Professional Documents

Culture Documents

Aspen Exchanger Design and Rating Shell & Tube V11

Uploaded by

ElfrinaUliPoebaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Aspen Exchanger Design and Rating Shell & Tube V11

Uploaded by

ElfrinaUliPoebaCopyright:

Available Formats

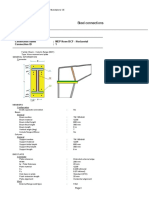

Aspen Exchanger Design and Rating Shell & Tube V11 Page 1

File: Printed: 5/18/2020 at 12:37:35 PM

Basic Geometry

Unit Configuration

Exchanger type BEM Tube number 235

Position Hor Tube length actual m 1.8

Arrangement 4 parallel 1 series Tube passes 4

Baffle type Single segmental Tube type Plain

Baffle number 2 Tube O.D. mm 19.05

Spacing (center-center) mm 345 Tube pitch mm 23.81

Spacing at inlet mm 686.98 Tube pattern 30

Shell Kettle Front head Rear Head

Outside diameter mm 558.8 558.8 558.8

Inside diameter mm 539.75 539.75 539.75

Shell Side Tube Side

Nozzle type Inlet Outlet Inlet Outlet

Number of nozzles 1 1 1 1

Actual outside diameter mm 406.4 406.4 88.9 60.32

Inside diameter mm 387.35 387.35 77.93 52.5

Height under nozzle mm 142.94 122.31

Dome inside diameter mm

Vapor belt inside diameter mm

Vapor belt inside width mm

Vapor belt slot area mm2

No No

Impingement protection

impingement impingement

Distance to tubesheet mm 1475 315

Aspen Exchanger Design and Rating Shell & Tube V11 Page 2

File: Printed: 5/18/2020 at 12:37:35 PM

Tubes

Tubes

Type Plain Total number of tubes 235

Outside diameter mm 19.05 Number of tubes plugged 0

Inside diameter mm 14.83 Tube length actual m 1.8

Wall thickness mm 2.11 Tube length effective m 1.7189

Area Ratio Ao/Ai 1.284247 Front tubesheet thickness mm 37.52

Pitch mm 23.81 Rear tubesheet thickness mm 37.52

Pattern 30 Material Carbon Steel

External enhancement Thermal conductivity W/(m-K) 50.4126

Internal enhancement

Low fins Longitudinal fins

Fin density #/m Fin number 0

Fin height mm Fin thickness mm

Fin thickness mm Fin height mm

Tube root diameter mm Fin spacing mm

Tube wall thickness under fin mm Cut and twist length mm

Tube inside diameter under fins mm

Other (high) fins

High Fin Type Default High Fin Thick mm

High Fin Tip Diameter mm High Fin Frequency #/m

Aspen Exchanger Design and Rating Shell & Tube V11 Page 3

File: Printed: 5/18/2020 at 12:37:35 PM

Baffles

Baffles

Type Single segmental Baffle cut: inner/outer/interm

Tubes in window Yes Actual (% diameter) / 23.76 /

Number 2 Nominal (% diameter) / 23.76 /

Spacing (center-center) mm 345 Actual (% area) / 18.23 /

Spacing at inlet mm 686.98 Cut orientation H

Spacing at outlet mm 686.97 Thickness mm 6.35

Spacing at center in/out for G,H,I,J mm Tube rows in baffle overlap 11

Spacing at center for H shell mm Tube rows in baffle window 0.5

End length of the front head mm 727.5 Baffle hole - tube od diam clearance mm 0.79

