Professional Documents

Culture Documents

Value Stream Mapping - Casos Practicos

Uploaded by

JOHAN FERNANDO QUIROZ SERNAQUE0 ratings0% found this document useful (0 votes)

40 views13 pagesOriginal Title

Value stream mapping - casos practicos

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

40 views13 pagesValue Stream Mapping - Casos Practicos

Uploaded by

JOHAN FERNANDO QUIROZ SERNAQUECopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 13

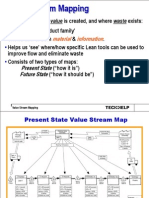

Value Stream Mapping

Helps us see where value is created, and where waste exists:

• Developed by ‘product family’

• Shows flow of both material & information.

• Helps us ‘see’ where/how specific Lean tools can

be used to improve flow and eliminate waste

• Consists of two types of maps:

Present State (“how it is”)

Future State (“how it should be”)

Value Stream Mapping

Present State Value Stream Map

Value Stream Mapping

Map Features

1: DOCUMENT CUSTOMER DEMAND

2: DEFINE PROCESSES w/OPERATION

DATA

3: SHOW MATERIAL FLOW

4: SHOW INFORMATION FLOW

5: COMPUTE LEAD TIMES

Value Stream Mapping

Process Data Boxes

- Cycle time: Observed & Effective

- Changeover time & frequency

- % Availability to Demand

- Number of operators

- % Quality level (first-pass yield)

- Batch size

Value Stream Mapping

Questions – Part 1

1. Are there any symbols on the map that

you don’t recognize?

2. What determines the work schedule at

each station?

3. How is ‘time’ data in the map acquired?

4. What is the bottleneck in the ACME

manufacturing process?

5. Where is the biggest changeover time?

What does this mean for downstream

processes?

Value Stream Mapping

Questions – Part 2

1. What is the manufacturing lead time for

a product (definition and value)? How

does that compare to the value added

time?

2. What is the impact of 1 truck a day

leaving with finished goods and trucks

arriving on Tuesday and Thursday with

coils of steel?

Value Stream Mapping

Questions – Part 3

1. Where do you see waste in this process

and what types of waste from the

mnemonic CLOSED MITT do you see?

2. What countermeasures could be taken

to reduce the most significant forms of

waste?

Value Stream Mapping

Mapping Methodology

•Focus on a product family within single

plant.

•Seek leadership from the value stream

manager.

•Go and see. Conduct door-to-door process

walk.

•Work backwards, starting at the shipping

door.

•Capture and quantify basic operations

involved.

Value Stream Mapping

Investigation Etiquette

• Get management approval

• Communicate to all areas before visit

• Make introductions when you get there

• Remember, the workers are the

experts for their tasks!

• Respect people’s work space

• Explain your purpose

Value Stream Mapping

Strategies for Process Improvement

#1: Produce to your Takt Time.

#2: Develop continuous flow where

possible

to reduce inventory. Eliminate

isolated

islands of production.

#3: Use supermarkets to control

production

where continuous flow does not

extend

upstream (often outside the plant).

#4: Try to send customer schedule to

only

one

Value Stream production process

Mapping

Establish Takt Time

Takt Time = Demand Rate

Takt Time = Work Time Available

Number of Units Sold

Takt Time = 900 Seconds = 10.6 Sec/Board

85 Boards

Cycle Time

Takt Time = Minimum # of People

GOAL: Produce to Demand

Value Stream Mapping

Questions – Part 4

1. What is the company’s Takt time if the

demand is 460 parts per 8 hour shift

(with two 10 minute breaks)?

2. Where is it not practical to achieve

continuous flow? How could a a

supermarket be used to overcome this?

3. How can the welding and assembly

operations be configured to Takt time?

4. What should be the pacemaker process?

5. What other improvements are possible?

Value Stream Mapping

Future State Value Stream Map

Value Stream Mapping

You might also like

- Creating a One-Piece Flow and Production Cell: Just-in-time Production with Toyota’s Single Piece FlowFrom EverandCreating a One-Piece Flow and Production Cell: Just-in-time Production with Toyota’s Single Piece FlowRating: 4 out of 5 stars4/5 (1)

- How to Create Continuous Production Flow?: Toyota Production System ConceptsFrom EverandHow to Create Continuous Production Flow?: Toyota Production System ConceptsRating: 5 out of 5 stars5/5 (1)

- 4 Slides Value Stream MappingDocument13 pages4 Slides Value Stream MappingRanjan Raj Urs100% (2)

- Lecture 4: Overview: Principles For Implementing Lean ManufacturingDocument20 pagesLecture 4: Overview: Principles For Implementing Lean Manufacturingthedjoss2000No ratings yet

