Professional Documents

Culture Documents

Manufacturing and Performance

Uploaded by

ALEXA FRYOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Manufacturing and Performance

Uploaded by

ALEXA FRYCopyright:

Available Formats

Manufacturing and Performance Evaluation of Polyurethane Composites Using One-part and Two-part Resin Systems

Manufacturing and Performance Evaluation of Polyurethane

Composites Using One-part and Two-part Resin Systems

M. Mohamed, S. Hawkins and K. Chandrashekhara*

Department of Mechanical and Aerospace Engineering, Missouri University of Science and Technology, Rolla, MO

65409, USA

Received: 16 September 2014, Accepted: 22 September 2014

SUMMARY

Polyurethane (PU)-based composites show superior performance compared to polyester and vinylester composites.

The demand for PU composites is increasing in high technology as well as conventional applications such as

infrastructure and automobile. In this study, glass fiber reinforced composite laminates using one-part and two-part

PU resin are manufactured using vacuum-assisted resin transfer molding (VARTM) process. A new generation

two-part thermoset PU resin system is investigated and compared with commercial one-part PU resin systems.

The mechanical performance of glass fiber reinforced composites manufactured using two different PU resin

systems is evaluated. Tensile and flexure tests are conducted on both neat resin and glass/PU composites. Low-

velocity impact tests are performed on both types of glass fiber reinforced PU composite specimens. Mechanical

properties including strength and modulus were measured and analyzed for the two resin systems. Differential

scanning calorimetry (DSC) is used to study the cure behavior of both resin systems. A Brookfield LVDV-II

programmable rotational type viscometer is employed to study the viscosity profiles of the resin systems. The

influence of resin properties on the overall performance of glass fiber reinforced composites is discussed.

Keywords: Polyurethane, VARTM, Composite, Viscosity, Low velocity impact

1. Introduction Polyurethane (PU) is a better and • Lower resin viscosity compared

promising alternative to polyester and to epoxy resins and facilitate easy

Composite materials are advantageous vinylester as it offers the potential in fabrication of composite part.

over metals in various engineering terms of fast cycle times and high

applications due to their high specific • Longer pot-life compared to

toughness. There is no styrene emission

stiffness, high specific strength, commercial urethane-based resins.

during PU VARTM processes and the

enhanced dimensional stability, energy final product has superior durability5. • A reduction in cycle time through

absorption and corrosive resistance For two-part resins, the urethane a snap-cure mechanism.

as well as reduced cost for typical system begins to react after mixing and

applications1-2. However, a thorough • Higher mechanical performance

the viscosity increases, constraining the

understanding of the material behavior compared to commercial urethane

infusion of the resin into large parts.

of these composites is necessary resins, fracture toughness in

Novel catalysis chemistry is used to

to achieve optimum performance3. particular.

overcome the viscosity and pot-life

Analyzing the neat resin properties limitations of PU resins. This dual • Good thermal stability, excellent

in addition to the composite behavior catalyst system extends the pot-life fire performance without added

is necessary to assess the overall of mixed resins at room temperature flame retardants, lower smoke

performance of the composite. with a tunable induction period and a density and less toxicity according

Mechanical properties of neat resins snap-cure profile at high temperatures6. to NF P52-901 standard7-11.

are important to study because this can This chemistry offers the following

contribute to the initial damage in the Recent advancements in PU chemistry

advantages:

composite material which is primarily for vacuum assisted resin transfer

due to matrix cracking4. molding (VARTM) and Resin Transfer

Molding (RTM) processes have leaded

to a dramatic increase in commercial

*Author for correspondence: chandra@mst.edu, Phone: 573-341-4587 interest for producing a wide range of

composite products, including those

©

Smithers Information Ltd., 2015 utilized in wind energy production.

Polymers & Polymer Composites, Vol. 23, No. 5, 2015 333

M. Mohamed, S. Hawkins and K. Chandrashekhara

VARTM process is one of the most upon the performance of a new PU unidirectional type composites.

widely used composite manufacturing resin system versus traditional epoxy The woven fiber structure provides

processes developed in recent years and vinylester resins used for wind obstruction to matrix splitting and

for several engineering applications. blades and investigated the effects of delamination growth13. In this work,

VARTM process has advantages carbon nanotubes on the performance woven E-glass fibers which are

over conventional Resin Transfer of PU. These urethane systems compatible with PU resins are used

Mold (RTM) by eliminating the showed improved fatigue and fracture obtained from Owens Corning Inc. OH.

costs associated with matched-metal toughness properties as well as faster

mold making and volatiles emission. de-mold times than other resins. Two types of PU resin systems

In VARTM process, the polymer compatible with VARTM are obtained

resin is infused through the fiber In this study, glass fiber reinforced PU from Bayer Material Science, PA. The

reinforcements under atmospheric composite laminates are fabricated two PU resin systems investigated in

pressure. using VARTM process. Two types this study are a two-part RTM NB#

of PU resin systems, PU 90IK01 840871 resin system and a one-part

Not many researchers have and new generation PU 840871, PU 901K01 resin system. These resin

investigated the behavior of PU are used for manufacturing the systems possess better manufacturing

composites manufactured with composite laminates. Thermal studies feasibility. Table 1 shows the typical

VARTM process. Michael et al.11 of both resins were conducted using impact properties of PU resin system

investigated the physical and differential scanning calorimetry when compared to conventional resin

mechanical properties of pultruded (DSC) and viscosity measurement. systems, such as polyester and vinyl

