Professional Documents

Culture Documents

Connexion de Cable MT Avec Boite Jonction

Uploaded by

Walid KhelfaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Connexion de Cable MT Avec Boite Jonction

Uploaded by

Walid KhelfaCopyright:

Available Formats

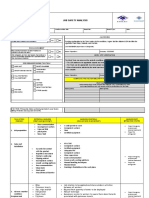

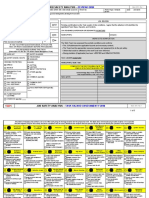

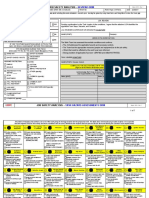

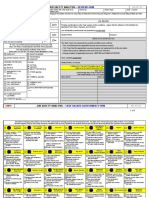

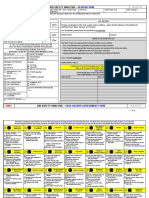

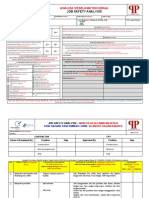

JOB SAFETY ANALYSIS

Facility / Site: GORDHAB TATAOUINE Location within Site: Permit No: Permit Type: Date:

Task Description: connection de cable MT via boite junction

REQUIRED REFERENCES JSA REVIEW

Have the relevant Procedures, Standards, Guidelines,

Yes N/A

or Safe Work Practices been reviewed? Pending confirmation by the Task Leader of site conditions, I agree that the attached JSA identifies the

significant Task Steps, Hazards, and Controls.

JSA REVIEWER (Supervisor or Designate):

RISK ASSESSMENT

Must existing Procedures or Work Practices be

Yes No Name / Signature : Company: ETELEC

modified to perform this work?

After mitigation, are there any hazards that continue to WORK SITE VERIFICATION

present a potentially significant risk? (Scenario-Based Yes No

Risk Assessment required)

The Work Team has assessed the worksite conditions and confirms:

The JSA addresses the applicable hazards and necessary controls.

PPE REQUIRED DURING THIS TASK

The Team has the appropriate resources (people and equipment) to do the job safely.

HARD HAT SAFETY GLASSES

Others that could be affected by the work have been informed.

FACE SHIELD TASK LEADER:

SAFETY SHOES / BOOTS

GOGGLES

FALL PROTECTION Name / Signature: Company: SOCOBAT

FALL RESTRAINT COMPLETE THE SECTION BELOW IF THIS JSA IS NOT PART OF A PERMIT PACK

GLOVES:

COTTON Work Team Declaration:

LEATHER I acknowledge that I have reviewed the attached JSA, I understand my roles

and responsibilities, and I will comply with the instructions for this task.

IMPACT PROTECTION

Name (print): Name (print):

Dust mask

OTHER (specify):

Work clothes

OTHER PPE (specify): Worker performing task inside to wear Double

Earing Protection (ear plugs and ear muffs)

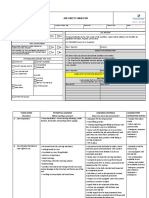

TASK STEPS POTENTIAL HAZARDS HAZARDS CONTROLS HAZARD PORT

(Number) (What could go wrong?) (How can harm be prevented?) MITIGATION STATES

• Poor communication • A valid permit to work Project Emergency

• incompetent workers • Competent workers response plan

1. Job preparation • trips and falls • TBM (medical treatment)

• pinch point • Certified equipment Proper fire

extinguisher

• PTW/TBT

2. Connexion • Proper PPE

• Hand, eye, ear, shock

injuries • Competent workers

• Flying metal; pieces • Certified equipment

• Electrical shock • Adequate PPE

• Sharp objects • Competent workers

Project Emergency

• Pinch point • Close supervision

response plan

• Poor communication • Good communication (medical treatment)

• Incompetent workers • Check equipment before use Proper fire

• Working in an • Watchman in place extinguisher

excavation

• Trips and falls

• Electrical equipment

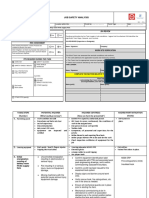

• Bites • Job rotation to be applied and share outdoors activities

• Poisonous insects between all workers

• Slip, trips and fall • Big and fresh quantity of water to be displayed

3. Adverse weather • Dehydration • Manual technique Project Emergency

condition: • Heat struck • Awareness session to workers to aware them about hazards response plan

