Professional Documents

Culture Documents

Granulation Example Demo Guide PDF

Uploaded by

Magdy SalehOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Granulation Example Demo Guide PDF

Uploaded by

Magdy SalehCopyright:

Available Formats

Granulation

Guide to the Granulator Demo

Aspen Technology

Bedford, MA

2013

© 2013 Aspen Technology, Inc. All rights reserved

Granulation

Growth of particles due to deposition of solid material on

primary particles (seeds)

– Granulation: Seed particles and deposited solids are made of

the same material

– Coating: Seed and deposited solids are made of different

material)

© 2013 Aspen Technology, Inc. All rights reserved | 2

Agglomeration

Agglomeration: Aggregation of two or more primary particles

– Agglomeration by use of a binder

Binder could be water, a suspension, solution or melt

Particles are ‘glued together’

– Agglomeration by use of mechanical forces

No binder is added

Particles are ‘pressed together’

© 2013 Aspen Technology, Inc. All rights reserved | 3

Modeling Agglomeration and Granulation

The Aspen Plus Granulator allows to model:

– Granulation and Coating

Drum Fluidized Bed Plate

– Agglomeration

using binder

Drum Fluidized bed Plate

using mechanical forces

Compacting Press

Roller Aggl

omerator

© 2013 Aspen Technology, Inc. All rights reserved | 4

Granulation - Model

Particle Growth

– Population balance

– Mixed

Ideal mixing in radial and axial direction

Growth rate proportional to

– Surface, Volume or Diameter

– Plug flow

Ideal mixing in radial direction

No mixing in axial direction

Drying of particles

Define solids moisture content at the outlet

Entrainment in Fluidized Beds

Upstream gas velocity

Terminal velocity of the particles

© 2013 Aspen Technology, Inc. All rights reserved | 5

Modeling Granulation in Aspen Plus

- Granulator Input Form

Model Specifications Tab

Total mass

of bed

Set outlet solids

moisture content.

Active if a mositure

component is specified

in the “Solids“ tab

Wet or dry basis

© 2013 Aspen Technology, Inc. All rights reserved | 6

Thermodynamic effect of the moisture definition

After the granulator calculations are completed a equilibrium

calculation is performed

– If the moisture is in the MIXED

substream (Liquid components)

Some liquid may evaporate

– If the moisture is in the CISolid

substream (Solids Moisture components)

Liquid trapped within the solid is not

evaporated

SMC is considered with its enthalpy during

the equilibrium calculation

Effect on the solids density and heat

capacity is considered

Shortcut drying model allows to define the amount of liquid

that is “stored” within the particles (CISolid substream)

© 2013 Aspen Technology, Inc. All rights reserved | 7

Modeling Granulation in Aspen Plus

- Granulator Input Form

Model Specifications Tab

Mixed or Plug

Flow model

Surface, diameter or

volume proprotional

particle growth.

Only active for

mixed flow.

Model entrainment

of fine particles in

fluidized bed

granulators.

Only active if vapor

streams are

attached.

© 2013 Aspen Technology, Inc. All rights reserved | 8

Modeling Granulation in Aspen Plus

- Granulator Results Form

Results tab

Seed and Product particle

size measures.

Additional details

available on the stream

results solids tab.

Entrainment of fine

particles with vapor

stream in a fluidized

bed granulator.

© 2013 Aspen Technology, Inc. All rights reserved | 9

Modeling Granulation in Aspen Plus

- Granulator PSD Plot

PSD Plot

Plots particle size

distributions of seed,

product , and offgas

streams.

© 2013 Aspen Technology, Inc. All rights reserved | 10

Granulation Example

The following example will demonstrate how a industrial

granulation process can be simulated and optimized with

Aspen Plus

– Simulation of a granulation process with external

classification/grinding circuit and product cooling

– Optimization study to increase throughput

© 2013 Aspen Technology, Inc. All rights reserved | 11

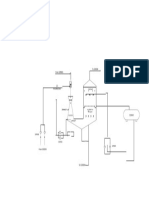

Open the File Granulation_Example.bkp

Urea solution is

sprayed on a bed Middle fraction from

of seed particles. the screen is cooled

Particles grow by in a fluidized bed

pure granulation cooler and leaves the

process as product.

