Professional Documents

Culture Documents

Icf MD Spec-167a Rev-02 PDF

Icf MD Spec-167a Rev-02 PDF

Uploaded by

Universal Laboratory0 ratings0% found this document useful (0 votes)

413 views6 pagesOriginal Title

ICF MD SPEC-167A REV-02.pdf

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

413 views6 pagesIcf MD Spec-167a Rev-02 PDF

Icf MD Spec-167a Rev-02 PDF

Uploaded by

Universal LaboratoryCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 6

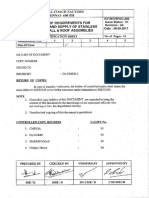

FACT ', CHENNAL-38

INTEGRAL COACH FACTORY, Ci ICRIMDISPEC.-167A

‘SCHEDULE OF REQUIREMENTS FOR FRP PANEL —_| 1gSUE STATUS : 01

(USING POLYSTER RESIN) USED IN RAILWAY REV. No: 02

PASSENGER COACHES DATE : 07-09-2006

IDENTIFICATION SHEET ‘No.OF PAGES: 5

‘NATURE OF DOCUMENT

COPY NUMBER

ISSUEDTO

ISSUED BY : DY.CME/DESIGN.

RETURN OF COPIES

In case of transfer / retirement, the holder of controlled copies shall return the same either

to SSE/D/MS or to his/her successor under intimation to SSE/D/MS.

NOTE

1. Controlled copy holders of this DOCUMENT are expected to bring the

content of this document to the knowledge of the concerned officials who

are working in his / her department /section.

2. Unauthorised copying of this document is prohibited

Prepared, verified and approved Page Nos. 5 of 5.

CONTROLLED COPY HOLDERS C.COPY No.

1. CME/QA OL

2. Dy.CC&M 02

3. AME/MPO/Fur : 03,

4, Design Library 04

CONTROLLED BY | PREPARED BY VERIFIED BY | APPROVED BY

eps bho

SSE/D/MS SME /DSS DY.CME / DESIGN CDE/MECH

SCHEDULE OF REQUIREMENTS FOR FRP PANELS (USING POLYSTER

10

1d

20

24

RESIN) USED IN RAILWAY PASSENGER COACHES,

ICF/MD/SPEC-167A

Issue status: O1

Rev.02

Page 1 of 5

SCOPE: This specification is divided into two sections.

Section A establishes the requirements of material, testing and performance for

Fibre Glass Reinforced Plastic (FRP) panels used in Railway passenger coaches.

Section B establishes the technical and other requirements of firms which make

Fibreglass Reinforced Plastic (FRP) panels used in Railway passenger coaches.

i

SEC’

A

REFERENCE:

avaene

IS: 1998

ASTM D 792

ASTM D 2583

ASTM D-570

UIC 564-2 Appendix 4,15

NCD 1409

DESCRIPTION OF MATERIAL:

i)

iii)

iv)

‘The material shall be composed of thermosetting polyester isopthalic resin

with suitable isopthalic gel coat and E-glass stitched chopped strand mat

(CSM) and stitched mat / woven roving combination or E-glass continuous

filament mat-compatible with the polyester isopthalic resin system.

The thickness of the finished FRP panel shall not be less than 3mm. In

addition the thickness of polyester compatible gel coat (with FR

properties) should be 0.4 to 0.5 mm. The colour of the base panel shall be

to RAL shade No. 9018 (papyrus white), with “Distant blue” granules to

the RAL shade No. 5023.The density shall be 75 to 110 spots per square

‘inch.

‘The exterior surface of the FRP finished product shall be semi gloss. Gloss

value shall be between 21 to 50 measured at 60°.

Approved sample for colour and surface finish can be seen with design

office for guidance and reference purpose only.

RESIN SYSTEM:

a)

‘The resin shall be Fire retardant grade isopthalic acid based Polyester

resin, No filler shall be used. Necessary additive may be used for obtaining

fire retardant property inthe resin system.