PU composites, and compared them Tensile and flexure tests are conducted ester. The two-part PU with a trade

to unsaturated polyesters (UPE), on both the neat resin and glass fiber name of RTM NB# 840871 comes in

vinylester (VE) and hybrid unsaturated reinforced PU composite laminates. two separate parts which will react

polyester-urethane (UPE-PU) resin Low velocity impact tests are once combined. The “A” component

profiles with identical reinforcements. performed on both types of glass fiber is an Isocyanate NB#840859 ISO,

The authors observed PU pultruded reinforced PU composite laminates. Diphenylmethane diisocyanate (MDI-

composites to exhibit superior In the previous study by the same Aromatic) and the “B” component is a

strength and toughness compared to author, Mohamed5 has investigated Polyol RTM NB#840871.The mix ratio

VE, UPE and hybrid UPE-PU based the impact characterization of PU by weight for the A and B components

composites. Husic et al.9 studied and one-part composites manufactured is 92:100. These two components

compared the mechanical properties with VARTM process experimentally are referred to as a PU 840871 resin

of untreated E-glass fiber reinforced and numerically using finite element system in the rest of the paper. One-

composites prepared with soybean oil- analysis. The results showed that component Blendur PU 901K01 is

based PU to the petrochemical polyol PU composites manufactured using a modified polyisocyanurate casting

based ones. The results showed that thermoset PU resins and VARTM resin based on Diphenylmethane

soy-based PU offers better mechanical process have good mechanical Diisocyanate (MDI). The casting resin

properties. properties such as tensile strength, reacts on heating without the addition

flexural strength, tensile modulus and of a catalyst to from a crosslinked

Usama10 investigated the chemistry flexural modulus. thermoset with excellent thermal

and properties of the PU material, stability. The major challenge is

with emphasis on structure/property 2. Materials and moisture sensitivity while using PU

relationship and the development of resin system for vacuum infusion

Manufacturing

high surface quality (Class A) VARTM processes. The isocyanate portion of

composites. The author has also Woven fiber based composites the reacting components tends to react

discussed the advantages of PU resins offer improved performance over with water to produce carbon dioxide,

including room temperature cure, no

volatile organic compounds (VOCs) Table 1. Impact properties of polyurethane and other conventional resins11

and high impact properties. The results ASTM standard, Dynatup D3763 12.55 tup and 2.29 m/s

showed that PU chemistry for use in 2.54 mm thick, 2 x 300 g/m2 continuous strand mat, ~68 wt.% fiberglass

RTM and vacuum infusion applications Property Vinylester Unsaturated Polyurethane

are an attractive alternative to other Polyester

materials. Usama and Srekan12 have Maximum Load (N) 3260 3047 4088

studied the new generation of PU

Energy to Max Load (N-m) 18.2 11.4 24.8

resin systems developed by Bayer

Material Science. The study focused Total Energy (N-m) 29.3 27.7 38.4

334 Polymers & Polymer Composites, Vol. 23, No. 5, 2015

Manufacturing and Performance Evaluation of Polyurethane Composites Using One-part and Two-part Resin Systems

which results in foaming. To address For the two-part resin system, the laminate specimens with dimensions of

this issue, the mold was heated to infusion was at room temperature 127 mm x 12.7 mm x 3 mm (5 in x 0.5 in

250 °C and cooled to approximately and the curing cycle was 70 °C for x 0.118 in). These tests were performed

50 °C ensuring removal of all moisture 1 hour and 80 °C for 4 hours, the final on an Instron4469 electro-mechanical

from the mold. This process is done thickness of the composite plate was UTM machine at a crosshead speed of

prior to placement of fabric lay-up. measured to be approximately 3 mm 0.06 in/min.

(0.12 in). Standard coupon tests were

conducted including tension, flexure, 2.5 Impact Test

2.1 Preparation of PU Neat and low velocity impact as per ASTM

Resin Tensile and Flexure standards. Both Differential Scanning Low velocity impact tests were

Samples Using Blendur® Calorimetry (DSC) and viscosity performed on a Dynatup Instron Model

TP.PU90IK01 and PU840871 measurement tests were conducted on 9250 Impact Testing machine with

neat resin samples. impulse control and data system. At

Eighteen tensile and flexure samples the beginning of the test, impact or

were manufactured using Blendur® was secured with a hook at the desired

TP PU 90IK01 one-part thermoset Tensile specimens were manufactured

height. When the release mechanism

resin system and PU 840871 two- using three layers of woven E-glass

was activated, the impactor was

part thermoset resin system. The for tensile test, and impact and flexure

allowed to free-fall under gravity.

resin was degassed under vacuum to specimens were manufactured with

The drop height was varied as per the

remove dissolved air. The one-part six layers. By using six layers in the

required impact energy by adjusting the

resin system, PU90IK01, was heated tensile test the samples were thick and

position of the impactor. The position

to 50 °C to reduce the viscosity such the failure occurred in the grips was not

was measured with either a meter stick

that it can be easily filled into the mold. acceptable. The thickness was reduced

or a tape measure. A 12.7 mm (0.5 in.)

