Professional Documents

Culture Documents

Equipment Definition: Component Literature

Uploaded by

Abbas AkbarOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Equipment Definition: Component Literature

Uploaded by

Abbas AkbarCopyright:

Available Formats

GE Energy

Rev.: B

Page: 1/5

OPERATION AND MAINTENANCE MANUAL

COMPONENT LITERATURE

EQUIPMENT DEFINITION

GE DEVICE : 96QV-1

DESIGNATION : TANK'S AIR VACUUM DIFFERENTIAL

PRESSURE TRANSMITTER

SUPPLIER : GE DRUCK

TYPE : PTX661-3433

LITERATURE REFERENCE : PTX 600 SERIES (4 PAGES)

All right reserved copyright

OMML_0416_17_96QV-1_B_EN Revision: B Date: 12/2013

PTX 600 SERIES

Precision Pressure

Transmitters

• Excellent characteristics

Stability: 0.1% F.S./year

Thermal performance: 1%, -20° to 80°C

Linearity and hysteresis: ±0.08% F.S.

• High overload and burst pressure

• Hastelloy and stainless steel

wetted parts

• RFI protected

• Intrinsically safe versions available

• Electrical and pressure connection

options

PTX 600 SERIES

PTX 600 Series - 01/99 1

PTX 600 SERIES: Precision Pressure Transmitters

INTRODUCTION

For critical applications in industrial and research potting of the electronics to ensure integrity under high

environments the PTX 600 series of two wire, 4-20mA levels of shock and vibration, with environmental ratings

output pressure transmitters improves upon the available from IP50 to IP68 standards dependant upon the

performance of previous models by offering new levels of electrical connection selected.

stability, versatility and measurement accuracy from a

standard production device. To fully represent operating conditions the transmitters are

calibrated in terms of end point characteristics, expressed

Druck’s well proven silicon technology has been developed as the Terminal Straight Line (TSL) for non-linearity,

to provide a miniature micro-machined diaphragm which is hysteresis and repeatability, and the thermal effects are

electrostatically bonded to a glass substrate and stitch expressed as a maximum change in output from the

bonded within a glass to metal seal assembly to provide calibration as room temperature.

exceptional thermal and stress isolation.

Every sensor is fully calibrated and compensated for

The glass to metal seal is completed with an electron-beam thermal effects, and then stocked as a “core” (PTX 600

welded Hastelloy C276 isolation diaphragm and 316 model) with the test results in standard DIN pressure

stainless steel pressure port (NACE compatible materials for ranges.

sour gas service). The reduced internal volume of this

assembly and advanced design features of the new sensor Prior to despatch the core is adjusted to intermediate

significantly improves the stability and thermal performance ranges, or alternative pressure units if required, and

of the transmitter. completed with the appropriate electrical connection

format.

The two-wire electronics incorporate power supply

regulation and amplifier stages with independent zero and When intermediate ranges are required the core is selected

span controls, reverse polarity and over voltage protection to ensure that the thermal effects remain within

with an RFI bulkhead providing feedthrough filters within specifications after adjustment.

the body tube assembly.

The transmitter provides an integral G1/4 female pressure

The PTX 600 series provides the user with a high accuracy, port and a range of screw-in stainless steel male to male

high stability pressure transmitter, based upon well proven adaptors are available as options, to be mounted via a

techniques with the benefit of the latest sensor and bonded industrial seal supplied with the option.

electronics technology within a robust, compact design able

to withstand the rigours of industrial sites whilst providing The detachable electrical and pressure connection formats

the performance of a precision instrument. allow the user to reconfigure or change these parts on site

if they are damaged or an alternate location is required

A high level of protection against electrical interference has (conduit and submersible connections are not detachable).

been combined with surface mount components and total

The PTX 500/600 series pressure transmitter core contains at its heart and advanced micro-machined silicon pressure sensor restrained in a high integrity glass to metal

seal providing both electrical and physical isolation from the pressure media. An isolating diaphragm of Hastelloy is welded to the seal and transmits system pressure

to the sensor via the silicone filling. The front end is screwed and welded over the seal to complete the pressure containment module.

