 4

35 13

Threaded end, ASME-B16.10, EL +1666 0

10

A105 1

4 >

15 Ball valve, full port, CL600, 20 VAIAPBUZZAAFABQZZBFUS 1 D01 <5 178 15 161

300X20DN STEM EAST

Threaded end, ASME-B16.10,

10ENA01AA703

A105

370

INSTRUMENTS

<4> 7

176

16 PRESSURE INDICATOR 20 1 D01 0 88

15 <3 20DN

PI10ENA01CP501 >

E 341926 E 342076 7

17 PRESSURE TRANSMITTER 20 1 D01 13

PT10ENA01CP001 20

D 178 28

6 D

161

4

370

12 0 195 300X20DN

15 20

176

TT10ENA01CT001 <1 8

> <2> 7

7 20DN 16

17 14 PI10ENA01CP501

0 178 88 STEM EAST

15 28 10ENA01AA704

E 341776 6

300DN

20

3 SEE SHT

300X25DN 10ENA01BR003 SHT 02

ORIENT E 341701

U N 354153

EL +1666 20 8

P5

E E

8 200 300 BEVEL BEVEL PAAZZBOZZABAABSAAZZUS

7 300 300 BEVEL BEVEL PAAZZBOZZABAABSAAZZUS

6 987 300 BEVEL BEVEL PAAZZBOZZABAABSAAZZUS OWNER

5 6855 300 BEVEL BEVEL PAAZZBOZZABAABSAAZZUS

4 176 20 SQ.CUT SCREWED PAAZZBPZZABAABSAAZZUS DISTRIBUTION W/C

3 88 20 SQ.CUT SQ.CUT PAAZZBPZZABAABSAAZZUS MATRIX

2 176 20 SQ.CUT SCREWED PAAZZBPZZABAABSAAZZUS

1 88 20 SQ.CUT SQ.CUT PAAZZBPZZABAABSAAZZUS NOTES:- EPC

PIECE

NO

LENGTH

MM

SIZE

MM

END PREP END PREP ITEM CODE

1. ALL DIMENSIONS AND ELEVATIONS ARE IN MILLIMETERS

2. FINISHED GROUND LEVEL (FGL) OF PLANT IS (-)0.300 WHICH

CORRESPONDS TO MSL (+)8.50M

PESCO

3. FOR PAINTING & SURFACE PREPARATION DETAILS REFER "TECHNICAL

SPECIFICATION FOR PAITING" DOC NO. TCE.11191A-SP-3903 MAIN PLANT EQUIPMENT SUPPLIER

4. FOR INSULATION DETAILS REFER "TECHNICAL SPECIFICATION FOR

INSULATION" DOC NO. TCE.11191A-SP-3902

5. ALL ELEVATIONS INDICATED ARE CENTER LINE OF PIPES UNLESS

OTHERWISE NOTED. PROJECT NAME

6. SMALL BORE PIPING (DN 50 & BELOW) ARE FIELD RUN. ISOMETRICS

ISSUED FOR THE SAME IS INDICATIVE AND MAY BE ADJUSTED TO SUIT ADEN POWER PLANT - PHASE 1

F SITE CONDITIONS. F

7. FOR SUPPORT ARRANGEMENT, REFER TYPICAL STANDARD SKETCH

DRAWING - TCE.11191A-D-4909 DRAWING TITLE ISOMETRICS FOR LIGHT CRUDE OIL SYSTEM

10ENA01BR003 03 of 03

P&ID NO. ENGINEERING JOB No. DRAWING NUMBER REV

PIPING LAYOUT DRAWING NO. No. DATE REVISION DESCRIPTION BY CHK APPR Civil Mech Elect I/C PIP HSE PROS

11191A TCE.11191A-D-4914 P5

FILE NAME 10ENA01BR003.SHA DATE : DESIGNED : DRAWN : CHEF ENGR : TATA CONSULTING ENGINEERS LIMITED

1 2 3 4 5 6 7 8

You might also like

- Pesco: Isometrics For Light Crude Oil System Aden Power Plant - Phase 1Document1 pagePesco: Isometrics For Light Crude Oil System Aden Power Plant - Phase 1Valesh MonisNo ratings yet

- Fabrication materials and pipe supports bill of materialsDocument1 pageFabrication materials and pipe supports bill of materialsValesh MonisNo ratings yet

