Professional Documents

Culture Documents

Fast16 PDF

Fast16 PDF

Uploaded by

Jason Jia0 ratings0% found this document useful (0 votes)

14 views35 pagesOriginal Title

FAST16.pdf

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

14 views35 pagesFast16 PDF

Fast16 PDF

Uploaded by

Jason JiaCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 35

Paves

Pere

eile g

@ AIRBUS INDUSTRIE

ACARS

ADF

AFS

APU

ARINC

ATA

ATC

BITE

cap

CFDS

crDIe

cmc

cus

DME

ECAM

EFIS

EFCS

eg

Gr

ETOPS

FIM

FIN

FL

Fs

FWe

Geru

LOCAL

1oBsy

wit

Ica

IDG

ISO

JAA

ke

LRU

McbU

MpbU

MMEL

Mu

ND

PC

PFD

PER

PIN

SD

SGML

SLW

SLWe

SM

ure

VHF

Abbreviations used in this issue of FAST

Aircraft Communication Addressing and Reporting System

Auiomatie Direction Finding

Automatic Plight System

Auxidiary Power Unit

Aeronautical Radio Ine

Air Transport Association

Air Traffic Controt

Built-In Test Equipment

Canadian Atlantic Storms Program

Centralised Fault Display System

Centralised Fauli Display fmerface Unit

Central Maintenance Computer

Central Maintenance System

Disiance Measuring Equipment

Electronic Centralised Aircraft Monitor

Electronic Flight Instrument System

Electronic Flight Contvot System

For example

Exhaust Gas Temperauure

Extended Range Twin Engine Operations

Fault Isolation Document

Functional fem Number

Flight Level

Flight Management System

Flight Warning Computer

Grownd Power Control Unit

Index of CMS fault messages

Index of EFIS, ND and PFD fault messages

Index of local warnings

Index of crew and maintenance observations

Index of warnings and matfinetions

International Civil Aviation Organisation

Integrated Drive Generator

Internarionat Standardisation Organisation

Joine Airworthiness Authorities (European)

Knots

Line Replaceable Unis

‘Multi-pu pose Control and Display Unit

‘Multi-purpose Disc Drive Unit

Master Minimum Equipment Lise

Management Unit

Navigation Display

Nautical mites

Personal Computer

Primary Flight Display

Post Flight Report

Part Number

System Display

Standardised General Mark-up Language

Supereooted Liquid Water

Supercootedt Liquid Water Content

Trouble Shooting Manual

Universal Coordinated Time

Very High Frequency

AIRBUS

TECHNICAL

DIGEST

NUMBER 16

APRIL 1994

A330/A340 CENTRAL MAINTENANCE SYSTEM

MARC VIRILLI

EVOLUTION OF THE TROUBLE SHOOTING MANUAL >,

ON THE A319/A320/A321/A330/A340 ore

KENNETH JOHNSON

A330/A340 RAMP HANDLING

DAVID SAXTON

ACCELERATED ETOPS FOR THE A330 } )

ANDRE QUET AND THE ETOPS GROUP

ETOPS CONFERENCE

ACCRETION

CLAUDIUS LA BURTHE

‘p ». }

UNDERSTANDING THE PROCESS OF ICE / q =

RESIDENT CUSTOMER SUPPORT

REPRESENTATION

A NEW HOME FOR ofe

AIRBUS PRODUCT SUPPORT

‘The anicles herein may be reprinted without permission except where copyright source is indicated, but with

acknowledgement to Aisbus Industrie, Articles which may be subject to ongoing review must i

sd on the

RAMP HANDLING - PART II

Verified prior to reprint. The statements made herein do not coastitute an offer. They sumptions

a a faith, Where the supporting grounds for thore statements aro not shawa, the Company

ie basis thereo (© AIRBUS INDUSTRIE 1994

Cedex, France

Buber: Abs Inge Product Support | nd point Maurice Bente, 31707

Telephone +33 6193.33 33,"Telex AIRBUS Tek 933148

Editor: Denis Dempster ~ Graphie desi

Photo-eneraving; SERPAL, 31130 Balmua, France

Printer SIA, $1500 Lavaur, France ok

This iseue of PAST has been printed on paper produced without using ehlorine, to reduce waste

