Professional Documents

Culture Documents

CE579 Spanish PDF

Uploaded by

Riccardo VianelloOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

CE579 Spanish PDF

Uploaded by

Riccardo VianelloCopyright:

Available Formats

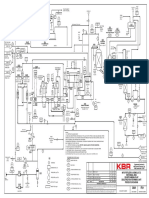

TRATAMIENTO DE AGUAS PROCESOS MECÁNICOS

CE 579 FILTRACIÓN DE LECHO PROFUNDO

El aparato óptimo para aprender y enseñar la filtración de lecho profundo

con una orientación global

Filtración y lavado en sentido inverso

Numerosas funciones técnica de medición y regulación

Panel de manómetros para medir las presiones en el lecho filtrante

Software moderno con funciones de control y adquisición de datos

ENT

ENVIRONM

ENERGY &

CE 579 ENERGY &

DEPTH FILTRATIO ENVIRONM

ENT

N N

DEPTH FILTRATIO

CE 579

Measuring point

1: Differential press

Filtration through the sand ure

3.3.1.1 raw water flows in The differential

During filtration, solids suspended pressure (PDIR

to bottom. The The between the ) is recorded

filter from top in the filter bed.

sand filter inlet

and outlet. This

are retained 1 done by hydra

the raw water

s the sand filter at the lower pressure senso

ulically conne

cting the differe

is

leave ntial

treated water treated water

tank.

flange connection.

r to the upper

and lower sand

into the filter

end and flows

The hoses must

be completely

To fill the pipes filled with water

, the valves (1) .

Fig. 3.15 Differential pressu pressure senso on the differe

r must be opene ntial

Germany 03/2010

re sensor

more air in the d until there is

pipes. no

Germany 03/2010

Measuring point

2/3: System

pressure /

au, Barsbüttel,

temperature

The system press

ure (PIR) and

(TIR) of the water the temperature

au, Barsbüttel,

are recorded

, G.U.N.T. Geräteb

feed line. in the sand filter

, G.U.N.T. Geräteb

Fig. 3.16

F System pressu

re and

temperature sensor

All rights reserved

Measuring point

4: Flow rate

All rights reserved

The flow rate

(FIR) is recor

inductive flow ded using a magn

rate sensor. The eto-

as a control sensor outpu

variable for the t acts

backwash pump raw water pump

. The flow rate or

ing mode adjusted and sensor is pre-

filtration operat requires no furthe

Fig. 3.25 Flow paths in r calibration.

par-

s line can be

water, the bypas

To mix the raw V10.

d using the valve

tially or fully opene pre-

in the feed line Fig. 3.17

3

butterfly valve Magneto-indu

ctive flow rate

The non-return flowing back in the oppo- sensor

water from

vents the raw

site direction.

26 3 Unit descrip

tion

tion

3 Unit descrip 17

El material didáctico, bien estructurado, impreso en Uso de componentes de alta calidad:

papel, reunidos en un archivador, y además como Sensor de caudal electromegnético, bomba para lavado

archivos PDF en un CD. en sentido inverso y válvulas de bola con accionamiento

eléctrico

Software LabVIEW

Panel de manómetros Banco de ensayos

17

You might also like

- Wall Chart SEDEX Filters EngDocument1 pageWall Chart SEDEX Filters EngGermano BissonNo ratings yet

- Filter Unit: North Side ElevationDocument1 pageFilter Unit: North Side ElevationMd SuruzzamanNo ratings yet

- Arunesh Prescription 1Document1 pageArunesh Prescription 1Arunesh ArulkumarNo ratings yet

- Disclosure Summary Page: (Must BeDocument5 pagesDisclosure Summary Page: (Must BeZach EdwardsNo ratings yet

- Pesco: TCE.11191A-D-4206 Sheet 1 of 1 F-2 Instrument AirDocument1 pagePesco: TCE.11191A-D-4206 Sheet 1 of 1 F-2 Instrument AirValesh MonisNo ratings yet