- 0310212-TD-000042-01 Boiler Aux Steel Structure - Column Beam and Bracing (Is Standard)Document1 page0310212-TD-000042-01 Boiler Aux Steel Structure - Column Beam and Bracing (Is Standard)Rizwan AhmadNo ratings yet

- Pesco: Isometrics For Light Crude Oil System Aden Power Plant - Phase 1Document1 pagePesco: Isometrics For Light Crude Oil System Aden Power Plant - Phase 1Valesh MonisNo ratings yet

- Section C - C Section B - B: LNG Canada ProjectDocument2 pagesSection C - C Section B - B: LNG Canada ProjectHasmukhNo ratings yet

- Blister DetailsDocument14 pagesBlister Detailsmohd solihin bin mohd hasanNo ratings yet

- Typical Slab On Metal Deck Detail: Deck Parallel To Beam Deck Perpendicular To BeamDocument1 pageTypical Slab On Metal Deck Detail: Deck Parallel To Beam Deck Perpendicular To BeamAlbert GalagNo ratings yet

- SHOP MATERIALS BILL OF MATERIALSDocument1 pageSHOP MATERIALS BILL OF MATERIALSDeborah Jasmine Saldarriaga CrisantoNo ratings yet

- 11010P1-DG6206001 0 PDFDocument1 page11010P1-DG6206001 0 PDFNidhin T BNo ratings yet

- Fabrication materials and pipe supports bill of materialsDocument1 pageFabrication materials and pipe supports bill of materialsValesh MonisNo ratings yet

- Eep 000097 0102148005 3 ST Det 0669 R02Document1 pageEep 000097 0102148005 3 ST Det 0669 R02Vikram DalalNo ratings yet

- Low Pressure Low Pressure: Hydraulic Hoses OverviewDocument1 pageLow Pressure Low Pressure: Hydraulic Hoses OverviewNaseema SulaimanNo ratings yet

- Tal Wsa PNG Iso 1LS051901 - 01 - A01 - 00Document1 pageTal Wsa PNG Iso 1LS051901 - 01 - A01 - 00Deborah Jasmine Saldarriaga CrisantoNo ratings yet

- J3BGDF02BR005 01 01Document1 pageJ3BGDF02BR005 01 01saleem naheedNo ratings yet

- Tal Wsa PNG Iso 1CS106701 - 01 - A01 - 00Document1 pageTal Wsa PNG Iso 1CS106701 - 01 - A01 - 00landeopauloNo ratings yet

- General NotesDocument1 pageGeneral Notesmustafa1989ocNo ratings yet

- Conveyor 8F1 Head Chute and Liner DrawingsDocument10 pagesConveyor 8F1 Head Chute and Liner Drawingsjosseph fabianNo ratings yet

- J3BGDF02BR009 01 01Document1 pageJ3BGDF02BR009 01 01saleem naheedNo ratings yet

- J3BGDF02BR010 01 05Document1 pageJ3BGDF02BR010 01 05Naheed AkhtarNo ratings yet

- J3BGDF02BR009 01 05Document1 pageJ3BGDF02BR009 01 05Naheed AkhtarNo ratings yet

- J3BGDF02BR011 01 01Document1 pageJ3BGDF02BR011 01 01saleem naheedNo ratings yet

- Epcc05 MDR 421 STR DWG 000 0072 05Document1 pageEpcc05 MDR 421 STR DWG 000 0072 05RANJEET PRATAP SINGHNo ratings yet

- Concept 5 Ac19 Pt21Document1 pageConcept 5 Ac19 Pt21Nehemiah KoechNo ratings yet

- J3BGDF02BR025 01 06Document1 pageJ3BGDF02BR025 01 06Naheed AkhtarNo ratings yet

- 30lae25br004-Rev 2Document1 page30lae25br004-Rev 2Mohd Effiezool YaserNo ratings yet

- Tal Wsa PNG Iso 1CS106901 - 02 - A01 - 00Document1 pageTal Wsa PNG Iso 1CS106901 - 02 - A01 - 00landeopauloNo ratings yet

- Bill of Materials: See Iso 10-P-1202 SHT 02Document2 pagesBill of Materials: See Iso 10-P-1202 SHT 02Junaid AdnanNo ratings yet

