Professional Documents

Culture Documents

Job Safety Analysis: Trench Preparation & Thrust Boring Activity Required References Jsa Review

Uploaded by

Moaatazz Nouisri100%(1)100% found this document useful (1 vote)

1K views4 pagesRisk assessment thrust boring

Original Title

JSA Thrust boring

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentRisk assessment thrust boring

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

100%(1)100% found this document useful (1 vote)

1K views4 pagesJob Safety Analysis: Trench Preparation & Thrust Boring Activity Required References Jsa Review

Uploaded by

Moaatazz NouisriRisk assessment thrust boring

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You are on page 1of 4

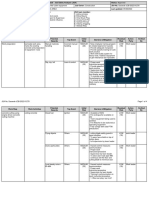

JOB SAFETY ANALYSIS

Ref: C5+– JSA- 004

Facility / Site:……………………………………………… Location within Site:…………………….. Permit No:……………………. Permit Type: ……………… Date:…………………….

Task Description: Trench preparation & Thrust Boring Activity

REQUIRED REFERENCES JSA REVIEW

Have the relevant Procedures, Standards, Guidelines,

or Safe Work Practices been reviewed? Yes N/A

Pending confirmation by the Task Leader of site conditions, I agree that the attached JSA identifies the

significant Task Steps, Hazards, and Controls.

JSA REVIEWER (Supervisor or Designate):

RISK ASSESSMENT

Must existing Procedures or Work Practices be

Yes No Name / Signature: Company:

modified to perform this work?

After mitigation, are there any hazards that continue to WORK SITE VERIFICATION

present a potentially significant risk? (Scenario-Based Yes No

Risk Assessment required)

The Work Team has assessed the worksite conditions and confirms:

The JSA addresses the applicable hazards and necessary controls.

PPE REQUIRED DURING THIS TASK

The Team has the appropriate resources (people and equipment) to do the job safely.

HARD HAT SAFETY GLASSES

Others that could be affected by the work have been informed.

FACE SHIELD TASK LEADER:

SAFETY SHOES / BOOTS

GOGGLES

FALL PROTECTION Name / Signature: Company:

FALL RESTRAINT COMPLETE THE SECTION BELOW IF THIS JSA IS NOT PART OF A PERMIT PACK

GLOVES:

COTTON Work Team Declaration:

LEATHER I acknowledge that I have reviewed the attached JSA, I understand my roles

and responsibilities, and I will comply with the instructions for this task.

IMPACT PROTECTION

Name (print): Name (print):

Dust mask

OTHER (specify):

Work clothes

OTHER PPE (specify):

TASKS/STEPS POTENTIAL HAZARDS HAZARDS CONTROLS HAZARD PORT

(Number) (What could go wrong?) (How can harm be prevented?) MITIGATION STATES

1. Permitting work Work condition not safe PTW system

Procedures and tasks not clear All necessary permissions and authorization Tool Box Talk

Lack of supervisory shall be obtained from the relevant Certificates

Miscommunication Authorities concerned before starting any inspection

Not correct PPE worn work

Equipment not inspected and certified HSE team to assess continuously the

conditions of work in the assigned area

One person to issue work permits

Toolbox talks

Competency of personnel and supervisory for

the activity

Define hierarchy and reporting flowcharts

Define proper PPE to be used for the work

Check inspection certificates of equipment for

the job

Check in/check out system to access to the

excavation (confined space)

2. Checking equipment Punch point / hand injuries Wear correct PPE PPE

Falling from machines Smart grip / 3 points of contact when climbing Ladder

Diesel / oil spill onto machines Plastic cover

Use proper ladders / steps

Use containment cans/ plastic covers to

prevent spills

3. Use of heavy machines Equipment structure damaged by heavy machines Have competent banksman at workplace PPE

Personnel crushed by excavated materials Ground personnel to wear high visibility Subterranean plan

Awareness

Ground personnel hit by heavy machines jackets

Exposure to dusty environment Machines operators watch for ground workers

High noise area Put a dust mask

Swing of machines and roll-over Put ear defenders

Damage to buried power lines and/or Do not exceed machines capacity

pipelines Respect approved plan of buried power lines

Risk of fire due to the engine failure and pipelines

Risk of collision with overhead powerline Fire extinguisher in place

Preventive maintenance

Goal post in place and banksman presence is

mandatory

4. Trench preparation for Person fall in the trench Install stakes and warning tape around trenches PPE

Dust goes in respiratory system Ground personnel to wear high visibility jackets First aid kit

boring activity

Mishandled or poorly placed material Remove debris and excavated soil near excavation site Warning tape

