Professional Documents

Culture Documents

Job Safety Analysis: Required References Jsa Review

Job Safety Analysis: Required References Jsa Review

Uploaded by

Walid KhelfaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Job Safety Analysis: Required References Jsa Review

Job Safety Analysis: Required References Jsa Review

Uploaded by

Walid KhelfaCopyright:

Available Formats

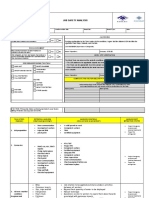

JOB SAFETY ANALYSIS

Facility / Site: GORDHAB TATAOUINE Location within Site: MTR Permit No: Permit Type: Date:

Task Description: connexion de cable MT

REQUIRED REFERENCES JSA REVIEW

Have the relevant Procedures, Standards, Guidelines,

Yes N/A

or Safe Work Practices been reviewed? Pending confirmation by the Task Leader of site conditions, I agree that the attached JSA identifies the

significant Task Steps, Hazards, and Controls.

JSA REVIEWER (Supervisor or Designate):

RISK ASSESSMENT

Must existing Procedures or Work Practices be

Yes No Name / Signature : Company:

modified to perform this work?

After mitigation, are there any hazards that continue to WORK SITE VERIFICATION

present a potentially significant risk? (Scenario-Based Yes No

Risk Assessment required)

The Work Team has assessed the worksite conditions and confirms:

The JSA addresses the applicable hazards and necessary controls.

PPE REQUIRED DURING THIS TASK

The Team has the appropriate resources (people and equipment) to do the job safely.

HARD HAT SAFETY GLASSES

Others that could be affected by the work have been informed.

FACE SHIELD TASK LEADER:

SAFETY SHOES / BOOTS

GOGGLES

FALL PROTECTION Name / Signature: Company: SOCOBAT

FALL RESTRAINT COMPLETE THE SECTION BELOW IF THIS JSA IS NOT PART OF A PERMIT PACK

GLOVES:

COTTON Work Team Declaration:

LEATHER I acknowledge that I have reviewed the attached JSA, I understand my roles

and responsibilities, and I will comply with the instructions for this task.

IMPACT PROTECTION

Name (print): Name (print):

Dust mask

OTHER (specify):

Work clothes

OTHER PPE (specify): Worker performing task inside to wear Double

Earing Protection (ear plugs and ear muffs)

TASK STEPS POTENTIAL HAZARDS HAZARDS CONTROLS HAZARD PORT

(Number) (What could go wrong?) (How can harm be prevented?) MITIGATION STATES

• A valid permit to work

• Poor communication

• Competent workers Project Emergency

• incompetent workers

• TBM response plan

• lack of oxygen

1. Pre – entry • Ensure the entry is free from obstacles (medical treatment)

• unauthorized entry Proper fire

• Ensure the space is free from gazes

• Flammable/ toxic extinguisher

atmosphere

• Watchman in place : manhole

• Only competent workers

• Dark / insufficient light • Frequent break

• Heat / humid • Only authorized persons

• Poor communication • Close supervision

2. Entry • Incompetent workers • Ensure a sufficient ventilation and air circulation

• Gazes • Limit the area

Project Emergency

• Ensure good lighting response plan

(medical treatment)

Proper fire

extinguisher

• Pinch point Project Emergency

• Sharp objects response plan

(medical treatment)

• Heavy load Proper fire

3. Cable connexion • Incompetent workers • PTW/TBT

extinguisher

• Proper PPE

• Poor communication

• Competent workers

• Tripping hazard

• Certified equipment

TASK STEPS POTENTIAL HAZARDS HAZARDS CONTROLS HAZARD PORT

(Number) (What could go wrong?) (How can harm be prevented?) MITIGATION STATES

• Ensure good communication

• Close supervision

• Limit the area

• Ensure area free from tripping hazard

• Certified technicians

• Fire risk • Adequate fire extinguisher

• Poor supervision • Insulated tools

• No smoking in the working area

• Bites • Job rotation to be applied and share outdoors activities

• Poisonous insects between all workers

• Slip, trips and fall • Big and fresh quantity of water to be displayed

4. Adverse weather • Dehydration • Manual technique Project Emergency

condition: • Heat struck • Awareness session to workers to aware them about hazards response plan

