Professional Documents

Culture Documents

"Made It Myself" Tow-Behind Forklift

Uploaded by

Bandivz BandivzOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

"Made It Myself" Tow-Behind Forklift

Uploaded by

Bandivz BandivzCopyright:

Available Formats

“Made It Myself” Tow-Behind Forklift

Marty Gallaher, Hartford, Alabama, needed a variety of jobs,” says Gallaher. “I paid $350

a forklift to load his home-built barbeque for a used forklift that wasn’t in operating

grills onto customers’ trucks. He couldn’t condition and about $50 more on parts.

justify the cost of a self-propelled forklift so “I mounted the forklift’s original hydrau-

he picked up an old forklift mast and con- lic control levers on the frame behind the trac-

verted it into a 2-wheeled, pull-type rig. tor where I can reach them from the tractor

The mast mounts on a steel frame that he seat. There isn’t enough fluid in the tractor’s

made out of 6-in. channel iron and fitted with hydraulic system to make the lift go all the

a home-built axle and a 10-ft. tongue. Two way up, so I mounted the air compressor tank

cylinders tilt the mast back and forth. Two from a semi tractor on front of the frame and

more cylinders are used to raise or lower the use it as a hydraulic reservoir.”

forks, which reach 9 ft. high. Power is sup- Contact: FARM SHOW Followup, Marty

plied by the tractor’s hydraulics. Gallaher, 7553 East State Hwy. 52, Hartford,

“It does the work of a self-propelled fork- Alabama 36344 (ph 334 588-6700; email:

lift at a far lower cost and I can go anywhere gallaher@lycos.com).

without getting stuck. It comes in handy for

“Roller” Screed Works

Marty Gallaher converted an old forklift mast into this 2-wheeled , pull-type rig. He

Concrete Up To 20 Ft. Wide can reach the forklift’s original hydraulic control levers from the tractor seat.

Contractor Joe Churchill, Quincy, Illinois, els the high spots and fills the low spots in

figured there had to be a faster, easier way to front of it. Churchill claims the Spin Screed

screed concrete than using his old heavy vi- doesn’t bring excess water to the surface as

brating power screed. it brings up the concrete paste. For this rea-

Churchill has more than 30 years experi- son, he says the surface will be more durable

ence in concrete work. He says he’d used than that created with a vibrating screed,

vibrating screeds most of this time and found which can bring water to the surface.

them too heavy, too noisy and too hard to By setting the screed pipes on stakes, you

clean. can make multiple parallel passes over slabs

After working on it awhile, he developed wider than 20 ft. Churchill says the screed

the Spin Screed. He figures his invention is pipe can be set to produce crowned or swaled

the easiest-to-use power screed ever devel- surfaces, in addition to flat ones.

oped. It’s so light one person can pick it up The total weight of a Spin Screed with a

and load it into a truck. It consistently leaves 20-ft. aluminum pipe is less than 100 lbs. The

the aggregate material just below the surface, motor weighs 13 lbs. and the T handles about

unlike vibrating screeds that can sometimes 3 lbs. The motor and T handles will work with

cause the aggregate to sink too deeply into any length of aluminum pipe up to 20 ft., so Spin Screed uses a heavy duty r ight

the mixture and leave the surface weak. no matter what the width of the pour, you angle drill to rotate an aluminum pipe

The design is simple. Churchill mounted can cut a screed to fit it. (above). Pipe is laid over the poured

one end of a length of aluminum pipe on a Churchill says his simple invention has concrete and then pulled along the

surface opposite the direction pipe spins.

heavy-duty right angle drill. He mounted the allowed his construction crews to screed con- Spinning pipe levels high spots and fills

drill in a specially designed T handle to make crete faster and easier, which improves both low spots in front of it. Drill is mounted

it easy to use. The opposite end of the pipe profits and morale. in a specially designed “T” handle to

attaches to a similar T handle, so it spins Sells for $1,080, including drill. If you mak e it easy to use (right).

freely. supply the drill and pipe, $485.