- A-Form 6Document5 pagesA-Form 6NaveedNo ratings yet

- Summary of Blasting Activity & Explosives Usage Prepared By, Approved ByDocument8 pagesSummary of Blasting Activity & Explosives Usage Prepared By, Approved Bydidi setiawanNo ratings yet

- 30 11 41 Rev.19 Pneumatic de IcersDocument130 pages30 11 41 Rev.19 Pneumatic de Icersfabio andres guarin curbeloNo ratings yet

- FFB BrochureDocument4 pagesFFB Brochureprashant_mahitkar4532No ratings yet

- General Notes Legends & Abbreviations: Mr. & Mrs. Sire Henrik Andersson As-Built 3 - Storey Residential BuildingDocument1 pageGeneral Notes Legends & Abbreviations: Mr. & Mrs. Sire Henrik Andersson As-Built 3 - Storey Residential BuildingChrysler DuasoNo ratings yet

- BD Tournaire Extraction Fiche UK 2019Document2 pagesBD Tournaire Extraction Fiche UK 2019Diego ArroyaveNo ratings yet

- Graficki Prikaz Objedinjene Procedure ENGDocument1 pageGraficki Prikaz Objedinjene Procedure ENGĐorđeDražićNo ratings yet

- Backgrounder: Transformative Urban Recovery From COVID-19Document2 pagesBackgrounder: Transformative Urban Recovery From COVID-19Aliya RahmanNo ratings yet

- LS 924 eHTX Separator BrochureDocument6 pagesLS 924 eHTX Separator BrochureLucius VorenusNo ratings yet

- 0127 R8B 07 WP 311 01Document1 page0127 R8B 07 WP 311 01ABDERRAZZAKNo ratings yet

- S RGFG' (F: Disclosure Summary Page Dr-2Document13 pagesS RGFG' (F: Disclosure Summary Page Dr-2Zach EdwardsNo ratings yet

- Freudenberg Filtration Technologies Product Catalog 2019-2020 January-2019-EnDocument150 pagesFreudenberg Filtration Technologies Product Catalog 2019-2020 January-2019-EnJhonny Velasquez PerezNo ratings yet

- Hatch Jack - 1304 - ScannedDocument3 pagesHatch Jack - 1304 - ScannedZach EdwardsNo ratings yet

- Samsung Bloomington r0.9 SchematicsDocument44 pagesSamsung Bloomington r0.9 SchematicsDomingo79No ratings yet

- Sample Floor Plans For General Clinical Laboratory 8-5-2021Document3 pagesSample Floor Plans For General Clinical Laboratory 8-5-2021Kristoffer Lawrence Bucad Mansueto86% (7)

- 10 1061@9780784480021Document247 pages10 1061@9780784480021AnupEkboteNo ratings yet

- Properties of Fluids - 23Document52 pagesProperties of Fluids - 23ytfhfdhjgNo ratings yet

- 2006-07-14 DR2 SummaryDocument2 pages2006-07-14 DR2 SummaryZach EdwardsNo ratings yet

- Bloque Pared 22Document1 pageBloque Pared 22Cristhian RamosNo ratings yet

- CS Form No. 34-C Plantilla of Casual Appointment - LGU RegulatedDocument1 pageCS Form No. 34-C Plantilla of Casual Appointment - LGU RegulatedBhabes Belen CreusNo ratings yet

- Signet and Ultrasonic Flow Sensor Brochure Rev ADocument16 pagesSignet and Ultrasonic Flow Sensor Brochure Rev AMETHOR SERVICE GROUPNo ratings yet

- O Over Olxo Configuration: As Of: 05/15/19 Entrance-Arcadia-Thermal-5000-All-Series PDFDocument14 pagesO Over Olxo Configuration: As Of: 05/15/19 Entrance-Arcadia-Thermal-5000-All-Series PDFAnonymous 7MdZQn1No ratings yet

- Doc20230519144156cc2023117 PPTDocument10 pagesDoc20230519144156cc2023117 PPTNicolas Mon BiancoNo ratings yet

- 42QCP Remote Control OMDocument8 pages42QCP Remote Control OMPontharani MarimuthuNo ratings yet