Scorpions and • Dizziness associated with poisonous insects (medical treatment)

snakes • MSD • First aid kit and first aider should be available Proper fire

extinguisher

• Fatigue • Frequent breaks to be taken for recovery

• Working in extreme • Workers should wear adequate coverall

temperature • Time management culture among work force

• Silica exposure

• Struck by equipment

• Entanglement h • Dust mask to be worn to avoid inhalation contact and respiratory

• Severe injuries Back pain system protection Project Emergency

• Falling/Flying Debris • Use ear plugs and adequate PPE response plan

5. HOUSEKEEPING • Tool Malfunction and • Ensure machine guard are well fixed (medical treatment)

Electric Shock • Frequent breaks should be taken for recovering Proper fire

extinguisher

• Loss of Control Over Tool • Ensure work area is clear of other workers.

• Excessive Noise • Housekeeping and cleaning the area after EACH SHIFT

• Looseness Perforator bit

Name Position Date Signed

Prepared By HSSE

TASK STEPS POTENTIAL HAZARDS HAZARDS CONTROLS HAZARD PORT

(Number) (What could go wrong?) (How can harm be prevented?) MITIGATION STATES

Checked By Area HSSE Supervisor

Approved By PTW coordinator

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5814)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

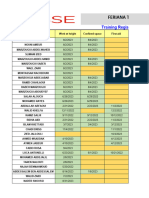

- Trainings Log 12-12-2023Document6 pagesTrainings Log 12-12-2023Walid KhelfaNo ratings yet

- Fire Extinguishers Registre 12-12-2023Document2 pagesFire Extinguishers Registre 12-12-2023Walid KhelfaNo ratings yet

- PTW REGISTER 11-12-2023 To 16-12-2023Document1 pagePTW REGISTER 11-12-2023 To 16-12-2023Walid KhelfaNo ratings yet

- Scaffolding Registre 12-12-2023Document6 pagesScaffolding Registre 12-12-2023Walid KhelfaNo ratings yet

- Chemical Products Register 12-12-2023Document1 pageChemical Products Register 12-12-2023Walid KhelfaNo ratings yet

- Waste Management 21-11-2023Document6 pagesWaste Management 21-11-2023Walid KhelfaNo ratings yet

- Fire Extinguishers Registre 04-10-2023Document2 pagesFire Extinguishers Registre 04-10-2023Walid KhelfaNo ratings yet

- Air Conditioner InstallationDocument3 pagesAir Conditioner InstallationWalid KhelfaNo ratings yet

- 00332100dwpv12001 - Precommissioning Commissioning Procedure-Rev B-ConvertiDocument41 pages00332100dwpv12001 - Precommissioning Commissioning Procedure-Rev B-ConvertiWalid KhelfaNo ratings yet

- Job Safety Analysis: Required References Jsa ReviewDocument3 pagesJob Safety Analysis: Required References Jsa ReviewWalid KhelfaNo ratings yet

- Job Safety Analysis: Required References Jsa ReviewDocument3 pagesJob Safety Analysis: Required References Jsa ReviewWalid KhelfaNo ratings yet

- Connexion de Cable MT Avec Boite JonctionDocument3 pagesConnexion de Cable MT Avec Boite JonctionWalid KhelfaNo ratings yet

- Electrical InstallationDocument3 pagesElectrical InstallationWalid KhelfaNo ratings yet

- Job Safety Analysis: Required References Jsa ReviewDocument3 pagesJob Safety Analysis: Required References Jsa ReviewWalid KhelfaNo ratings yet

- Cutting ActivitiesDocument3 pagesCutting ActivitiesWalid KhelfaNo ratings yet