To use the Spin Screed, you simply lay the Contact: FARM SHOW Followup, Spin

aluminum pipe over the poured concrete. One Screed, 4932 Lake View Drive, Quincy, Ill.

worker takes each handle and the one with 62305 (ph toll free 888 329-6039; email: Lift Pole Snare

the power unit turns it on. Then they pull it spinscreed@adams.net; website: www.spin If you’ve got some pests hanging around

along the surface opposite the direction the screed.com). the farm that you’d like to eliminate without

pipe spins. That way, as the pipe spins, it lev- having to buy expensive traps, you might just

try this old-time idea.

The lift pole snare has probably been

around for centuries. You need a Y-shaped

branch to balance it on. A pole laying across

the “Y” is fitted with a slip-not loop of wire

that hangs down at head height over the trail.

A weight is tied to one end of the pole – such

as a chunk of wood – and the other end is

held lightly in place by a notched stick. When Lift pole snare is balanced on a Y-shaped

an animal’s head goes into the loop, the pole branch.

yanks him up, choking him. depending on the size of the animal you’re

You can make the trap as big as needed, trying to trap. Backwoodsman Magazine

in heavier material,” she says. the bag as full as we can, I tie the end shut

They haul loose hay in from the field in a with baler twine and then haul the bag from

hayrack made to fit on a two-wheeled trailer the field on the cart.”

frame welded together by Art and their son. This is her first year at making silage this

Wendy Pasman adapted a number of machines to go with their Deere garden tractor. “We use it so much I just made a new bottom way, but she says the heavy plastic bags she’s

They use them to produce feed for their dairy goats and sheep. and sides for it,” she says. “I have hay rack using have resisted puncturing and the mate-

sides for it that fit on the sides, front and back. rial inside has the appearance and smell of

Small Farm Operation It’s lower in the back to make it easier to pitch

the hay on, but it will handle a big load of

good quality silage.

When they need to work the soil, they have

Makes Do With “Mini Tools” hay.”

Pasman says they can’t always count on

an old horse-drawn cultivator that works quite

well as a small chisel plow. All they had to

Wendy Pasman says she and her husband, den tractor. “The tractor runs almost every good hay drying weather, so she devised an do was devise a hitch so they could pull it

Art, can’t justify the cost of big equipment day, summer and winter,” she says. To handle alternative system that lets her bag wet hay with the 111. They break up clods with a small

to produce feed for their small flock of dairy all the fieldwork with the 111, the Pasmans to make silage. It consists of a rolling plat- spike-toothed harrow. Then they seed and

goats and Shetland sheep, but still have to made or adapted a number of machines. form fitted with a wire panel that’s bent into fertilize with a lawn spreader they adapted

cut and store forage for them, and maintain They cut hay with a walk-behind 34-in. a circle. to pull it behind the tractor.

their fields. So they do everything with mini- sickle mower. A year ago, she found a small “I hang the biggest black plastic trash bags Contact: FARM SHOW Followup, Wendy

size tools, some of which they built them- wheel rake at a farm sale and adapted that I can buy on the wire, which holds the bags Pasman, RR 3, Rocky Mountain House,

selves. for raking hay. “It was made for raking lawn open and supports them while we pitch in Alberta, Canada T4T 2A3 (ph 403 845-6121).