A printed circuit board secured to the rear of the pressure module contains the elements required to rationalise the output, provide temperature compensation and

allow customer adjustment of zero and span. A stainless steel body tube encloses the electronics and its encapsulant and permits subsequent fitment of the RFI/EMI

protection assembly. Units will be stocked at this level, awaiting orders, leaving only the electrical interface of the customers choice to be assembled prior to dispatch.

RFI/EMI Protection Strain Gauge

Integral ground plane incorporating Diffused into integrated Wire Bonding

feed-through capacitive filters silicon chip Stitch bonding

connections from

chip to module pin

Etched Cavity

Micro-machined

silicon sensor

Temperature Sensor

On-chip diode

Circuit Board Pressure Module for optimum

High-spec. components, Stainless steel glass to metal seal with temperature

fully encapsulated Hastelloy isolating diaphragm and silicone fluid fill performance

PTX 600 Series - 01/99 2

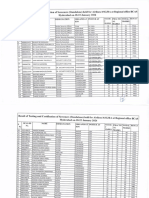

PTX 600 SERIES: Specification

Operating Temperature Range Zero Offset and Span Setting Volumetric Displacement

Any pressure unit and (zero Based) span ±0.05mA Not greater than 0.1cm3 for nominal span.

available between 250mbar and 700 bar full ±5% site adjustable by sealed, non-

RFI Protection

scale to gauge and absolute formats: spans interacting potentiometers (resolution of From 10kHz to 500MHz:-

down to 100mbar available in gauge format potentiometers ±1 A).

Cables in conduit: ±0.1% span change at

only. (PTX 630 not adjustable). 30V/m

Standard Ranges: Long Term Stability Cables unshielded: ±1% span change at

0 to 100, 160mbar (gauge only) At standard reference conditions the 10V/m.

0 to 250, 400, 600 mbar, 1, 1.6, 2.5, 4, 6, 10, 16, calibration will not change by more than

Voltage Spike Protection

25, 40, 60 bar gauge and absolute. 0.1% F.S./annum (0.05% F.S. typical) Units will withstand 2kV spike test to

0 to 100, 160, 250, 400, 600, 700 bar sealed Operating Temperature Range IEC 801-4 form without damage, applied

gauge and absolute. Ambient: -20° to + 80°C between excitation lines or excitation line

Process media: -30° to + 120°C and case.

Compound, offset and reversed sensitivity

Storage: -40° to + 125°C

ranges available. e.g. Marine Approval

-1 to +1 barg, +1 to +3 barg, Temperature Effects Certified for use in vessels classed with

3 to 0 barg. For ranges of 400mbar and above the output RINA (certificate 5/437/93).

For further information please refer to will not deviate from room temperature

ACCESSORIES AVAILABLE TO ORDER:

manufacturer. calibration by more than

0.5%F.S. over -10° to +50°C or Screw-in Male/Male Adaptors

Overpressure 1%F.S. over -20° to +80°C. G1/4 male (P/N 190-040)

The rates pressure can be exceeded by the 1/ NPT male (P/N 190-038)

Typically 0.3%F.S., -10° to +50°C. 4

following multiples without degrading 7/ UNF male (MS33656-4 compatible)

0.7%F.S., -20° to +80°C. 16

performance:- For ranges below 400 mbar these values will (P/N 190-042)

2 bar for ranges up to 600mbar increase pro-rata with calibration span. M14 x 1.5 male (P/N 190-036)

3 x for 1 bar to 40 bar ranges. G1/2 (pressure gauge connection)

2 x for ranges above 40 bar. Mounting Position Effect (P/N 190-039)

Negligible effect. Adaptors manufactured in 316 stainless

Pressure Containment For ranges below 600mbar the “g” offset steel).

Application of the following pressure may effect on zero can be adjusted using the zero

damage the transmitter but process media Bonded Seal (P/N 204-053)

potentiometer. To fit between transmitter and screw-in

leakage will not occur:-

Humidity male/male adaptors (Nitrile and zinc plated

Gauge Reference Versions: up to 100% RH non-condensing. steel).