‘and help 0 conserve natural resources. ‘Every tile helps

FAST / NUMBER 16 1

ean

3 Pr

Pe a er a ee

ee al

mn:

oe

centralised maintenance experience

started with the design of the A300, 1n1974, the Auto Flight

System consisted of 20 computers, two of which already

tal were dedicated to help maintenance of the system, The

cenity into service of the glass cockpit A310 in 1983 was the

jnning of a now era from the aircraft technology point of

view, and also for line maintenance activities

Taking advantage of the performance of new digital tec

nology, the fault isolation devices were integrated into the

basic system design. The best examples are the A310 Auto

Flight System (AFS), he Flight Management System (FMS),

the Electronic Flight Instrument System (EFIS) and the Elee-

tronic Centralised Aircraft Monitoring (ECAM). These sys.

tems were the first to provide automatic trouble-shooting and

test procedures, and were the first to introduce plain English

for the identilication of faulty Line Replaceable Units (LRU)

(Figure 1).

Although these systems provided many benefits for mainte

‘nance personnel, more development was necessary to provide:

more maintenance data and wider fault isolation coverage.

This is why in 1988, when the A320entered service, the CFDS

was one of the features of this aircraft. This system resulted

from a common position take

facturers, They identified the need within the airline world for

‘a system that concentrates maintenance data into one location

‘and provides maintenance personnel with clear information

needing litte interpretation. The guidelines for the design of

such a system materialized in the ARINC Report 604, Guid

lines for design and use of Built-In Test Equipment (BITE).

The A320 CFDS is in fact a man/machine interface for

maintenance purposes, which allows the display of fault

messages in plain English, to interrogate the BITE of various

electronic systems and 10 initiate system tests from a central

point located in the cockpit: the MCDU (Multipurpose Con:

(rol and Display Unit). The architecture of the A320 CFDS is

of the distributed type, compared to the centralised type

chosen by another aircraft manufacturer. This means that the

by the major airf

maintenance data and formatting the failure messages is

included in the BITE of each individual avionies component.

The main advantage of this architecture is thatall conditions

jencrating a message depend on one system only: the

inator of the message, thus making information more

relinble and easier to manage. It is important co note that this

approach does not prevent the Centralised Fault Display

Interface Unit (CFDIU) from automatically correlating events,

thereby minimizing the number of messages. This is an

advantage shared with the centralised architecture,

[EET Eure ak

The A330/A340 CMS architecture includes two fully redundant

Central Maintenance Computers (CMC), instead of one on the

:20,the CMC 2 being ahot spare. Four user interfaces are also

defined: the three MCDUs, the printer, the Aircraft Commu-

nication Addressing and Reporting System (ACARS) Man:

agement Unit (MU) and the Multipurpose Disk Drive Unit

(MDDU), the last (wo being optional

This variety ofinterfacesis aimed to answerall airline needs

n terms of efficiency of operation of their aircraft:

@ the printer (Ad size) and MCDU for on-board use,

@ the ACARS MU for preparation of the work durin

transit

@ the MDDU for downloading data for further analysis

Both CMCsare direcily connected to 48 basic systems plus

11 optional ones, which represent 91 reporting units expand-

able to 102 reporting units with options.

The sysiems which ate connected to the CMCs have been

divided into 3 types:

© Zype 1 systems are characterized by an inputfoutput inter

face of the ARINC 429 bus type (there are 34 basic and 9

optional systems for a total of 75 units)

(© Type systems ace characterized bya discrete input fromthe

CMC and an ARINC 429 bus output (there are 10 basic and

‘optional systems fora total af 19 units)

© ype 3 systems have an inputfouiput interface of diserete

ype (there are 4 basic and 1 optional system for a total of 8

| units)

| intelligence required for identifying the faults, processing the

On 4320, A330 and A3 i

@ single location (MCDU in the cockpit) |

@ alphanumeric display

f@ menu driven procedure

Easier access 10 maintenance data on A320 family, A330 and A340

On previous generation aiter

@ various locations (avionic eompariment, cockpit

@ different types of display

© operating procedure varies from system to system

i

GUDO00 6

£65

ay a

a

e

a

300

35 of umnm

£O)

g

cS

of

oo o@ulise °

FAST / NUMBER 16

Central Mainte

e System architecture

—> Bus

— Discree

Type I

Type 2 Type 3

AIRCRAFT SYSTEMS

Each member system memorizes the failure messages de

tected by its BITE an

CMC. The CMS architecture is shown in Figure

Cree ed

Reporting mode

d transmits them in clear F

slish to the

In the report he units connected to the CMC

automatically and permanently transmit the failures affectin

them, These failures can be either of internal orexternal or

that isto say affecting LRUs belonging to the system or LRUS

so divided into

three classes dependin;