Scorpions and • Dizziness associated with poisonous insects (medical treatment)

snakes • MSD • First aid kit and first aider should be available Proper fire

extinguisher

• Fatigue • Frequent breaks to be taken for recovery

• Working in extreme • Workers should wear adequate coverall

temperature • Time management culture among work force

TASK STEPS POTENTIAL HAZARDS HAZARDS CONTROLS HAZARD PORT

(Number) (What could go wrong?) (How can harm be prevented?) MITIGATION STATES

• Silica exposure

• Struck by equipment

• Entanglement h • Dust mask to be worn to avoid inhalation contact and respiratory

• Severe injuries Back pain system protection Project Emergency

• Falling/Flying Debris • Use ear plugs and adequate PPE response plan

4. HOUSEKEEPING • Tool Malfunction and • Ensure machine guard are well fixed (medical treatment)

Electric Shock • Frequent breaks should be taken for recovering Proper fire

extinguisher

• Loss of Control Over Tool • Ensure work area is clear of other workers.

• Excessive Noise • Housekeeping and cleaning the area after EACH SHIFT

• Looseness Perforator bit

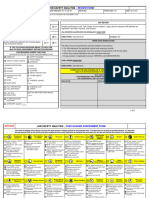

Name Position Date Signed

Prepared By HSSE

Checked By Area HSSE Supervisor

Approved By PTW coordinator

You might also like

- JSA-Use of Temporary Energization (Power Generator)Document4 pagesJSA-Use of Temporary Energization (Power Generator)MajdiSahnoun100% (1)

- 6.ZXSDR B8200 (V4.1) Commissioning Guide 109pDocument109 pages6.ZXSDR B8200 (V4.1) Commissioning Guide 109pRamiz Rzaoglu100% (1)

- Job Safety Analysis: Required References Jsa ReviewDocument3 pagesJob Safety Analysis: Required References Jsa ReviewMoaatazz Nouisri100% (1)

- JSA-Loading-Offloading of Chemical Products With ForkliftDocument4 pagesJSA-Loading-Offloading of Chemical Products With ForkliftMajdiSahnoun100% (2)

- JSA - Drilling ActivitiesDocument4 pagesJSA - Drilling ActivitiesAMIN100% (1)

- Mobile Offensive Security Pocket Guide: A Quick Reference Guide For Android And iOSFrom EverandMobile Offensive Security Pocket Guide: A Quick Reference Guide For Android And iOSRating: 1 out of 5 stars1/5 (1)

- Moving Die Rheometer Cure PropertiesDocument4 pagesMoving Die Rheometer Cure PropertiesMehroz Anjum0% (1)

- Questions For Dental MaterialsDocument7 pagesQuestions For Dental MaterialsBalakrishna Reddy100% (1)

- Job Safety Analysis: Required References Jsa ReviewDocument3 pagesJob Safety Analysis: Required References Jsa ReviewWalid KhelfaNo ratings yet

- Job Safety Analysis: Required References Jsa ReviewDocument3 pagesJob Safety Analysis: Required References Jsa ReviewWalid KhelfaNo ratings yet

- Job Safety Analysis: Required References Jsa ReviewDocument3 pagesJob Safety Analysis: Required References Jsa ReviewWalid KhelfaNo ratings yet

- Job Safety Analysis for Right-of-Way ClearingDocument5 pagesJob Safety Analysis for Right-of-Way ClearingMoaatazz Nouisri100% (1)

- Job Safety Analysis: Required References Jsa ReviewDocument4 pagesJob Safety Analysis: Required References Jsa ReviewMoaatazz Nouisri100% (4)

- JSA Road Crossing With CasingDocument6 pagesJSA Road Crossing With CasingMoaatazz NouisriNo ratings yet

- Electrical InstallationDocument3 pagesElectrical InstallationWalid KhelfaNo ratings yet

- Job Safety Analysis: Trench Preparation & Thrust Boring Activity Required References Jsa ReviewDocument4 pagesJob Safety Analysis: Trench Preparation & Thrust Boring Activity Required References Jsa ReviewMoaatazz Nouisri100% (1)

- JSA - Repair-Coating and Finition WorkDocument3 pagesJSA - Repair-Coating and Finition WorkAMIN100% (1)

- Battery Room HVAC Safety AnalysisDocument3 pagesBattery Room HVAC Safety AnalysisMajdiSahnounNo ratings yet