Product from

the granulator

is cooled in a

fluidized bed

cooler

Cooled particles are classified on

a double–deck screen:

- Coarse particles are milled,

mixed with the fines from the

screen and recycled as seed

particles back to the granulator

- Middle fraction is product

© 2013 Aspen Technology, Inc. All rights reserved | 12

Review the Model for the Granulator

In the current case the granulator has three chambers

– First two chambers for granulation

– Third chamber of drying

Described by use of a hierarchy block

© 2013 Aspen Technology, Inc. All rights reserved | 13

Review the Model for the Granulator

Granulator parameterization (chambers 1 and 2)

Particles grow by granulation

Outlet moisture is Vessel is assumed to be

set to be 0.5 wt-% adiabatic (heat duty = 0).

Temperature of gas and solids

is the mixing temperature of

Growth is proportional

all inlet streams.

to the particles surface

Entrainment of solids from

the bed is considered (air

streams connected to the

block).

Cross-section of the vessel

needs to be defined in order

to calculate the upstream

velocity of the gas.

© 2013 Aspen Technology, Inc. All rights reserved | 14

Review the Model for the Granulator

Dryer parameterization (chamber 3)

Shortcut dryer is used

Specify outlet moisture (no drying kinetics)

Convective dryer will allow for that if

needed.

No additional heat

provided by the dryer

Pure convective drying

Outlet moisture content

is defined on wet basis

© 2013 Aspen Technology, Inc. All rights reserved | 15

Review the Model for the Cooler

The fluidized bed cooler is described by an hierarchy block

– It is assumed that gas and solids reach thermodynamic equilibrium

mix gas and solids stream results in the mixing temperature

– Fluidized bed cooler will entrain particles with the exhaust air

Use of a Classifier (uses classification function) that classifies the particles

according to their settling velocity

Controller is used to set the cut velocity in the classifier according based on

the gas volume flow and the cross-section of the cooler

© 2013 Aspen Technology, Inc. All rights reserved | 16

Run the Model

Run the model

Ignore Warnings Open the layout

“ProductResults-BaseCase”

It is a reminder

that the PSD in

the granulator

outlet has been

normalized

© 2013 Aspen Technology, Inc. All rights reserved | 17

Review results for the Base Case

Custom table allows to:

• enter values for key parameters

(spray rate, energy input of

mill)

• Review the key result

parameter (product flow rate,

recycle flow rate, product D10

and D90)

© 2013 Aspen Technology, Inc. All rights reserved | 18

Review results for the Base Case

Plot shows the

development of the

PSD along the

granulator

Granulation in the 1st

and the 2nd chamber.

Drying in the 3rd

chamber.

© 2013 Aspen Technology, Inc. All rights reserved | 19

Process Optimization – Task Definition

Base Case:

– Spray rate 5 kg/s (97 wt-% Urea, 3 wt-% Water)

– Energy input to the mill 2 kW

Objective

– Increase throughput by at least 60%

– Keep product within specifications

Constraints:

– Keep product within specifications

D10 > 1.2 mm (base case: D10 = 1.35 mm)

D90 < 2.9 mm (base case: D90 = 2.89 mm)

– Maximum recycle mass flow 3 kg/s (base case 2.23 kg/s)

© 2013 Aspen Technology, Inc. All rights reserved | 20

Process Optimization – Change flow Rate

Open the layout Flowsheet-Optimization

Change urea spray rate to

8 kg/s (5 kg/s = 60%)

and run the model

© 2013 Aspen Technology, Inc. All rights reserved | 21

Process Optimization – Review Results

Changing the urea spray rate to 8

kg/s increases the product flow

rate by 60%

BUT

- Recycle flow rate above limit of 3

kg/s

- D90 above limit of 2.9 mm

Idea: Adjust energy input to the mill in order to fulfill

the constraints

First test: Set energy input to 3 kw and run the model

© 2013 Aspen Technology, Inc. All rights reserved | 22

Process Optimization – Review Results

Increasing the energy input to the mill For explanation

of warnings,

– decreases the recycle flow rate see appendix

– decrease D90

Question: What is the necessary energy input?