All the moisture content was removed to three layers 1.5 mm (0.05 in) for the

hemispherical hardened steel tup of

from the aluminum mold by heating for tensile test and the failure occurred in

mass 6.5 kg was connected to the

2 hours at 250 °C before the measured the middle of the samples between the

drop tower impactor. During the low

quantity of the resin was poured into upper and lower grips.

velocity impact tests, the specimens

the mold. The curing cycles were were clamped in a fixture concentric

200 °C for 3 hours for PU 90IK01. 2.3 Tensile Test with the axis of a drop tower passing

A70°C hold for 1 hour and 80 °C for through the tup. The low velocity

Tensile tests were performed on

4 hours for PU 840871, as manufacturer impact test fixture was made of steel,

both the neat resin and composite

recommended. with a 44.45 mm x 44.45 mm (1.75 in

laminate specimens according to

ASTM D638-10 and D3039/D3039M- x 1.75 in) opening to ensure that the

2.2 Manufacturing Composite 08,respectively 14,15.The composite test specimens remained clamped

Specimens specimens measured 250 mm x along all four edges. Experiments were

25.4 mm x 1.5 mm (10 in. x 1in. x conducted at three different energy

Vacuum Assisted Resin Transfer levels, 10J, 20J and 30J to estimate

0.05 in). The specimens’ end tabs were

Molding (VARTM) process was the impact force required to initiate

produced from the same glass fiber and

utilized to manufacture the composite visible and invisible damage in the

PU resin, to protect against the gripping

laminates. Five panels 10 in. x 10 in. PU composites.

stress produced from the tensile

are manufactured for each resin system.

testing machine fixture. The tests

To test the mechanical properties of the

were performed on an Instron 5985 3. Results and

composite laminates, specimens are cut

test machine with load cell 250 kN for Discussion

from the panels manufactured. Fiber

composites specimens and 10 kN for

reinforcement layup is prepared on a neat resin specimens. Ten glass fiber/

rigid aluminum mold with a layer of 3.1 Differential Scanning

PU 90IK01 and ten glass fiber/PU Calorimetry

removable plastic flow-enhancement 840871 specimens were tested.

medium (to reduce fill time) along with Differential Scanning Calorimetry

peel ply (to facilitate easy removal of (DSC) is an experimental tool used

manufactured part). The layup is sealed 2.4 Flexure Test extensively for thermal property

using a vacuum bag. The whole setup Flexure experiments were performed analysis. It works by detecting heat

is then sealed to the rigid mold using on both the neat resin and the composite flow from the samples as a function

a bagging tape. The layup is infused laminate specimens according to of time. DSC is used to characterize

at 50 °C and cured at 28 in. of Hg ASTM standard (D790-10)16. Nine cure kinetics for thermosetting polymer

vacuum pressure at 200 °C and held samples were manufactured for neat resins. The heat of reaction, the rate

for 3 hours for one-part resin system. resin and ten samples for composite of cure, and the degree of cure can

Polymers & Polymer Composites, Vol. 23, No. 5, 2015 335

M. Mohamed, S. Hawkins and K. Chandrashekhara

be measured using a DSC. In this of the extrapolated endothermic in Figure 2. The reason why the Tg of

work, a Model 2010 DSC was used shifts observed during the re-scans. one-part PU 90IK01 is higher is that

to study the cure kinetics from two The glass-transition temperatures of it contains a large number of aromatic

formulations of polyurethane resins. the two PU resins were observed to rings (Figure 3), which decreases the

Resin samples weighing 5-10 mg were be significantly different. The Tg for free volume in the PU polymer. The

encapsulated in an aluminum pans. PU90IK01 was found to be 127 °C results are shown in Table 2.

Dynamic runs at a heating rate of 5 °C/ and 71.28 °C for PU840871 as seen

min were conducted to determine the

maximum heat reaction temperature

Figure 1. Heat flow vs. temperature at 175 °C for PU 840871 and 200 °C for PU

during the curing cycle from the two 90IK01

PU formulations, as shown in Figure 1.

The 5-10 mg resin samples were

placed in the DSC furnace at ambient

temperature. They were cooled rapidly

to -35 °C under liquid nitrogen. The

exotherm was then monitored from

-35 °C to 200 °C for PU 90IK01

and from -35 °C to 175 °C for PU

840871 with same heating rate 5 °C/

min to determine the glass-transition

temperature (Tg).

The glass transition temperature Tg is

one of the most important properties

of any polymer and is the temperature

region where the polymer transitions

from a hard, glassy material to a

soft, rubbery material. As PU are

thermosetting materials and chemically

crosslink during the curing process, Figure 2. Glass-transition temperature at 175 °C for PU 840871 and 200 °C for PU

the final cured PU material does 90IK01

not melt or flow when reheated

(unlike thermoplastic materials), but

experiences a slight softening (phase

change) at high temperatures. The

ultimate Tg is determined by a number

of factors: the chemical structure of the

PU resin, the type of hardener and the

degree of cure. After the PU passes

through the glass transition temperature

range, its material properties change

significantly. It is important that design

engineers understand the nature of this

transition, so that they can choose the

best system for a specific application.

The glass-transition temperature is

reported as the midpoint temperature

Table 2. DSC test

On-Set Temperature (°C) End-Set Temperature (°C) Glass Transition Temperature

(°C)

PU 90IK01 128.51 141.54 127

PU 840871 69.48 71.27 71.28

336 Polymers & Polymer Composites, Vol. 23, No. 5, 2015

Manufacturing and Performance Evaluation of Polyurethane Composites Using One-part and Two-part Resin Systems