- VSM PDFDocument52 pagesVSM PDFChip ChopNo ratings yet

- Time Trap AnalysisDocument22 pagesTime Trap AnalysiswongsosoegaliNo ratings yet

- Value Stream MappingDocument54 pagesValue Stream MappingQuynh Chau TranNo ratings yet

- Vs M PresentationDocument73 pagesVs M PresentationMaiNo ratings yet

- Value Stream Mapping: Bill Paolucci Ipfw March 17, 2009Document73 pagesValue Stream Mapping: Bill Paolucci Ipfw March 17, 2009AkNo ratings yet

- Lean ManufacturingDocument90 pagesLean ManufacturingSasa TesijaNo ratings yet

- Value Stream MappingDocument40 pagesValue Stream MappingAli Raza AnjumNo ratings yet

- OM Session 1 v1Document56 pagesOM Session 1 v1Nishchay Edmund PaschalNo ratings yet

- Value Stream Mapping Visualizes Production ProcessDocument41 pagesValue Stream Mapping Visualizes Production ProcessNOSHEEN MEHFOOZ100% (1)

- Value Stream Analysis TrainingDocument78 pagesValue Stream Analysis TrainingWilmer Chacon100% (1)

- MSE507 Lean Manufacturing: Learning To See Parts I, II, IIIDocument65 pagesMSE507 Lean Manufacturing: Learning To See Parts I, II, IIIcristianpetriceanNo ratings yet

- Production and Operation Management (MAN406) Lesson 3Document34 pagesProduction and Operation Management (MAN406) Lesson 3sharee khanNo ratings yet

- Lean Manufacturing Value Stream GuideDocument51 pagesLean Manufacturing Value Stream GuideGustavo Moreno de MenezesNo ratings yet

- Lean and Kanban-Based: Software DevelopmentDocument42 pagesLean and Kanban-Based: Software Developmentanafc1403No ratings yet

- Value Stream Analysis Kaizen TrainingDocument38 pagesValue Stream Analysis Kaizen TrainingShah ZaibNo ratings yet

- Module IV (A) - Work StudyDocument19 pagesModule IV (A) - Work StudyTulika AgarwalNo ratings yet

- Process Selection, Design and AnalysisDocument35 pagesProcess Selection, Design and AnalysisRhia Shin PasuquinNo ratings yet

- Module 3 - Process & Capacity AnalysisDocument34 pagesModule 3 - Process & Capacity AnalysisPallav AgarwalNo ratings yet

- Lean Manufacturing REPORTDocument15 pagesLean Manufacturing REPORTSandeep GrNo ratings yet

- Value Stream Mapping & Management - VSMM: Chee HongDocument9 pagesValue Stream Mapping & Management - VSMM: Chee Hongyogesh sharmaNo ratings yet

- Lean Manufacturing Lec 5.1Document41 pagesLean Manufacturing Lec 5.1Muhammad KhalilNo ratings yet

- Initial PresentationDocument14 pagesInitial PresentationBaljeetNo ratings yet

- Lean Manufacturing and It's Implementation in Automotive IndustryDocument48 pagesLean Manufacturing and It's Implementation in Automotive IndustryshenoyniteshNo ratings yet

- Lean Production: Week 4: StandardizationDocument34 pagesLean Production: Week 4: StandardizationQuynh Chau TranNo ratings yet

- Lean Manufacturing & VSMDocument131 pagesLean Manufacturing & VSMRa Balamurugan100% (1)

- NIFT VSM ASSIGNMENT OPTIMIZES JACKET PRODUCTIONDocument11 pagesNIFT VSM ASSIGNMENT OPTIMIZES JACKET PRODUCTIONNailaNo ratings yet

- 16 Lean ManufacturingDocument75 pages16 Lean ManufacturingSyed Lissan HaiderNo ratings yet

- Toyota Inventory ManagementDocument26 pagesToyota Inventory ManagementHarshGarbyal63% (16)

- 16 Lean ManufacturingDocument71 pages16 Lean ManufacturingGaurav KumarNo ratings yet

- Production and Operation Management ReviewDocument3 pagesProduction and Operation Management Reviewjona gamerNo ratings yet

- Applying Lean Concepts-Wp PDFDocument6 pagesApplying Lean Concepts-Wp PDFEdgar PedrazaNo ratings yet

- Lean Supply Chain and Its Effect On ProductDocument21 pagesLean Supply Chain and Its Effect On Productafridi4240% (1)

- Value Stream MappingDocument32 pagesValue Stream Mappingnmmribeiro100% (1)

- System (Totals) M L L L: Product Quality Service QualityDocument1 pageSystem (Totals) M L L L: Product Quality Service QualityChad FreemanNo ratings yet