Idea: Use sensitivity to see how the energy input of the mill

influences the recycle flow rate and the D10 and D90 of

the product ( find optimal value for the energy input).

© 2013 Aspen Technology, Inc. All rights reserved | 23

Process Optimization – Setup Sensitivity

Activate the pre-defined sensitivity task

Open the layout SensitivitySetup

© 2013 Aspen Technology, Inc. All rights reserved | 24

Process Optimization – Setup Sensitivity

Recycle flow rate, D10 and

D90 of the product will be

saved for each step of the

sensitivity analysis

Energy input of the mill is

varied from 2 kW to 5 kW

in 11 steps

Recycle flow rate, D10 and

D90 of the product will be

tabulated as function of

the energy input

© 2013 Aspen Technology, Inc. All rights reserved | 25

Process Optimization – Run the Sensitivity

Run the model

Open the layout SensitivityResults

© 2013 Aspen Technology, Inc. All rights reserved | 26

Process Optimization – Review the Results

Energy input of 4.2

kW fulfills all

constraints

Energy input of ~5

kW produces so

much fines that the

recycle flow rate

jumps to ~8.9 kg/s

© 2013 Aspen Technology, Inc. All rights reserved | 27

Process Optimization

- Run with Optimized Values

Deactivate the sensitivity task

Switch to layout Flowsheet-Optimization.

Enter optimal value (4.2 kW) for the

energy input and run the model

© 2013 Aspen Technology, Inc. All rights reserved | 28

Process Optimization – Review Results

With the optimized energy input it is possible to increase

the product flow rate by 60%

All constraints are fulfilled

– D10 > 1.2 mm

– D90 < 2.9 mm

– Maximum recycle mass flow 3 kg/s

Base Case Optimized Case

© 2013 Aspen Technology, Inc. All rights reserved | 29

Appendix- Warnings

When running the second

variation of the base case,

you may have come

across a warning stating

that the given moisture

content is not possible.

In the second granulator,

the moisture content at

the outlet was set to

0.005 kg/kg dry. The

moisture content

calculated was 0.00495

kg/kg, which is slightly

lower than what was

specified.

© 2013 Aspen Technology, Inc. All rights reserved | 30

Appendix- Warnings

Sensitivity Analysis

Warnings are a result of

the previous warnings and

also can be ignored.

© 2013 Aspen Technology, Inc. All rights reserved | 31

You might also like

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Crash Reconstruction BasicsDocument40 pagesCrash Reconstruction Basicsrobin_lanigan100% (3)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Decision Model Using ExcelDocument236 pagesDecision Model Using Excelসামিউল ইসলাম রাজু100% (3)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Hysys 8.8 - ManualDocument606 pagesHysys 8.8 - ManualCarlos Vaz88% (8)

- Refinery Planning and Optimation Using Linear ProgrammingDocument11 pagesRefinery Planning and Optimation Using Linear ProgrammingSenthil Kumar100% (2)

- Mastering EES Themechangers - Blogspot.inDocument608 pagesMastering EES Themechangers - Blogspot.inGabrielle Tan100% (2)

- Planning RequirementDocument50 pagesPlanning RequirementLilet P. DalisayNo ratings yet

- Pipeline River Crossing StrategyDocument165 pagesPipeline River Crossing Strategyim4uim4uim4u100% (1)

- Drawpoint Spacing at Panel Caving PDFDocument6 pagesDrawpoint Spacing at Panel Caving PDFDiegoNo ratings yet

- Aspen Plus Urea Synthesis Loop ModelDocument19 pagesAspen Plus Urea Synthesis Loop ModelMagdy SalehNo ratings yet

- Life Cycle Costing: StandardDocument22 pagesLife Cycle Costing: StandardTata OdoyNo ratings yet