- Cutting ActivitiesDocument3 pagesCutting ActivitiesWalid KhelfaNo ratings yet

- Battery FillingDocument3 pagesBattery FillingMajdiSahnounNo ratings yet

- CPF-JSA-018 Drilling and Pipes Support Erection ZONE CLASS0Document5 pagesCPF-JSA-018 Drilling and Pipes Support Erection ZONE CLASS0MajdiSahnounNo ratings yet

- JSA-Visual Inspection and Ultrasonic Thickness Measurement On Pressure VesselsDocument2 pagesJSA-Visual Inspection and Ultrasonic Thickness Measurement On Pressure VesselsMajdiSahnoun100% (1)

- JSA - Repair-Coating and Finition Work THDocument3 pagesJSA - Repair-Coating and Finition Work THKhorbi AbdeltifNo ratings yet

- HVAC Fans Initial Energisation Battery RoomDocument3 pagesHVAC Fans Initial Energisation Battery RoomMajdiSahnoun0% (1)

- Air Conditioner InstallationDocument3 pagesAir Conditioner InstallationWalid KhelfaNo ratings yet

- Energization and Commissioning SafetyDocument3 pagesEnergization and Commissioning SafetyMajdiSahnounNo ratings yet

- Diesel RefuelingDocument3 pagesDiesel RefuelingAMINNo ratings yet

- JSA For Loading in ZB-481Document6 pagesJSA For Loading in ZB-481Mohammed HamzaNo ratings yet

- CPF-JSA-022 Welding Cutting and Drilling of Underground and Above Pipes Night ShiftDocument3 pagesCPF-JSA-022 Welding Cutting and Drilling of Underground and Above Pipes Night Shiftaioudi100% (1)

- Topography SurveyDocument2 pagesTopography SurveyAMIN100% (2)

- Travaux Genie Civil MTR JSADocument5 pagesTravaux Genie Civil MTR JSAAMINNo ratings yet

- Travaux Genie Civil MTR JSADocument5 pagesTravaux Genie Civil MTR JSAHichem FarhatNo ratings yet

- Lifting and Removing Using The Forklift or Telescopic Loader in SiteDocument3 pagesLifting and Removing Using The Forklift or Telescopic Loader in SiteAMINNo ratings yet

- Lifting and Removing Using Unloading, Loading and Placing 0F Cable ReelsDocument3 pagesLifting and Removing Using Unloading, Loading and Placing 0F Cable ReelsAMINNo ratings yet

- Diesel RefuelingDocument3 pagesDiesel RefuelingAMINNo ratings yet

- Job Safety Analysis for Scaffolding ErectionDocument3 pagesJob Safety Analysis for Scaffolding Erectionaioudi100% (2)

- Job Safety Analysis - : Review FormDocument5 pagesJob Safety Analysis - : Review FormMohammed HamzaNo ratings yet

- FUEL TANK FOUNDATION FoundationDocument7 pagesFUEL TANK FOUNDATION FoundationMohammed HamzaNo ratings yet

- JSA - System Walk DownDocument4 pagesJSA - System Walk DownMkd OfficialNo ratings yet

- JSA Review for Installing Electrical PanelDocument6 pagesJSA Review for Installing Electrical PanelMohammed HamzaNo ratings yet

- JSA Review FormDocument7 pagesJSA Review FormIndriyo Saputro (JALU)No ratings yet

- Job Safety Analysis - : Review FormDocument4 pagesJob Safety Analysis - : Review FormMohammed HamzaNo ratings yet

- Electrical Cable Laying With Breaking AsphaltDocument7 pagesElectrical Cable Laying With Breaking AsphaltMohammed HamzaNo ratings yet

- Cable Tray Installation JSADocument5 pagesCable Tray Installation JSAazerNo ratings yet

- Toaz - Info Jsa Maintenance Activity PRDocument12 pagesToaz - Info Jsa Maintenance Activity PRAnshad ShahNo ratings yet

- PDF 6jsa of Batching Plant Installation - CompressDocument4 pagesPDF 6jsa of Batching Plant Installation - CompressRiandoNo ratings yet

- Hot Work SafetyDocument3 pagesHot Work SafetyNasir Mehmood Aryani100% (1)

- Thyssenkrupp Industrial Solutions (India) Job Safety Analysis 1 6Document6 pagesThyssenkrupp Industrial Solutions (India) Job Safety Analysis 1 6Nitesh kumar yadavNo ratings yet

- JSA (Rev1 6.4.13) Set-Up Safe House Habitat.Document4 pagesJSA (Rev1 6.4.13) Set-Up Safe House Habitat.Danial AfandiNo ratings yet