- General notes for retaining wall constructionDocument7 pagesGeneral notes for retaining wall constructionascdfgNo ratings yet

- Piping Isometric - 10Document1 pagePiping Isometric - 10CosminMarianNo ratings yet

- Piping Isometric Building:: Pengerang Cogeneration PlantDocument1 pagePiping Isometric Building:: Pengerang Cogeneration PlantMohd Effiezool YaserNo ratings yet

- Eep 000097 0102148005 3 ST Det 0682 R02Document1 pageEep 000097 0102148005 3 ST Det 0682 R02Vikram DalalNo ratings yet

- ST32 (KSS021-D-1477) - Stringer-R0 PDFDocument1 pageST32 (KSS021-D-1477) - Stringer-R0 PDFmo3azNo ratings yet

- A01-W-12 (As Built-For Approval)Document1 pageA01-W-12 (As Built-For Approval)HasmukhNo ratings yet

- R0 - Col Fot - MR - Sameer - 17.10.2023Document1 pageR0 - Col Fot - MR - Sameer - 17.10.2023Shaikh ImranNo ratings yet

- J3BGDF02BR030 09 02Document1 pageJ3BGDF02BR030 09 02Nauman TahirNo ratings yet

- J3BGDF02BR012 01 01Document1 pageJ3BGDF02BR012 01 01saleem naheedNo ratings yet

- J3BGDF02BR025 01 01Document1 pageJ3BGDF02BR025 01 01saleem naheedNo ratings yet

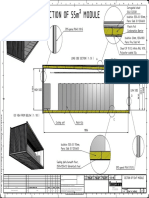

- Module Reference DrawingDocument1 pageModule Reference DrawingWilliam Fernando Moyano GonzalezNo ratings yet

- Scubber Seal Tank (6a25-T12) 12kl-MasterDocument2 pagesScubber Seal Tank (6a25-T12) 12kl-MasterJayan VKNo ratings yet

- Remove Support: Issued For ConstructionDocument1 pageRemove Support: Issued For Construction86tejasNo ratings yet

- Grid location coordinates for structural steel beamDocument1 pageGrid location coordinates for structural steel beamzaheerNo ratings yet

- Spreader Beam Drawings & MTODocument3 pagesSpreader Beam Drawings & MTOsales ntscompaniesNo ratings yet

- IQ360-000-M6-SG-00004 02Document1 pageIQ360-000-M6-SG-00004 02mustafa1989ocNo ratings yet

- Pesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Document1 pagePesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Valesh MonisNo ratings yet

- Doosan Schematic All ModelsDocument20 pagesDoosan Schematic All Modelsstanley100% (53)

- 206-Sheet - S 100 C - Excavation Layout-Layout1Document1 page206-Sheet - S 100 C - Excavation Layout-Layout1sameer khanNo ratings yet

- Lh25-E08-G02-003 R0 SLD Generator Main Transformer & Line ProtectionDocument1 pageLh25-E08-G02-003 R0 SLD Generator Main Transformer & Line ProtectionasygafNo ratings yet

- HLC - TLC - DR - 12 - S0088 - Balcony Lifting Frame - Typical BalconyDocument1 pageHLC - TLC - DR - 12 - S0088 - Balcony Lifting Frame - Typical BalconyPhú NguyễnNo ratings yet

- PipelineDocument9 pagesPipelineRhoteram VikkuNo ratings yet

- 9820 9100 45-01 GA37L-75VSD+ Pack, MetricDocument1 page9820 9100 45-01 GA37L-75VSD+ Pack, MetricZulex Prodaja1No ratings yet

- Bus ShelterDocument1 pageBus ShelterCHVN NH173No ratings yet

- B1.2 B2.1 B3 B2.2 B1.3 B1.1: Saddle Arrangement in Intermediate YardDocument1 pageB1.2 B2.1 B3 B2.2 B1.3 B1.1: Saddle Arrangement in Intermediate YarddeniNo ratings yet

- Site Leveling Layout Plan With Change Zone (28-09-2023) - Layout1Document1 pageSite Leveling Layout Plan With Change Zone (28-09-2023) - Layout1Mian M KhurramNo ratings yet

- 1C6 (KSS021-D-530) - Column-R1Document1 page1C6 (KSS021-D-530) - Column-R1mo3azNo ratings yet