Their primary tractor is a Deere 111 gar- clippings, so we had to strengthen it to work the wet hay,” she explains. “When we pack

phone: 1-800-834-9665 • e-mail: editor@farmshow.com • web site: www.farmshow.com • FARM SHOW • 35

You might also like

- Flying Cart Hovercraft PlansDocument8 pagesFlying Cart Hovercraft PlansJimNo ratings yet

- Straw Chopper Chops Stalks: "Made It Myself" ATV AttachmentsDocument1 pageStraw Chopper Chops Stalks: "Made It Myself" ATV AttachmentsJohn AndersonNo ratings yet

- Building Tips and Tricks PDFDocument16 pagesBuilding Tips and Tricks PDFcodeethylNo ratings yet

- Home Building TipsDocument245 pagesHome Building TipsoltaiyrxNo ratings yet

- The Boys' Guide to Outdoor Activities - Including Hints on Camping and the Boy ScoutsFrom EverandThe Boys' Guide to Outdoor Activities - Including Hints on Camping and the Boy ScoutsNo ratings yet

- A Study of Wick Drain MachinesDocument90 pagesA Study of Wick Drain MachinesGilberto YoshidaNo ratings yet

- The Woodwright’s Guide: Working Wood with Wedge and EdgeFrom EverandThe Woodwright’s Guide: Working Wood with Wedge and EdgeRating: 4 out of 5 stars4/5 (6)

- This Fit-Bottomed Cruising Kuyak Over-All Length o F Feet, Inches %&inch BeamDocument7 pagesThis Fit-Bottomed Cruising Kuyak Over-All Length o F Feet, Inches %&inch BeamFrenchwolf420100% (2)

- Mini BikeDocument6 pagesMini BikeraadianNo ratings yet

- Digital Media Primer 3rd Edition Wong Solutions Manual Full Chapter PDFDocument23 pagesDigital Media Primer 3rd Edition Wong Solutions Manual Full Chapter PDFstrangstuprumczi100% (10)

- Mechanical Appliances, Mechanical Movements and Novelties of ConstructionFrom EverandMechanical Appliances, Mechanical Movements and Novelties of ConstructionRating: 4 out of 5 stars4/5 (2)

- Popular Mechanics Article - Via FerrataDocument6 pagesPopular Mechanics Article - Via FerrataJohn HallNo ratings yet

- DIY Solar Collector Hot WaterDocument30 pagesDIY Solar Collector Hot Waterglobalrevolution100% (1)

- A Guide to Making Your Own Fishing-Rod and TackleFrom EverandA Guide to Making Your Own Fishing-Rod and TackleRating: 5 out of 5 stars5/5 (1)

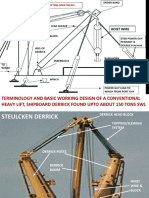

- Terminology and Basic Working Design of A Conventional Heavy Lift, Shipboard Derrick Found Upto About 150 Tons SWLDocument11 pagesTerminology and Basic Working Design of A Conventional Heavy Lift, Shipboard Derrick Found Upto About 150 Tons SWLRoshan MaindanNo ratings yet

- 26Document3 pages26Muhammad Umer FarooqNo ratings yet

- Practical Blacksmithing Vol. IV: A Collection of Articles Contributed at Different Times by Skilled Workmen to the Columns of "The Blacksmith and Wheelwright" and Covering Nearly the Whole Range of Blacksmithing from the Simplest Job of Work to Some of the Most Complex ForgingsFrom EverandPractical Blacksmithing Vol. IV: A Collection of Articles Contributed at Different Times by Skilled Workmen to the Columns of "The Blacksmith and Wheelwright" and Covering Nearly the Whole Range of Blacksmithing from the Simplest Job of Work to Some of the Most Complex ForgingsRating: 5 out of 5 stars5/5 (1)

- Building Meerkat, A Very Small CatboatDocument8 pagesBuilding Meerkat, A Very Small CatboatJohn M. Watkins100% (8)

- Cable Tool DrillingDocument13 pagesCable Tool DrillingAHMED100% (2)

- Crouch HydroDocument12 pagesCrouch HydroKeith WilliamsNo ratings yet

- Naval Architects Notebook - Vol 2 - David P MartinDocument102 pagesNaval Architects Notebook - Vol 2 - David P MartinRenato Pereira De BulhoesNo ratings yet

- Rolamite BearingDocument41 pagesRolamite Bearingfrankieb99No ratings yet

- Star Lite SailboatDocument13 pagesStar Lite SailboatJim100% (8)