- 18-JSA Dismantling of Batching PlantDocument5 pages18-JSA Dismantling of Batching Plantmohamed.elkomyNo ratings yet

- S3117 - John Cockerill Supervisors Site Risk AnalysisDocument17 pagesS3117 - John Cockerill Supervisors Site Risk Analysishakan tatlisuNo ratings yet

- 1 - JSA Erectoin and Dismantling of ScaffoldingDocument5 pages1 - JSA Erectoin and Dismantling of ScaffoldingAijaz AhmedNo ratings yet

- PJO'sDocument2 pagesPJO'smkhwanazithobani129No ratings yet

- JSA ELETRICAL MaintenanceDocument17 pagesJSA ELETRICAL MaintenanceWeru MorrisNo ratings yet

- JSA Communication Tower Painting Foundation Repairs at WR - 501 WR - 617) - 6-20-21Document23 pagesJSA Communication Tower Painting Foundation Repairs at WR - 501 WR - 617) - 6-20-21Shaikh Abu bakarNo ratings yet

- R.C.C and P.C.C Work JsaDocument1 pageR.C.C and P.C.C Work JsaAKBAR ALINo ratings yet

- JHA - Lifting of Air Receiver Tank AR 1 ADocument4 pagesJHA - Lifting of Air Receiver Tank AR 1 AAizuddinNo ratings yet

- ANALISA KESELAMATAN KERJA SURVEYDocument5 pagesANALISA KESELAMATAN KERJA SURVEYEthos SeptiansyahNo ratings yet

- Splicing, Termination and Test Power Cable JSADocument3 pagesSplicing, Termination and Test Power Cable JSAEthos SeptiansyahNo ratings yet

- Height WorkDocument2 pagesHeight WorkDautsons InfratechNo ratings yet

- Form Job Safety Analysis: PT Perdana Karya UtamaDocument1 pageForm Job Safety Analysis: PT Perdana Karya UtamaEkaNo ratings yet

- PTW REGISTER 11-12-2023 To 16-12-2023Document1 pagePTW REGISTER 11-12-2023 To 16-12-2023Walid KhelfaNo ratings yet

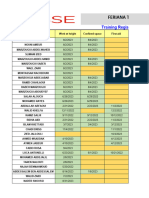

- Trainings Log 12-12-2023Document6 pagesTrainings Log 12-12-2023Walid KhelfaNo ratings yet

- Fire Extinguishers Registre 12-12-2023Document2 pagesFire Extinguishers Registre 12-12-2023Walid KhelfaNo ratings yet

- Connexion Cable MTDocument3 pagesConnexion Cable MTWalid KhelfaNo ratings yet

- Scaffolding Registre 12-12-2023Document6 pagesScaffolding Registre 12-12-2023Walid KhelfaNo ratings yet

- Connexion Cable MTDocument3 pagesConnexion Cable MTWalid KhelfaNo ratings yet

- Waste Management 21-11-2023Document6 pagesWaste Management 21-11-2023Walid KhelfaNo ratings yet

- Chemical Products Register 12-12-2023Document1 pageChemical Products Register 12-12-2023Walid KhelfaNo ratings yet

- Connexion Cable MTDocument3 pagesConnexion Cable MTWalid KhelfaNo ratings yet

- Connexion Cable MTDocument3 pagesConnexion Cable MTWalid KhelfaNo ratings yet

- Connexion Cable MTDocument3 pagesConnexion Cable MTWalid KhelfaNo ratings yet

- 00332100dwpv12001 - Precommissioning Commissioning Procedure-Rev B-ConvertiDocument41 pages00332100dwpv12001 - Precommissioning Commissioning Procedure-Rev B-ConvertiWalid KhelfaNo ratings yet

- Connexion Cable MTDocument3 pagesConnexion Cable MTWalid KhelfaNo ratings yet

- Electrical InstallationDocument3 pagesElectrical InstallationWalid KhelfaNo ratings yet

- Connexion Cable MTDocument3 pagesConnexion Cable MTWalid KhelfaNo ratings yet

- Connexion Cable MTDocument3 pagesConnexion Cable MTWalid KhelfaNo ratings yet

- Cutting ActivitiesDocument3 pagesCutting ActivitiesWalid KhelfaNo ratings yet

- Air Conditioner InstallationDocument3 pagesAir Conditioner InstallationWalid KhelfaNo ratings yet