4 bar for ranges up to 600mbar For condensing atmospheres please refer to

Cable (P/N 192-004)

10 bar for ranges 600mbar to 1.6 barg manufacturer. For gauge ranges of 60 bar and below the

5 x rated pressure (200 bar maximum) Weight PTX 610 required this 6mm O.D. vented

for ranges above 1.6 barg to 60 barg. PTX 600 core: 330 gms. Excluding optional cable.

Absolute/Sealed Gauge Reference electrical connections, cable etc.

Lighting Suppression (P/N*)

Versions: Intrinsic Safety (Optional) Alternate mating part to DIN 43650 assembly

200 bar for ranges up to 60 bara. These transmitters can be certified for use including lightning suppression components.

1400 bar for ranges above 60 bara. with barrier systems to EEx ia gas group IIC (Not available for Intrinsically Safe models).

with T4 rating for ambient temperatures up

Pressure Media

to 80°C to BS5501 part 7 and Cenelec Continuing development sometimes

Fluids compatible with a fully welded

EN50 020. necessitates specification changes without

assembly of 316 stainless steel and Hastelloy

Maximum integral cable length 29 meters for notice.

C276 (NACE compatible grades).

PTX 620/630-01.

Transmitter Supply Voltage Extra cable can be added during installation

9-30V d.c. in accordance with system certificate.

This voltage must appear across the Electrical Connection

transmitter terminals. Versions available for IP50 to IP68 ratings

(see ordering information).

TOTAL LOAD RESISTANCE (OHMS)

Mating parts supplied with plug/socket

versions (PTX 610 & 660)

1 metre integral cable supplied as standard

on PTX 620 and PTX 630 models.

Longer lengths available on request.

For junction box version please refer to

PTX 651/PTX 671 data sheet.

Pressure Connection

POWER SUPPLY VOLTAGE (V.d.c) G 1/4 female.

Supply Sensitivity Screw-in male/male adaptors available

0.005% F.S./Volt with excellent 50Hz and (see accessories).

100Hz supply ripple rejection. For 1/2 NPT version please refer to

Insulation PTX 651/PTX 671 data sheet.

Greater than 10Mohms at 500V d.c. For open face please refer to

(3 Mohms at 500V a.c. due to RFI filters) from PTX 700 data sheet.

excitation lines to case. Acceleration Sensitivity

0.044% F.S./g for 400mbar decreasing to

Output Current

0.0003% F.S./g for 60 bar.

4-20mA (two-wire configuration)

proportional for zero to full scale pressure. Mechanical Shock

1000g 1ms half sine pulse in each 3

Combined Non-Linearity, Hysteresis and mutually perpendicular axis will not effect

Repeatability calibration.

Terminal definition: The output will not

Deviate from the straight line connecting zero Vibration

and full scale output by more than 0.15% F.S. response less than 0.05% F.S./g at 30G peak

(Typically 0.1% F.S.). 10Hz-2kHz, limited by 12mm double

Best straight line deviation: amplitude (MIL-STD 810C Proc 514.2-2

PTX 600 SERIES

±0.05% F.S. (Typically ±0.5% F.S.). Curve L).

PTX 600 Series - 01/99 3

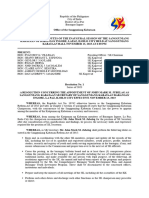

INSTALLATION DRAWINGS Dimensions: mm

DETACHABLE/INTERCHANGEABLE INTEGRAL Electrical Connector Versions

Electrical Connector Versions

ORDERING INFORMATION

Please state the following:-

(1) Type number

PTX 6X X - X

Approvals

0 Commercial

I Celelec

N N Type*

U U.L.

F F.M.*

L Lloyds*

C C.S.A *Future releases

Temperature Effects

0 -10° to +50°C

1 -20° to +80°C

Electrical Connection

0 Solder tags (IP50)

1 DIN 43650 plug/socket (IP65)

2 Integral cable assembly (IP63)

3 Submersible cable assembly

(IP68 to 700mH2Og)

4 Rotatable conduit (IP65)

5 M20 conduit (IP65)

6 MIL-C-26482 plug/socket

(2) Operating pressure range.

(3) Accessories (if required).