- BB BB: Code and SpecificationsDocument1 pageBB BB: Code and SpecificationsandersonNo ratings yet

- SET P&ID - Filter Cellar - Tibasosa PDFDocument9 pagesSET P&ID - Filter Cellar - Tibasosa PDFJairo Hernando Rojas PulidoNo ratings yet

- MBPP-Pondok Bas-ModelDocument1 pageMBPP-Pondok Bas-ModelFendy RoynNo ratings yet

- Erection details and component weightsDocument1 pageErection details and component weightsmo3azNo ratings yet

- Contract / Purchase Order Number Description: CertifiedDocument1 pageContract / Purchase Order Number Description: CertifiedGabriel PulidoNo ratings yet

- Pesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Document1 pagePesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Valesh MonisNo ratings yet

- Pesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Document1 pagePesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Valesh MonisNo ratings yet

- Pesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Document1 pagePesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Valesh MonisNo ratings yet

- Pesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Document1 pagePesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Valesh MonisNo ratings yet

- Pesco: E 394705 N 265622 EL +917 Screwed End To Gt#11 AreaDocument1 pagePesco: E 394705 N 265622 EL +917 Screwed End To Gt#11 AreaValesh MonisNo ratings yet

- Pesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Document1 pagePesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Valesh MonisNo ratings yet

- Pesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Document1 pagePesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Valesh MonisNo ratings yet

- Pesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Document1 pagePesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Valesh MonisNo ratings yet

- Pipe Support Fabrication and Erection Materials ListDocument1 pagePipe Support Fabrication and Erection Materials ListValesh MonisNo ratings yet

- Petro Masila Company: Tata Consulting Engineers Limited - Phase 1Document1 pagePetro Masila Company: Tata Consulting Engineers Limited - Phase 1Valesh MonisNo ratings yet

- Pesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Document1 pagePesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Valesh MonisNo ratings yet

- Raw Water & Service Water Distribution System: Isometric Drawing ListDocument1 pageRaw Water & Service Water Distribution System: Isometric Drawing ListValesh MonisNo ratings yet

- 10ENA01BR004 Sheet5-ModelDocument1 page10ENA01BR004 Sheet5-ModelValesh MonisNo ratings yet

- Pesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Document1 pagePesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Valesh MonisNo ratings yet

- Pesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Document1 pagePesco: Isometrics For Raw Water and Service Water Distribution System Aden Power Plant - Phase 1Valesh MonisNo ratings yet

- 10ENA01BR003 Sheet1-ModelDocument1 page10ENA01BR003 Sheet1-ModelValesh MonisNo ratings yet

- Fabrication and Erection Materials Bill of MaterialsDocument1 pageFabrication and Erection Materials Bill of MaterialsValesh MonisNo ratings yet

- Pesco: Isometrics For Light Crude Oil System Aden Power Plant - Phase 1Document1 pagePesco: Isometrics For Light Crude Oil System Aden Power Plant - Phase 1Valesh MonisNo ratings yet

- 10ENA01BR003 Sheet2-ModelDocument1 page10ENA01BR003 Sheet2-ModelValesh MonisNo ratings yet

- Tce.11191a-D-4213 - Ldo P&id - R4 (Ur)Document2 pagesTce.11191a-D-4213 - Ldo P&id - R4 (Ur)Valesh MonisNo ratings yet

- Fabrication materials and pipe supports bill of materialsDocument1 pageFabrication materials and pipe supports bill of materialsValesh MonisNo ratings yet

- Pesco: Isometrics For Light Crude Oil System Aden Power Plant - Phase 1Document1 pagePesco: Isometrics For Light Crude Oil System Aden Power Plant - Phase 1Valesh MonisNo ratings yet

- TCE LDO Isometric Drawings for Aden Power Plant Phase 1Document1 pageTCE LDO Isometric Drawings for Aden Power Plant Phase 1Valesh MonisNo ratings yet

- Pesco: Isometrics For Light Crude Oil System Aden Power Plant - Phase 1Document1 pagePesco: Isometrics For Light Crude Oil System Aden Power Plant - Phase 1Valesh MonisNo ratings yet

- Pesco: Isometrics For Light Crude Oil System Aden Power Plant - Phase 1Document1 pagePesco: Isometrics For Light Crude Oil System Aden Power Plant - Phase 1Valesh MonisNo ratings yet