- Unsinkable UniboatDocument6 pagesUnsinkable UniboatJim100% (4)

- Skidder: From Wikipedia, The Free EncyclopediaDocument3 pagesSkidder: From Wikipedia, The Free EncyclopediaZerotheoryNo ratings yet

- FTW Weav 4Document64 pagesFTW Weav 4Kannan KumarNo ratings yet

- Camp TrailerDocument6 pagesCamp TrailerGreg Phillpotts100% (3)

- Madera25 100 2Document89 pagesMadera25 100 2martin789No ratings yet

- Katalog - Downs Crane Hoist - Sheet LiftersDocument2 pagesKatalog - Downs Crane Hoist - Sheet LiftersDemy Iman TaufikNo ratings yet

- River Boat Built For White WaterDocument5 pagesRiver Boat Built For White WaterJim100% (2)

- Power HackSawDocument6 pagesPower HackSawMike Nichlos100% (2)

- Lodge & Shipley LathesDocument8 pagesLodge & Shipley LathesRey SantanaNo ratings yet

- Oval Boxes: How To Make Steambent ContainersDocument4 pagesOval Boxes: How To Make Steambent ContainersAnonymous QJ5j94luLmNo ratings yet

- Belt SanderDocument2 pagesBelt SanderFrenchwolf420No ratings yet

- Happy Clam SkiffDocument11 pagesHappy Clam SkifffccfNo ratings yet

- Shaker Chest of DrawersDocument8 pagesShaker Chest of DrawersMonte William NorthNo ratings yet

- Analysis For Financial Management 11th Edition Higgins Solutions Manual Full Chapter PDFDocument22 pagesAnalysis For Financial Management 11th Edition Higgins Solutions Manual Full Chapter PDFleightonayarza100% (14)

- Archimedes Screw Generator Working Model - Final Year B.Tech ProjectDocument18 pagesArchimedes Screw Generator Working Model - Final Year B.Tech Projectiota0% (1)

- Spill Plane DirectionsDocument3 pagesSpill Plane DirectionsTom SturnerNo ratings yet

- ButterflyDocument4 pagesButterflyJim100% (3)

- Popular Mechanics Encyclopedia 06 PDFDocument260 pagesPopular Mechanics Encyclopedia 06 PDFeuqehtb100% (1)

- 1901 PackardDocument8 pages1901 PackardZosmo Simiao CostaNo ratings yet

- Adeventure Theme ParkDocument1 pageAdeventure Theme ParkMeghana NavuluruNo ratings yet

- Simple Machine-Wps OfficeDocument4 pagesSimple Machine-Wps OfficeJordan RamosNo ratings yet

- Wattle and DaubDocument6 pagesWattle and DaubdolphinNo ratings yet

- Shaker Table Plans From WWW Jgokey ComDocument6 pagesShaker Table Plans From WWW Jgokey Comearthplight67% (3)

- Steam Engine PlansDocument20 pagesSteam Engine Planstszabi26100% (2)

- Small Logging EquipmentDocument8 pagesSmall Logging EquipmentAndre VorsterNo ratings yet

- 1 SmitBorad - UG191352 - 10PGDocument10 pages1 SmitBorad - UG191352 - 10PGAI AINo ratings yet

- IHC S70 & S90: Hydro Hammer No. 42127, No. 42128 and Power Pack No. 42129Document2 pagesIHC S70 & S90: Hydro Hammer No. 42127, No. 42128 and Power Pack No. 42129gobyshomeNo ratings yet

- Dave Nelson On Edward Leedskalnin (13 Pages)Document55 pagesDave Nelson On Edward Leedskalnin (13 Pages)theherbsmithNo ratings yet

- Mechanics 4 Young America 1910Document129 pagesMechanics 4 Young America 1910filipe01976100% (1)

- Legacy San Jose-Manduao FMRDocument1 pageLegacy San Jose-Manduao FMRBandivz BandivzNo ratings yet