Druck Limited Agent:

Fir Tree Lane, Groby

Leicester LE6 0FH, England

Telephone: +44 (0) 116 231 7100

Facsimile: + 44 (0) 116 231 7101

E-Mail: sales@druck.com

Internet: http://www.druck.com

PTX 600 SERIES 1/99

PTX 600 Series - 01/99 4

You might also like

- PTX 600 Series: Precision Pressure Transm IttersDocument4 pagesPTX 600 Series: Precision Pressure Transm IttersRICHAR MORENONo ratings yet

- Ptx-600 Pressure TransducerDocument4 pagesPtx-600 Pressure Transducerhvdb72No ratings yet

- Druck PTX-500 TransmitterDocument2 pagesDruck PTX-500 TransmitterTuan TranNo ratings yet

- Ajax Tocco Inductron PT - 092003 PDFDocument2 pagesAjax Tocco Inductron PT - 092003 PDFViraj ShiroleNo ratings yet

- Changeover SwitchesDocument16 pagesChangeover SwitchesBENNo ratings yet

- DIN-Rail EMC/RFI Filter With Minimum Leakage Current: Sheet 3-Phase Filters FN 3025/FN 3026Document6 pagesDIN-Rail EMC/RFI Filter With Minimum Leakage Current: Sheet 3-Phase Filters FN 3025/FN 3026Santosh KumarNo ratings yet

- Caudalimetro MFE 600EDocument13 pagesCaudalimetro MFE 600EMarioNo ratings yet

- Ultra-Compact EMC/RFI Filter For Motor Drives Applications: Sheet 3-Phase Filters FN 3258Document5 pagesUltra-Compact EMC/RFI Filter For Motor Drives Applications: Sheet 3-Phase Filters FN 3258huyvuNo ratings yet

- Ge Druck PTX 7535Document2 pagesGe Druck PTX 7535ICSSNo ratings yet

- The Pluggable Transformer: Flexibility For Future GridsDocument8 pagesThe Pluggable Transformer: Flexibility For Future GridsChumporn SaraphatmarkyingNo ratings yet

- Cbip 88Document14 pagesCbip 88Sai Kanth100% (1)

- MFE600E Electromagnetic FlowmeterDocument39 pagesMFE600E Electromagnetic FlowmeterFrancisco SantanaNo ratings yet

- Manual Motor Starter Catalog USEH530c PDFDocument92 pagesManual Motor Starter Catalog USEH530c PDFLin ZawNo ratings yet

- Electrical Tender NoticeDocument163 pagesElectrical Tender NoticeRaja Bharath DonthiNo ratings yet

- PrismaDocument10 pagesPrismaRavi SankarNo ratings yet

- Pressure Trasducers ArkerDocument26 pagesPressure Trasducers ArkerVictor Hugo Benitez Paez100% (1)

- HT4 - RS485 - Class - 0.2 Category B - Rev 01Document11 pagesHT4 - RS485 - Class - 0.2 Category B - Rev 01Sristi MitraNo ratings yet

- TM 160-315 DatasheetDocument8 pagesTM 160-315 DatasheetThouraya HbsNo ratings yet

- 3 PH 3wire 11 KV FDR New - Dated 21.11.2011Document18 pages3 PH 3wire 11 KV FDR New - Dated 21.11.2011David AriasNo ratings yet

- Wilo-Datasheet International en 2537343 Siboost-Smart-3-Helix-Ve1003Document7 pagesWilo-Datasheet International en 2537343 Siboost-Smart-3-Helix-Ve1003sanaaNo ratings yet

- 60.32-069 - 1994 Pressure TransmittersDocument5 pages60.32-069 - 1994 Pressure TransmitterspradeepNo ratings yet

- Frako KBR Compensare ComponenteDocument62 pagesFrako KBR Compensare ComponenteMilton HernandezNo ratings yet

- Neutral Grounding ResistorsDocument4 pagesNeutral Grounding ResistorsLong LeoNo ratings yet

- Ecosine Max, 480 VAC 60 HZ Full Performance Passive Harmonic FiltersDocument5 pagesEcosine Max, 480 VAC 60 HZ Full Performance Passive Harmonic FiltersOmar Alfredo Del Castillo QuispeNo ratings yet

- Littelfuse PDM EPC DatasheetDocument2 pagesLittelfuse PDM EPC DatasheetRudi WernikNo ratings yet

