Professional Documents

Culture Documents

ECP-VST-P-CIN-FT-018 Engineering Proposal Centrifugal Pump For Fire Protection NFPA 20

Uploaded by

Fernando Vallesteros0 ratings0% found this document useful (0 votes)

62 views3 pagesOriginal Title

ECP-VST-P-CIN-FT-018 Engineering Proposal Centrifugal Pump for fire Protection NFPA 20 (1)

Copyright

© © All Rights Reserved

Available Formats

XLS, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as XLS, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

62 views3 pagesECP-VST-P-CIN-FT-018 Engineering Proposal Centrifugal Pump For Fire Protection NFPA 20

Uploaded by

Fernando VallesterosCopyright:

© All Rights Reserved

Available Formats

Download as XLS, PDF, TXT or read online from Scribd

You are on page 1of 3

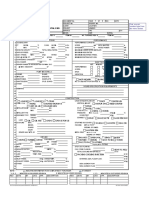

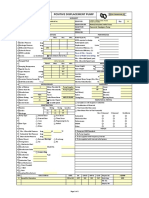

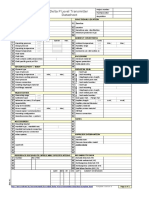

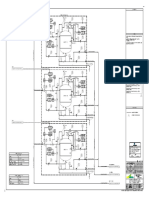

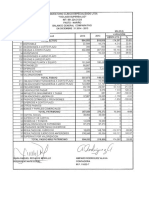

ENGINEERING PROPOSAL CENTRIFUGAL PUMP FOR FIRE PROTECTION NFPA 20

VICEPRESIDENCIA DE SERVICIOS Y TECNOLOGÍA

CORPORATIVO DE NORMAS Y ESTÁNDARES

CÓDIGO CNE Elaborado Versión:

ECP-VST-P-CIN-FT-018 17/02/2012 1

PROJECT:

CÓDIGO DEL DOCUMENTO: VENDOR:

TAG: DATE:

PARAMETER PROPOSAL PARAMETER PROPOSAL

1 PROCESS 52 COUPLING

2 N° OF UNITS 53 BASE PLATE - TYPE, MATERIAL

3 SERVICE 54 MAX. WORKING PRESSURE. PSIG

4 LIQUID 55 MAXIMUM TEMPERATURE, °F

5 PUMPING TEMP. °F 56 CASE HYDROTEST PRESS. PSIG

6 SPECIFIC GRAVITY AT P.T. 57 MAX SOUND PRES LEVEL REQ.

7 VISCOSITY AT P.T. CP 58 FLANGES

8 VAPOR PRESSURE AT P.T.,PSIA 59 SUCTION FLANGE:

9 SUCTION PRESSURE, PSIG 60 SIZE / RATING / FACING

10 DISCHARGE PRESSURE, PSIG 61 DISCHARGE FLANGE:

11 DIFFERENTIAL PRESSURE, PSI 62 SIZE / RATING / FACING

12 DIFFERENTIAL HEAD, FT 63 TESTS

13 NPSH AVAILABLE, FEET (WATER) 64 INSPECTION CLASS

14 NPSH REQUIRED, FEET (WATER) 65 HYDROSTATIC TEST

15 CAPACITY NORMAL, GPM 66 PERFORMANCE TEST

16 CAPACITY RATED, GPM 67 NPSH TEST

MINIMUM CONTINUOUS STABLE AND

17 68 COMPLETE UNIT TEST

THERMAL FLOW, GPM

PUMP EFFICIENCY IN RATED CAPACITY,

18 % (WITHOUT MECHNICAL OR DRIVER 69 AUXILIARY EQUIPMENT TEST

LOSS)

DISASSEMBLY AFTER TEST FOR

19 HORSEPOWER-RATED, BHP 70

INSPECTION

20 HORSEPOWER-MAX., BHP 71 CERTIFIED MATERIAL

VERIFICATION CASING FINAL

21 HYDRAULIC HORSEPOWER, HP 72

THICKNESS

FINAL INSPECTION BOOK - SHOP

22 PUMP SPEED, RPM 73

INSPECTION

ROTATI0N VIEWED FROM COUPLING

FINAL ASSEMBLY RUNNING

23 END 74

CLEARANCE

(CCW / CW)