End length of the rear head mm 727.5 Shell id - tube od diam clearance mm 4.76

Variable Baffle Spacings

Supports-Misc. Baffles

Supports - tube Longitudinal Baffle

Supports in endspace at front head 0 Thickness mm

Supports in endspace at rear head 0 Window length at front end mm

Supports between baffles 0 Window length at center mm

Support blanking baffle No Window length at rear end mm

Supports at U-bend 0

Supports at each G,H,J shell inlet and I shell outlet 0

Supports at center of H shell 0

Supports for K,X shells 0

Special support at inlet nozzle No

Aspen Exchanger Design and Rating Shell & Tube V11 Page 4

File: Printed: 5/18/2020 at 12:37:35 PM

Bundle

Bundle

Shell ID to center 1st tube row mm Tube passes 4

From top 122.31 Tube pass layout Mixed (H)

From bottom 142.94 Tube pass orientation Standard (horizontal)

From right 16.67 U-bend orientation Undefined

From left 16.67 Horizontal pass lane width mm 15.88

Impingement protection None Vertical pass lane width mm 15.88

Impingement plate clearance to tube edge mm Interpass tube alignment No

Impingement plate diameter mm Deviation in tubes/pass 4.26

Impingement plate width mm Outer tube limit mm 527.05

Impingement plate length mm Shell id - bundle otl diam clearance mm 12.7

Impingement plate thickness mm Tie rod number 6

Gross surface area per shell m² 25.3 Tie rod diameter mm 9.55

Effective surface area per shell m² 24.2 Sealing strips (pairs) 3

Bare tube area per shell m² 24.2 Tube to Tubesheet joint Exp. 2 grv

Finned area per shell m² 0 Tube projection from front tsht mm 3

U-bend area per shell m² 0 Tube projection from rear tsht mm 3

Enhancements

Inserts & Internal enhancements

Tube insert type None

Twist tape 360 deg twist pitch mm

Twisted tape thickness mm

hiTRAN part number

Aspen Exchanger Design and Rating Shell & Tube V11 Page 5

File: Printed: 5/18/2020 at 12:37:35 PM

Setting Plan

Views on arrow A

A 2751 Overall

1718

T1

308 167 315 1160

429

T1 S2

429

T2

S2

429

429

466

S1

T2 S1

167 649 492

Pulling Length 1350

75 75

484

484

121

121

150 150

2 Bolts 2 Bolts

Fixed Sliding

Nozzle Data Design Data Units Shell Channel Notes: Company:

Ref OD Wall Standard Notes Design Pressure bar 3 3 Location:

S1 406 mm 9.5 mm Slip on Design Temperature °C 105 135 Service of Unit: Our Reference:

S2 406 mm 9.5 mm Slip on Full Vacuum Item No.: Your Reference:

T1 89 mm 5.5 mm Slip on Corrosion Allowance mm 3.175 3.175 Date: Rev No.: Job No.:

T2 60 mm 3.9 mm Slip on Test Pressure bar

Number of Passes 1 4

Radiography Company Name

PWHT City, State

Internal Volume m³ 0.3306 0.2667 Scale:

Rev: Date: Description Dwg. Chk. Appd. ASME Section VIII Div. 1

Setting Plan

Weight Summary TEMA Type: BEM

Empty Flooded Bundle Size: 540 - 1800 Dwg No.: Rev:

1117 kg 1580 kg 543 kg TEMA Class: R 1

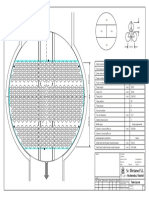

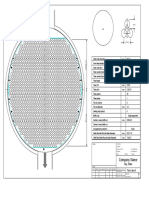

Aspen Exchanger Design and Rating Shell & Tube V11 Page 6

File: Printed: 5/18/2020 at 12:37:36 PM

Tubesheet Layout

55

19.05

60 60

60

23.8125

Shell inside diameter mm 539.75

Front head inside diameter mm 539.75

Outer tube limit mm 527.05

138.04 mm

Tube number (calcs.) 235

Tube number (layout) 235

Tube length mm 1799.999

Tube O.D. mm 19.05

Tube pitch mm 23.8125

Tube pattern 30

Tube passes 4

117.41 mm

Tie rod number 6

Tie rod diameter mm 9.55

Sealing strips (pairs) 3

Baffle type Single segmental

Centre to outer baffle cut mm 141.6156

Centre to inner baffle cut

Impingement protection None

Shell Side Inlet Nozzle Inside Diameter mm 387.35

Shell Side Outlet Nozzle Inside Diameter mm 387.35

Notes: Company:

Location:

Service of Unit: Our Reference:

Item No.: Your Reference:

Date: Rev No.: Job No.:

Company Name

City, State

Scale:

Rev: Date: Description Dwg. Chk. Appd. ASME Code Sec VIII Div 1

TEMA Type: BEM Tube Layout

Size: 540 - 1800 Dwg No.: Rev:

TEMA Class: R - refinery service 2

Costs/Weights

Weights kg Cost data Dollar(US)

Shell 395.2 Labor cost 74834

Front head 81.9 Tube material cost 4068

Rear head 96.6 Material cost (except tubes) 12967

Shell cover

Bundle 543

Total weight - empty 1116.7 Total cost (1 shell) 22967

Total weight - filled with water 1580.2 Total cost (all shells) 91868

You might also like

- Aspen Exchanger Design and Rating Shell & Tube V11Document6 pagesAspen Exchanger Design and Rating Shell & Tube V11ElfrinaUliPoebaNo ratings yet

- Heat Exchanger Design SheetDocument5 pagesHeat Exchanger Design SheetfaroukNo ratings yet

- Plastic Injection Mold Design for Toolmakers - Volume II: Plastic Injection Mold Design for Toolmakers, #2From EverandPlastic Injection Mold Design for Toolmakers - Volume II: Plastic Injection Mold Design for Toolmakers, #2No ratings yet

- 130-CJ Current UpdateDocument15 pages130-CJ Current UpdateFaizan AhmedNo ratings yet

- SNL 508-607 - 20221026Document5 pagesSNL 508-607 - 20221026unaihot3291No ratings yet

- SKF SNL 532 SpecificationDocument5 pagesSKF SNL 532 Specificationshalini15_85No ratings yet

- Fytb 30 WF - 20221021Document6 pagesFytb 30 WF - 20221021FendyNo ratings yet

- SKF SNL 3136 G SpecificationDocument6 pagesSKF SNL 3136 G SpecificationMohamed HardmanNo ratings yet

- SNL 205 - 20220719Document5 pagesSNL 205 - 20220719WapdanNo ratings yet

- E 101EsquemaDentroDocument1 pageE 101EsquemaDentroJ. GonzálezNo ratings yet

- Requirements For Shell and Tube Heat Exchangers - TEMA StandardsDocument1 pageRequirements For Shell and Tube Heat Exchangers - TEMA StandardsLuis Fernando Castrillón MadrigalNo ratings yet

- Tubesheet LayoutDocument1 pageTubesheet LayoutTIPAZONo ratings yet

- SKF SNL 516-613 SpecificationDocument5 pagesSKF SNL 516-613 SpecificationMohamed AliNo ratings yet

- SKF SNL 3134 SpecificationDocument5 pagesSKF SNL 3134 SpecificationwiwinsaputramanikNo ratings yet

- RAM Connection Standalone CE ReportDocument4 pagesRAM Connection Standalone CE ReportThanh ViệtNo ratings yet

- Heat Exchanger Thermal Design Shell&Tube V7.3.1 CP1Page 1: Basic GeometryDocument8 pagesHeat Exchanger Thermal Design Shell&Tube V7.3.1 CP1Page 1: Basic GeometryaminNo ratings yet

- Detailed Design of Free Pot BearingDocument7 pagesDetailed Design of Free Pot BearingDevesh SinghNo ratings yet

- Company Name: City, StateDocument1 pageCompany Name: City, Stateanggun 119280087No ratings yet

- Detailed DataDocument11 pagesDetailed DataDaniswara Krisna PrabathaNo ratings yet