- Proy. Electrónico DC Power MeterDocument20 pagesProy. Electrónico DC Power Metervpol25No ratings yet

- Catalog GlassfireDocument76 pagesCatalog GlassfireNajib KiwanNo ratings yet

- Technical PublicationsDocument3 pagesTechnical PublicationsGanesh KumarNo ratings yet

- 250 - C30R, U Operation and Maintenance: Export ControlledDocument8 pages250 - C30R, U Operation and Maintenance: Export ControlledturboshaftNo ratings yet

- Calculating The Size of A Server Room Air Conditioner OpenxtraDocument89 pagesCalculating The Size of A Server Room Air Conditioner Openxtraeric_engelbrechtNo ratings yet

- Ultralow-Noise, High PSRR, Fast RF 1-A Low-Dropout Linear RegulatorsDocument18 pagesUltralow-Noise, High PSRR, Fast RF 1-A Low-Dropout Linear RegulatorskarkeraNo ratings yet

- 12 DBS3800 Hardware System StructureDocument25 pages12 DBS3800 Hardware System StructureriamaNo ratings yet

- Building Maintenance Inspection and Facilities Assessment: Case Study: Office Block A2, University Malaysia PahangDocument11 pagesBuilding Maintenance Inspection and Facilities Assessment: Case Study: Office Block A2, University Malaysia PahangNrsyfqah SuleimanNo ratings yet

- Monograph Function: Definition and AnalysisDocument13 pagesMonograph Function: Definition and AnalysisdesignbaseNo ratings yet

- Kamstrup Multical 602 - Installation and User GuideDocument28 pagesKamstrup Multical 602 - Installation and User GuideMarco RamosNo ratings yet

- API To Assign Item To An Organization in Inventory)Document47 pagesAPI To Assign Item To An Organization in Inventory)deepunym0% (1)

- SYNTHETIC POLYDUR FIRE HOSE FOR CONSTRUCTIONDocument1 pageSYNTHETIC POLYDUR FIRE HOSE FOR CONSTRUCTIONAmirHossein SaberBaghabnNo ratings yet

- I-2.54-E Penetrant Procedure RevizeDocument14 pagesI-2.54-E Penetrant Procedure RevizeMohanadNo ratings yet

- Flexible Pavement: Topic 631 - Types of Flexible Pavements & MaterialsDocument19 pagesFlexible Pavement: Topic 631 - Types of Flexible Pavements & MaterialsMaejann CuarteroNo ratings yet

- CO2 Baseline Database For The Indian Power Sector.Document41 pagesCO2 Baseline Database For The Indian Power Sector.Pooja JainNo ratings yet

- International Standard: Brazing - Filler MetalsDocument11 pagesInternational Standard: Brazing - Filler Metalsanish nairNo ratings yet

- QBDocument51 pagesQBd anjilappaNo ratings yet

- Sound Pressure Meter (08-4c4)Document10 pagesSound Pressure Meter (08-4c4)Sri Krishna RakeshNo ratings yet

- UIU EC-II Lecture#9Document18 pagesUIU EC-II Lecture#9Montosh RoyNo ratings yet

- BS 7884-1997 Specification For Copper and Copper-Cadmium Stranded Conductors For Overhead Electric Traction and Power Transmission SystemsDocument16 pagesBS 7884-1997 Specification For Copper and Copper-Cadmium Stranded Conductors For Overhead Electric Traction and Power Transmission SystemsThanh DangNo ratings yet

- MiG-23 Flogger FightersDocument6 pagesMiG-23 Flogger FightersAndrea MatteuzziNo ratings yet

- CXC - CSEC Mechanical Eng Technology Paper 2 (May 2010)Document12 pagesCXC - CSEC Mechanical Eng Technology Paper 2 (May 2010)Marie Henry0% (1)

- KLUBER Cost Benefits Comparison-ELGIDocument15 pagesKLUBER Cost Benefits Comparison-ELGIrajkumar_kesirajuNo ratings yet

- Acceleration EnvelopingDocument2 pagesAcceleration EnvelopingNhà Đất Tân AnNo ratings yet

- RS400 Upwind PowerDocument6 pagesRS400 Upwind PowerDaniel CockerillNo ratings yet

- Jewellary Management SystemDocument2 pagesJewellary Management SystemsunnyNo ratings yet

- Piano Stool PDFDocument16 pagesPiano Stool PDFaguinaldo6690No ratings yet