Excavated material or other objects falling on Wear respiratory mask if working downwind High visibility jackets

Place excavated material at safe distance from the trench Banksman

workers

Never walk under and beside excavator loader, wheel

Personnel hit by excavator, grader or wheel loader loader or front end loader and backhoe

Mobile equipment incident due to unstable Be aware of nearby vehicles and mobile equipment causing

adjacent structures soil to vibrate

Workers go down in trenches while trenching Keep heavy equipment away from trench edges

Back injury when working with shovel under bad Do not go down in the trench while excavating the trench

Wear correct safety boots and mind steps / do not rush

posture

Watch for venomous animals and wear safety boots and

Personnel trip / falling hazards due to excavated leather gloves

material Avoid hand and fingers injuries.

Personnel get bite by snakes or scorpions Safety signs in place.

Mechanical hazards (pinch points). Goal posts to avoid collision with overhead power lines.

Working near underground utilities. Banksman permantly presence in mandatory.

Area Underground utilities maps.

Overhead power lines hazards.

Collision with moving vehicles.

5. Use of the Boring Machine Entanglement with rotating drum or drive motor. Location of the machine on firm, level ground. PPE

Drawing in at nip-point between motor and drive mechanism. Location away from traffic or where traffic is controlled. First aid kit

Crushing between drum and drum stop when tipping. Fixed guards to motor and drive mechanism. Warning tape

Friction or abrasion on contact with moving drum. Routine inspection and portable appliance. Awareness

Ergonomics and manual-handling injuries during loading. Safe storage of petrol and control of ignition sources for

Health hazard from dust inhalation petrol-powered equipment; avoid use in confined spaces

Fire Hazards due to the fuel (electricity or petrol). because of emission of exhaust gases.

Dust goes in respiratory system Reduction in manual handling or positioning of

Mishandled or poorly placed material cement bags close to the equipment.

Mobile equipment incident due to Hand protection, respiratory protection, overalls and eye

unstable adjacent structures protection (splash resistant).

Back injury when working with shovel under bad posture Hearing protection to reduce noise exposure.

Personnel trip / falling hazards Fire extinguishers in place.

Personnel get bite by snakes or scorpions Install stakes and warning tape around trenches

Injury caused by falling objects, by stepping on sharp objects, Ground personnel to wear high visibility jackets

and by impact and collision with sharp or Remove debris and excavated soil near excavation site

protruding objects Wear respiratory mask if working downwind

Dermatitis caused by contact with irritating and allergenic Never walk under and beside the boring machine

materials. Be aware of nearby vehicles and mobile equipment causing

Mechanical hazards (pinch points). soil to vibrate

Working near underground utilities. Wear correct safety boots and mind steps / do not rush

Overhead power lines hazards. Watch for venomous animals and wear safety boots and

Collision with moving vehicles. leather gloves.

Avoid hand and fingers injuries.

Safety signs in place.

Goal posts to avoid collision with overhead power lines.

Banksman presence in mandatory.

Area Underground utilities maps.

6. Cleaning &Housekeeping • Equipment and tools remain on site • Training for good work practices to be held on Plastic bags

site

• Slip trip and fall • TBT in place before job, housekeeping issue to waste bins

• Trash left in the work place be mentioned in all TBT

• After working day, team leader must ensure

cleaning, inspecting equipment and good

housekeeping.

• Waste management plan is in force during

project

• Waste to be removed in time as per

CONTRACTOR waste management plan

Name Position Date Signed

Prepared By

Checked By

Approved By

You might also like

- Battery FillingDocument3 pagesBattery FillingMajdiSahnounNo ratings yet

- JSA Template 5 - Plumbing and Wastewater System InspectionsDocument13 pagesJSA Template 5 - Plumbing and Wastewater System InspectionsSayed Darwish100% (2)

- ISC-JSA Grouting Works For Shared FenceDocument4 pagesISC-JSA Grouting Works For Shared FenceSameer AlmahboubNo ratings yet

- JSA Erection of Gathering TentDocument12 pagesJSA Erection of Gathering TentMuhammad Tariq100% (2)

- SRB-JSA-41-Thrust Boring - 01 Febr 2010 - 56PL - KM 1+578Document9 pagesSRB-JSA-41-Thrust Boring - 01 Febr 2010 - 56PL - KM 1+578kkalvi100% (1)