‘The isopthalic FR resin shall be procured from a reputed manufacturer in

sealed containers along with the test certificates. Traceability of resin

should be demonstrated if called for by ICF.

SCHEDULE OF REQUIREMENTS FOR FRP PANELS (USING POLYSTER

RESIN) USED IN RAILWAY PASSENGER COACHES

ICE/MD/SPEC-I67A

Issue status: O1

Rev.02

Page 2 of 5

b) The manufacturer should provide details of the catalyst used along with

the FR resin and as called for by ICF and demonstrate the test there of.

3.0 TYPE ACCEPTANCE:

34 PROPERTIES OF LAMINATE TO BE TESTED FOR TYPE TEST:

‘The RRP laminate shall have the properties mentioned in the TABLE 1 below:

: TABLE 1

# | CHARACTERISTICS [REQUIREMENT | STANDARD

T | Resistance to spread of | Class B IS:6746 UIC 564-2 Appendix 4

flame

2 | Toxicity 1.00 MAX NCD 1409

3_| Smoke index Class B UIC 564-2 Appendix 15

4 | Tensile strength ‘80 MPa TS 1998-62

5_| Cross breaking strength | 120 MPa 1S 1998-62

6 | Water absorption (0.5 % (MAX) ‘ASTM D-570 , 24 hours

7_| Specific Gravity. 14-15 ASTM D-792

3 | Fibre glass content| 28% min. to be| IS: 13411 Annexure-A

(nin) evaluated after

removing 0.5 top layer.

D | Resistance to stains for [Should not show any | 1S: 2046-95

a) Acetone ° | visible changes on

|__b) Black Tea surface. _|

T0| Total ash content | 10 % max. =

(excluding fibre glass ) 7

3.2 The first time supplier shall type test the FRP panels in the presence of ICF

representatives as per clause3.1 above. Wherever the facilities for testing the

above characteristics such as Toxicity and Smoke Index are not available with the

firms the same shall be tested at an ICF approved Lab. The test results for

Toxicity and Smoke Index shall be submitted by the firm after testing at ICF

approved Labs once in a year or during quality audits.

40 INSPECTION CRITERIA FOR ACCEPTANCE OF THE FINISHED PRODUCT

AT ICF /FIRM’S PREMISES:

4.1 The manufacturer shall supply three advance laminates to size 600 mm x 600 mm.

x3.5 mm thickness for testing at ICF for every purchase order..

‘The following tests shall be carried out at ICF for every purchase order.

SCHEDULE OF REQUIREMENTS FOR FRP PANELS (USING POLYSTER

RESIN) USED IN RAILWAY PASSENGER COACHES

ICE/MD/SPEC-167A,

Issue status: OF

Rev.02

Page 3 of S

42 VISUAL:

42.1. The color and surface finish shall be visually inspected on 20 % of the lot subject

to a minimum of two numbers. All the samples must pass the test for the lot to be

accepted

42.2 The dimensions shall be checked on 50% of the lot cleared in 4.2.1 subject to a

rinjium of two numbers. All the samples checked for dimensions shall pass.

43 DESTRUCTIVE TESTING:

43.1 Specimens shall be cut from the advance samples for destructive testing at ICF as

per sl. No. 4 to 8 of clause 3.1

44 — Stage inspection and final inspection will be carried out by RITES/any other

ICF nominated agency at Firms premises

50 PACKING CONDITIONS:

‘The product must be supplied in an eco-friendly packing material.

60 MARKING: The manufacturer’s logo shall be embossed on the reverse side of

the items. The batch number, identification number for traceability and date of

manufacture shall be made available on each and every item.

SECTION B

7.0 SCOPE:

7.1 This specification covers the technical and other requirements of the firm for

manufacture and supply of fibre glass reinforced plastic (FRP) panels using

‘Vacuum Assisted RTM / Resin infusion (using Vacuum bag) process to obtain the

required mechanical and fire retardant properties.