Figure 3. The chemical structure shows the aromatic rings in PU90IK91

3.2 Viscosity Measurements Figure 4. Schematic of rotating spindle inside the chamber

A Brookfield LVDV-II programmable

rotational type viscometer was used to

obtain rheological measurements on

thermosetting resins.Adynamic viscosity

measurement was utilized to determine

the optimum infusion temperature. A

Brookfield LVDV-II programmable

rotational-type viscometer was used to

perform the viscosity measurements. The

viscous resistance is related to both the

spindle rotational speed and the spindle

geometry. For both the PU 90IK01

and PU 840871, the spindle number

SC4-18 was used with a speed of 0.30

RPM and 5.0 RPM respectively, and the

chamber used is 13R. The resin sample

temperature was controlled with a hot

water bath. The thermocouple attached

to the chamber to measures the real-time

temperature of the resin in the chamber, the sample, the more torque required to

providing feedback to the temperature rotate the spindle. Thus, a constant shear

controller. stress is applied on the cylinders, the

speed being inversely proportional to the

Brookfield viscometers constructed distance between the two cylinders. There

generally consisted of a chamber (outer are no mechanical devices attached to the

cylinder) attached to the instrument and spindle, so that all frictional dissipation of

energy occurs in the liquid itself. The ratio of shear stress and shear rate

a spindle (inner cylinder) driven at a

constant speed (Figure 4). Pour some resin are given us the apparent viscosity η.

sample in the chamber and the spindle The accuracy of calculated average

is immersed in the resin and rotates at a shear stresses for this viscometer

constant speed around its central axis. The should also be examined. Thus, the

spindle will experience a retarding force rotational speed, measured torque, and

due to the viscous drag of the resin. The consideration of the spindle size and

torque transmitted through the liquid to shape allow us to determine shear rate

a static outer cylinder the more viscous and shear stress using equations below:

Polymers & Polymer Composites, Vol. 23, No. 5, 2015 337

M. Mohamed, S. Hawkins and K. Chandrashekhara

Where γ is the shear rate, τ is the 3.3 Tensile and Flexure Testing maximum stress needed to cause failure.

shear stress , ω is the angular velocity In the case of PU 90IK01 resin, had no

Figure 7 illustrates the average tensile

(RPM), T is the torque, r1 is the radius plastic deformation range causing it to

stress-strain behavior of the PU 90IK01

of the spindle (inner cylinder), r2 is the fail abruptly and fracture was observed

and PU 840871 neat resin specimens

radius of the chamber (outer cylinder), at a much lower stress. This resin was

at a crosshead speed of 0.06 in/min;

r is a radius at any point between the observed to be more brittle than the

between the two resin systems, there

two cylinders and L is the spindle PU 840871 resin because it contains

was a significant difference in the

length. In practice, these constant

factors and measured variables are

used by computer software to calculate

Figure 5. Viscosity vs. temperature of PU 90IK01 one-part resin system

viscosity.

The viscosity of the PU 90IK01 resin

was found to be 5.5 times greater

than that of the PU 840871 resin at

room temperature due to the length

of the chemical chain and good

entanglement between the molecules

at room temperature as shown in

Figures 3, 5 and 6. However, when

both resins are heated, the PU 90IK01

resin becomes less viscous than the

PU 840871 due to the faster gel

time of the PU 840871 resin. The

viscosity of the PU90IK01dropped

from 2053 cPs at room temperature to

33 cPs at 89 °C. For the PU 840871,

the viscosity dropped from 357 cPs at Figure 6. Viscosity vs. temperature of PU 840871 two-part resin system

room temperature to 352 cPs at 33 °C.

The viscosity had then increased due

to the resin’s low pot life resulted of

the catalyst part (Isocyanate) which

started to react directly after mixing

at room temperature, on the contrary

one-part PU 90IK01 which started

reacting at certain temperature due

to the thermal stability and high heat

distortion temperature. The results

were agreed with findings by U.

Younes. The measured viscosities

of both PU90IK01 and PU840871

at various temperatures are given in

Tables 3 and 4 respectively.

Table 3. Viscosity measurements of PU90IK01

Viscosity cP Speed RPM Torque % Shear Stress D/cm2 Shear Rate s-1 Temperature °C

2053.56 0.30 102.65 7.53 0.37 25.00

1683.64 0.30 84.24 6.18 0.37 27.00

733.84 0.30 36.68 2.69 0.37 35.00

189.96 0.30 9.46 0.7 0.37 55.00

105.98 0.30 5.30 0.39 0.37 65.00

41.99 0.30 2.12 0.15 0.37 85.00

33.99 0.30 1.73 0.12 0.37 89.00

338 Polymers & Polymer Composites, Vol. 23, No. 5, 2015

Manufacturing and Performance Evaluation of Polyurethane Composites Using One-part and Two-part Resin Systems

Table 4. Viscosity measurements of PU840871

Viscosity cP Speed RPM Torque % Shear Stress Shear Rate Temperature °C

D/cm2 s-1

356.92 5.00 59.51 23.56 6.60 25.00

356.92 5.00 59.49 23.56 6.60 27.00

355.12 5.00 59.23 23.44 6.60 29.00

353.32 5.00 58.88 23.32 6.60 31.00

352.12 5.00 58.69 23.24 6.60 33.00

353.92 5.00 58.97 23.36 6.60 35.00

375.52 5.00 62.58 24.78 6.60 37.00

large numbers of hydroxyl group (OH) Figure 7. Tensile stress vs. strain of PU90IK01and PU840871 neat resins

and the benzene rings in the chemical

structure which make the chain stiffer.

In contrast, the PU 840781 was able to

endure 54% higher stress and 0.027 %

higher strain and fails gradually. Figure

8 shows the average flexure stress-strain

behaviors of the PU 90IK01 and PU

840871 neat resin specimens. The stress-

strain behavior displayed an increase

in the region of linear elasticity with

increasing strain. The ductility property

of two part resin PU 840871 it’s appear

again and a significant difference exists

between the two resin systems, in the

maximum stress needed to cause failure.