- OTM Slides1Document24 pagesOTM Slides1Sushuma NallaNo ratings yet

- Materi 4Document24 pagesMateri 4AuliamNo ratings yet

- Value Stream MappingDocument5 pagesValue Stream Mappingrizwan ziaNo ratings yet

- Learning To See - Book SummaryDocument1 pageLearning To See - Book Summarysooraj kuteNo ratings yet

- Lean Manufacturing and It's Implementation in Automotive IndustryDocument48 pagesLean Manufacturing and It's Implementation in Automotive IndustryshenoyniteshNo ratings yet

- Value Stream Mapping Guide for Garment ManufacturingDocument9 pagesValue Stream Mapping Guide for Garment ManufacturingAanchal ChawlaNo ratings yet

- Toyota Production System & Dual Kanban System: Irfan Kazi & Naresh SDocument25 pagesToyota Production System & Dual Kanban System: Irfan Kazi & Naresh SLabiz Saroni ZidaNo ratings yet

- OM Session 1-4Document39 pagesOM Session 1-4Rashi GaikwadNo ratings yet

- Attachment 1614632949Document62 pagesAttachment 1614632949Usama AliNo ratings yet

- Session 24 Aug-VSM and Lab 5Document39 pagesSession 24 Aug-VSM and Lab 5V PNo ratings yet

- MO Salemba Bab 4 Process DesignDocument17 pagesMO Salemba Bab 4 Process DesignPutriska RazaniNo ratings yet

- Unit - IV VALUE STREAM MAPPING - 092548Document15 pagesUnit - IV VALUE STREAM MAPPING - 092548Praful PandeyNo ratings yet

- Process Analysis IDocument31 pagesProcess Analysis IsreevaishnavNo ratings yet

- Lean Engineering Concepts ENMG 642: Lecture 5-Process MappingDocument59 pagesLean Engineering Concepts ENMG 642: Lecture 5-Process MappingAmmar1994No ratings yet

- Premiere Manufacturing Case Study, Step 1: Background: The Present SituationDocument161 pagesPremiere Manufacturing Case Study, Step 1: Background: The Present Situationaqsa imranNo ratings yet

- Value Stream MappingDocument5 pagesValue Stream Mappingrizwan ziaNo ratings yet

- 7 Slides Cell DesignDocument30 pages7 Slides Cell DesignLuis Alberto Lamas LavinNo ratings yet

- Value Stream Mapping Guide to Lean Enterprise ImprovementDocument11 pagesValue Stream Mapping Guide to Lean Enterprise ImprovementcyngnoNo ratings yet

- Lean Operations and The Toyota Production SystemDocument31 pagesLean Operations and The Toyota Production SystemRajShekarReddyNo ratings yet

- Analyzing and Improving Process FlowsDocument17 pagesAnalyzing and Improving Process Flowschandru5gNo ratings yet

- Process Strategy Analysis & OptimizationDocument46 pagesProcess Strategy Analysis & OptimizationAris AlfarizalNo ratings yet

- Takt Time: A Guide to the Very Basic Lean CalculationFrom EverandTakt Time: A Guide to the Very Basic Lean CalculationRating: 5 out of 5 stars5/5 (2)

- AlcoaDocument71 pagesAlcoaJOHAN FERNANDO QUIROZ SERNAQUENo ratings yet

- CQE Practice ExamDocument35 pagesCQE Practice ExamgogasinghNo ratings yet

- Daniel Lawson PMBOK Quick Implementation Guide FULL EDITIONDocument168 pagesDaniel Lawson PMBOK Quick Implementation Guide FULL EDITIONNy Laza Alexias RandrianoelinaNo ratings yet

- Recipes For Project Success PDFDocument136 pagesRecipes For Project Success PDFJOHAN FERNANDO QUIROZ SERNAQUENo ratings yet

- People in Projects PDFDocument328 pagesPeople in Projects PDFJOHAN FERNANDO QUIROZ SERNAQUENo ratings yet

- Certified Associate in Project Management (CAPM) Role Delineation Study PDFDocument48 pagesCertified Associate in Project Management (CAPM) Role Delineation Study PDFJOHAN FERNANDO QUIROZ SERNAQUENo ratings yet

- TPMDocument51 pagesTPMsinghjagwantNo ratings yet

- TPMDocument51 pagesTPMsinghjagwantNo ratings yet

- Project Management Competency Development Framework (PMCD)Document108 pagesProject Management Competency Development Framework (PMCD)La Isla Surf Shop100% (3)