- Man Machine InterfaceDocument22 pagesMan Machine Interfaceamdarrif3723100% (1)

- NSRP Project: Confined Space Entry CertificateDocument1 pageNSRP Project: Confined Space Entry CertificateThanh Tung DongNo ratings yet

- EF 1931-STCC-JSA-33 Fire Proofing of The Steel Structure and Vessel Foun...Document5 pagesEF 1931-STCC-JSA-33 Fire Proofing of The Steel Structure and Vessel Foun...Anis Uddin100% (2)

- 9 Use of Hand Roller Compactor SafetyDocument2 pages9 Use of Hand Roller Compactor SafetyarchieNo ratings yet

- Sarawak JSA for Concrete CuttingDocument4 pagesSarawak JSA for Concrete CuttingMohammad Irfan Kiki IsmailNo ratings yet

- Confine Space at Water TankDocument7 pagesConfine Space at Water TanknaraNo ratings yet

- jsa-for-electrical-conduit-installationdocx - compress-đã chuyển đổiDocument6 pagesjsa-for-electrical-conduit-installationdocx - compress-đã chuyển đổiMon Trang NguyễnNo ratings yet

- PVCMS-BMV-HSE-JSA-001 InsulationDocument6 pagesPVCMS-BMV-HSE-JSA-001 InsulationBkdn DungNo ratings yet

- Job Safety Analysis WorksheetDocument7 pagesJob Safety Analysis WorksheetMohamedSaidNo ratings yet

- Job Safety Analysis Sheet: KOC Emergency-160 90030980 (PIL)Document3 pagesJob Safety Analysis Sheet: KOC Emergency-160 90030980 (PIL)Sreeraj Reghunathan Nair VanmazhyNo ratings yet

- JSA-020-Safety Watch-Hot WorkDocument2 pagesJSA-020-Safety Watch-Hot WorkNishad MuhammedNo ratings yet

- One Direct Method Statement: Preventative MeasuresDocument4 pagesOne Direct Method Statement: Preventative MeasuresAyu Wanda SaraswatiNo ratings yet

- Jha RebarsDocument7 pagesJha RebarsJaycee QuinNo ratings yet

- Risk-Assessment-Clean Agent - 369852Document10 pagesRisk-Assessment-Clean Agent - 369852Mohammed Amer Pasha100% (1)

- Kaztec Fabrication Yard, Snake Island: Job Safety Analysis (JSA)Document3 pagesKaztec Fabrication Yard, Snake Island: Job Safety Analysis (JSA)Ogunwa EmmanuelNo ratings yet

- Job Safety Analysis: Night Work at SiteDocument2 pagesJob Safety Analysis: Night Work at SiteSaiyad RiyazaliNo ratings yet

- 4-Safety Violation Report Hemendra Kumar SinghDocument2 pages4-Safety Violation Report Hemendra Kumar Singhjithin shankar100% (1)

- Work Permit Request For HydrotestingDocument3 pagesWork Permit Request For HydrotestingZeyad Rezk50% (2)

- JS A Excavation Work For Electrical CableDocument3 pagesJS A Excavation Work For Electrical CableMohammed MinhajNo ratings yet

- Fall Prevention PlanDocument6 pagesFall Prevention PlanMohammed KhatibNo ratings yet

- Daily JSADocument4 pagesDaily JSAumn_mlkNo ratings yet

- Installation Safety AnalysisDocument5 pagesInstallation Safety AnalysisLeo PascualNo ratings yet

- Area Hard Barrication JsaDocument4 pagesArea Hard Barrication JsanishantNo ratings yet

- JHA Pump CreteDocument2 pagesJHA Pump CretePopo EaldamaNo ratings yet

- Job Safety Analysis Lifting and RiggingDocument17 pagesJob Safety Analysis Lifting and RiggingSam Seed100% (1)

- Excavation PermitDocument2 pagesExcavation PermitRajesh Kumar SinghNo ratings yet

- Akk Jha Installation of Diesel TankDocument3 pagesAkk Jha Installation of Diesel TankDouglas Delly0% (1)

- JSA For Painting Works-Hazards ControlDocument4 pagesJSA For Painting Works-Hazards Controlkaleem0% (2)

- Tower Crane Work Permit ChecklistDocument1 pageTower Crane Work Permit Checklistfaisal nadeemNo ratings yet