- Schematic U-LineDocument1 pageSchematic U-LineTenda Dos MarujosNo ratings yet

- Amguri Satra EstimateDocument3 pagesAmguri Satra EstimateDhritimanDasNo ratings yet

- Blast Furnace RunnersDocument39 pagesBlast Furnace Runnershengki100% (4)

- ASSIGNMENT-Construction Contracts and ContractingDocument27 pagesASSIGNMENT-Construction Contracts and Contractingvkvarun11No ratings yet

- Glossary of Terms and Definitions: Section 1: Sheet 1Document2 pagesGlossary of Terms and Definitions: Section 1: Sheet 1CAR6No ratings yet

- Hydraulic Bottle JackDocument36 pagesHydraulic Bottle JackGebeyaw DemekeNo ratings yet

- Improving The Rigidity of Sheet Metal by Embossing and PDFDocument10 pagesImproving The Rigidity of Sheet Metal by Embossing and PDFalexcus1539No ratings yet

- Unit 305 Understanding The Practices and Procedures For The Preparation and InstallationDocument43 pagesUnit 305 Understanding The Practices and Procedures For The Preparation and InstallationRob PettitNo ratings yet

- Medidor Digital B&W-4Document2 pagesMedidor Digital B&W-4Aaron Quispe PinedaNo ratings yet

- PC Beam Slab Pham2017Document17 pagesPC Beam Slab Pham2017Corona DrawingNo ratings yet

- Occupational Safety and Health Simplified For The Construction IndustryDocument198 pagesOccupational Safety and Health Simplified For The Construction Industryhugo fariaNo ratings yet

- Saudi Law Final VersionDocument13 pagesSaudi Law Final VersionMohamed EltaiebNo ratings yet

- Case Study Brent Civic CentreDocument3 pagesCase Study Brent Civic CentreAgnes Cheverloo Castillo100% (3)

- Ith Bolt Tensioning Cylinders BTC 2014 en WebDocument28 pagesIth Bolt Tensioning Cylinders BTC 2014 en WebMatiasNo ratings yet

- Design of RC Membrane ElementsDocument11 pagesDesign of RC Membrane ElementsRodain NajjarNo ratings yet

- CRS New Brochure 2018Document24 pagesCRS New Brochure 2018gugiNo ratings yet

- Concrete Pouring Permit FormDocument1 pageConcrete Pouring Permit FormGenevieve GayosoNo ratings yet

- Proposed Marudi Bridge Over Batang Baram, Miri Division, SarawakDocument8 pagesProposed Marudi Bridge Over Batang Baram, Miri Division, SarawakKelvin LauNo ratings yet

- Installation Check Sheet For Ahu FahuDocument2 pagesInstallation Check Sheet For Ahu FahuSamer AliNo ratings yet

- XLPE Insulated Low Voltage Cables PDFDocument40 pagesXLPE Insulated Low Voltage Cables PDFtwinvbooksNo ratings yet

- Water Cooler Day 4-3Document10 pagesWater Cooler Day 4-3Laka 98No ratings yet

- Cost EstimateDocument1 pageCost EstimateCire OmalinNo ratings yet

- BFC 31802 Chapter 1 PDFDocument38 pagesBFC 31802 Chapter 1 PDFqqwertyuioppNo ratings yet

- Viraj Catalouge-2Document21 pagesViraj Catalouge-2Vinod GuptaNo ratings yet

- Tara Pharmacology PDF Medicalstudyzone - Com - CompressedDocument572 pagesTara Pharmacology PDF Medicalstudyzone - Com - Compressedunbridled.instinct.218No ratings yet

- NGPDU For BS SelectDocument14 pagesNGPDU For BS SelectMario RamosNo ratings yet

- Specifications of Ductile Iron Pipes and Carbon Steel Pipes - en - 01Document3 pagesSpecifications of Ductile Iron Pipes and Carbon Steel Pipes - en - 01djrote4No ratings yet

- Self Compacting ConcreteDocument101 pagesSelf Compacting ConcreteMOHAMMED RAYYAN N100% (1)

- Astm D4024 00Document3 pagesAstm D4024 00Anghelo AlcaldeNo ratings yet

- Case Study Sc14 en v01 Steel University ChallengeDocument5 pagesCase Study Sc14 en v01 Steel University ChallengeJatin BangaliNo ratings yet