- Hysys 2020 PDFDocument357 pagesHysys 2020 PDFMagdy Saleh100% (4)

- Quiz 1Document8 pagesQuiz 1doan nguyenNo ratings yet

- Improved Anti-Submarine Warfare (ASW) Effectiveness MSSE Capstone Project PDFDocument263 pagesImproved Anti-Submarine Warfare (ASW) Effectiveness MSSE Capstone Project PDFFernando Raúl LADINO100% (1)

- Etude Du Systeme Quasi Ternaire H2O NH4NDocument10 pagesEtude Du Systeme Quasi Ternaire H2O NH4NMagdy SalehNo ratings yet

- Tertre Granulation Plant:: NH3 Acidic Purge of Scrubbing Section SprayersDocument11 pagesTertre Granulation Plant:: NH3 Acidic Purge of Scrubbing Section SprayersMagdy SalehNo ratings yet

- Guidance For Compatibility2 PDFDocument16 pagesGuidance For Compatibility2 PDFMagdy SalehNo ratings yet

- Straight Ammonium Nitrate Fertilizer Stabilization:theoritical PossibilitiesDocument26 pagesStraight Ammonium Nitrate Fertilizer Stabilization:theoritical PossibilitiesMagdy SalehNo ratings yet

- Sick GM31Document54 pagesSick GM31Magdy SalehNo ratings yet

- Reaction Kinetics of Ammonia & Nitric AcidDocument116 pagesReaction Kinetics of Ammonia & Nitric AcidMonica Garcia100% (1)

- 2001 ANPSG Participants List: AbocolDocument10 pages2001 ANPSG Participants List: AbocolMagdy SalehNo ratings yet

- Hot Ammonia VJ 05112014Document44 pagesHot Ammonia VJ 05112014Magdy SalehNo ratings yet

- United States Patent (19) : (Aziz 2Document8 pagesUnited States Patent (19) : (Aziz 2Magdy SalehNo ratings yet

- Information Producction NPKDocument154 pagesInformation Producction NPKCristian M. Choque CataNo ratings yet

- Petroleum Refining Materials and EquipmentDocument23 pagesPetroleum Refining Materials and EquipmentAli AlengineerNo ratings yet

- Recent Developments in Urea Plant Design: Pan OrphanidesDocument17 pagesRecent Developments in Urea Plant Design: Pan OrphanidesMagdy SalehNo ratings yet

- Drawing123121 PDFDocument1 pageDrawing123121 PDFMagdy SalehNo ratings yet

- Powder Technology: H. Nemati, S.A. ShekoohiDocument10 pagesPowder Technology: H. Nemati, S.A. ShekoohiMagdy SalehNo ratings yet

- Heat Capacities and Thermodynamic Properties of Ammonium NitrateDocument12 pagesHeat Capacities and Thermodynamic Properties of Ammonium NitrateMagdy SalehNo ratings yet

- Drawing 123121Document1 pageDrawing 123121Magdy SalehNo ratings yet

- Proceedings of The Annual Meeting Fertilizer Industry RoundtableDocument170 pagesProceedings of The Annual Meeting Fertilizer Industry RoundtableMagdy SalehNo ratings yet

- Simulink06 PDFDocument16 pagesSimulink06 PDFFarid AfifiNo ratings yet

- ReadmeDocument1 pageReadmeMagdy SalehNo ratings yet

- IFA Technical Conference: Amman, Jordan 2-6 October 1994Document6 pagesIFA Technical Conference: Amman, Jordan 2-6 October 1994Magdy SalehNo ratings yet

- 46 - Powder DolomiteDocument1 page46 - Powder DolomiteMagdy SalehNo ratings yet

- Computer Simulation of Fertilizer Granulation PlantsDocument29 pagesComputer Simulation of Fertilizer Granulation PlantsMagdy SalehNo ratings yet