- F2B 40M-WF: Flanged Ball Bearing Unit With Composite or Cast Metal HousingDocument6 pagesF2B 40M-WF: Flanged Ball Bearing Unit With Composite or Cast Metal HousingSakiNo ratings yet

- Asme Sec 8 Div 1 - App 1-10Document11 pagesAsme Sec 8 Div 1 - App 1-10BibinBabuNo ratings yet

- Bearing FYTB 25 LF - 20221015 PDFDocument6 pagesBearing FYTB 25 LF - 20221015 PDFRamy ChaayaNo ratings yet

- Tube Lay Out Gas ExchangerDocument1 pageTube Lay Out Gas ExchangerHudaFiHayyatNo ratings yet

- Vessel Weight Calculation'sDocument6 pagesVessel Weight Calculation'sDesign SadhanaNo ratings yet

- TEE Data SheetDocument12 pagesTEE Data SheetKing1971No ratings yet

- Page 1 of 6Document6 pagesPage 1 of 6Devesh SinghNo ratings yet

- Fine-Fin: High Performance Tubes For Heat ExchangersDocument12 pagesFine-Fin: High Performance Tubes For Heat ExchangersPankaj RaneNo ratings yet

- Sy 55 LF: Pillow Block Ball Bearing UnitsDocument5 pagesSy 55 LF: Pillow Block Ball Bearing UnitsDuy KhánhNo ratings yet

- F2B 102-TF: Oval Flanged Ball Bearing Unit With Set Screw Locking, Cast Iron, North American StandardsDocument6 pagesF2B 102-TF: Oval Flanged Ball Bearing Unit With Set Screw Locking, Cast Iron, North American StandardsMor Talla ThiamNo ratings yet

- ManufacturerDocument6 pagesManufacturerVipul ChourasiyaNo ratings yet

- SKF SY 508 M SpecificationDocument4 pagesSKF SY 508 M Specificationrinaldo KurniawanNo ratings yet

- Horton Sphere Flange & Nozzle Reinforcement CalculationDocument11 pagesHorton Sphere Flange & Nozzle Reinforcement CalculationparveshNo ratings yet

- Technical Specifications: PlateDocument2 pagesTechnical Specifications: PlateIgnacio LopezNo ratings yet

- TRAUMA Product CatalogueDocument162 pagesTRAUMA Product Cataloguealexander sumaykuNo ratings yet

- Square Flanged Ball Bearing Units: The Values Depend On The Included BearingDocument5 pagesSquare Flanged Ball Bearing Units: The Values Depend On The Included BearingFarhan Ali RabbaniNo ratings yet

- Banjo Bolt Heat Sink BremboDocument4 pagesBanjo Bolt Heat Sink BremboD4designNo ratings yet

- CSC - 115 - R - II DHBVN LT XlpeDocument15 pagesCSC - 115 - R - II DHBVN LT XlpeAshish bhattNo ratings yet

- Blind Flange DesignDocument1 pageBlind Flange DesignSachin5586No ratings yet

- Rotabest TCT Cutter Depth 50 MMDocument1 pageRotabest TCT Cutter Depth 50 MMMoh Widodo Nur CNo ratings yet

- UCFL 216: Flanged Ball Bearing Unit With Composite or Cast Metal HousingDocument5 pagesUCFL 216: Flanged Ball Bearing Unit With Composite or Cast Metal HousingBaris YeltekinNo ratings yet

- Weld Work Volume CalculationDocument2 pagesWeld Work Volume CalculationVlanic StudioNo ratings yet

- E-100 Tubesheet LayoutDocument1 pageE-100 Tubesheet Layoutuse for school google drive storageNo ratings yet

- Fictitious Calculation Method For Determination of Dimensions of Protective Layer of HT CableDocument8 pagesFictitious Calculation Method For Determination of Dimensions of Protective Layer of HT CableChocki100% (1)