In case of the PU 90IK01 resin, fracture

occurred at the yield stress. It proved Figure 8. Flexure stress vs. strain of PU90IK01 and PU840871 neat resins

to be more brittle than the PU 840871

resin, causing fracture at a much lower

stress. The PU 840871 specimen was

able to handle 39% more flexural stress

and more strain (Table 5).

Figure 9 illustrates the average

tensile stress-strain behavior of the

glass fiber/PU90IK01 and glass fiber/

PU840871 composite specimens. A

linear relationship is clearly visible

between stress and strain. Since the

tensile property is fiber domain and in

this work same type of fiber was used

therefore, we cannot see much difference

Table 5. Tensile and flexure testing of PU neat resins

Tensile Strength Tensile Tensile Failure Flexural Strength Flexural Flexure Failure

(MPa) Modulus (MPa) Strain (%) (MPa) Modulus (MPa) Strain (%)

PU 840871 64.47 ±2.0 2594.67±102.4 0.034±0.003 109.34±6.4 26.146±2.2 5.21±0.21

Neat Resin

PU 90IK01 29.02±2.4 3352.50±111.3 0.009±0.002 66.05±1.43 31.34±2.8 2.18±0.04

Neat Resin

Polymers & Polymer Composites, Vol. 23, No. 5, 2015 339

M. Mohamed, S. Hawkins and K. Chandrashekhara

Figure 9. Tensile stress vs. strain of glass fiber/PU90IK01 and glass fiber / in the tensile strength. However, some of

PU840871 composite laminates the characteristics of the neat resins can

be seen in the composites. The brittle

nature of the PU 90IK01 resin does not

allow the composite to reach either the

same load or extension as the other

resin. Both composites demonstrated

a linear elastic behavior, but lack a

plastic deformation range making

the yield stress the breaking point.

Fracture occurred at the yield stress for

glass fiber/PU840871 at higher tensile

strength than the glass fiber/PU90IK01

composites. Also, there is difference in

the failure modes of the specimens. The

glass fiber/PU840871 specimens failed

laterally and the glass fiber/PU90IK01

specimens failed by splaying of the

fibers as shown in Figure 10.

Figure 10. Tensile specimens after testing. The glass fiber/PU840871 specimens Estimates of tensile strength were

(right) typically failed laterally. The glass fiber/PU90IK01 specimens (left) based on both the stress at linear

typically failed by splaying of the fibers elastic limit and the maximum stress

levels. Results show no significant

change in maximum strain in the case

of specimens belonging to PU840871

resin and the average strain was 0.024%

at the maximum stress 350 MPa which

is slightly higher than the value of

300 MPa for the case of PU90IK01.

Figure 11 illustrates the average flexure

stress-strain behavior of the glass fiber/

PU90IK01and glass fiber/PU840871

composite specimens. Figure 11

indicates that the composite specimens

take on some characteristics of their

respective matrix. The neat resin

flexure test in Figure 8 implies that the

PU840871 resin had better properties

than the PU90IK01. Even though the

glass fiber/PU840871 composite was

able to handle a slightly higher strain,

the glass fiber/PU840871 composite

could handle a higher stress of 642 MPa

(Table 6).

Table 6. Tensile and flexure testing of glass fiber/PU composites

Tensile Strength Tensile Modulus Tensile Failure Flexure Flexure Flexure Failure

(MPa) (MPa) Strain (%) Strength (MPa) Modulus (MPa) Strain (%)

PU 840871 351.77±±15.40 19,534.08±±1800 0.024±±0.02 642.34±± 22 14,560.91±±105 4.96±±0.1

Composite

PU 90IK01 309.06±±17.83 21,430.3±±2.39 0.023±±0.01 618.88±±31 17,110.6±± 210 3.82±±0.1

Composite

340 Polymers & Polymer Composites, Vol. 23, No. 5, 2015

Manufacturing and Performance Evaluation of Polyurethane Composites Using One-part and Two-part Resin Systems

3.4 Impact Test Figure 11. Flexural stress vs. strain of glass fiber /PU90IK01 and glass fiber /PU

840871 composite laminates

In this study, the effects of three

different impact energies (10J, 20J,

30J) on the maximum contact force,

maximum deflection, contact time

and absorbed energy of the glass

fiber reinforced PU90IK01 and glass

fiber reinforced PU840871 laminated

composite were investigated.

Front face for two type composite

specimens subjected to impact energy

at10J initially there was slight damage

at the front face crossovers under

the impact head. Then fiber damage

occurred at the center, aggravated

and then increases by increasing the

energy levels. Finally shear failure

of the fibers occurred as the impact

Figure 12. The damaged area of glass fiber/PU90IK01

head hit the specimen. A circular area

of delamination centered under the

impact head formed with increasing

impact energy. In the back face of the

specimens at 10J the damage barely

visible, at 20J and 30J at the center was

a rough diamond shaped area of matrix

cracking within the fiber bundles. This

damage extent and matrix damage

started, followed by fiber damage.

The percentage of the impact damage

absorbed by the glass fiber/PU 90IK01

Figure 13. The damaged area of glass fiber/PU 840871

specimen increases with impact energy.

It can be seen that the force varies

fairly broad peak with time, however,

at higher energies the peak becomes

sharper as damage occurs under the

impactor. Again, there was a fair degree

of damage even in the specimens

subjected to the lowest energy impacts.

The same styles as for the glass fiber/

PU 840871 specimens were seen, but

generally buckling of the surfaces

occur at high energy level. Total

perforation of the specimens subjected

to the highest energies did not occur.

