Professional Documents

Culture Documents

Mod. Upb/Ev Mod. Upba/Ev: Biodiesel Production Pilot Plant

Uploaded by

Riccardo VianelloOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Mod. Upb/Ev Mod. Upba/Ev: Biodiesel Production Pilot Plant

Uploaded by

Riccardo VianelloCopyright:

Available Formats

BIODIESEL PRODUCTION PILOT PLANT

Mod. UPB/EV

Mod. UPBa/EV automated

RE

INTRODUCTION

Biodiesel is a liquid fuel obtained by transesterification from

renewable raw materials such as, for instance, vegetable oils

or animal fats. If compared to fossil fuels, this type of fuel offers

a lot of advantages:

• Very low content of sulphur (< 0.001%) that provokes the

phenomenon of acid rains

• Reduction of dust emissions down to 50%

• Absence of benzene and of other carcinogenic components

• As it has a high flash point, it is not classified as dangerous

CHEMICAL ENGINEERING

material, consequently it can be handled easily and safely

• High biodegradation (in case of dispersion it does not pollute)

• High lubricating power (it reduces the wear of engines)

• It develops a closed loop of CO2 (the quantity of CO2 released

by its combustion is equal to that absorbed by plants from

the air during their growing process).

This unit is mainly equipped with a multi-function reactor that

enables to carry out all the typical operations of biodiesel

production: esterification, transesterification, washing and

restoring of methanol. • Supervision software for Windows: it enables to control ON-

OFF signals, analog signals coming from PID controller, real-

TRAINING PROGRAM time trend and historical trend

This unit enables to deepen Power supply: 230 Vac 50 Hz single-phase - 2 kVA

the following issues: (Other voltage and frequency on request)

• Transesterification of a vegetable oil Dimensions: 1300 × 700 × 1900 mm

• Separation of glycerine Weight: 180 kg

• Washing of biodiesel

• Restoring methanol

REQUIRED

TECHNICAL SPECIFICATIONS: UTILITIES (PROVIDED BY THE CUSTOMER)

• Tap water (valve with ½” hose connector)

• Framework of AISI 304 stainless steel with castors

• Water drain

• Multi-function reactor of borosilicate glass and AISI 304

• Compressed air (valve with connection of ¼” F)

stainless steel, with capacity of 18 litres, equipped with

motor-driven stirrer and condenser ACCESSORIES (NOT INCLUDED)

• Heating system by electric heaters, provided with thermostat • Personal Computer running Windows (for mod. UPBa only)

• Tank of borosilicate glass and AISI 304 stainless steel for

reagent/catalyst, including stirring system SUPPLIED WITH

• 2 restoring tanks of borosilicate glass

THEORETICAL – EXPERIMENTAL

• Switchboard IP55, complying with EC conformity mark, HANDBOOK

including plant synoptic and ELCB

OPTIONAL

24B-E-RE-UPB-1

Mod. UPBa/EV • Screw press for extracting oil from seeds mod. VIT/EV

Besides being provided with all the characteristics of mod.

UPB/EV, this model also includes the following additional items: VARIATIONS OF THE PLANT ON REQUEST

• Microprocessor digital PID controller with serial card The equipment can be modified on request of the Customer.

RE 17 ELETTRONICA VENETA S.P.A. - 31045 Motta di Livenza (TV) Italy - Via Postumia 16 - Tel. +39 0422 765 802 - Fax +39 0422 861 901 - E-mail: export@elettronicaveneta.com

You might also like

- How Industrial Businesses Can Reduce Production Costs With Reverse Osmosis: Industrial Reverse OsmosisFrom EverandHow Industrial Businesses Can Reduce Production Costs With Reverse Osmosis: Industrial Reverse OsmosisRating: 5 out of 5 stars5/5 (1)

- Mod. REC1/EV Mod. REC1c/EV Mod. REC1a/EV: Continuous Reaction (CSTR) Pilot PlantDocument2 pagesMod. REC1/EV Mod. REC1c/EV Mod. REC1a/EV: Continuous Reaction (CSTR) Pilot Plantcgjp120391No ratings yet

- Mod. Ume/Ev Mod. Umec/Ev Mod. Umea/Ev: Single-Effect Evaporation Pilot PlantDocument2 pagesMod. Ume/Ev Mod. Umec/Ev Mod. Umea/Ev: Single-Effect Evaporation Pilot PlantRiccardo VianelloNo ratings yet

- Mod. Fse/Ev Mod. Fsea/Ev: Coagulation, Flocculation and Settling Pilot PlantDocument4 pagesMod. Fse/Ev Mod. Fsea/Ev: Coagulation, Flocculation and Settling Pilot Plantessam essNo ratings yet