BEST EFFICIENCY CAPACITY OF THE

24 75 MATERIALS

FURNISHED IMPELLER, GPM

LOCATION OF RATED CAPACITY, %

FLOW

25 76 CASE / COLUMN

(CAPACITY RATED / BEST EFFICIENCY

CAPACITY FURNISHED IMPELLER)

DISCHARGE HEAD / SUCTION CAN

26 PUMP SHUT OFF HEAD, FEET 77

(FOR VERTICAL PUMP)

HEAD RESERVE AVAILABLE, %

27 (PUMP SHUTOFFHEAD / DIFFERENTIAL 78 IMPELLER

HEAD)

NPSH REQUIRED AT BEP CAPACITY,

28 FEET 79 BOWLS, (FOR VERTICAL PUMP)

(WITH MAXIMUM IMPELLER)

BOWLS BEARING, (FOR VERTICAL

29 BEP CAPACITY (MAX. IMPELLER), GPM 80

PUMP)

30 BEP EFFICIENCY (MAX. IMPELLER), % 81 CASE / BOWL WEAR RINGS

BEP SUCTION SPECIFIC SPEED Nss

31 (ENGLISH UNITS) (WITH MAXIMUM 82 IMPELLER WEAR RINGS

IMPELLER)

32 OPERATION SUCTION SPECIFIC SPEED 83 SHAFT / LINE SHAFT

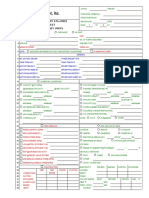

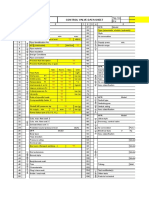

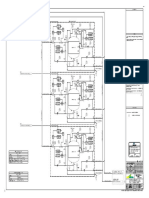

ENGINEERING PROPOSAL CENTRIFUGAL PUMP FOR FIRE PROTECTION NFPA 20

VICEPRESIDENCIA DE SERVICIOS Y TECNOLOGÍA

CORPORATIVO DE NORMAS Y ESTÁNDARES

CÓDIGO CNE Elaborado Versión:

ECP-VST-P-CIN-FT-018 17/02/2012 1

OPERATION IMPELLER SPECIFIC SPEED COLUMN SHAFT, (FOR VERTICAL

33 84

(Ns), (RATED FLOW) PUMP)

BOWL SHAFT, (FOR VERTICAL

34 PERFORMANCE CURVE NUMBER 85

PUMP)

LINE SHAFT BEARING, (FOR

35 CONSTRUCTION 86

VERTICAL PUMP)

36 REQUESTED STANDARD 87 SHAFT SLEEVE

37 MODEL 88 ELECTRICAL MOTOR

38 SIZE 89 IINCLUDED / QUANTITY

39 PUMP TYPE 90 POWER, BHP

40 CASING SPLIT (Axial / Radial) 91 NAMEPLATE POWER

41 CASING SUPPORT 92 DIESEL ENGINE DRIVE

42 NO OF STAGES 93 INCLUDED / QUANTITY

43 IMPELLER: TYPE (CLOSED / OPEN) 94 POWER, BHP

BASIC TYPE (OVERH, BETWEEN BEAR,

44 95 NAMEPLATE POWER

VERT.)

45 DIAMETER MAX., INCHES (DM) 96 STEAM TURBINE

46 DIAMETER DESIGN, INCHES (DD) 97 INCLUDED / QUANTITY

47 IMPELLER REDUCTION (%R=DD/DM) 98 POWER, BHP

48 RADIAL BEARINGS 99 NAMEPLATE POWER

49 THRUST BEARING 100 SHIPMENT

50 LUBRICATION 97 WEIGHT (LB / UNIT)

51 COOLING WATER 98 VOLUMEN (M3/UNIT)

NOTES: 99 SHIPMENT (EXPORT BOXING)

You might also like

- Mitsubishi 6D22 Engine Manual PRINTDocument336 pagesMitsubishi 6D22 Engine Manual PRINTUn'gallu0% (1)

- Workover OpertionsDocument365 pagesWorkover Opertionsjayant89% (9)

- IPB-OCS-KEA-MEC-DAT-0024 Rev0 Mechanical Data Sheet For Fire Water PumpDocument4 pagesIPB-OCS-KEA-MEC-DAT-0024 Rev0 Mechanical Data Sheet For Fire Water PumpsudjonoNo ratings yet

- API 673 3rd Ed Data SheetsDocument27 pagesAPI 673 3rd Ed Data Sheetsjuan ninaNo ratings yet