- Assgn 2 Has+muto+fdel+anto+irvi+raysDocument134 pagesAssgn 2 Has+muto+fdel+anto+irvi+raysFadel PutraNo ratings yet

- Pillow Block Ball BearingDocument5 pagesPillow Block Ball Bearingmynor8josh8juarezNo ratings yet

- Pillow UcfDocument5 pagesPillow UcfFarid Impact TubesNo ratings yet

- UCFL 204 Oval Flanged Ball Bearing Units - 20210825Document5 pagesUCFL 204 Oval Flanged Ball Bearing Units - 20210825Pistoleiro PapacoNo ratings yet

- Niigata Seiki Welding Gauge: Welding Gauge, WG-1 M-Type (Order No. 1101170001) Accuracy of Welding GaugeDocument2 pagesNiigata Seiki Welding Gauge: Welding Gauge, WG-1 M-Type (Order No. 1101170001) Accuracy of Welding GaugecaiohoffmanNo ratings yet

- Crowen Site B+G+9 SN Material StandardDocument7 pagesCrowen Site B+G+9 SN Material StandardbirukNo ratings yet

- Fynt 70 L - 20221026Document6 pagesFynt 70 L - 20221026muhammad mujahidNo ratings yet

- Final PresentationDocument49 pagesFinal PresentationDhruv ShedshyalNo ratings yet

- P2B 212-TF: Pillow Block Ball Bearing UnitsDocument5 pagesP2B 212-TF: Pillow Block Ball Bearing UnitsMatii Galdámez VerdejoNo ratings yet

- 125 128Document4 pages125 128Majdi JerbiNo ratings yet

- Threading Formulas and DefinitionsDocument17 pagesThreading Formulas and Definitionsx9kqm6pz24No ratings yet

- SKF FYJ 509 SpecificationDocument4 pagesSKF FYJ 509 SpecificationgulieionutNo ratings yet

- Automotive - Presentation - Plastics-3rd June-2015 (Compatibility Mode) (Repaired)Document108 pagesAutomotive - Presentation - Plastics-3rd June-2015 (Compatibility Mode) (Repaired)Annavarapu Gopalakrishna100% (1)

- Specs PLS C-TDocument12 pagesSpecs PLS C-TMichael MallariNo ratings yet

- PanduitProductDetails LCCX4 - 0 38D XDocument2 pagesPanduitProductDetails LCCX4 - 0 38D XabaileyNo ratings yet

- Module No 3: Liquefied Natural Gas Markets, Consumption, Measurement & CalculationDocument30 pagesModule No 3: Liquefied Natural Gas Markets, Consumption, Measurement & CalculationAndreiNo ratings yet

- EPT12 EZ Error CodesDocument5 pagesEPT12 EZ Error CodesKiều Văn TrungNo ratings yet

- Washing Machine: Service ManualDocument41 pagesWashing Machine: Service Manualimagex5No ratings yet

- E510 Startup Installation ManualDocument147 pagesE510 Startup Installation Manualpermitha sariNo ratings yet

- Working and Maintenance of Crushing EquipmentDocument53 pagesWorking and Maintenance of Crushing EquipmentKeshav ChhawchhariaNo ratings yet

- Smart Energy Coordination of Autonomous ResidentiaDocument13 pagesSmart Energy Coordination of Autonomous ResidentiaAhmed SabriNo ratings yet

- Diagnostic Study For Cement Mill OptimizationDocument9 pagesDiagnostic Study For Cement Mill OptimizationHilmy MuhammadNo ratings yet

- 1,917 New Applications in New Spark Plug & Glow Plug CatalogueDocument6 pages1,917 New Applications in New Spark Plug & Glow Plug Catalogue08088338No ratings yet

- Gardner Denver: Operating and Service ManualDocument41 pagesGardner Denver: Operating and Service ManualCESAR MORANo ratings yet