- Mod. Udc/Ev Mod. Udcc/Ev Mod. Udca/Ev: Pilot PlantDocument2 pagesMod. Udc/Ev Mod. Udcc/Ev Mod. Udca/Ev: Pilot PlantdiegoNo ratings yet

- Spesifikasi Steelco Steam Sterilizer VS4-2Document1 pageSpesifikasi Steelco Steam Sterilizer VS4-2Rico AnandaNo ratings yet

- SCS Series: Industrial FiltrationDocument4 pagesSCS Series: Industrial FiltrationJamin SmtpngNo ratings yet

- As D Cut Sheet ML IND0011 RevCDocument2 pagesAs D Cut Sheet ML IND0011 RevCmeloszNo ratings yet

- FS1292ENDocument2 pagesFS1292ENFranco YnquillaNo ratings yet

- GEA Ariete Homogenizer 5315: Homogenizer & High Pressure Pump Technical DatasheetDocument2 pagesGEA Ariete Homogenizer 5315: Homogenizer & High Pressure Pump Technical DatasheetJorge A. TorresNo ratings yet

- Ebara Monoblock Centrifugal Pump - Close Coupled - 3D SeriesDocument66 pagesEbara Monoblock Centrifugal Pump - Close Coupled - 3D SeriesYudha Trias RusmanaNo ratings yet

- AirSep As-Q DatasheetDocument2 pagesAirSep As-Q Datasheetdj22500No ratings yet

- PK1024-MKF-MDB060-365097 01Document9 pagesPK1024-MKF-MDB060-365097 01waqas_a_shaikh4348No ratings yet

- AS-E Cut-Sheet ML-IND0012 Rev DDocument2 pagesAS-E Cut-Sheet ML-IND0012 Rev Dinstrumed_globalNo ratings yet

- Tetra Pak Homogenizer 30G: Homogenizer or High-Pressure Pump For Liquid Food ApplicationsDocument2 pagesTetra Pak Homogenizer 30G: Homogenizer or High-Pressure Pump For Liquid Food ApplicationsThinura SamarawickramaNo ratings yet

- M 110yDocument2 pagesM 110yjawadNo ratings yet

- Gea Ariete Homogenizer 5400 High Pressure Homogenizer Pump Technical Data - tcm25 38679 PDFDocument2 pagesGea Ariete Homogenizer 5400 High Pressure Homogenizer Pump Technical Data - tcm25 38679 PDFJorge A. TorresNo ratings yet

- AirSep As-W DatasheetDocument2 pagesAirSep As-W Datasheetdj22500No ratings yet

- Prime 2 2 0 e K W 2 7 5 K V A 50 HZ 1500 RPM 400 Volts: Diesel Generator SetDocument6 pagesPrime 2 2 0 e K W 2 7 5 K V A 50 HZ 1500 RPM 400 Volts: Diesel Generator Setvanaselvan vpNo ratings yet

- AirSep As-Z DatasheetDocument2 pagesAirSep As-Z Datasheetdj22500No ratings yet

- Standby 4 8 0 e K W 6 0 0 K V A 50 HZ 1500 RPM 400 Volts: Diesel Generator SetDocument6 pagesStandby 4 8 0 e K W 6 0 0 K V A 50 HZ 1500 RPM 400 Volts: Diesel Generator SetRainier AyapNo ratings yet

- Broad PumpsetDocument12 pagesBroad PumpsetJulian Yepes MartinezNo ratings yet

- As G Cut Sheet ML IND0013 Rev.DDocument2 pagesAs G Cut Sheet ML IND0013 Rev.DmeloszNo ratings yet

- ZL 440 Product Data SheetDocument3 pagesZL 440 Product Data SheetVishal ChudasamaNo ratings yet

- 08-Chemical Dosing EquipmentDocument48 pages08-Chemical Dosing Equipmentagung ramdhaniNo ratings yet

- AS-J Cut-Sheet ML-IND0014 Rev.dDocument2 pagesAS-J Cut-Sheet ML-IND0014 Rev.dinstrumed_globalNo ratings yet

- Brew-250Document4 pagesBrew-250Eray YILMAZNo ratings yet

- Chiller o Enfriador Parker Hiross Bulice-03-EnDocument4 pagesChiller o Enfriador Parker Hiross Bulice-03-EnDaniel MarNo ratings yet

