Professional Documents

Culture Documents

5 PDF

Uploaded by

Gerald See Toh0 ratings0% found this document useful (0 votes)

26 views1 pageOriginal Title

5.pdf

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

26 views1 page5 PDF

Uploaded by

Gerald See TohCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 1

An Overview of Failure Analysis of Tantalum Capacitors

(continued from page 20)

of kilo-to mega-ohms range, and no thermal hot spot,

is observed, then the leakage should be measured at,

the rated voltage (see the manufacturer's specificar

tion) to ensure that the part indeed has high leakage.

Based on the failure mode, the tantalum CAP could

be chemically stripped to examine the tantalum an-

ode’s integrity and the dielectric quality!®! Tantalum.

diclectricis typically clectrochemically grown at two

to three times the CAP’s rated voltage to provide a

more robust dielectric. Fawsin the dielectric, suchas

a crystalline oxide (Fig. 5), could be examined by strip»

ping away the counterclectrode layers. Crystalline

oxide nodules weaken the amorphous dielectric and

provide a conductive path. The presence of a few of

these sites could beisolated by the healing mechanism.

of the tantalum CAP. With everything else being the

same, crystalline oxide is more pronounced for high-

voltage CAPs (typically 35 V and higher), and the

presence of a significant number of these sites could

be a problem. Over the years, many processes have

been developed to minimize /climinate crystalline

oxide growth J671

Tantalum CAPs, like any other electronic compo-

nent, could also fail due to their application conditions

(Fig. 3a). As a polar device, the tantalum CAP can

withstand a small amount of reverse bias fora short,

period of time; however, itis not very forgiving when

subjected to reverse polarity Ifa CAP is suspected to

have experienced reverse bias, it may be possible in

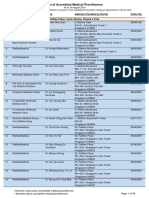

Fig. 4 Thermal image ofa tantalum CAP shows 2

io sp inate of a fat site Fig.5 Crystals on tantalum anodes. Souee: Ref 6

‘22 Electronic Device Failure Analysis

some cases to do a reverse knee voltage test on sister

CAPs taken from the same circuit!" This could help

show if the CAPS have been subjected to reverse bias.

Stability of the circuit is also an important factor.

High current and voltage surges can also damage

the dielectric, which can lead to a failure. Localized

heating will appear as evidence of both abusive ap-

plication conditions and a weak dielectric. Ensuring

that an appropriate CAP is used for a particular ap-

plication is yet another factor to be considered.

In general, surface-mount tantalum CAPs are not

hermetically sealed and therefore can absorb mois-

ture. The presence of significant moisture inside the

CAP during reflow can createa largeamount of steam

inside the CAP, which, in some cases, can crack the

mold epoxy and allow more moisture to penetrate

into the internal elements. Extended exposure to

high humidity and temperature during storage and /

could also result in chemical /electro-

chemical migration of the conductive species inside

the CAP, resulting in a leakage path.

Hi,

‘The cause of high ESR can be divided into two

main categories: a loose connection or an increase in

the resistivity of the material (Fig. 3b). Again, before

performing any destructive analysis, the high-ESR

condition must be verified at the appropriate fre-

quency, and, more importantly, proper connections

between the testing probes and the CAP terminals

must be ensured. The presence of any conformal

Coating or fax onthe solder joint, improper solder /

adhesive joints, oxidation of the terminals/solder

joint, inappropriate probes, and so on could falsely

show a higher ESR than the actual value.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- 6 PDFDocument1 page6 PDFGerald See TohNo ratings yet

- Lee 1989Document14 pagesLee 1989Gerald See TohNo ratings yet

- 1 PDFDocument1 page1 PDFGerald See TohNo ratings yet

- GP - Updated 14082019Document36 pagesGP - Updated 14082019Gerald See TohNo ratings yet

- TM 2.1.2A - Pinhole Evaluation, Dye Penetration Method 3-76Document1 pageTM 2.1.2A - Pinhole Evaluation, Dye Penetration Method 3-76Gerald See TohNo ratings yet

- IPCDocument8 pagesIPCGerald See TohNo ratings yet

- IPCDocument6 pagesIPCGerald See TohNo ratings yet

- Interpretation of Infrared Spectra, A Practical ApproachDocument24 pagesInterpretation of Infrared Spectra, A Practical ApproachLucas TimmerNo ratings yet

- TM 1.3A - Ambient Conditions 1-03Document1 pageTM 1.3A - Ambient Conditions 1-03Gerald See TohNo ratings yet