Professional Documents

Culture Documents

Surface Preparation Prior To - American Galvanizers Association

Uploaded by

yugandharOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Surface Preparation Prior To - American Galvanizers Association

Uploaded by

yugandharCopyright:

Available Formats

5/14/2020 Surface Preparation Prior to… | American Galvanizers Association

» Surface Preparation Prior to Galvanizing

Surface Preparation Prior to Galvanizing

June 21, 2013

Authored by Bernardo A. Duran III

What surface preparation of the steel or iron is necessary prior to it arriving at the hot-dip galvanizing plant?

Many specifications for protective coatings include provisions for surface preparation prior to coating application and

inspection requirements during/a er coating application. For galvanizing there is usually no special preparation required.

Let me explain.

ASTM specifications for batch hot-dip galvanizing are arranged di erently. For example, ASTM

A123/A123M and A153/A153M (the most commonly used hot-dip galvanizing specifications in North America) cover the

inspection requirements of the finished galvanized product but do not discuss surface preparation of the steel or iron prior

to it being galvanized. ASTM A143/A143M, A384/A384M, and A385/A385M discuss fabrication procedures for steel to be hot-

dip galvanized and address some surface preparation recommendations prior to galvanizing.

Surface Preparation Prior to Hot-Dip Galvanizing

Batch hot-dip galvanizers have a simple process they use to prepare

steel or iron prior to galvanizing. A er the steel has been inspected to

ensure it has adequate vent and drain holes, it is dipped into a series of

cleaning chemicals. The first chemical is a degreasing bath that removes

organic contaminants such as dirt, grease, and oil from the metal. The

next chemical used is pickling acid, which removes mill scale and rust

(oxides) from the steel. The last step before galvanizing is dipping the

steel or iron into a flux bath, which prevents oxidation of the metal prior

to entering the galvanizing bath and also aids the galvanizing reaction in

developing the hot-dip galvanized coating.

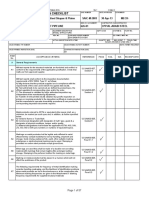

ASTM specifications do not have required parameters for cleaning

chemicals used in the galvanizing process. There are general

concentration ranges these chemicals are most e ective and each

galvanizer optimizes their cleaning chemicals to give them the best Surface preparation

results at cleaning the steel or iron and achieving a high-quality hot-dip

galvanized coating.

Materials the Cleaning Chemicals Cannot Remove

There are some materials the cleaning chemicals used prior to galvanizing cannot remove or have great di iculty removing.

Here is a list of the most common of these materials:

https://galvanizeit.org/knowledgebase/article/surface-preparation-prior-to-galvanizing 1/2

5/14/2020 Surface Preparation Prior to… | American Galvanizers Association

Weld slag and other welding flux residues

Weld splatter and anti-splatter

Burrs (could include excessively rough edges from flame cutting)

Very heavy or extremely adherent mill scale

Mill coatings such as varnishes or lacquers present on some types of pipe

Epoxies, types of vinyl, and asphalt

Sand and other impurities on castings

Oil-based paints and markers

Crayon markers

Very heavy or thick deposits of wax or grease

These materials should be removed from the metal prior to it being delivered to the galvanizing plant. SSPC and NACE have

a variety of commonly used standards for abrasive blast cleaning, hand cleaning, and power tool cleaning, e ective at

removing these materials. Abrasive blasting is usually necessary on castings to remove sand and other impurities from the

casting process. Alternatively, di erent products can be used on the steel or iron which are compatible with the hot-dip

galvanizing process to reduce the need for blasting or hand/power tool cleaning. For example, using uncoated electrodes

avoids the problem of depositing flux on the metal during welding, and galvanizing-safe markers are available that dissolve

in the cleaning baths used in the galvanizing process. Di erent types (specifications) of pipe can be ordered that are free of

mill coatings such as varnishes, lacquers, or oils.

Other Considerations

Some specifiers use generic preparation processes for steel or iron that will be coated, such as always abrasive blasting it. In

most cases, this is not necessary prior to the galvanizing process unless the metal to be galvanized is contaminated with the

materials listed above. The cleaning steps prior to the hot-dipping process adequately clean the metal and ensure a high-

quality hot-dip galvanized coating develops on the metal. In fact, the only way a galvanized coating can develop is if the

metal is free of organic contaminants, mill scale, and oxides. This is a built-in quality control process in that if a galvanized

coating has developed, the underlying metal must have been free of contaminants.