(Figure 3)

© Class 1 failures are indicated to the crew by means of

warnings and flags

© Class 2 faitures are indicated to the erew on th

bout have no impact on the current flight,

© Class 3 failures are not indicated to the crew al all

available on request only and are checked at the next sched:

uled maintenance check

‘AS mentioned previously, the maintenance messages are

transmitted to the CMC in plain English using ISO 5 codin

‘As A320 experience had shown that some messages could be

interpreted in different ways, the rules for writ

nance messages have been further refined and are requested 10

be strictly followed by each computer designer (computer

supplier)

‘The CMC compiles Post Flight Report (PER) by merging

oundon

mainte

mre

Operational consequences

on current flight?

(er

NO.

maintenance team + Automatic print-out atthe

Dispatch consequences | + Refer MMIEL may be Noneed toreferto MMEL | + MMEL not applicable

GO" £°GO" without conditions | + Can be let uncorrected

Got + Can be left uncorrected | unt the next scheduled

NO GO" nll the next opportunity | maintenance check

Indication to flight crew YES | YES | ‘NO

Automatically dxplayed in| = Marualy displayed by |

real time activation ofthe sats on

Warning or caution messages | ECAMContol Panels |

+ Flags on PED or ND or display

| _ Sistem dspa |

Indication to YES VES

nd of each flight:

Failure messages on the CMC PR

+ Manually displayed:

Failure messages on CMC

Class 3 Report

FAST | NUMBER 16

Example of Post Flight Repor

MAINTENANCE

POST FLIGHT REPORT

[Ese

| AIRCRAFT IDENTIFICATION :F - GGEA

|

lz

DATE MAR3t

FUGHT NUMBER : ITF 1027

cooxeirerrect | |

Sees se ears

|

Le-co

PRINTING

ENGINE ON / ENGINE OFF :1015/ 1220 | pave: apRo2

FROM/TO LFPO : LFBT UIC: 1408

ATA36-14 | ute: 1023 ATA35(1-43 INTERMITTENT LASS |

SOURCE :BlCe IDENTIFIERS

| _ MessaGe FLIGHT PHASE MESSAGE. ze EIVMUS

ENG 3 BLEED FAULT TAKEOFF ROLL | THC GHABVFAN AIR

| ({2HAS)/SENSE LINE |

| aragoss ure: 1038 ATA3011-46 | HARD cuss |

| ‘SOURCE :PHc2 wweNTIFIERS: |

MESSAGE DISPLAYED FLIGHTPHASE: | MESSAGE ADIRUY ADIRU2 |

| avmicemoracse | cume | STATIC PROBE leDA2) ADIRUS

|, Pica (60a), |

| atazz.00 uro:i1s8 | ATA 34-12-94 HARD CLASS 1 |

SOURCE :AFS IDENTIFIERS :

MESSAGE DISPLAYED: | FLIGHT PHASE: | MESSAGE

AUTOFLT AP OFF CRUISE | aoinuicrPH) |

bctisesegseses i dee ee ——- od

END OF REPORT |

all class 1 and 2 messages received from all computers as well

as all Flight Deck Effects received from the Flight War

Computer and Data Management Computer. This report al-

lows the maintenance personnel to have an overall view of

what occurred during the last flight le;

complement to the Flight Log,

Although the system architecture is of the distributed type,

the CMC performs an event correlation. For a given failure,

‘only one failure message is printed on the PFR, The systems

which have reacted to this primary failure are mentioned on

the PER as “identifiers”. Ifthe unit which is affected is able to

transmit a message, itis this message (internal) which will be

mentioned, the other messages (external) appearing as "iden:

liflers” (Figure 4), I'the unit affected by the failure is not able

totransmit anything to the CMC, the first message reported by

its peripherals will be printed in the PFR, the others bein

‘idemtifiers”. In all cases the detail of each detected fail

memorized ineach individual unit’s BITE,

interactive mode,

This CMC function is based on the ATA chapter associated

«d which corresponds to the LRU.