Figures 12 and 13 show the damaged energies, a sharp increase of maximum plots, no obvious difference was seen

areas obtained by visual inspection for defection is seen as partial perforation between different composite laminates.

both composite laminates. of some of the specimens occurs. Again However, the glass fiber/PU840871

the higher stiffness of the glass fiber/ has slightly higher energy absorption.

As expected, the glass fiber/PU 90IK01 PU specimens can be seen in Figure 14

specimens are stiffer than glass fiber/ through the higher forces comes Flexible plates glass fiber/PU840871

PU 840871. For the glass fiber/PU across. For the maximum deflection, give high bending strains that lead to

90IK01 specimens at higher impact maximum force and absorbed energy compressive and/or tensile failure on

Polymers & Polymer Composites, Vol. 23, No. 5, 2015 341

M. Mohamed, S. Hawkins and K. Chandrashekhara

the faces of the plate. Stiffer plates lead the composite sample. A downward was slightly higher in the glass fiber//

to higher contact forces and internal trajectory and a consecutive plateau in PU840871 composite. Figure 16

shear and normal stresses give complex the curve depict the transfer of energy illustrates the load versus deflection

inter laminar and matrix damage from the sample to the impactor and behavior of both the composite

modes. The use of a hemispherical final energy absorbed by the sample, specimens at three energy levels.

impactor even for small energy level respectively. The energy absorption The effect of load on the deflection is

and forces a smaller contact area

occurs, leading to higher shear and Figure 14. Load vs. time curves recorded in a low-velocity impact test up to

normal stresses. Close to the impactor failure at different energy levels (10J, 20J, 30J) for glass fiber/PU 90IK01 and

a first approximation leads to a circular glass fiber/PU 840871

region of high shear stress around the

circumference of the area of contact.

This leads to delamination that spreads

inwards faster than outwards17,18. In

reality the stress under the impactor

is complex. From the results, in-plane

stresses cause transverse matrix tensile

cracks which can cause delamination.

These cracks are important in marine

and infrastructure applications due

to the problems of material property

degradation through moisture diffusion.

Table 7 gives the low velocity impact

response of the two laminates. At 10J,

the contact force was approximately

the same for both composite laminates.

Figure 14 illustrates the load versus Figure 15. Energy vs. time curves recorded in a low-velocity impact test at different

time curves at three different energy energy levels (10J, 20J, 30J) for glass fiber/PU90IK01 and glass fiber/PU840871

levels. Additional delaminations

were observed as the impact energy

increased. The glass fiber/PU90IK01

composite carried approximately 13%

more load at the 30J energy level than

the glass fiber/PU840871 composite.

From Figure 14, the maximum load

was 8000 N for both the 20 J and

30 J energy levels in the PU 840871

composite. This is mainly due to the

flexibility of the PU 840871 resin.

Figure 15 illustrates the variation of

impact energy with respect to time. An

initial increase in the impact energy

(in the curves) relates to the transfer

of energy from the drop weight to

Table 7. Low velocity impact test results

E-glass/PU90IK01 E-glass/PU840871

Impact Level 10J 20J 30J 10J 20J 30J

Contact Force (N) 5772.13 8075.1 9444.6 5770.82 7554.65 8184.17

Energy Absorbed (J) 3.26 11.40 23.63 5.48 12.04 24.13

Velocity (m/s) 1.75 2.48 3.05 1.80 2.68 3.15

Displacement (mm) 3.20 5.08 6.38 3.40 5.03 6.39

342 Polymers & Polymer Composites, Vol. 23, No. 5, 2015

Manufacturing and Performance Evaluation of Polyurethane Composites Using One-part and Two-part Resin Systems

Figure 16. Load vs. deflection curves recorded in a low-velocity impact test up to Dr. John Hayes from Bayer Material

failure at different energy levels (10J, 20J, 30J) for glass fiber/PU90IK01 and glass Science for their help.

fiber/PU840871

References

1. K.S. Pandya, C. Veerraju, and N.K.

Naik, “Hybrid Composites made of

Carbon and Glass Woven Fabrics

under Quasi-Static Loading.”

Materials and Design 32 (2011)

4094-4099.

2. L. Hammond and R. Grzebieta,

“Structural Response of Submerged

Airbacked Plates by Experimental

and Numerical Analyses.” Shock

Vibration 7 (2000) 333-341.

3. C. Wonderly, J. Grenestedt, F.

Goran, and E. Cepus, “Comparison

of Mechanical Properties of Glass

Fiber/Vinyl Ester and Carbon

Fiber/Vinyl Ester Composites.”

Composites Part B: Engineering 36

significantly increased with increasing times greater than that the PU90IK01. (2005) 417-426.

energy levels. The neat PU 840781 samples were 4. G.E. Husman, J.M. Whitney, and

capable of enduring about 54% higher J.C. Halpin, “Residual Strength

stress and 0.027% higher strain. The Characterization of Laminated

4. Conclusions Composites Subjected to Impact

flexure stress-strain behavior showed

In this study, glass fiber reinforced an increase in the region of linear Loading.” Foreign Object Impact

elasticity, with higher strength. The Damage to Composites, ASTM STP

composite laminates were fabricated

568. ASTM (1975) 92-113.

using a VARTM process. Thermoset PU90IK01 resin was more brittle

compared to PU 840871 resin allowing 5. M. Mohamed, R.R. Vuppalapati, S.

polyurethane PU90IK01 and new

Hawkins, K. Chandrashekhara, and T.

generation PU 840871 resin systems, it to fracture at a much lower stress.