- An Introduction To Design of Experiments - A Simplified Approach-ASQ Quality Press (1999)Document116 pagesAn Introduction To Design of Experiments - A Simplified Approach-ASQ Quality Press (1999)Khalid El Masry100% (1)

- Team Effectiveness Survey Workbook - Bauer - Robert W. (Author)Document161 pagesTeam Effectiveness Survey Workbook - Bauer - Robert W. (Author)JOHAN FERNANDO QUIROZ SERNAQUE100% (1)

- Using Designed Experiments To Shrink Health Care Costs 1996Document234 pagesUsing Designed Experiments To Shrink Health Care Costs 1996JOHAN FERNANDO QUIROZ SERNAQUENo ratings yet

- Ogp1 Pintura PDFDocument19 pagesOgp1 Pintura PDFEl_memito100% (1)

- MagnetismDocument30 pagesMagnetismManiratna RoyNo ratings yet

- Autotrol PerformaLOGIX 740 760 ManualDocument68 pagesAutotrol PerformaLOGIX 740 760 ManualHyacinthe KOSSINo ratings yet

- Nakshatra Revati: According To Prash TrivediDocument8 pagesNakshatra Revati: According To Prash TrivediazzxdNo ratings yet

- AVSCAN. FlightDocument113 pagesAVSCAN. FlightjuanpgutierrezNo ratings yet

- Language Development 1Document2 pagesLanguage Development 1Felipe Cabrera InostrozaNo ratings yet

- CNC USB Controller API: User ManualDocument29 pagesCNC USB Controller API: User ManualVisajientoNo ratings yet

- Crossing The Great Divide: Coproduction, Synergy, and DevelopmentDocument15 pagesCrossing The Great Divide: Coproduction, Synergy, and Development3113TNo ratings yet

- Learning in Artificial IntelligenceDocument6 pagesLearning in Artificial IntelligenceAnikNo ratings yet

- Rising StrongDocument3 pagesRising StrongPatricia CoyNo ratings yet

- Dana 30 InformationDocument14 pagesDana 30 InformationBrianssrt4No ratings yet

- Qognify-VisionHub-Brochure - Rev.01Document4 pagesQognify-VisionHub-Brochure - Rev.01Sarah BerlianiNo ratings yet

- User Manual Servo Driver SZGH-302: (One Driver To Control Two Motors Simultaneously)Document23 pagesUser Manual Servo Driver SZGH-302: (One Driver To Control Two Motors Simultaneously)Zdeněk HromadaNo ratings yet

- Ref1 Tc-211 Eng Ver2Document10 pagesRef1 Tc-211 Eng Ver2Naim ParvejNo ratings yet

- Partner Competency - E Pumps & SolutionDocument57 pagesPartner Competency - E Pumps & SolutionAhmed KotbNo ratings yet

- Statement of QualificationsDocument1 pageStatement of Qualificationsrf12345No ratings yet

- Teaching Styles in PE WCUDocument7 pagesTeaching Styles in PE WCUReliArceoNo ratings yet

- CropWat 4 Windows calculates crop water requirementsDocument2 pagesCropWat 4 Windows calculates crop water requirementsadam_pengeranNo ratings yet

- 2 - Class UnpackingDocument22 pages2 - Class UnpackingPhuong Linh ToNo ratings yet

- Se Unit 1Document77 pagesSe Unit 1sathyaaaaa1No ratings yet

- Project Plan For Implementation of ISO 20000 20000academy ENDocument7 pagesProject Plan For Implementation of ISO 20000 20000academy ENit20645984 Imashi H.M.G.G.M.No ratings yet

- Test Bank For Sociology A Brief Introduction 9th Edition by SchaeferDocument35 pagesTest Bank For Sociology A Brief Introduction 9th Edition by Schaefercashiersulphidetmvsc0100% (41)

- Finning CAT Event CodesDocument20 pagesFinning CAT Event CodesSebastian Rodrigo Octaviano100% (2)

- The Global CityDocument16 pagesThe Global CityBryan Marzo100% (2)

- Human Strategies For A Virtual World: Baldwin BergesDocument32 pagesHuman Strategies For A Virtual World: Baldwin BergesmoisesNo ratings yet

- 2008 Leonardoda Vinci AReviewDocument15 pages2008 Leonardoda Vinci AReviewOkeyman XlapatsasNo ratings yet

- Chapter 1-3Document9 pagesChapter 1-3jhamaymaNo ratings yet

- 4.3.c-Technology and IndustrializationDocument23 pages4.3.c-Technology and Industrializationjjamppong09No ratings yet

- Fabric in ArchitectureDocument28 pagesFabric in ArchitecturesubalakshmiNo ratings yet

- NumerologyDocument44 pagesNumerologyKrishna CH100% (2)