ndisaccessible in

with each failure mess

incriminated,

In reporting mode the CMC compiles a Class 3 Report

which contains all class 3 failures that occurred during the last

flight leg as a complement to th

Finally the Avionics Status g al time the list of units

which are affected at least by one failure ine

3. This report provides a quick overview of the status of the

various computers of the aircraft, I also makes it possible to

check that all computers have correctly satisfied the power-up

tests,

Interactive Mode

‘The interactive mode or menu mode, for type I systems, is

a mode which allows the connection of the BITE of any unit

FAST | NUMBER 16

via the MCDUs, in order to display the data memorized and

formatted by each member system, This mode can be activated

‘on the ground only and one of ts important purposes is tocase

activation of system tests. The reason why this mode is

sometimes called “menu mode"

guided by menus. Some of these menus are generated by the

CMC, and others are generated and transmitted by the con:

cerned units for display on the MCDUs.

Inorderto have aman/machine interface as user-friendly as

possible and to break oneself from the distributed architecture

while keepi ues, all MCDU screens sent by the

systems have been normalized to standard format (Figure 5).

is because the users are

Inpractice these various items of CMS menu can be illustrated

using the following Electronic Flight Control System (EFCS)

System menu

®

8

Bere

ad

es

nora

Renn

rhe

CU (Ground Power Control Unit) examples (Figures 6

pully sedav Avera MalntenanceMantal AMM) removal |

compat

cautions are displayed on the MCDUs before activating them

Figure 6), the safety procedures themselves being in 1

AMM.

© The guided tests axe those where all the requested actions

are clearly mentioned on the MCDUs, along with questions

bout the results of the actions.

The complementary (ests and the guided tests increase the | }

coverage level of the system tests when it is useful and

possible. In both tests, all initial conditions necessary for

successful accomplishment of the test are written on the

MCDUs, no documentation is required for test activation,

Ithough they are duplicated in the AMM for checking the

The information available on the GPCU (Figure 74) is as

follows

EB The Last Leg Reportis.a smnplified back-up to the PFR.

The Previous Legs Report records the maintenance and

p

Warning messages which occurred during previous flights

(imited 1 64) and

Sa

Exoboa ck

Eira atL

POTN TY

ec aera a

ar aese mecca

Cini sty

Seren

PL os

Mids ss2o tee

Pere

Pc

Boonen

Puy)

EMERG & DISPLAY LIGH’

Pras

PrN Eee

Seca

ea)

Preiat

< REPORT

aol

< LAU IDENT

ous

Cc

Portes

Crea

FAST / NUMBER 16

lures which have to be tracked on several flights |

EBB The LRU Ldemtification junction displuyson the ground

the Part Number of the computers ofthe selected system and |

possibly thei Serial Numbers Iisa configuration manage-

rent ai,

The Ground Scanning enables fault touble shooting

hased on ground activation by the operators of functions

normally performed during a flight, The mechanic decides

‘what type of action has to be performed, depending on the

problem tobe investigated (which may includecontol surface

nowentent, for example)

The Trouble Shooting Data consist of primary and

coded data, to be used in case of events which do not result

from effective eomponent failure.

The Class 3 Faults report contains messages which are

otshownon the PFR and to which atention can wait unl the

next maintenance opportunity

The Ground Reporthas lhe same usefulness asa PFR but

iLconcems new faults detected on the ground since the last

flight

CMS OPTIONAL FUNCTIONS

Inorder to complete the basic CMS, a set of adcltional functions

have been developed jointly with our customers and are pro:

posed as an option, These other CMS features are the Service

Report, the Aircraft Configuration Report, the Flag and Ad-

visory recording function and the Downloading function.