- Data Sheet Mks Units Centrifugal Pump Api-610: Operating Conditions Site and Utility Data (Cot D)Document3 pagesData Sheet Mks Units Centrifugal Pump Api-610: Operating Conditions Site and Utility Data (Cot D)André HeunisNo ratings yet

- Know and Understand Centrifugal PumpsFrom EverandKnow and Understand Centrifugal PumpsL. BachusRating: 4 out of 5 stars4/5 (1)

- Superior 2406GDocument79 pagesSuperior 2406GDavid Rene Martinez100% (1)

- Data Sheet For LBV ActuatorDocument1 pageData Sheet For LBV ActuatorSinaNo ratings yet

- (API 674-2nd) Reciprocating PumpDocument6 pages(API 674-2nd) Reciprocating PumpadistiNo ratings yet

- Centrifugal Pump - Horizontal End Suction - Asme B73.1Document3 pagesCentrifugal Pump - Horizontal End Suction - Asme B73.1wado11No ratings yet

- Line Information: Instrument Specification RotameterDocument3 pagesLine Information: Instrument Specification Rotametermilton1987No ratings yet

- Brown & Root, Inc.: Rotary Pump (Api 676-2Nd) Data Sheet Si UnitsDocument4 pagesBrown & Root, Inc.: Rotary Pump (Api 676-2Nd) Data Sheet Si UnitsLipika GayenNo ratings yet

- Data Sheet Multiphase Pump BornermanDocument5 pagesData Sheet Multiphase Pump BornermanUmar Ijaz KhanNo ratings yet

- Rotary Pump - Customary UnitsDocument2 pagesRotary Pump - Customary UnitsVicky ANo ratings yet

- Api 674 Pump Data SheetDocument5 pagesApi 674 Pump Data Sheetroronoa_zorro11No ratings yet

- Polna Inquiry WebDocument1 pagePolna Inquiry WebTifano KhristiyantoNo ratings yet

- Brown & Root, Inc.: Rotary Pump (Api 676-2Nd) Data Sheet U.S. Customary UnitsDocument4 pagesBrown & Root, Inc.: Rotary Pump (Api 676-2Nd) Data Sheet U.S. Customary UnitsLipika GayenNo ratings yet

- Controlled Volume Pump (Api 675-2Nd) Data Sheet U.S. Customary UnitsDocument3 pagesControlled Volume Pump (Api 675-2Nd) Data Sheet U.S. Customary UnitshamedNo ratings yet

- PVVDocument10 pagesPVVJorge Arturo Rodríguez HerreraNo ratings yet

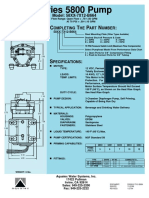

- Series 5800 Pump: C T P NDocument2 pagesSeries 5800 Pump: C T P NYESSYTAESNo ratings yet

- Feuilles Des Données de Nouveau Groupe de Pompage Moteur DieselDocument7 pagesFeuilles Des Données de Nouveau Groupe de Pompage Moteur DieselBilel MahjoubNo ratings yet

- DS FITUltrasonDocument1 pageDS FITUltrasonabelegpNo ratings yet

- Feuilles Des Données de Nouveau Groupe de Pompage Moteur ÉlectriqueDocument6 pagesFeuilles Des Données de Nouveau Groupe de Pompage Moteur ÉlectriqueBilel MahjoubNo ratings yet

- Api 674Document6 pagesApi 674meisamNo ratings yet

- 6800 Series 24vdc 0.9 LPMDocument2 pages6800 Series 24vdc 0.9 LPMipuc palma aldeaNo ratings yet

- Doc. Title Document No. Phase Area Unit Disc. Doc. Seq. Rev. Blow Down Valve Data SheetDocument4 pagesDoc. Title Document No. Phase Area Unit Disc. Doc. Seq. Rev. Blow Down Valve Data SheetHoomanrrNo ratings yet

- Reciprocating Pump (Api 674-2Nd) Data Sheet Si Units: GeneralDocument10 pagesReciprocating Pump (Api 674-2Nd) Data Sheet Si Units: GeneraltxagusNo ratings yet

- Pressure Regulator Back PressureDocument1 pagePressure Regulator Back Pressureswiper akoNo ratings yet

- 22-DS-R-001 Rev 1 API 617 GTCPsDocument25 pages22-DS-R-001 Rev 1 API 617 GTCPsChike Nwachukwu100% (1)