- Concreting of Road, Barangay Pal-Ew (Additional Allocation)Document1 pageConcreting of Road, Barangay Pal-Ew (Additional Allocation)Bandivz BandivzNo ratings yet

- Legacy San Jose-Manduao FMRDocument1 pageLegacy San Jose-Manduao FMRBandivz BandivzNo ratings yet

- Concreting of Road, Barangay Sta. Cruz Nuevo: Republic of The Philippines Province of Negros Oriental City of TanjayDocument1 pageConcreting of Road, Barangay Sta. Cruz Nuevo: Republic of The Philippines Province of Negros Oriental City of TanjayBandivz BandivzNo ratings yet

- 02 - Veif - 2019 - Updates - On - The - CNP - Interconnection - NGCP PDFDocument10 pages02 - Veif - 2019 - Updates - On - The - CNP - Interconnection - NGCP PDFBandivz BandivzNo ratings yet

- 19-20academic Small SundayDocument214 pages19-20academic Small SundayJohn Ray Esmama CalasicasNo ratings yet

- 12.5 Natural Ground PDFDocument1 page12.5 Natural Ground PDFBandivz BandivzNo ratings yet

- D-5 STD - RCBC-5 PDFDocument1 pageD-5 STD - RCBC-5 PDFBandivz BandivzNo ratings yet

- D-5 STD - RCBC-5 PDFDocument1 pageD-5 STD - RCBC-5 PDFBandivz BandivzNo ratings yet

- Analysis 2009Document953 pagesAnalysis 2009Farhat Abbas DurraniNo ratings yet

- D-6 SPL RCBC-2-6 PDFDocument1 pageD-6 SPL RCBC-2-6 PDFBandivz BandivzNo ratings yet

- D-6 SPL RCBC-2-6 PDFDocument1 pageD-6 SPL RCBC-2-6 PDFBandivz BandivzNo ratings yet

- D-4 Std. Det - of RCBC WW and Ext-4 PDFDocument1 pageD-4 Std. Det - of RCBC WW and Ext-4 PDFBandivz BandivzNo ratings yet

- D-4 Std. Det - of RCBC WW and Ext-4 PDFDocument1 pageD-4 Std. Det - of RCBC WW and Ext-4 PDFBandivz BandivzNo ratings yet

- ABC Press Release and AllocationDocument28 pagesABC Press Release and AllocationAndrew Finn KlauberNo ratings yet

- Supg NS 2DDocument15 pagesSupg NS 2DruNo ratings yet

- Module 1-Grade 9Document19 pagesModule 1-Grade 9Charity NavarroNo ratings yet

- Art & Science: Meeting The Needs of Patients' Families in Intensive Care UnitsDocument8 pagesArt & Science: Meeting The Needs of Patients' Families in Intensive Care UnitsRiaNo ratings yet

- Lac CultureDocument7 pagesLac CultureDhruboNo ratings yet

- Technical Seminar Report CV94Document62 pagesTechnical Seminar Report CV941MS19CV053 KARTHIK B SNo ratings yet

- Define-Phase Yellow BeltDocument52 pagesDefine-Phase Yellow BeltBhadri NarayananNo ratings yet

- Literature Review 1Document7 pagesLiterature Review 1api-609504422No ratings yet

- Getting You To Test Day: An 8-Week Prep Plan For The TOEFL TestDocument2 pagesGetting You To Test Day: An 8-Week Prep Plan For The TOEFL Testsmith90No ratings yet

- Certipur Certified Reference Material: Sodium Standard Solution 1000 MG/L NaDocument1 pageCertipur Certified Reference Material: Sodium Standard Solution 1000 MG/L NaJuan BenitezNo ratings yet

- Thermal Stress AnalysisDocument11 pagesThermal Stress AnalysisFahad KhanNo ratings yet

- Action Research MethodDocument27 pagesAction Research MethodNiño Czar RaroNo ratings yet