- EP0229421A2Document7 pagesEP0229421A2Magdy SalehNo ratings yet

- EP0107870A1Document9 pagesEP0107870A1Magdy SalehNo ratings yet

- Fluidized BedDocument5 pagesFluidized BedMagdy SalehNo ratings yet

- Principles of Risk Analysis Decision Making Under Uncertainty 93Document6 pagesPrinciples of Risk Analysis Decision Making Under Uncertainty 93JK AlmaNo ratings yet

- International Financial Management 3Document46 pagesInternational Financial Management 3胡依然No ratings yet

- Hybrid Type-2 Fuzzy KM Observer For Biogas Production From POME in Anaerobic DigesterDocument9 pagesHybrid Type-2 Fuzzy KM Observer For Biogas Production From POME in Anaerobic DigesterJavier OoiNo ratings yet

- Cost-Volume-Profit Analysis: Transition NotesDocument12 pagesCost-Volume-Profit Analysis: Transition NotesEduardo Latorre UribeNo ratings yet

- Laboratory Ruggedness Tests Compared With Those Derived From Collaborative Trials of Six Microbiological Measurement Methods-1Document15 pagesLaboratory Ruggedness Tests Compared With Those Derived From Collaborative Trials of Six Microbiological Measurement Methods-1Cinthia Anyela Ramos YnjanteNo ratings yet

- CEE - rb19 Civil Eng ResearchDocument113 pagesCEE - rb19 Civil Eng ResearchshunmugathasonNo ratings yet

- GT7R6A1 Convergence-Confinement MethodeDocument11 pagesGT7R6A1 Convergence-Confinement MethodefededaNo ratings yet

- 05 Cafmst14 - CH - 03Document40 pages05 Cafmst14 - CH - 03Mahabub AlamNo ratings yet

- CH 07Document41 pagesCH 07Mrk KhanNo ratings yet

- Gile Observational and Experimental Studies in InterpretingDocument16 pagesGile Observational and Experimental Studies in InterpretingSol AlvaradoNo ratings yet

- Dynamic Comput Able General Equilibrium ModelDocument18 pagesDynamic Comput Able General Equilibrium Modelamilson1No ratings yet

- Astm e 1970 - 16Document5 pagesAstm e 1970 - 16Bushra Shaukat100% (1)

- Checklist For Evaluating A Research ReportDocument13 pagesChecklist For Evaluating A Research ReportJerome HubillaNo ratings yet

- Economic Capital in Banking v03Document10 pagesEconomic Capital in Banking v03AndreKochNo ratings yet

- OrCAD PSpice Advanced AnalysisDocument2 pagesOrCAD PSpice Advanced AnalysisdavkavkaNo ratings yet

- Trabalho 3Document4 pagesTrabalho 3Paulo MoraisNo ratings yet

- PDS - ANSYS PresentationDocument33 pagesPDS - ANSYS PresentationRoberto Jesus Arias Espada100% (2)

- Environment, Development and Sustainability Volume issue 2020 [doi 10.1007_s10668-019-00583-2] Vendoti, Suresh; Muralidhar, M.; Kiranmayi, R. -- Techno-economic analysis of off-grid solar_wind_biogaDocument22 pagesEnvironment, Development and Sustainability Volume issue 2020 [doi 10.1007_s10668-019-00583-2] Vendoti, Suresh; Muralidhar, M.; Kiranmayi, R. -- Techno-economic analysis of off-grid solar_wind_biogaBharath ykNo ratings yet

- Jiajing Zhneg ResumeDocument1 pageJiajing Zhneg Resumeapi-534374168No ratings yet

- Chapter 2 - Linear ProgrammingDocument85 pagesChapter 2 - Linear Programmingwubied100% (2)

- Linear Programming: Sensitivity AnalysisDocument61 pagesLinear Programming: Sensitivity AnalysisVishakha VNo ratings yet

![Environment, Development and Sustainability Volume issue 2020 [doi 10.1007_s10668-019-00583-2] Vendoti, Suresh; Muralidhar, M.; Kiranmayi, R. -- Techno-economic analysis of off-grid solar_wind_bioga](https://imgv2-2-f.scribdassets.com/img/document/504558596/149x198/94ab1df31d/1710543010?v=1)