- Analizador de AzufreDocument10 pagesAnalizador de AzufreDesiree MolinaNo ratings yet

- Methanol Storage Facility Project: No. Dok.: - Revision No.Document1 pageMethanol Storage Facility Project: No. Dok.: - Revision No.Adhya RazanNo ratings yet

- 9572 TBA Progressive Cavity Pump - Rev.0Document4 pages9572 TBA Progressive Cavity Pump - Rev.0budy wening setyo wibowoNo ratings yet

- Aquatec 8800 High Flow Booster Pump Spec PDFDocument2 pagesAquatec 8800 High Flow Booster Pump Spec PDFMandiriNo ratings yet

- (GPM) (GPM) (PSIG) (ºF) (PSIG) (PSIA) (PSI) S. G. (FT) (PSIA) (CP) CP (BTU/Lb ºF)Document3 pages(GPM) (GPM) (PSIG) (ºF) (PSIG) (PSIA) (PSI) S. G. (FT) (PSIA) (CP) CP (BTU/Lb ºF)Said ArjonaNo ratings yet

- Operating Conditions Liquid: Client: ServiceDocument1 pageOperating Conditions Liquid: Client: ServiceAde IskandarNo ratings yet

- Ata 29 Hydro Emb 170Document103 pagesAta 29 Hydro Emb 170nejib benamorNo ratings yet

- Api 610 Datasheet PDF FreeDocument7 pagesApi 610 Datasheet PDF FreeRisyda PutriNo ratings yet

- Adobe Scan Mar 22, 2024Document25 pagesAdobe Scan Mar 22, 2024gautam balwantNo ratings yet

- ANEXO 3.1 - Hoja de Datos PSV-110A - Version 2 - Rta 6Document1 pageANEXO 3.1 - Hoja de Datos PSV-110A - Version 2 - Rta 6Annie De WildeNo ratings yet

- Lavalin Bomba SumergibleDocument3 pagesLavalin Bomba SumergibleEyffer Cabrera PalominoNo ratings yet

- Pump DatasheetsDocument10 pagesPump DatasheetsNavNo ratings yet

- Positive Displacement PumpDocument2 pagesPositive Displacement Pumpanon_884425478No ratings yet

- Mechanical Data Sheet Backwash Pump: Pt. Yusonda Mahayasa NusantaraDocument5 pagesMechanical Data Sheet Backwash Pump: Pt. Yusonda Mahayasa NusantaraAhmad RifaiNo ratings yet

- Delta P Level Transmitter Datasheet: TAG Number ServiceDocument1 pageDelta P Level Transmitter Datasheet: TAG Number ServiceLucas RossiniNo ratings yet

- SGPC-GIZ-HD-002 - Hoja de Datos Medidor Masico (Coriolis) - RevADocument1 pageSGPC-GIZ-HD-002 - Hoja de Datos Medidor Masico (Coriolis) - RevAاليخاندرو اغيليراNo ratings yet

- GeneralDocument6 pagesGeneralmilton1987No ratings yet

- Delta P Level Transmitter Template SmallDocument1 pageDelta P Level Transmitter Template SmallfernandopetitsterNo ratings yet

- Hoja de Datos de BombaDocument5 pagesHoja de Datos de Bombaluis zambranoNo ratings yet

- Control Valve Data Sheet: Tag. NoDocument4 pagesControl Valve Data Sheet: Tag. NoGiftObionochieNo ratings yet

- Pressure Switch Mechanical Template SmallDocument1 pagePressure Switch Mechanical Template Smallali AlinezhadNo ratings yet

- Pressure Switch Mechanical TemplateDocument1 pagePressure Switch Mechanical TemplateUTKARSH GADVENo ratings yet

- Veco Engineering Ltd. Equipment Data Sheet: Centrifugal FanDocument9 pagesVeco Engineering Ltd. Equipment Data Sheet: Centrifugal Fanwado11No ratings yet

- Coriolis Flowmeter Spec Form 20F2521Document1 pageCoriolis Flowmeter Spec Form 20F2521benditasea3352No ratings yet

- S770 Hyd Std-Op V-1676Document2 pagesS770 Hyd Std-Op V-1676Teknik MakinaNo ratings yet

- PI16008GTE-008-IN-HD-001-R1 (Hoja de Datos Disco y Reguladoras) )Document3 pagesPI16008GTE-008-IN-HD-001-R1 (Hoja de Datos Disco y Reguladoras) )Annie De WildeNo ratings yet