- 3D 32-160 PDFDocument4 pages3D 32-160 PDFنبيل عبد المجيدNo ratings yet

- 3D 32-160 PDFDocument4 pages3D 32-160 PDFنبيل عبد المجيدNo ratings yet

- 3D 32-160 PDFDocument4 pages3D 32-160 PDFنبيل عبد المجيدNo ratings yet

- 3D Series: Centrifugal Pumps Close Coupled and Standardized en 733Document4 pages3D Series: Centrifugal Pumps Close Coupled and Standardized en 733نبيل عبد المجيدNo ratings yet

- 3D 32-160 PDFDocument4 pages3D 32-160 PDFنبيل عبد المجيدNo ratings yet

- Biofuel Vacuum PumpDocument4 pagesBiofuel Vacuum Pumpkla_alkNo ratings yet

- AirSep As-R DatasheetDocument2 pagesAirSep As-R Datasheetdj22500No ratings yet

- Brochure Gieffe Systems 01 2018 UKDocument16 pagesBrochure Gieffe Systems 01 2018 UKJosé Mauricio Bonilla TobónNo ratings yet

- Econet Heat Recovery SlidesDocument82 pagesEconet Heat Recovery Slidesbusterwong9958No ratings yet

- Blenders MRCDocument48 pagesBlenders MRCjmatallanaNo ratings yet

- BAUDOUIN 825-1100 kVA: Technical SpecificationsDocument2 pagesBAUDOUIN 825-1100 kVA: Technical SpecificationsabdiNo ratings yet

- Ficha TecnicaDocument4 pagesFicha TecnicaRodrigo LeónNo ratings yet

- Ashirwad Carbonics (India) Private Limited: Co2 Recovery Plant Technical LiteratureDocument5 pagesAshirwad Carbonics (India) Private Limited: Co2 Recovery Plant Technical LiteratureRaul BautistaNo ratings yet

- Thermal Fluid Heaters TPC B Babcock WansonDocument2 pagesThermal Fluid Heaters TPC B Babcock Wansonjuliancardona0% (1)

- Evaporation Bath: Manual and Semi-Automatic Analysers: Gum - RubberDocument1 pageEvaporation Bath: Manual and Semi-Automatic Analysers: Gum - RubberJorge EpbNo ratings yet

- Optimum Brochure 1Document2 pagesOptimum Brochure 1Ahmed Al-OsoulyNo ratings yet

- Standby 400 Ekw 500 Kva: Diesel Generator SetDocument6 pagesStandby 400 Ekw 500 Kva: Diesel Generator Setvbazan5299No ratings yet

- AirSep As-N DatasheetDocument2 pagesAirSep As-N Datasheetdj22500No ratings yet

- PresentationDocument36 pagesPresentationapi-3834081100% (1)

- Mod. Uou/Ev Mod. Uouc/Ev: Reverse Osmosis and Ultrafiltration Pilot PlantDocument1 pageMod. Uou/Ev Mod. Uouc/Ev: Reverse Osmosis and Ultrafiltration Pilot PlantRiccardo VianelloNo ratings yet

- Barnstead EASYpure IIDocument2 pagesBarnstead EASYpure IITako JankhoteliNo ratings yet

- CDX PDFDocument5 pagesCDX PDFThanhnam PhanNo ratings yet

- Mine Air Systems No Idle System BrochureDocument2 pagesMine Air Systems No Idle System Brochureelia nugraha adiNo ratings yet

- HDCV5100 CatlaogueDocument4 pagesHDCV5100 CatlaoguealeksandrNo ratings yet

- Column Pumps - LowaraDocument100 pagesColumn Pumps - LowarayutNo ratings yet

- Quotation # 3526 BIOPure - CO2 Extraction SystemDocument13 pagesQuotation # 3526 BIOPure - CO2 Extraction SystemMichael MacDonaldNo ratings yet

- Water Softeners Residential Cabinet Softeners Canadian ENGLISH BrochureDocument6 pagesWater Softeners Residential Cabinet Softeners Canadian ENGLISH BrochurePromagEnviro.comNo ratings yet

- Prime 292 Ekw 365 Kva: Diesel Generator SetDocument6 pagesPrime 292 Ekw 365 Kva: Diesel Generator Setvanaselvan vpNo ratings yet

- Ebara Gs DatasheetDocument132 pagesEbara Gs DatasheetWalter PerezNo ratings yet

- Ebara 3DDocument62 pagesEbara 3Dkikokiko KarimNo ratings yet

- Milk Processing Technological Cycle - Tabletop UnitsDocument8 pagesMilk Processing Technological Cycle - Tabletop Unitslusoegyi 1919No ratings yet

- Ficha Técnica Agua PuraDocument1 pageFicha Técnica Agua Purasara kubikaNo ratings yet