- S14048-DD-570-HD-003 - Hvac Duct Support Drawing (U85 Module) 1ST Deck-Rev. A1Document3 pagesS14048-DD-570-HD-003 - Hvac Duct Support Drawing (U85 Module) 1ST Deck-Rev. A1DHANEESH VELLILAPULLINo ratings yet

- ESQUEMATICO Samsung N150 - ByLeo037 PDFDocument44 pagesESQUEMATICO Samsung N150 - ByLeo037 PDFEnzoquirozNo ratings yet

- 8 (4 4) X8X3M (H) - Layout1Document1 page8 (4 4) X8X3M (H) - Layout1Erick YuseNo ratings yet

- Pmsi29f01l0204940139mu00 220822Document1 pagePmsi29f01l0204940139mu00 220822JOSE GILBERTONo ratings yet

- Network Connection Scheme For Station Lan For Farakka STG3Document4 pagesNetwork Connection Scheme For Station Lan For Farakka STG3siddharth507No ratings yet

- V0.1Document1 pageV0.1Thea Marie M HernandezNo ratings yet

- Climate 2014Document27 pagesClimate 2014GauravSinhaNo ratings yet

- Poster 156Document1 pagePoster 156Gerard ValdezNo ratings yet

- Disclosure Summary Page DR-2 67: See BackDocument6 pagesDisclosure Summary Page DR-2 67: See BackZach EdwardsNo ratings yet

- TILLEY Et Al 2014 S-11 Anaerobic FilterDocument2 pagesTILLEY Et Al 2014 S-11 Anaerobic FilterAshish GargNo ratings yet

- TILLEY Et Al 2014 S-11 Anaerobic Filter PDFDocument2 pagesTILLEY Et Al 2014 S-11 Anaerobic Filter PDFJohn Paul AlegreNo ratings yet

- Disclosure Summary Page DR-2: For Instructions - See Back ofDocument3 pagesDisclosure Summary Page DR-2: For Instructions - See Back ofZach EdwardsNo ratings yet

- RenalDocument1 pageRenalYezin Shamoon100% (1)

- Standpipe Piezometer: Typical InstallationDocument2 pagesStandpipe Piezometer: Typical InstallationGauri 'tika' Kartika0% (1)

- Matix PFD1 Rev3 CompleteDocument7 pagesMatix PFD1 Rev3 CompleteSanju ChauhanNo ratings yet

- 07 HWDP 5Document2 pages07 HWDP 5khalilNo ratings yet

- Pile DetailDocument1 pagePile DetailYuefei WuNo ratings yet

- 2006-01-02 DR2 SummaryDocument3 pages2006-01-02 DR2 SummaryZach EdwardsNo ratings yet

- Testing PDFDocument1 pageTesting PDFMichelle CandelariaNo ratings yet

- Section A Rebar Detail Interior Face Exterior Face: 26 2Pcw Qty. PCDocument1 pageSection A Rebar Detail Interior Face Exterior Face: 26 2Pcw Qty. PCMichelle CandelariaNo ratings yet

- Testing PDFDocument1 pageTesting PDFMichelle CandelariaNo ratings yet

- Fill in The Data For The Grey Shaded Areas Only: 2019 Inlet Spacing - Curb and Gutter Spreadsheet (English Units)Document3 pagesFill in The Data For The Grey Shaded Areas Only: 2019 Inlet Spacing - Curb and Gutter Spreadsheet (English Units)Mauricio DelgadoNo ratings yet

- Testing SD PDFDocument1 pageTesting SD PDFMichelle CandelariaNo ratings yet

- DM s2023 148 JHSDocument29 pagesDM s2023 148 JHSALEX SARAOSOSNo ratings yet

- SLB - Wemco-Silver-Band-PsDocument4 pagesSLB - Wemco-Silver-Band-PsblondtumbalaNo ratings yet

- FFB CatalogDocument4 pagesFFB CatalogCatolico CristianoNo ratings yet

- Siphar Bod-03-06-2011Document4 pagesSiphar Bod-03-06-2011Indra NeelNo ratings yet