If steel is excessively rusted or pitted, these problems should be discussed with the engineer to ensure there will not be any

structural integrity concerns. Additionally, excessively rough or pitted steel or iron will tend to develop a rough galvanized

coating.

If you have questions concerning the condition or contamination of the steel or iron you would like galvanized, you can

discuss them with your galvanizer or contact the American Galvanizers Association Technical Department at 720-361-4485.

© 2020 American Galvanizers Association. The material provided herein has been developed to provide accurate and

authoritative information about a er-fabrication hot-dip galvanized steel. This material provides general information only

and is not intended as a substitute for competent professional examination and verification as to suitability and

applicability. The information provided herein is not intended as a representation or warranty on the part of the AGA.

Anyone making use of this information assumes all liability arising from such use.

https://galvanizeit.org/knowledgebase/article/surface-preparation-prior-to-galvanizing 2/2

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (589)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (842)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5806)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- Step by Step Log House ConstructionDocument62 pagesStep by Step Log House ConstructionSteve Peachey100% (3)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Productivity Constraints: S. No. DescriptionDocument32 pagesProductivity Constraints: S. No. Descriptionrehan84075% (4)

- AWS D1.1 Equivalent Steels - AWS (Welding) Code Issues - Eng-TipsDocument6 pagesAWS D1.1 Equivalent Steels - AWS (Welding) Code Issues - Eng-TipsyugandharNo ratings yet

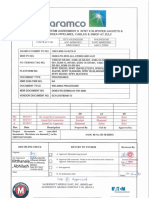

- SAIC-M-2003 Rev 7Document57 pagesSAIC-M-2003 Rev 7yugandhar100% (1)

- Natural ResinsDocument125 pagesNatural Resinsricky4763No ratings yet

- Astm D7359-18Document3 pagesAstm D7359-18Tiêu Linh Tiểu LoanNo ratings yet

- Din 11852Document20 pagesDin 11852MANGESH MANE100% (1)

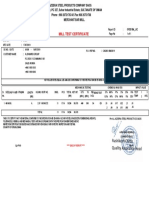

- Mill Test Certificate: Run Date 12/07/2018 OR0019M - JAZ User ID E1037Document1 pageMill Test Certificate: Run Date 12/07/2018 OR0019M - JAZ User ID E1037yugandhar100% (3)

- Stabilization of Peat Soil Using Locally AdmixtureDocument7 pagesStabilization of Peat Soil Using Locally AdmixtureElaMazlanNo ratings yet

- Specification For The Design, Manufacture & Construction of Precast StructuresDocument95 pagesSpecification For The Design, Manufacture & Construction of Precast StructuresL YO Pin100% (2)

- ARBURG ALLROUNDER 370A TD 526447 en GBDocument6 pagesARBURG ALLROUNDER 370A TD 526447 en GBARRKAY DESIGN100% (1)

- Celik Crosswire 6X6 Astm A1011 - (2017-445-3) (51200267)Document1 pageCelik Crosswire 6X6 Astm A1011 - (2017-445-3) (51200267)yugandharNo ratings yet

- W 10x60Document1 pageW 10x60yugandharNo ratings yet

- 1.11111 Hyu Flo Flu Steel: Tensile Test Impact Test (L) Chemical Composition Yield Bend MN S Cu Ni Mo CR NB SNDocument1 page1.11111 Hyu Flo Flu Steel: Tensile Test Impact Test (L) Chemical Composition Yield Bend MN S Cu Ni Mo CR NB SNyugandharNo ratings yet

- Celik Crosswire 6X6 Astm A1011 - (2017-445-3) (51200267)Document1 pageCelik Crosswire 6X6 Astm A1011 - (2017-445-3) (51200267)yugandharNo ratings yet

- L100X100X6Document1 pageL100X100X6yugandharNo ratings yet

- Angles MitwalliDocument1 pageAngles MitwalliyugandharNo ratings yet

- ANG 40 X 5 X 6 MtrsDocument1 pageANG 40 X 5 X 6 MtrsBastin NavinNo ratings yet

- 1-1.5 Pipe MTCDocument1 page1-1.5 Pipe MTCyugandharNo ratings yet

- Appleman - SalzeinflussDocument6 pagesAppleman - SalzeinflussyugandharNo ratings yet