- Ratio ControlDocument9 pagesRatio ControlRiccardo VianelloNo ratings yet

- HFT Food Technology 2015Document35 pagesHFT Food Technology 2015Riccardo VianelloNo ratings yet

- D2892 PDFDocument32 pagesD2892 PDFLuis Ernesto Marin JaimesNo ratings yet

- D2892 PDFDocument32 pagesD2892 PDFLuis Ernesto Marin JaimesNo ratings yet

- Exercise: Xercise BjectiveDocument12 pagesExercise: Xercise BjectiveMara Gizette SantosNo ratings yet

- Didacta - Catalogue 2016Document74 pagesDidacta - Catalogue 2016Riccardo VianelloNo ratings yet

- CE579 Spanish PDFDocument1 pageCE579 Spanish PDFRiccardo VianelloNo ratings yet

- Exercise: Xercise BjectiveDocument16 pagesExercise: Xercise BjectiveRiccardo VianelloNo ratings yet

- PID ModesTraining LabVoltDocument34 pagesPID ModesTraining LabVoltRiccardo VianelloNo ratings yet

- Feed ForwardDocument12 pagesFeed ForwardRiccardo VianelloNo ratings yet

- Cascade Control TutorialDocument12 pagesCascade Control Tutorialpleco4me100% (1)

- Mod. UTC-1/EV Mod. UTC-1c/EV Mod. UTC-1a/EV: Heat Transfer Pilot Plant With Plate and U-Tube Heat ExchangerDocument2 pagesMod. UTC-1/EV Mod. UTC-1c/EV Mod. UTC-1a/EV: Heat Transfer Pilot Plant With Plate and U-Tube Heat ExchangerRiccardo VianelloNo ratings yet

- Instrumentation and Process ControlDocument42 pagesInstrumentation and Process ControlRiccardo VianelloNo ratings yet

- D2892 PDFDocument32 pagesD2892 PDFLuis Ernesto Marin JaimesNo ratings yet

- 01 Script Hydrodynamic Layout PDFDocument0 pages01 Script Hydrodynamic Layout PDFMas Arman TewoNo ratings yet

- Studies On The Efficiency PDFDocument8 pagesStudies On The Efficiency PDFRiccardo VianelloNo ratings yet

- CE579 Spanish PDFDocument1 pageCE579 Spanish PDFRiccardo VianelloNo ratings yet

- Metallurgical Extractions - SL - LLDocument37 pagesMetallurgical Extractions - SL - LLRoger RumbuNo ratings yet

- 01 Script Hydrodynamic Layout PDFDocument0 pages01 Script Hydrodynamic Layout PDFMas Arman TewoNo ratings yet

- 05 Refractometer en LR 2016Document4 pages05 Refractometer en LR 2016Riccardo VianelloNo ratings yet

- Mod. Uou/Ev Mod. Uouc/Ev: Reverse Osmosis and Ultrafiltration Pilot PlantDocument1 pageMod. Uou/Ev Mod. Uouc/Ev: Reverse Osmosis and Ultrafiltration Pilot PlantRiccardo VianelloNo ratings yet

- Metallurgical Extractions - SL - LLDocument37 pagesMetallurgical Extractions - SL - LLRoger RumbuNo ratings yet

- Isomerization of Glucose To FructoseDocument4 pagesIsomerization of Glucose To FructoseOoi Ah GuanNo ratings yet

- Mod. ULL/EV Mod. ULL-1/EV: Extraction Pilot PlantDocument1 pageMod. ULL/EV Mod. ULL-1/EV: Extraction Pilot PlantRiccardo VianelloNo ratings yet

- Ams Amsac MF EngDocument68 pagesAms Amsac MF EngRiccardo VianelloNo ratings yet

- Instruction For Instalation and Commisioning Pressure TransmitterDocument24 pagesInstruction For Instalation and Commisioning Pressure TransmitterChristian VanderNo ratings yet

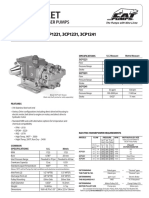

- Data Sheet: Direct-Drive Plunger PumpsDocument4 pagesData Sheet: Direct-Drive Plunger PumpsRiccardo VianelloNo ratings yet

- P P T S 21 Y: Iezoresistive Ressure Ransmitters EriesDocument2 pagesP P T S 21 Y: Iezoresistive Ressure Ransmitters EriesRiccardo VianelloNo ratings yet

- Results 2020: Climate Change Performance IndexDocument32 pagesResults 2020: Climate Change Performance IndexTonyNo ratings yet