- A-Method Statement Painting and Touch-Up Painting For Furnace-CDocument20 pagesA-Method Statement Painting and Touch-Up Painting For Furnace-CTrương Đông HưngNo ratings yet

- 94may Thornton PDFDocument245 pages94may Thornton PDFmuhammadazharNo ratings yet

- Ratio ControlDocument9 pagesRatio ControlRiccardo VianelloNo ratings yet

- HFT Food Technology 2015Document35 pagesHFT Food Technology 2015Riccardo VianelloNo ratings yet

- Didacta - Catalogue 2016Document74 pagesDidacta - Catalogue 2016Riccardo VianelloNo ratings yet

- Exercise: Xercise BjectiveDocument16 pagesExercise: Xercise BjectiveRiccardo VianelloNo ratings yet

- PID ModesTraining LabVoltDocument34 pagesPID ModesTraining LabVoltRiccardo VianelloNo ratings yet

- Instrumentation and Process ControlDocument42 pagesInstrumentation and Process ControlRiccardo VianelloNo ratings yet

- Mod. UTC-1/EV Mod. UTC-1c/EV Mod. UTC-1a/EV: Heat Transfer Pilot Plant With Plate and U-Tube Heat ExchangerDocument2 pagesMod. UTC-1/EV Mod. UTC-1c/EV Mod. UTC-1a/EV: Heat Transfer Pilot Plant With Plate and U-Tube Heat ExchangerRiccardo VianelloNo ratings yet

- 05 Refractometer en LR 2016Document4 pages05 Refractometer en LR 2016Riccardo VianelloNo ratings yet

- Feed ForwardDocument12 pagesFeed ForwardRiccardo VianelloNo ratings yet

- Mod. Uou/Ev Mod. Uouc/Ev: Reverse Osmosis and Ultrafiltration Pilot PlantDocument1 pageMod. Uou/Ev Mod. Uouc/Ev: Reverse Osmosis and Ultrafiltration Pilot PlantRiccardo VianelloNo ratings yet

- Mod. Upb/Ev Mod. Upba/Ev: Biodiesel Production Pilot PlantDocument1 pageMod. Upb/Ev Mod. Upba/Ev: Biodiesel Production Pilot PlantRiccardo VianelloNo ratings yet

- Consistency Control Loop Dynamic Specification PDFDocument4 pagesConsistency Control Loop Dynamic Specification PDFRiccardo VianelloNo ratings yet

- Data Sheet: Direct-Drive Plunger PumpsDocument4 pagesData Sheet: Direct-Drive Plunger PumpsRiccardo VianelloNo ratings yet

- Mod. Ume/Ev Mod. Umec/Ev Mod. Umea/Ev: Single-Effect Evaporation Pilot PlantDocument2 pagesMod. Ume/Ev Mod. Umec/Ev Mod. Umea/Ev: Single-Effect Evaporation Pilot PlantRiccardo VianelloNo ratings yet

- Mod. ULL/EV Mod. ULL-1/EV: Extraction Pilot PlantDocument1 pageMod. ULL/EV Mod. ULL-1/EV: Extraction Pilot PlantRiccardo VianelloNo ratings yet

- Ams Amsac MF EngDocument68 pagesAms Amsac MF EngRiccardo VianelloNo ratings yet

- TH3 Saturation Pressure PDFDocument56 pagesTH3 Saturation Pressure PDFRiccardo VianelloNo ratings yet

- CE 620 Liquid-Liquid Extraction Unit: Instruction ManualDocument39 pagesCE 620 Liquid-Liquid Extraction Unit: Instruction ManualRiccardo Vianello100% (1)

- Experiment Instructions: CE 220 Fluidised Bed FormationDocument51 pagesExperiment Instructions: CE 220 Fluidised Bed FormationRiccardo VianelloNo ratings yet

- Dimensions and Weights of Plain End Steel Pipes To ANSI B36.10-1979Document46 pagesDimensions and Weights of Plain End Steel Pipes To ANSI B36.10-1979freddycito21247No ratings yet

- Exp.# 12: A (Series Pumps) .: Series, So That WaterDocument10 pagesExp.# 12: A (Series Pumps) .: Series, So That WaterAbdulrazzaqAL-MalikyNo ratings yet