- Engineering Evaluation Centrifugal Pumps For Fire Protection Nfpa 20Document5 pagesEngineering Evaluation Centrifugal Pumps For Fire Protection Nfpa 20Fernando VallesterosNo ratings yet

- Pressure Gauge TemplateDocument1 pagePressure Gauge TemplateUTKARSH GADVENo ratings yet

- 150FV104-IFT-Data SheetDocument1 page150FV104-IFT-Data SheetgerardoNo ratings yet

- Pressure Transmitter Datasheet: TAG Number ServiceDocument1 pagePressure Transmitter Datasheet: TAG Number ServiceEyuNo ratings yet

- Centrifugal Pump Datasheet Api 610 11Th Edition: US CustomaryDocument1 pageCentrifugal Pump Datasheet Api 610 11Th Edition: US CustomaryAthiphap Srisupareerath100% (1)

- Engro Daharki - Pakistan Small Capacity Ammonia Pump-Preliminary Data Sheet 0Document6 pagesEngro Daharki - Pakistan Small Capacity Ammonia Pump-Preliminary Data Sheet 0Arslan NisarNo ratings yet

- Microturbines: Applications for Distributed Energy SystemsFrom EverandMicroturbines: Applications for Distributed Energy SystemsRating: 5 out of 5 stars5/5 (1)

- Engineering Evaluation Centrifugal Pumps For Fire Protection Nfpa 20Document5 pagesEngineering Evaluation Centrifugal Pumps For Fire Protection Nfpa 20Fernando VallesterosNo ratings yet

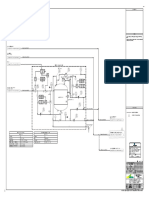

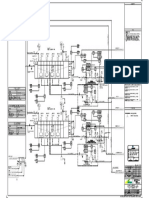

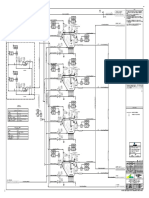

- SCC Ma0034027 14001 Id Pro Pid 001 - 10 2Document1 pageSCC Ma0034027 14001 Id Pro Pid 001 - 10 2Fernando VallesterosNo ratings yet

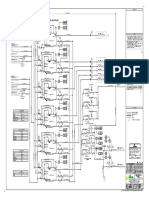

- SCC Ma0034027 14001 Id Pro Pid 001 - 9 2Document1 pageSCC Ma0034027 14001 Id Pro Pid 001 - 9 2Fernando VallesterosNo ratings yet

- SCC Ma0034027 14001 Id Pro Pid 001 - 11 2Document1 pageSCC Ma0034027 14001 Id Pro Pid 001 - 11 2Fernando VallesterosNo ratings yet

- SCC Ma0034027 14001 Id Pro Pid 001 - 8 2Document1 pageSCC Ma0034027 14001 Id Pro Pid 001 - 8 2Fernando VallesterosNo ratings yet

- SCC Ma0034027 14001 Id Pro Pid 001 - 7 2Document1 pageSCC Ma0034027 14001 Id Pro Pid 001 - 7 2Fernando VallesterosNo ratings yet

- SCC Ma0034027 14001 Id Pro Pid 001 - 6 2Document1 pageSCC Ma0034027 14001 Id Pro Pid 001 - 6 2Fernando VallesterosNo ratings yet

- SCC Ma0034027 14001 Id Pro Pid 001 - 3 2Document1 pageSCC Ma0034027 14001 Id Pro Pid 001 - 3 2Fernando VallesterosNo ratings yet

- SCC Ma0034027 14001 Id Pro Pid 001 - 5 2Document1 pageSCC Ma0034027 14001 Id Pro Pid 001 - 5 2Fernando VallesterosNo ratings yet

- SCC Ma0034027 14001 Id Pro Pid 001 - 4 2Document1 pageSCC Ma0034027 14001 Id Pro Pid 001 - 4 2Fernando VallesterosNo ratings yet

- SCC Ma0034027 14001 Id Pro Pid 001 - 1 2Document1 pageSCC Ma0034027 14001 Id Pro Pid 001 - 1 2Fernando VallesterosNo ratings yet

- SCC Ma0034027 14001 Id Pro Pid 001 - 2 2Document1 pageSCC Ma0034027 14001 Id Pro Pid 001 - 2 2Fernando VallesterosNo ratings yet

