Professional Documents

Culture Documents

2 PDF

Uploaded by

Gerald See Toh0 ratings0% found this document useful (0 votes)

27 views1 pageOriginal Title

2.pdf

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

27 views1 page2 PDF

Uploaded by

Gerald See TohCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 1

EDFAAO (2014) 2:18:23

1537-0755/$19.00 ©ASM International®

Tantalum Capacitor FA

An Overview of Failure Analysis of

Tantalum Capacitors

Javaid Qazi, Kemet Electronics

javaidgazi@kemet.com

Introduction

‘A meaningful failure analysis of a capacitor (CAP)

requires a thorough understanding of its construct

tion. Capacitors can be classified into different types

based on their materials and construction: tantalum,

ceramics, aluminum, and so on (Table 1). Each of-

fers. unique set of properties suited for a particular

application. A simple CAP consists of a dielectric

material sandwiched between two conductors with

a bias applied across them. The capacitance (C) of a

CAP is given by the following equation, where, A,

and tare the dielectric constant, surface area, and

thickness, respectively:

C=eA/t (Eq1)

Miniaturization of electronic devices demands

higher and higher capacitance in a smaller volume.

One way to achieve higher capacitance in a small

volumes to increase the “A” in Eq 1. Thisis achieved

differently in different types of capacitors. In the case

of tantalum CAPs, for example, it is achieved with

porous tantalum anodes (high surface area/volume),

which are produced by pressing and sintering tane

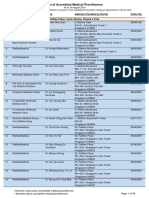

Table 1 Different types of CAPs

talum powder, with an attached tantalum wire. An

amorphous TaOs dielectric is then electrochemically

grown on this high-surface-area porous tantalum an

de. The TayQs is typically a few tens of nanometers

thick. The porous anode is then impregnated with a

counterelectrode layer (MnO; or conductive poly

mer), providing high capacitance in a small volume

(Fig. 1). Solid-state tantalum capacitors are typically

used for 100 V or below, with most of them being

50 V or lower. Wet tantalum capacitors (the coun-

terelectrode being a liquid) allow higher working,

voltages, up to a few hundred volts

In film and ceramic CAPs, thin layers of dielectric

and electrode materials are stacked alternately, with

alternating electrodes displaced to avoid contact

between the opposing terminals. Figure 2 shows the

typical construction ofa ceramic capacitor. A few tens

tohundreds (in ceramic CAPs) or even thousands (in

film CAPs) of these layers can be stacked to obtain

the desired capacitance.

Because of significant dissimilarity in the mate=

rials and construction of different types of CAPs

(Table 1, Fig. 1 and 2), the cause oftheir failure is also

different. Consequently,

each condition requires

Type Dielectric Electrodelcounterelctode Construction Polardevices nique failure analysis

Tantalum Tantalum, Tantalum/MnO; Porous tantalum Yes (FA) approach. Itis worth

‘oxide Tantalum/conduetive polymer anode for high noting that the FA of the

Tantalum/liquid eletrohyte surface aea failed CAP is part of the

Aluminum Aluminum Aluminum/conductive polymer Etchedaluminum Yes overall roat-cause analy

oxide Aluminum/Iiquid clecnolyte foils for high sis, along with circuit

surface aea and application analy-

Ceramics BaTiO:, _Basometalelectode (BME), _Layeredstricture Noses, This paper provides

ZeMiO, ete, suchascopper nickel for highsurface tea an overview of FA for

Peet accivenpeliaiven surface-mount tantalum

Film Polypropylene, Metal, such as zine, Layered structure No CAPs

polyethylene alumiaim, te for high surface area Electrical failure modes

T

18 Electronic Device Failure Analysis

of tantalum CAPS can be

You might also like

- 6 PDFDocument1 page6 PDFGerald See TohNo ratings yet

- Lee 1989Document14 pagesLee 1989Gerald See TohNo ratings yet

- 1 PDFDocument1 page1 PDFGerald See TohNo ratings yet

- GP - Updated 14082019Document36 pagesGP - Updated 14082019Gerald See TohNo ratings yet

- TM 2.1.2A - Pinhole Evaluation, Dye Penetration Method 3-76Document1 pageTM 2.1.2A - Pinhole Evaluation, Dye Penetration Method 3-76Gerald See TohNo ratings yet

- IPCDocument8 pagesIPCGerald See TohNo ratings yet

- IPCDocument6 pagesIPCGerald See TohNo ratings yet

- Interpretation of Infrared Spectra, A Practical ApproachDocument24 pagesInterpretation of Infrared Spectra, A Practical ApproachLucas TimmerNo ratings yet

- TM 1.3A - Ambient Conditions 1-03Document1 pageTM 1.3A - Ambient Conditions 1-03Gerald See TohNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5795)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)