- Date Tehnice 436 ZXDocument6 pagesDate Tehnice 436 ZXMB ViorelNo ratings yet

- Blacksmithing 101 - How To Make A Forge and Start Hammering Metal - Popular MechanicsDocument6 pagesBlacksmithing 101 - How To Make A Forge and Start Hammering Metal - Popular MechanicsByram JNo ratings yet

- Suzuki GSXS 1000 Manual Servicio Tecnico PDFDocument86 pagesSuzuki GSXS 1000 Manual Servicio Tecnico PDFRoberto Nicolás Mera Velásquez75% (8)

- NEF67 TM3 DS P4A04N018E Mar06Document2 pagesNEF67 TM3 DS P4A04N018E Mar06altieresmirandaNo ratings yet

- Pcm120 Brochure PDFDocument2 pagesPcm120 Brochure PDFshyroro2010No ratings yet

- Manual Qrod PDFDocument17 pagesManual Qrod PDFEzequiel GuerreroNo ratings yet

- Boardworks - Magnetic FieldsDocument43 pagesBoardworks - Magnetic Fieldsdiane hoyles100% (6)

- Ii 2G Ex D Iic T6 GB Cesi 03 Atex 323 X: Sonde A Transmetteur 4÷20ma Pour Gaz InflammablesDocument10 pagesIi 2G Ex D Iic T6 GB Cesi 03 Atex 323 X: Sonde A Transmetteur 4÷20ma Pour Gaz Inflammablesdewidewi76No ratings yet

- Como Sobreviver A Um Apocalipse ZumbiDocument30 pagesComo Sobreviver A Um Apocalipse ZumbirejaneNo ratings yet

- Quantum Mechanics For Scientists and Engineers: David MillerDocument40 pagesQuantum Mechanics For Scientists and Engineers: David MillerBobbette BobbertNo ratings yet

- % Manpower Planned VS UtilizedDocument1 page% Manpower Planned VS UtilizedRavi ShankarNo ratings yet

- Eaton Busure (En)Document16 pagesEaton Busure (En)Danish NasimNo ratings yet

- Topic 1 Stoichiometric RelationshipsDocument56 pagesTopic 1 Stoichiometric Relationshipsapi-546066323No ratings yet

- Environmental and Social Impacts of Solar Energy: A View Point With Reference To India Abhishek Gawande & Pradeep ChaudhryDocument11 pagesEnvironmental and Social Impacts of Solar Energy: A View Point With Reference To India Abhishek Gawande & Pradeep ChaudhrySafikul HossainNo ratings yet

- MRV 5 T3 Service Manual 202203Document253 pagesMRV 5 T3 Service Manual 202203asadadNo ratings yet

- API Standards ListDocument9 pagesAPI Standards ListSohail Aziz Ahmad MalikNo ratings yet

- Essentials of Economics, 10th Edition (2016)Document468 pagesEssentials of Economics, 10th Edition (2016)Luis EstradaNo ratings yet

- Electrolysis Plant Size Optimization and Benefit Analysis of A Far Offshore Wind-Hydrogen System Based On Information Gap Decision Theory and Chance Constraints ProgrammingDocument13 pagesElectrolysis Plant Size Optimization and Benefit Analysis of A Far Offshore Wind-Hydrogen System Based On Information Gap Decision Theory and Chance Constraints ProgrammingHumberto van OolNo ratings yet

- Carbon Adsorption VaporDocument12 pagesCarbon Adsorption VaporMehdi Hajd KacemNo ratings yet

- Fire Issue: BNBC 2006 and BNBC 2017 (Upcoming) PDFDocument3 pagesFire Issue: BNBC 2006 and BNBC 2017 (Upcoming) PDFSayemAbusadat100% (1)

- A GCE Physics B 2865 01 January 2006 Question PaperDocument24 pagesA GCE Physics B 2865 01 January 2006 Question PaperMitul KaziNo ratings yet