- APTET 2014 Social Question Paper II With Solutions PDFDocument47 pagesAPTET 2014 Social Question Paper II With Solutions PDFgayathriNo ratings yet

- EER Model: Enhance Entity Relationship ModelDocument12 pagesEER Model: Enhance Entity Relationship ModelHaroon KhalidNo ratings yet

- 2020-21 Series Test 1 QPDocument1 page2020-21 Series Test 1 QPred18ggmuNo ratings yet

- Indian Standard: Methods of Test For Aggregates For ConcreteDocument22 pagesIndian Standard: Methods of Test For Aggregates For ConcreteAnuradhaPatraNo ratings yet

- 12auxiliary ViewsDocument22 pages12auxiliary Viewsmanishjangid9869No ratings yet

- Intermolecular Force Worksheet KeyDocument3 pagesIntermolecular Force Worksheet KeyBill alfonsoNo ratings yet

- ITP FORMAT - PSV Modified FormateDocument1 pageITP FORMAT - PSV Modified Formatemurthy challapalliNo ratings yet

- Tcexam Result 3174 419 20111208Document8 pagesTcexam Result 3174 419 20111208goldenkumarNo ratings yet

- AWS Lecture NotesDocument4 pagesAWS Lecture NotesAsad Bin Ala Qatari0% (1)

- Deep Face Lab PDFDocument29 pagesDeep Face Lab PDFHenry MorenoNo ratings yet

- Experiment 13 Ultrafiltration UnitDocument13 pagesExperiment 13 Ultrafiltration UnitKishen NaniNo ratings yet

- 2 Mathematics For Social Science-1-1Document58 pages2 Mathematics For Social Science-1-1ሀበሻ EntertainmentNo ratings yet

- Collaboration Proposal FormDocument4 pagesCollaboration Proposal FormGabriel TecuceanuNo ratings yet

- Gujarat Technological UniversityDocument2 pagesGujarat Technological UniversityShruti BiradarNo ratings yet

- Vocabulary Placement TestDocument3 pagesVocabulary Placement TestMonica Vergara MejiaNo ratings yet

- Ee - Lab ReportDocument36 pagesEe - Lab ReportNoshaba Noreen75% (4)

- Teaching Profession Activities On Modules 1 2Document9 pagesTeaching Profession Activities On Modules 1 2Ana Lea AlmazanNo ratings yet

- Nursery Car Seat Supplement 2023Document40 pagesNursery Car Seat Supplement 2023doniNo ratings yet

- Crazy for the Storm: A Memoir of SurvivalFrom EverandCrazy for the Storm: A Memoir of SurvivalRating: 3.5 out of 5 stars3.5/5 (217)

- Welcome to the Goddamn Ice Cube: Chasing Fear and Finding Home in the Great White NorthFrom EverandWelcome to the Goddamn Ice Cube: Chasing Fear and Finding Home in the Great White NorthRating: 4 out of 5 stars4/5 (59)

- The Gentle Art of Swedish Death Cleaning: How to Free Yourself and Your Family from a Lifetime of ClutterFrom EverandThe Gentle Art of Swedish Death Cleaning: How to Free Yourself and Your Family from a Lifetime of ClutterRating: 4 out of 5 stars4/5 (467)

- Merle's Door: Lessons from a Freethinking DogFrom EverandMerle's Door: Lessons from a Freethinking DogRating: 4 out of 5 stars4/5 (326)

- Clean Mama's Guide to a Healthy Home: The Simple, Room-by-Room Plan for a Natural HomeFrom EverandClean Mama's Guide to a Healthy Home: The Simple, Room-by-Room Plan for a Natural HomeRating: 5 out of 5 stars5/5 (2)

- The Last of His Kind: The Life and Adventures of Bradford Washburn, America's Boldest MountaineerFrom EverandThe Last of His Kind: The Life and Adventures of Bradford Washburn, America's Boldest MountaineerRating: 4 out of 5 stars4/5 (23)