- Short Checklist To Complete A Design Calculation According To The ASME Boiler and Pressure Vessel Code Section VIIIDocument3 pagesShort Checklist To Complete A Design Calculation According To The ASME Boiler and Pressure Vessel Code Section VIIIRamesh sivanNo ratings yet

- Migs BT Plumbing SpecsDocument26 pagesMigs BT Plumbing SpecsMiguel MontealtoNo ratings yet

- 07-PT11Centrifugal Compressors (Compatibility Mode)Document41 pages07-PT11Centrifugal Compressors (Compatibility Mode)moxlinde100% (1)

- Hydrualics & Hydraulic Machinery - Lecture - Notes-1 PDFDocument101 pagesHydrualics & Hydraulic Machinery - Lecture - Notes-1 PDFJitender NaiduNo ratings yet

- FU01-S01-02-005-01 Pipe Spec CS22Document8 pagesFU01-S01-02-005-01 Pipe Spec CS22Javed NasirNo ratings yet

- Ball Valve - : PN25 - PN32 - PN40Document1 pageBall Valve - : PN25 - PN32 - PN40shazeb aliNo ratings yet

- Tool String Flexing # 5 FlexingDocument6 pagesTool String Flexing # 5 FlexingmikoNo ratings yet

- SAE Flanges PDFDocument55 pagesSAE Flanges PDFG.SWAMI100% (2)

- DimplesDocument20 pagesDimplesrajuNo ratings yet

- BOMDocument9 pagesBOMRam KumarNo ratings yet

- Feed Tank and Pressure SizingDocument4 pagesFeed Tank and Pressure SizingodvutNo ratings yet

- XXXX-DS-PI-001-Rev.00-GATE VALVE DATASHEETDocument8 pagesXXXX-DS-PI-001-Rev.00-GATE VALVE DATASHEETDương HoàngNo ratings yet

- Asme 16.5Document2 pagesAsme 16.5Norman MoralesNo ratings yet

- Flange Pressure (Kpa) Vs Temperature (Oc) RatingDocument1 pageFlange Pressure (Kpa) Vs Temperature (Oc) RatingMSNo ratings yet

- LT & HT Panels RoomDocument4 pagesLT & HT Panels RoomMaxmore KarumamupiyoNo ratings yet

- 5c928989ac4f9 TSICanadaManualS PDFDocument144 pages5c928989ac4f9 TSICanadaManualS PDFAnggi SujiwoNo ratings yet

- Leser Certificate For Global ApplicationDocument3 pagesLeser Certificate For Global ApplicationErikikoNo ratings yet

- OGA Relief Valve Calculations 12-3-12Document31 pagesOGA Relief Valve Calculations 12-3-12penjualgasNo ratings yet

- Laminar Boundary Layer Order of Magnitude Analysis: DirectionDocument3 pagesLaminar Boundary Layer Order of Magnitude Analysis: Directionnanduslns07No ratings yet

- Cavitation in Restriction Orifices and Valves - NeutriumDocument8 pagesCavitation in Restriction Orifices and Valves - NeutriumAbbasNo ratings yet

- Jonson PumpDocument72 pagesJonson PumpRachid KerdidiNo ratings yet

- Turbine Drains PDFDocument13 pagesTurbine Drains PDFLakshmi Narayan100% (1)

- Catalog Pricelist: Periode: Oktober 2018Document22 pagesCatalog Pricelist: Periode: Oktober 2018Arip Ace DuosNo ratings yet

- Gates 2009 Hydraulic HoseDocument503 pagesGates 2009 Hydraulic HoseZackyD030% (1)

- Osborne Reynolds Experiment (Laminar and Turbulent Flow)Document6 pagesOsborne Reynolds Experiment (Laminar and Turbulent Flow)Jayasanka33% (3)

- Flow Control ValvesDocument7 pagesFlow Control ValvesSasko DimitrovNo ratings yet

- Pitot TubeDocument19 pagesPitot TubeDianita Citra Dewi0% (1)