- Utap 2019-2Document2 pagesUtap 2019-2Fernando VallesterosNo ratings yet

- Balance 2015Document2 pagesBalance 2015Fernando VallesterosNo ratings yet

- Knock Sensors PDFDocument21 pagesKnock Sensors PDFFernando VallesterosNo ratings yet

- Sheet5-Centrifugal PumpDocument5 pagesSheet5-Centrifugal Pumpyousef mohamedNo ratings yet

- 05 Grupos Electrogenos Mtu Onsite Energy PDFDocument40 pages05 Grupos Electrogenos Mtu Onsite Energy PDFracsoNo ratings yet

- Babupvdme: Mechanical TechnicianDocument4 pagesBabupvdme: Mechanical Technicianjohn MNo ratings yet

- Final Report of Dry CoolerDocument43 pagesFinal Report of Dry CoolerHailemariam WeldegebralNo ratings yet

- SPE 77730 Experimental Study of Two-Phase Pumping in A Progressive Cavity Pump Metal To MetalDocument10 pagesSPE 77730 Experimental Study of Two-Phase Pumping in A Progressive Cavity Pump Metal To MetalRonald LlerenaNo ratings yet

- Care Maintenance and HPLC Column TroubleshootingDocument52 pagesCare Maintenance and HPLC Column TroubleshootingducngoctrinhNo ratings yet

- PumpsDocument9 pagesPumpsMohamed TallyNo ratings yet

- M9319 - R3 - Hydrocyclones For Cleaners & ConditionersDocument23 pagesM9319 - R3 - Hydrocyclones For Cleaners & ConditionersRicardo VillarNo ratings yet

- Alfa Laval Disc Stack Separator - Vo5Document2 pagesAlfa Laval Disc Stack Separator - Vo5SuhardiWinaryoNo ratings yet

- PfeifferTC110ElectronicDriveUnit PDFDocument29 pagesPfeifferTC110ElectronicDriveUnit PDFFinsensius PeniNo ratings yet

- PolyScience 6000 ManualDocument29 pagesPolyScience 6000 Manualhytham.midani.63No ratings yet

- Athena PR Mode EmploiDocument56 pagesAthena PR Mode EmploiHector MendozaNo ratings yet

- Tanda-II Specification - TechnicalDocument1,483 pagesTanda-II Specification - TechnicalMathivanan Anbazhagan100% (1)

- List Instrument All Project PLTGUDocument24 pagesList Instrument All Project PLTGUDwi Mulyanti DwimulyantishopNo ratings yet

- Verkstadshandbok Ford 2-3-4000Document137 pagesVerkstadshandbok Ford 2-3-4000WillowNo ratings yet

- Shipboard Oil Pollution Emergency Plan (SOPEP)Document2 pagesShipboard Oil Pollution Emergency Plan (SOPEP)ibnuharyNo ratings yet

- Repfllr Pflrts . . I: at BoschDocument4 pagesRepfllr Pflrts . . I: at BoschEng-Mohammed SalemNo ratings yet

- Catalog-All1-EN VALVE REXPOWERDocument97 pagesCatalog-All1-EN VALVE REXPOWERJhon RodriguezNo ratings yet

- Dimension EsDocument12 pagesDimension EsMarcelo Elicer Hernandez DazaNo ratings yet

- TSSA-DLB-2020-Feb-09-2021-Biogas ProjectDocument9 pagesTSSA-DLB-2020-Feb-09-2021-Biogas ProjectNazrul IslamNo ratings yet

- Feralco Liquid Aluminium Sulphate BrochureDocument5 pagesFeralco Liquid Aluminium Sulphate BrochurenoelhalloranNo ratings yet

- 2116W Parts Manual 514018 R0Document434 pages2116W Parts Manual 514018 R0lrodr_guez_1100% (1)

- DPC Serie Brochure enDocument2 pagesDPC Serie Brochure enabdu taliaNo ratings yet

- Report ONGCDocument47 pagesReport ONGCMehul SutariyaNo ratings yet

- Industrial Steam TurbineDocument28 pagesIndustrial Steam TurbineReza AndriantonYa Ndud100% (2)

- PDFDocument106 pagesPDFArdhi WibowoNo ratings yet

- Machine Operating Information Report: CustomerDocument14 pagesMachine Operating Information Report: Customer黄文兵No ratings yet

- Diapact CRRT INGLES 4 Manejo y UsoDocument26 pagesDiapact CRRT INGLES 4 Manejo y UsoJairo AlvaradoNo ratings yet