- Okken Solution GuideDocument26 pagesOkken Solution GuideShailesh ChettyNo ratings yet

- A Fully Isolated Amplifier Based On Charge-Balanced SAR ConvertersDocument10 pagesA Fully Isolated Amplifier Based On Charge-Balanced SAR ConvertersnidhalNo ratings yet

- VC 06.07.07Document36 pagesVC 06.07.07Razvan SasuNo ratings yet

- TriMEC VC Catalog E 0901Document36 pagesTriMEC VC Catalog E 0901Razvan SasuNo ratings yet

- ProductSheetDocument2 pagesProductSheetmiko miladNo ratings yet

- publia1MRK504141-BEN C en Product Guide Transformer Protection RET6Document126 pagespublia1MRK504141-BEN C en Product Guide Transformer Protection RET6Abdullah AlmarriNo ratings yet

- Breaker Manual HPA 12Document6 pagesBreaker Manual HPA 12mukesh_kht1No ratings yet

- Breaker Manual HPA 12Document6 pagesBreaker Manual HPA 12mukesh_kht1100% (1)

- Kotef: Combined Metering Unit To KVDocument4 pagesKotef: Combined Metering Unit To KVLarocque11No ratings yet

- Asc LB Ds 3040Document2 pagesAsc LB Ds 3040Francisco MartinezNo ratings yet

- Sec10 - Termination and SplicesDocument16 pagesSec10 - Termination and SplicesYusufNo ratings yet

- Inductron Power SourceDocument2 pagesInductron Power SourceRohan KulkarniNo ratings yet

- Material SpecificationsDocument27 pagesMaterial Specificationssat palNo ratings yet

- 02 CSS SpecsDocument23 pages02 CSS Specsshimla kaurNo ratings yet

- RM848HE Product Sheet 2022 8 9 22Document2 pagesRM848HE Product Sheet 2022 8 9 22STC Hồng NgọcNo ratings yet

- Salient Features AHPFC PanelDocument5 pagesSalient Features AHPFC PanelYusuffNo ratings yet

- CT IMB Brochure PDFDocument4 pagesCT IMB Brochure PDFmanuelverdugo203No ratings yet

- Gas Insulation TransformerDocument16 pagesGas Insulation TransformerEnrique Medina CalvilloNo ratings yet

- Weidmuller OptocouplersDocument34 pagesWeidmuller Optocouplersspeedy65No ratings yet

- 60.30-069 - 1994specification For Differential PressureDocument5 pages60.30-069 - 1994specification For Differential PressurepradeepNo ratings yet

- Design and Optimization of Inter-Coil Insulation System of A Cast Resin Transformer Using FEMDocument4 pagesDesign and Optimization of Inter-Coil Insulation System of A Cast Resin Transformer Using FEMHarmonyNo ratings yet

- Epcos China (TDK) ER - 35!20!11Document7 pagesEpcos China (TDK) ER - 35!20!11leoNo ratings yet

- DLMS Spec For Bulk MetersDocument36 pagesDLMS Spec For Bulk MetersSuresh UmadiNo ratings yet

- Tyco Joints Single Core Unarmoured XlpeDocument4 pagesTyco Joints Single Core Unarmoured XlpeiamlpNo ratings yet

- Parts Derating Requirements and Application ManualDocument282 pagesParts Derating Requirements and Application Manualemilfrancu100% (1)

- Electroducto SCPDocument56 pagesElectroducto SCPCarqtre Carqtre TegNo ratings yet

- PDFDocument8 pagesPDFNorng VibolNo ratings yet

- TT 30Document2 pagesTT 30fabianrico2No ratings yet

- EATON E Series DX 20-40kVA BrochureDocument4 pagesEATON E Series DX 20-40kVA BrochureFlorin MNo ratings yet

- Sbs Ngbed2Document6 pagesSbs Ngbed2emiliaNo ratings yet

- Single Stage PFC AC - DC Converter Using Pi ControllerDocument5 pagesSingle Stage PFC AC - DC Converter Using Pi ControllerIJRASETPublicationsNo ratings yet