- PM 01 Hira For Excavation of Boiler FoundationDocument3 pagesPM 01 Hira For Excavation of Boiler FoundationSyed Shariq Hassan100% (1)

- RA For Man Lift OperationDocument6 pagesRA For Man Lift Operationalla malikNo ratings yet

- JSA - Suface Preparationand Brush PaintingDocument5 pagesJSA - Suface Preparationand Brush PaintingAzad pravesh khanNo ratings yet

- Job Safety Analysis FormDocument2 pagesJob Safety Analysis FormHSE S4No ratings yet

- CR 10 (2) D Safety Harness Inspector TEMPLATEDocument1 pageCR 10 (2) D Safety Harness Inspector TEMPLATELiam Du Piesanie0% (1)

- Job Safety Analysis (JSA) - Rebar Installation/steel Fixing DateDocument1 pageJob Safety Analysis (JSA) - Rebar Installation/steel Fixing DatenabeelNo ratings yet

- Jsa For The Installation of I EamDocument5 pagesJsa For The Installation of I EamMohammed MinhajNo ratings yet

- Checklist For Rope Suspended Platform HSE OCP 16Document1 pageChecklist For Rope Suspended Platform HSE OCP 16Mohamed KamalNo ratings yet

- JSA GC-5 Mobile ScaffoldingDocument6 pagesJSA GC-5 Mobile Scaffoldinggrande100% (2)

- Radiography JSADocument2 pagesRadiography JSAVipul ShankarNo ratings yet

- # 20 Installation of Cable Tray Trunking (SWP)Document5 pages# 20 Installation of Cable Tray Trunking (SWP)Anonymous kWfNFbNo ratings yet

- Project: Field Erection of 15000 Bbls Tank (Ik-2545) : Job Safety AnalysisDocument4 pagesProject: Field Erection of 15000 Bbls Tank (Ik-2545) : Job Safety AnalysisJohn100% (1)

- Jsa FormDocument3 pagesJsa Formmiaicarba100% (1)

- Job Safety Analysis: How To Use This FormDocument4 pagesJob Safety Analysis: How To Use This Formjithin shankar100% (1)

- Job Safety Analysis - Clinker StorageDocument4 pagesJob Safety Analysis - Clinker StorageMohammed MinhajNo ratings yet

- JSA Erection StructureDocument11 pagesJSA Erection StructureJAYESH JOSHINo ratings yet

- Rigging JSA RiggerDocument12 pagesRigging JSA RiggeraQiLGunawanNo ratings yet

- JHA - Survey WorksDocument3 pagesJHA - Survey WorksNazirul Syazwan100% (3)

- Manual Tig Welding (RRC) - Job ProcedureDocument3 pagesManual Tig Welding (RRC) - Job Proceduretitto84886100% (1)

- Plant: Work Location: Date:: Saudi Aramco PMT Saudi Aramco Project EngineerDocument6 pagesPlant: Work Location: Date:: Saudi Aramco PMT Saudi Aramco Project EngineerJoypee MacasamponNo ratings yet

- AL AIN MALL WORK PERMITDocument1 pageAL AIN MALL WORK PERMITVeterano 1968No ratings yet

- Job Safety Analysis For Pump Installation in Ts3 Area: Hcu & Lobs Revamp ProjectDocument5 pagesJob Safety Analysis For Pump Installation in Ts3 Area: Hcu & Lobs Revamp ProjectShilpiengg SafetyNo ratings yet

- JGS SHES JHRA 001 13 Grating Installation and RemovalDocument2 pagesJGS SHES JHRA 001 13 Grating Installation and Removalarnel sungkip100% (2)

- Topographic Survey JSADocument3 pagesTopographic Survey JSAMoaatazz Nouisri86% (7)

- Daily HSSE ReportDocument117 pagesDaily HSSE ReportMoaatazz NouisriNo ratings yet

- DAILY HSSE REPORT 29 - 11 To 02 - 12 2018Document70 pagesDAILY HSSE REPORT 29 - 11 To 02 - 12 2018Moaatazz NouisriNo ratings yet

- Hsse Requirements Trakcing RegisterDocument4 pagesHsse Requirements Trakcing RegisterMoaatazz NouisriNo ratings yet

- Daily Hsse Report 04 - 05 - 12 - 2018Document19 pagesDaily Hsse Report 04 - 05 - 12 - 2018Moaatazz NouisriNo ratings yet

- JSA for safe fence installationDocument5 pagesJSA for safe fence installationMoaatazz Nouisri50% (2)