Schuman, “Impact Characterization

and bi-directional E-glass fabric was The PU 840871 neat resin specimen of Polyurethane Composites

used as the reinforcing material. was able to handle 39% more flexural Manufactured using Vacuum Assisted

Differential scanning calorimetry stress and more strain. The brittle nature Resin Transfer Molding.” International

(DSC) and viscosity measurements of PU 90IK01 resin did not allow the Mechanical Engineering Congress

were used to study the properties of the composite to reach either the same & Exposition ASME Houston,

two PU resin systems. A performance load or extension as the other. The (November 9-15, 2012): 1-8.

evaluation was conducted using tensile, PU 840871 resin had absorbed more 6. D. Bareis, D. Heberer, and M.

flexure and low-velocity impact tests at energy than PU90IK01. Connolly, “Advances in Urethane

Composites Resins with Tunable

three different energy levels (10J, 20J

Reaction Times.” American

and 30J) for each resin system, and the Summarizing the results in terms of Composites Manufacturers

results were compared. mechanical properties, the resin system Association Ft. Lauderdale, Florida.

PU 840871 laminates outperformed Huntsman Polyurethanes Auburn

DSC tests were performed to the PU 90IK01glass fiber laminates Hills, MI (February 2-4, 2011): 1-7.

investigate and obtain the glass in all respects except for the contact 7. J. John, M. Bhattacharya, and

transition temperature Tg for both force in the low velocity impact test. R.B. Turner, “Characterization of

PU resin systems. Dynamic viscosity Both composites exhibit excellent Polyurethane Foams from Soybean

measurement was utilized to determine properties, and are considered suitable Oil.” Journal of Applied Polymer

Science 86 (2002): 3097-3107.

the optimum infusion temperature for for use in infrastructure and marine

both resin systems, and the results applications. 8. S. Desai, I.M. Thakore, B.D.

Sarawade, and S. Devi, “Effect

agreed with those of Usam. From the

of Polyols and Diisocyanates

tensile tests of the neat resin samples,

Acknowledgment on Thermo-Mechanical and

PU 90IK01 was observed to break Morphological Properties of

down fast due to its brittle nature. The The authors would like to thank Mr. Polyurethanes.” European Polymer

PU840871 resin could carry a load 2.5 Craig Snyder, Dr. Usama Younes and Journal 36 (2000) 711-725.

Polymers & Polymer Composites, Vol. 23, No. 5, 2015 343

M. Mohamed, S. Hawkins and K. Chandrashekhara

9. S. Husic´, I. Javni, and Z.S. Walled Carbon Nanotubes on their 16. ASTM D790-10 Standard Test

Petrovic, “Thermal and Mechanical Performance.” American Composites Methods for Flexural Properties

Properties of Glass Reinforced Soy- Manufacturing Association Las of Unreinforced and Reinforced

Based Polyurethane Composites.” Vegas, Nevada (February 21- Plastics and Electrical Insulating

Composites Science and Technology 23,2011): 1-14. Materials. ASTM International, 100

65 (2005) 19-25. 13. R. Karakuzua, E. Erbila, and M. Barr Harbor Drive, P.O. Box C700,

10. U. Younes, “Development of Aktas, “Impact Characterization of West Conshohocken, PA 19428-2959

PU-based RTM and VARTM Glass/Epoxy Composite Plates: An USA.

Technology.” American Composites Experimental and Numerical Study.” 17. G.A.O. Davies and X. Zheng,

Manufacturing Association Las Composites Part B 41 (2010) 388- “Impact damage prediction in carbon

Vegas, Nevada (February 9-11,2010): 395. composite structures.” International

1-17. 14. ASTM D638-10 Standard Test Journal of Impact Engineering 16

11. M. Connolly, J. King, T. Shidaker, Method for Tensile Properties of (1995) 149-170.

and A. Duncan, “Processing and Plastics. ASTM International, 100 Barr 18. M. Dale, B.A. Acha, and L.A.

Characterization of PU pultruded Harbor Drive, P.O. Box C700, West Carlsson, “Low Velocity Impact

Polyurethane Composites.” Technical Conshohocken, PA 19428-2959 USA. and Compression after Impact

Paper Huntsman International LLC 15. ASTM D3039/D3039M-08 Standard Characterization of Woven Carbon/

(2006): 1-16. Test Method for Tensile Properties of Vinylester at Dry and Water

12. U. Younes and S. Unal, “New Polymer Matrix Composite Materials. Saturated Conditions.” Composite

Generation Polyurethane-based ASTM International, 100 Barr Structures 94 (2012) 1582-1589.

Fiber Reinforced Composite for Harbor Drive, P.O. Box C700, West

Vacuum Infusion and Effect Multi- Conshohocken, PA 19428-2959 USA.

344 Polymers & Polymer Composites, Vol. 23, No. 5, 2015

Reproduced with permission of the copyright owner. Further reproduction prohibited without

permission.