7.2 Allvendors seeking approval with Integral Coach Factory to supply fibre glass

reinforced plastic (FRP) panels shall fulfill the requirements as given below

8.0 MANUFACTURING FACILITIES:

81 PLANT & MACHINERY

8.1.1 The firm shall have requisite machinery for Vacuum Assisted RTM process /

Resin infusion (using vacuum Bag) process. The RTM machine shall be of either

auto internal /external resin and catalyst mixing type with builtin provisions of

high pressure system for injection head, roller, spray gun and auto vent system

with solvent pump for flushing.

SCHEDULE OF REQUIREMENTS FOR FRP PANELS (USING POLYSTER

RESIN) USED IN RAILWAY PASSENGER COACHES

ICF/MD/SPEC-167A,

Issue status: O1

Rev.02

Page 4 of 5

8.1.2 PATTERNS AND MOULDS:

‘The firm should have adequate quality moulds to keep up the supply

requirements.

8.2 DEMONSTRATION OF PROCESS CAPABILITY:

£

82.1. The firm should demonstrate its process capability by producing one prototype

sample ofthe FRP panel successfully using Process as specified in the presence of

ICE representative or their nominated inspection agency. The sample will be

subjected to all type tests as specified in clause 3.1. Wherever the facilities for

testing the characteristics such as toxicity and smoke index are not available with

the firm, the same should be done at ICF approved labs and submit the test results

to ICF.

9.0 TESTING FACILITY:

‘The firm must have in-house facility as mentioned below:

Stop watch

Beakers

‘Thermometer

‘Apparatus for conducting flammability test.

Ford Cup for measuring viscosity. Firms can also have a Brooke Field viscometer

Electronic weighing balance with least count of 0.00018

1 Ton UTM for testing tensile /cross breaking strength.

Rovere

10.0 COVERED AREA:

‘The firm should have adequate covered area for working and storage of raw

‘material and work-in- progress

11.0 QUALIFIED PERSONNEL:

Skilled artisans, supervisor, with specialized qualification in the manufacture of

FRP products shall be available with the firm.

12.0 QUALITY ASSURANCE:

12.1 The firm must prepare a documented procedure for the manufacture of the FRP

item. The procedure must contain information regarding:-

> the properties of the resin used,

> the type of fibre glass used and the properties of the same,

> the tools used in the preparation of the laminate,

SCHEDULE OF REQUIREMENTS FOR FRP PANELS (USING POLYSTER

RESIN) USED IN RAILWAY PASSENGER COACHES

ICF/MD/SPEC-167A

Tesue status: OF

Rev.02

Page 5 of §

> additives added to the resin,

> the various stages of tests done on the raw material, work in progress and finished

product , and

> any other relevant information .

12.2 The firm shall have a system for traceability of the isothalic FR resin. Bach drum

of the resin should be traced to a finished product. Similarly each finished product

shall be traced back to the drum of resin from which it was manufactured.

123 180: The firm shall have ISO 9000 -2000 series certificate.

13.0 REGISTRATION & LICENCES:

13.1. FACTORY LICENCE: The firm must have a factory license,

13.2 SALES TAX: Tax Payer’s index number

You might also like

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- AS NZS 2885.3-2001 Pipelines - Gas and Liquid Petroleum - Operat PDFDocument75 pagesAS NZS 2885.3-2001 Pipelines - Gas and Liquid Petroleum - Operat PDFUniversal LaboratoryNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- B49 15 PDFDocument8 pagesB49 15 PDFUniversal LaboratoryNo ratings yet

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5810)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- MDTS 46303Document12 pagesMDTS 46303Universal Laboratory100% (1)

- Icf MD Spec 200 Rev 04 PDFDocument20 pagesIcf MD Spec 200 Rev 04 PDFUniversal LaboratoryNo ratings yet

- Icf MD Spec-167a Amd.01 PDFDocument1 pageIcf MD Spec-167a Amd.01 PDFUniversal LaboratoryNo ratings yet

- Coating Thickness Meter PDFDocument6 pagesCoating Thickness Meter PDFUniversal LaboratoryNo ratings yet