- Ground Vehicle Operations ICAODocument31 pagesGround Vehicle Operations ICAOMohran HakimNo ratings yet

- PUP 200 Quizzes 6Document47 pagesPUP 200 Quizzes 6Nam TranNo ratings yet

- KP For RamDocument23 pagesKP For RamMonu NarwarNo ratings yet

- Xgenus X-Ray PDFDocument61 pagesXgenus X-Ray PDFAli NuriNo ratings yet

- Accommodating Expansion of Brickwork: Technical Notes 18ADocument13 pagesAccommodating Expansion of Brickwork: Technical Notes 18AWissam AlameddineNo ratings yet

- Fiitjee All India Test Series: Concept Recapitulation Test - Iv JEE (Advanced) - 2019Document13 pagesFiitjee All India Test Series: Concept Recapitulation Test - Iv JEE (Advanced) - 2019Raj KumarNo ratings yet

- SPECIFIC ENERGY, ENERGY DENSITY OF FUELS and PRIMARY ENERGY SOURCESDocument17 pagesSPECIFIC ENERGY, ENERGY DENSITY OF FUELS and PRIMARY ENERGY SOURCESPranavBalarajuNo ratings yet

- Generic StructureDocument6 pagesGeneric StructureAndre AlvarezNo ratings yet

- Building SpecificationsDocument222 pagesBuilding SpecificationsdinaquaNo ratings yet

- Cusps: Ramesh 04-Jun-1976 12:30:00 PM Krishnagiri 78:14:0 E, 12:32:0 N Tzone: 5.5 KP (Original) Ayanamsha 23:26:2Document1 pageCusps: Ramesh 04-Jun-1976 12:30:00 PM Krishnagiri 78:14:0 E, 12:32:0 N Tzone: 5.5 KP (Original) Ayanamsha 23:26:2Suresh NatarajanNo ratings yet

- Pepperl KFD2 STC4 EX1.20 DatasheetDocument2 pagesPepperl KFD2 STC4 EX1.20 DatasheetAhmed HusseinNo ratings yet

- 1991 - Defect Chemistry of BaTiO3Document20 pages1991 - Defect Chemistry of BaTiO3Beh NaatNo ratings yet

- 1506a E88tag3 PDFDocument5 pages1506a E88tag3 PDFmohammad javad golNo ratings yet

- Assignment 2 Grammar Lesson PlanDocument26 pagesAssignment 2 Grammar Lesson PlanKesia Kerspay100% (1)

- Si2304 (Mosfet Sot 23)Document6 pagesSi2304 (Mosfet Sot 23)Alfredo Valencia RodriguezNo ratings yet

- Wearable BiosensorsDocument16 pagesWearable BiosensorsShreehari Haridasan100% (1)

- SCM 2011 PDFDocument4 pagesSCM 2011 PDFAakash KumarNo ratings yet

- Anatomy & Physiology MCQsDocument26 pagesAnatomy & Physiology MCQsMuskan warisNo ratings yet

- Submission Letter To LBUDocument46 pagesSubmission Letter To LBUramesh bajracharyaNo ratings yet

- THE INDIAN NAVY - Artificer Apprentice & Senior Secondary Recruit PDFDocument3 pagesTHE INDIAN NAVY - Artificer Apprentice & Senior Secondary Recruit PDFUjjwalNo ratings yet

- AS400 RPG400 BasicsDocument148 pagesAS400 RPG400 Basicscharaviz84100% (1)

- COCCIMORPHDocument13 pagesCOCCIMORPHmiminNo ratings yet

- Delonghi Pinguino Water To Air Pac We125 Instruction Manual 715678Document21 pagesDelonghi Pinguino Water To Air Pac We125 Instruction Manual 715678Luis AlbertoAlmeidaSilva100% (1)

- MiningDocument3 pagesMiningDherick RaleighNo ratings yet

- Is There Any Way To Download The Whole Package of Asphalt 8 Airborne So That I Can Install It On Any Android Device Without An Internet Connection - QuoraDocument4 pagesIs There Any Way To Download The Whole Package of Asphalt 8 Airborne So That I Can Install It On Any Android Device Without An Internet Connection - QuoraMounir2105No ratings yet

- MLAB 3 - BoilerDocument3 pagesMLAB 3 - BoilerReden LopezNo ratings yet

- 93c3 Document 3Document14 pages93c3 Document 3NONON NICOLASNo ratings yet

- Week 8: Spread-Spectrum Modulation - Direct Sequence Spread SpectrumDocument79 pagesWeek 8: Spread-Spectrum Modulation - Direct Sequence Spread SpectrumAmir MustakimNo ratings yet