- The Buy Nothing, Get Everything Plan: Discover the Joy of Spending Less, Sharing More, and Living GenerouslyFrom EverandThe Buy Nothing, Get Everything Plan: Discover the Joy of Spending Less, Sharing More, and Living GenerouslyRating: 4 out of 5 stars4/5 (40)

- How to Keep House While Drowning: A Gentle Approach to Cleaning and OrganizingFrom EverandHow to Keep House While Drowning: A Gentle Approach to Cleaning and OrganizingRating: 4.5 out of 5 stars4.5/5 (847)

- The Last Dive: A Father and Son's Fatal Descent into the Ocean's DepthsFrom EverandThe Last Dive: A Father and Son's Fatal Descent into the Ocean's DepthsNo ratings yet

- Success at Home with ADHD.: Practical Organization Strategies to Make Your Life Easier.From EverandSuccess at Home with ADHD.: Practical Organization Strategies to Make Your Life Easier.Rating: 4 out of 5 stars4/5 (17)

- Summary of Goodbye, Things: The New Japanese Minimalism by Fumio SasakiFrom EverandSummary of Goodbye, Things: The New Japanese Minimalism by Fumio SasakiRating: 4.5 out of 5 stars4.5/5 (5)

- Survive!: Essential Skills and Tactics to Get You Out of Anywhere—AliveFrom EverandSurvive!: Essential Skills and Tactics to Get You Out of Anywhere—AliveNo ratings yet

- The Life-Changing Magic of Tidying Up: The Japanese Art of Decluttering and OrganizingFrom EverandThe Life-Changing Magic of Tidying Up: The Japanese Art of Decluttering and OrganizingRating: 4 out of 5 stars4/5 (2997)

- The Martha Manual: How to Do (Almost) EverythingFrom EverandThe Martha Manual: How to Do (Almost) EverythingRating: 4 out of 5 stars4/5 (11)

- The Art of Resilience: Strategies for an Unbreakable Mind and BodyFrom EverandThe Art of Resilience: Strategies for an Unbreakable Mind and BodyRating: 4.5 out of 5 stars4.5/5 (118)

- Divided: A Walk on the Continental Divide TrailFrom EverandDivided: A Walk on the Continental Divide TrailRating: 4 out of 5 stars4/5 (17)

- Decluttering at the Speed of Life: Winning Your Never-Ending Battle with StuffFrom EverandDecluttering at the Speed of Life: Winning Your Never-Ending Battle with StuffRating: 4.5 out of 5 stars4.5/5 (578)

- Carpentry Made Easy - The Science and Art of Framing - With Specific Instructions for Building Balloon Frames, Barn Frames, Mill Frames, Warehouses, Church SpiresFrom EverandCarpentry Made Easy - The Science and Art of Framing - With Specific Instructions for Building Balloon Frames, Barn Frames, Mill Frames, Warehouses, Church SpiresRating: 1 out of 5 stars1/5 (2)

- The Joy of Less: A Minimalist Guide to Declutter, Organize, and SimplifyFrom EverandThe Joy of Less: A Minimalist Guide to Declutter, Organize, and SimplifyRating: 4 out of 5 stars4/5 (277)

- Martha Stewart's Organizing: The Manual for Bringing Order to Your Life, Home & RoutinesFrom EverandMartha Stewart's Organizing: The Manual for Bringing Order to Your Life, Home & RoutinesRating: 4 out of 5 stars4/5 (11)

- Organizing for the Rest of Us: 100 Realistic Strategies to Keep Any House Under ControlFrom EverandOrganizing for the Rest of Us: 100 Realistic Strategies to Keep Any House Under ControlRating: 4.5 out of 5 stars4.5/5 (204)

- 438 Days: An Extraordinary True Story of Survival at SeaFrom Everand438 Days: An Extraordinary True Story of Survival at SeaRating: 4.5 out of 5 stars4.5/5 (188)