- 120021-Hse-004 - Risk Assessment Procedure 001Document28 pages120021-Hse-004 - Risk Assessment Procedure 001Moaatazz Nouisri100% (1)

- Daily Hsse Report 27 - 28-11-2018Document12 pagesDaily Hsse Report 27 - 28-11-2018Moaatazz NouisriNo ratings yet

- Daily Hsse Report 04 - 05 - 12 - 2018Document19 pagesDaily Hsse Report 04 - 05 - 12 - 2018Moaatazz NouisriNo ratings yet

- Project HSE Plan for New Airstrip ConstructionDocument47 pagesProject HSE Plan for New Airstrip ConstructionMoaatazz NouisriNo ratings yet

- JSA-002 Civil WorksDocument6 pagesJSA-002 Civil WorksMoaatazz NouisriNo ratings yet

- 120021-Hse-003 - Waste Management PlanDocument21 pages120021-Hse-003 - Waste Management PlanMoaatazz NouisriNo ratings yet

- JSA-070 Desert Road TripDocument4 pagesJSA-070 Desert Road TripMoaatazz NouisriNo ratings yet

- JSA-020 Fence InstallationDocument4 pagesJSA-020 Fence InstallationMoaatazz Nouisri75% (4)

- Topographic Survey JSADocument3 pagesTopographic Survey JSAMoaatazz Nouisri86% (7)

- JSA-001 Earth Works & Civil WorksDocument5 pagesJSA-001 Earth Works & Civil WorksMoaatazz Nouisri50% (2)

- CIVIL WORKS SAFETY ANALYSISDocument7 pagesCIVIL WORKS SAFETY ANALYSISMoaatazz Nouisri67% (3)

- Daily HSSE Report for 24Document19 pagesDaily HSSE Report for 24Moaatazz NouisriNo ratings yet

- 120025-Hse-002 Company Hse Project StandardsDocument25 pages120025-Hse-002 Company Hse Project StandardsMoaatazz NouisriNo ratings yet

- Daily HSSE Report for 24Document19 pagesDaily HSSE Report for 24Moaatazz NouisriNo ratings yet

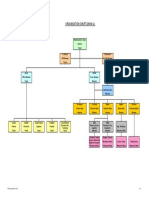

- 04 - Organisation ChartDocument1 page04 - Organisation ChartMoaatazz NouisriNo ratings yet

- 120025-Hse-001 Company Hse Management PlanDocument19 pages120025-Hse-001 Company Hse Management PlanMoaatazz NouisriNo ratings yet

- Daily HSSE Report for 24Document19 pagesDaily HSSE Report for 24Moaatazz NouisriNo ratings yet

- Daily HSSE Report for 24Document19 pagesDaily HSSE Report for 24Moaatazz NouisriNo ratings yet

- Daily HSSE Report for 24Document19 pagesDaily HSSE Report for 24Moaatazz NouisriNo ratings yet

- Daily HSSE Report for 24Document19 pagesDaily HSSE Report for 24Moaatazz NouisriNo ratings yet

- Daily HSSE Report for 24Document19 pagesDaily HSSE Report for 24Moaatazz NouisriNo ratings yet

- 119026-HSE-003 HSE StandardsDocument27 pages119026-HSE-003 HSE StandardsMoaatazz NouisriNo ratings yet

- CV Project Manager-M.Ammar PDFDocument6 pagesCV Project Manager-M.Ammar PDFMoaatazz NouisriNo ratings yet

- CV QAQC Manager-W.DORRI PDFDocument6 pagesCV QAQC Manager-W.DORRI PDFMoaatazz NouisriNo ratings yet

- HDU AuditDocument3 pagesHDU AuditAsdf DgfhgNo ratings yet

- PSM 09 Audits and Observations (MSA)Document16 pagesPSM 09 Audits and Observations (MSA)Shahzad RiazNo ratings yet

- SEED Geohazard-Structural-Earthquake Engineering Design Consultants HRVA GuideDocument3 pagesSEED Geohazard-Structural-Earthquake Engineering Design Consultants HRVA Guiderenzo1221No ratings yet

- Product and Company Identification: Revision Number: 004.0 Issue Date: 03/08/2017Document6 pagesProduct and Company Identification: Revision Number: 004.0 Issue Date: 03/08/2017Ali BakorNo ratings yet