You might also like

- GOMEZ - 2004 - A Literature Review ofDocument20 pagesGOMEZ - 2004 - A Literature Review ofALEXA FRYNo ratings yet

- Mohamed Et Al. 2015 - Manufacturing and Characterization of Polyurethane Based SandwichDocument11 pagesMohamed Et Al. 2015 - Manufacturing and Characterization of Polyurethane Based SandwichALEXA FRYNo ratings yet

- Theory Based Production & Project Management: January 2006Document12 pagesTheory Based Production & Project Management: January 2006sweetyNo ratings yet

- Sustainability: A Construction Management Framework For Mass Customisation in Traditional ConstructionDocument29 pagesSustainability: A Construction Management Framework For Mass Customisation in Traditional ConstructionALEXA FRYNo ratings yet

- Materials 13 00211 PDFDocument17 pagesMaterials 13 00211 PDFALEXA FRYNo ratings yet

- Materials 13 00211 PDFDocument17 pagesMaterials 13 00211 PDFALEXA FRYNo ratings yet

- Materials 13 00211 PDFDocument17 pagesMaterials 13 00211 PDFALEXA FRYNo ratings yet

- Sustainable Development of Construction Sme PDFDocument8 pagesSustainable Development of Construction Sme PDFALEXA FRYNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (120)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Dharani CatalogueDocument22 pagesDharani CatalogueIon Vairamuthu100% (1)

- Force, Work, Power and Energy - Daily Home Assignment 01 - (Victory 2024 - ICSE)Document5 pagesForce, Work, Power and Energy - Daily Home Assignment 01 - (Victory 2024 - ICSE)44 A Ritam BeraNo ratings yet

- EG85HLR 115-127 V 60 HZ 1Document4 pagesEG85HLR 115-127 V 60 HZ 11000tech refrigeracaoNo ratings yet

- Classification of CNC Machine ToolsDocument7 pagesClassification of CNC Machine ToolsRajendra Kumar YadavNo ratings yet

- Radiation Heat Transfer: Amit KakkarDocument11 pagesRadiation Heat Transfer: Amit KakkarRupesh TiwariNo ratings yet

- Ecs226 - Test 2 - Answer Scheme - 29 July 2021Document8 pagesEcs226 - Test 2 - Answer Scheme - 29 July 2021Mohd HasbulNo ratings yet

- Load Tests For Jet Grouting at MacauDocument8 pagesLoad Tests For Jet Grouting at MacauMatteoTrigliaReatoNo ratings yet

- Welding Procedure Specification PresentasiDocument3 pagesWelding Procedure Specification PresentasiHASIM HASIMNo ratings yet

- Step by Step Methods For WRC 107 and WRC 297 Checking in Caesar IIDocument7 pagesStep by Step Methods For WRC 107 and WRC 297 Checking in Caesar IIaap1No ratings yet

- Problem Sheet - 2 PDFDocument2 pagesProblem Sheet - 2 PDFJyotirmoy DekaNo ratings yet

- Motor Size: Ordering InformationDocument8 pagesMotor Size: Ordering Informationadefaizalmaizar12No ratings yet

- Alloy Steel Pipe Price List IndonesiaDocument14 pagesAlloy Steel Pipe Price List Indonesiaiandegs2010No ratings yet

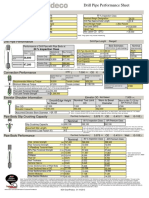

- Drill Pipe Performance Sheet 5.875 XT57 G105Document3 pagesDrill Pipe Performance Sheet 5.875 XT57 G105Garcia C L AlbertoNo ratings yet

- Deltalab - Introduction EX1100 - enDocument7 pagesDeltalab - Introduction EX1100 - enPetre TachitaNo ratings yet

- Racing Ski-Doo ADocument493 pagesRacing Ski-Doo ARobin H. WhiteNo ratings yet

- Pinned Base Plates 5Document1 pagePinned Base Plates 5pawkomNo ratings yet

- RR-Model 250 FADEC System Familiarization (Transcript)Document12 pagesRR-Model 250 FADEC System Familiarization (Transcript)killerghosts666No ratings yet

- Catalago Peças CA250D SN 6582BR0000Document164 pagesCatalago Peças CA250D SN 6582BR0000Jose Wellington Silva dos SantosNo ratings yet

- AC MachinesDocument8 pagesAC Machinesprince ian cruzNo ratings yet

- NMBS Composite Slab Engineering CourseDocument72 pagesNMBS Composite Slab Engineering CourseDario P. YanezNo ratings yet

- P QUIP Swab and Pony RodDocument5 pagesP QUIP Swab and Pony Rodkrishnsgk0% (1)

- Integration of A Single Cylinder Engine Model and A Boost System Model For Efficient Numerical Mapping of Engine Performance and Fuel ConsumptionDocument8 pagesIntegration of A Single Cylinder Engine Model and A Boost System Model For Efficient Numerical Mapping of Engine Performance and Fuel ConsumptionNambi RajanNo ratings yet

- Sp208-04ex 5Document17 pagesSp208-04ex 5Žarko LazićNo ratings yet

- MVS462-1 (Includes TAD1640GE Volvo + HCI544C1 Stamford)Document5 pagesMVS462-1 (Includes TAD1640GE Volvo + HCI544C1 Stamford)sakrgeorge2000No ratings yet

- ML T ML T ML T ML T ML T R L T MT: Separation Columns (Distillation, Absorption and Extraction)Document4 pagesML T ML T ML T ML T ML T R L T MT: Separation Columns (Distillation, Absorption and Extraction)Sami WhiteNo ratings yet

- Conexão Manômetro EN 837 PDFDocument4 pagesConexão Manômetro EN 837 PDFJoana MellerNo ratings yet

- Generator and Regulator - Gtdi 2.0L Petrol - Generator - Component LocationDocument11 pagesGenerator and Regulator - Gtdi 2.0L Petrol - Generator - Component LocationKent WaiNo ratings yet

- Piping Design HandbookDocument122 pagesPiping Design HandbookAbelardo ContrerasNo ratings yet

- L PDFDocument5 pagesL PDFElgi Alam PangestuNo ratings yet

- Complying With Nace Hardness RequirementsDocument5 pagesComplying With Nace Hardness Requirementsmanimaran100% (2)