- Vitthanala, AbhilashDocument4 pagesVitthanala, AbhilashyugandharNo ratings yet

- Futura Classic: Technical Data Sheet Application GuideDocument7 pagesFutura Classic: Technical Data Sheet Application GuideyugandharNo ratings yet

- TDS-Penguard HSP-GB-English-ProtectiveDocument5 pagesTDS-Penguard HSP-GB-English-ProtectiveyugandharNo ratings yet

- Salt Mitigation Study Final Report-Fat SquirrelDocument125 pagesSalt Mitigation Study Final Report-Fat SquirrelyugandharNo ratings yet

- Steelmaster 60WB: Technical Data Sheet Application GuideDocument10 pagesSteelmaster 60WB: Technical Data Sheet Application GuideyugandharNo ratings yet

- Soluble Salt Tester: Full Guide v. 1.2Document21 pagesSoluble Salt Tester: Full Guide v. 1.2yugandharNo ratings yet

- Nitratos MR Method 8171Document8 pagesNitratos MR Method 8171andreaNo ratings yet

- PQR Al 6xxxDocument7 pagesPQR Al 6xxxAmin ThabetNo ratings yet

- BA 03-01 Application Sulfide - Mercaptan UOP 163Document7 pagesBA 03-01 Application Sulfide - Mercaptan UOP 163Mr GhostNo ratings yet

- S-000-13a0-001 - 2a General Spesifikation For Painting and CoatingDocument57 pagesS-000-13a0-001 - 2a General Spesifikation For Painting and Coatingderi yuliantoNo ratings yet

- Handling of Fuel Oils: Ron Angelo P. Daguio Ma. Cristina Valdez BSME-4Document16 pagesHandling of Fuel Oils: Ron Angelo P. Daguio Ma. Cristina Valdez BSME-4Ronald Andrei DaguioNo ratings yet

- WCH12 01 2024 Jan QPDocument28 pagesWCH12 01 2024 Jan QPbmaniafuNo ratings yet

- Welding ReportDocument8 pagesWelding ReportRVNL GoaNo ratings yet

- Nový Kód Starý Kód Moc S DPH Odporúčaná Cena: Žiarovky, Pätice, MateriálDocument53 pagesNový Kód Starý Kód Moc S DPH Odporúčaná Cena: Žiarovky, Pätice, MateriálShadi AbdelsalamNo ratings yet

- Electronegativity and Bond TriangleDocument9 pagesElectronegativity and Bond TrianglePedro BarónNo ratings yet

- TDS PVP Povidone Iodine CAS 25655 41 8Document2 pagesTDS PVP Povidone Iodine CAS 25655 41 8Rabah ABBASNo ratings yet

- FCA Foam ChamberDocument5 pagesFCA Foam ChamberN AfiyahNo ratings yet

- Gold Analysis - Are There Alternative Methods Other Than Standard Fire Assay For The Analysis?Document9 pagesGold Analysis - Are There Alternative Methods Other Than Standard Fire Assay For The Analysis?neloar2010No ratings yet

- 13-Light Emitting ConcreteDocument39 pages13-Light Emitting Concretesinan.ayaseenNo ratings yet

- 3-Wood, Composite, and Transparent Plastic Structures TEXTDocument10 pages3-Wood, Composite, and Transparent Plastic Structures TEXTJecah Angelu S. SaquianNo ratings yet

- Tes SylineDocument40 pagesTes SylineBima SetiajiNo ratings yet

- ECP Spares Catalogue PDFDocument68 pagesECP Spares Catalogue PDFgoogle manNo ratings yet

- Humiseal 1A33 Conformal Coating English TdsDocument2 pagesHumiseal 1A33 Conformal Coating English TdsLee HitchensNo ratings yet

- Sec 15 - FinishingDocument34 pagesSec 15 - FinishingSaad HussainNo ratings yet

- Prosthesis For Symes AmputationDocument24 pagesProsthesis For Symes AmputationSHAIK SHABEENANo ratings yet

- Pipe ShoesDocument8 pagesPipe ShoeschabibNo ratings yet

- Marshall DesignDocument21 pagesMarshall Designomalpaul55No ratings yet

- Pureit Classic Ro MF ManualDocument17 pagesPureit Classic Ro MF ManualShyam0% (1)