- Thyristors For Commutation of Current Impulse With Extremely High AmplitudeDocument5 pagesThyristors For Commutation of Current Impulse With Extremely High AmplitudeAndres BornacellyNo ratings yet

- Empowering Networks: A Comprehensive Guide to Medium Voltage SwitchgearFrom EverandEmpowering Networks: A Comprehensive Guide to Medium Voltage SwitchgearNo ratings yet

- Atomizing Air PidDocument2 pagesAtomizing Air PidAbbas AkbarNo ratings yet

- 30-70 Nr. 428 - 2-2000 EnglischDocument52 pages30-70 Nr. 428 - 2-2000 EnglischZizhang Guo100% (2)

- COMPRESSOR WASHING PidDocument2 pagesCOMPRESSOR WASHING PidAbbas AkbarNo ratings yet

- Regulator - FLDocument52 pagesRegulator - FLMec JohnNo ratings yet

- Atomizing Air PidDocument2 pagesAtomizing Air PidAbbas AkbarNo ratings yet

- On The Synchronous Generator ParametersDocument6 pagesOn The Synchronous Generator ParametersAbbas AkbarNo ratings yet

- Governor Model GGOV1 and GGOV1DDocument2 pagesGovernor Model GGOV1 and GGOV1DAbbas AkbarNo ratings yet

- GE - Frame - 9E - LUBE - OIL - FILTER - LOF11Document14 pagesGE - Frame - 9E - LUBE - OIL - FILTER - LOF11Abbas AkbarNo ratings yet

- Exciter Model Esdc1aDocument1 pageExciter Model Esdc1aAbbas AkbarNo ratings yet

- Equipment Definition: Component LiteratureDocument4 pagesEquipment Definition: Component LiteratureAbbas AkbarNo ratings yet

- Equipment Definition: Component LiteratureDocument53 pagesEquipment Definition: Component LiteratureAbbas AkbarNo ratings yet

- Immersion Heater Lube Oil Tank (23QTX, Y) PDFDocument6 pagesImmersion Heater Lube Oil Tank (23QTX, Y) PDFAbbas AkbarNo ratings yet

- Equipment Definition: Component LiteratureDocument36 pagesEquipment Definition: Component LiteratureAbbas AkbarNo ratings yet

- Equipment Definition: Component LiteratureDocument5 pagesEquipment Definition: Component LiteratureAbbas AkbarNo ratings yet

- Equipment Definition: Component LiteratureDocument5 pagesEquipment Definition: Component LiteratureAbbas AkbarNo ratings yet

- Lubricating Oil System 1 - Definition: Rev.: A Page: 1/4Document4 pagesLubricating Oil System 1 - Definition: Rev.: A Page: 1/4Abbas AkbarNo ratings yet

- Equipment Definition: Component LiteratureDocument2 pagesEquipment Definition: Component LiteratureAbbas AkbarNo ratings yet

- Equipment Definition: Component LiteratureDocument11 pagesEquipment Definition: Component LiteratureAbbas AkbarNo ratings yet

- Equipment Definition: Component LiteratureDocument17 pagesEquipment Definition: Component LiteratureAbbas AkbarNo ratings yet

- Equipment Definition: Component LiteratureDocument65 pagesEquipment Definition: Component LiteratureAbbas Akbar0% (1)

- Equipment Definition: Component LiteratureDocument4 pagesEquipment Definition: Component LiteratureAbbas AkbarNo ratings yet

- Equipment Definition: Component LiteratureDocument3 pagesEquipment Definition: Component LiteratureAbbas AkbarNo ratings yet

- Instructions For The Safe Use Of: Web LashingsDocument2 pagesInstructions For The Safe Use Of: Web LashingsVij Vaibhav VermaNo ratings yet

- DCF ModelDocument14 pagesDCF ModelTera ByteNo ratings yet

- Renvoi in Private International LawDocument4 pagesRenvoi in Private International LawAgav VithanNo ratings yet

- 2 1 PDFDocument18 pages2 1 PDFالمهندسوليدالطويلNo ratings yet

- Millets: Future of Food & FarmingDocument16 pagesMillets: Future of Food & FarmingKIRAN100% (2)