- Scope of WorkDocument18 pagesScope of WorkEric James L. PinaraNo ratings yet

- Desmodur E15: Characterization Form SuppliedDocument3 pagesDesmodur E15: Characterization Form Suppliedsriatul2006No ratings yet

- SDS - Penguard - Comp. B - Marine - Protective - English (Uk) - United Kingdom - 612 - 01.11.2012Document13 pagesSDS - Penguard - Comp. B - Marine - Protective - English (Uk) - United Kingdom - 612 - 01.11.2012NPTNo ratings yet

- 14 Miscellaneous Occupancy ChecklistDocument4 pages14 Miscellaneous Occupancy ChecklistSylvester Lastrella YecyecNo ratings yet

- Crossbow: Portable CNC Cutting MachineDocument232 pagesCrossbow: Portable CNC Cutting Machineson phanNo ratings yet

- Fire Alarm and Detection System ProcedureDocument7 pagesFire Alarm and Detection System ProcedureProjects aissol100% (1)

- Safety Data Sheet: Section 1: Identification of The Substance/Mixture and of The Company/UndertakingDocument9 pagesSafety Data Sheet: Section 1: Identification of The Substance/Mixture and of The Company/UndertakingObydur RahmanNo ratings yet

- White Spirit SDS Safety Data SheetDocument10 pagesWhite Spirit SDS Safety Data Sheetfarah fadhlinaNo ratings yet

- IMS-F MR MASTER LIST OF DOCUMENTS & RECORDS Revised 07-11-2023Document9 pagesIMS-F MR MASTER LIST OF DOCUMENTS & RECORDS Revised 07-11-2023Sandeep Mazumdar100% (1)

- WA80 WA100M 7 Operation ManualDocument304 pagesWA80 WA100M 7 Operation Manualandres sanchez100% (1)

- P1848™/D6 Draft Standard For Techniques & Measures To Manage Functional Safety and Other Risks With Regard To Electromagnetic DisturbancesDocument159 pagesP1848™/D6 Draft Standard For Techniques & Measures To Manage Functional Safety and Other Risks With Regard To Electromagnetic DisturbancesJoão AbdalNo ratings yet

- Za Rec 4c SeriesDocument64 pagesZa Rec 4c SeriesMohamed SaadNo ratings yet

- Job Hazard Analysis Form Stripping Forms: ReferenceDocument2 pagesJob Hazard Analysis Form Stripping Forms: ReferenceReden Mejico PedernalNo ratings yet

- Operating Instructions: Inspection Machine CUB Machine Number: I 1347Document116 pagesOperating Instructions: Inspection Machine CUB Machine Number: I 1347Justine MarashanyeNo ratings yet

- ISO 45001:2018 Awareness OverviewDocument73 pagesISO 45001:2018 Awareness Overviewsanjeev kumar100% (15)

- Kema 09atex0048Document4 pagesKema 09atex0048Nafis TaqiyuddinNo ratings yet

- EOS Basic Biomedical Equipment Servicing L-3Document41 pagesEOS Basic Biomedical Equipment Servicing L-3ኮኾብ ጽባሕNo ratings yet

- Boq - Fire Alarm SystemDocument3 pagesBoq - Fire Alarm System毕文强No ratings yet

- Health and Safety Plan TemplateDocument24 pagesHealth and Safety Plan TemplateNeil McCarum77% (22)

- OSHA Slide Chapter 1Document56 pagesOSHA Slide Chapter 1Jia Yee Ten100% (1)

- Diagram of ISO 45001 Risk Management enDocument1 pageDiagram of ISO 45001 Risk Management enSarabjit Singh SanghaNo ratings yet

- CP and Lesson 1 - Chem. Safety Unit 1Document6 pagesCP and Lesson 1 - Chem. Safety Unit 1Quen CuestaNo ratings yet

- Terra Int'l Construction LLC P.O Box: 44456 Phone: +971 2 666 6121 Fax: +971 2 666 0312Document84 pagesTerra Int'l Construction LLC P.O Box: 44456 Phone: +971 2 666 6121 Fax: +971 2 666 0312Akhil RatnadasNo ratings yet

- Introduction to OSH LegislationDocument31 pagesIntroduction to OSH LegislationMohamad Salleh AbdullahNo ratings yet

- CP-NOC-005 Emergency Response PlanDocument77 pagesCP-NOC-005 Emergency Response PlanPrithivin RajNo ratings yet

- GS SCL eDocument28 pagesGS SCL erigo_skNo ratings yet