- A Comprehensive Review On Renewable and Sustainable Heating Systems For Poultry FarmingDocument22 pagesA Comprehensive Review On Renewable and Sustainable Heating Systems For Poultry FarmingPl TorrNo ratings yet

- Scientific American - Febuary 2016Document84 pagesScientific American - Febuary 2016Vu NguyenNo ratings yet

- You Wouldnt Want To Sail On A 19th-Century Whaling Ship 33 Grisly EnglishareDocument36 pagesYou Wouldnt Want To Sail On A 19th-Century Whaling Ship 33 Grisly EnglishareDušan MićovićNo ratings yet

- Personal Information: Witec Smaranda 11, A3 Bis, Blvd. Chisinau, Bucharest, Romania 0040722597553Document6 pagesPersonal Information: Witec Smaranda 11, A3 Bis, Blvd. Chisinau, Bucharest, Romania 0040722597553MirelaRoșcaNo ratings yet

- Ex 6 Duo - 2021 Open-Macroeconomics Basic Concepts: Part 1: Multple ChoicesDocument6 pagesEx 6 Duo - 2021 Open-Macroeconomics Basic Concepts: Part 1: Multple ChoicesTuyền Lý Thị LamNo ratings yet

- User Custom PP Install74Document2 pagesUser Custom PP Install74Zixi FongNo ratings yet

- (Rajagopal) Brand Management Strategy, Measuremen (BookFi) PDFDocument317 pages(Rajagopal) Brand Management Strategy, Measuremen (BookFi) PDFSneha SinghNo ratings yet

- Road To Recovery: Moving To A New NormalDocument10 pagesRoad To Recovery: Moving To A New NormalFOX5 VegasNo ratings yet

- HyderabadDocument3 pagesHyderabadChristoNo ratings yet

- Oil Refinery OpsDocument3 pagesOil Refinery OpsPhiPhiNo ratings yet

- Pavement Design - (Rigid Flexible) DPWHDocument25 pagesPavement Design - (Rigid Flexible) DPWHrekcah ehtNo ratings yet

- 4 FAR EAST BANK & TRUST COMPANY V DIAZ REALTY INCDocument3 pages4 FAR EAST BANK & TRUST COMPANY V DIAZ REALTY INCDanielleNo ratings yet

- 2023 Reso-01Document3 pages2023 Reso-01John Mark Mercado JubelagNo ratings yet

- Maverick Research: World Order 2.0: The Birth of Virtual NationsDocument9 pagesMaverick Research: World Order 2.0: The Birth of Virtual NationsСергей КолосовNo ratings yet

- ASTM A586-04aDocument6 pagesASTM A586-04aNadhiraNo ratings yet

- FC2060Document10 pagesFC2060esnNo ratings yet

- RA 9184 & RA 3019 NotesDocument5 pagesRA 9184 & RA 3019 Notesleng_evenNo ratings yet

- Problem SetDocument61 pagesProblem SetEmily FungNo ratings yet

- CDCS Self-Study Guide 2011Document21 pagesCDCS Self-Study Guide 2011armamut100% (2)

- Where To Eat PizzaDocument3 pagesWhere To Eat PizzaLiliancitaLcJsNo ratings yet

- Surface News - 20130704 - Low Res PDFDocument9 pagesSurface News - 20130704 - Low Res PDFYoko GoldingNo ratings yet

- Exercise Guide - Broad Crested WeirDocument18 pagesExercise Guide - Broad Crested Weirvipul anandNo ratings yet

- Joseph J. Fiumara v. Fireman's Fund Insurance Companies, 746 F.2d 87, 1st Cir. (1984)Document7 pagesJoseph J. Fiumara v. Fireman's Fund Insurance Companies, 746 F.2d 87, 1st Cir. (1984)Scribd Government DocsNo ratings yet

- KL1508 KL1516: 8/16-Port Cat 5 High-Density Dual Rail LCD KVM SwitchDocument5 pagesKL1508 KL1516: 8/16-Port Cat 5 High-Density Dual Rail LCD KVM SwitchnisarahmedgfecNo ratings yet

- Pertemuan - 12 MetopenDocument40 pagesPertemuan - 12 MetopenulviaNo ratings yet