Service report

This report, which is still under development, will gather

different parameters involved in periodic checks which might

lead 104 Servicing action, The parameters which compose the

Service Report are taken from the allowing systems,

>Engines

DIG:

SAPU

> Hydraulic

Fuel

2 Landing Gear

> Water/Waste

> Air conditioning

‘The Service Report will be programmable like the PER for

automatic print-out inthe cockpit, downloading to a diskette

fr transmission toa ground station through ACARS, and witl

be available in either case 15 minutes after last engine shut

down, An example ofthis report is shown on Figure 8. It will

also be possible for operators to customize the servicing

thresholds, using « Personal Computer (PC), thus allowing

them to get a report with parameters which need a servicing

[Example of Service Report

| vane

[TRE PRESSURE 3)

Uploaded free text i

NANCE

SERVICE REPORT |

AIRCRAFT IDENTIFICATION :F-GGEA | GATE OUT/ GATE IN 1080 / 1840 PRINTING.

| TAKEOFF /LANDINGON 1094/1834

CAPT BAUD | BLOCKTME 610 DATE : 1201

FO WARNER | FROM/TO_LFBT | KATL ure: 1809 |

| DATE 1101 {ase eS TTA

| auGHT NUMBER ala START OF LEG / ENDOFLEG 1032 / 1696

|

| ]

| Uanoinc GEAR | TIRE PRESSURE (-s) NOSE GEAR 146110

| ATA 121492, | TIRE PRESSURE (PS!) 170180, 198/183 ae7T7 166r181

| MAX BRAKE TEMPERATURE (°C) 186/171 174/180, 156/178 145/178,

CENTRAL GEAR 186168

mation prepared ap 2 PC

oxygen | CREW OXYGEN BOTTLE PRESSURE:

| CREW OXYGEN SUPPLEMENTARY 80

| atav24a5 | PAX OXYGEN BOTTLE PRESSURE

|

| FORWARD TANK WATER LEVEL: 080%

WATERWWASTE POTABLE WATER

ATA.121809 WATER | AFT TANK WATER LEVEL: 080%

1800 PSI

ian PS|

1808 PSI

TLE PRESSURE

WASTE WATER TANK NOT EMPTY

LEFT TANK LEVEL: 000%

RIGHT TANK LEVEL: 060%

uploaded fraa text infor

END OF REPORT

on prepares on a FC

FAST / NUMBER 16

ice Report Summary

MAINTENANCE

SERVICE REPORT SUMMARY

| AIRGRAFTIDeNTMcATION:F-cGeR | GATEOUT/GATEIN 1000 / 1810, | PRINTING

TAME OFF /LANONGON 1004 7 1834

caeT BAUD BLOCK TINE 0810 DATE: 1201

FO. WARNER FROM TO LFBT KATL UTC: 1903

Et 08 ‘START OF LEG / ENDOF LEG 1032 } 1836

LIGHT NUMBER AlB

(741 ENGINES - OIL LVL FLTR CHIPS FUEL FLTR REV : CHECK LANDING GEAR- TEMP PRESS ok

IDG. OLLVLSTSFLTR DISC OK OXYGENSOTTLES- STL PRESSURE OK

APU- OILLYLSTS CHIPS OK DOORS AND SLIDES BTL- PRESS STS OK

HYDRAULIC SYSTEMS LVLRSVRAIR PRESS: CHECK WATERIWASTE TANKS~ LVL OK

FUEL TANKS - QTY OK AIRGONDITIONING- EXCHANGER FLTR. OK

END OF SERVICING REPORT SUMIMARY

¥

co

| uanienance

_SenVOPENOMESTTEN |

| anomartoenmrcanoy:r-coee | carecuriewrem som / tao | PANTO |

Hot MBE A SAKE GF ANDNG ON. ee | te

DATE: 1101 BLOCK TINE 0810 Oar PO |

FROM /TO ‘LFBT / KATL UTC: 1908

a

uxioure — OULeveL aoor mcr mag waar |

| ATA121379 GIL CONSUMPTION 0.23 QT/HR: 0.22 THR 0.26 QTIHR 046 QTIHR |

‘ATA:792110 OIL FILTER STATUS: OK OK OK CLOGGED |

ATA731110 FUEL FILTER STATUS: OK OK OK OK |

‘ATA;783000 REVERSER INHIBITION OK OK OK OK |

AaTe2n0 — GLGPEOETECTIN Ok ok oe cfs pereo

| Uploaded free text information prepaved on

ENO OF ITEM

action based on their airline practices, In that ease only a

summary of the service report is obtained, associated with

servicing item coupons for parameters which actually need a

check (Figure 9), |

Avionics Configuration Reports

report with coupons), the operator can add free text informa

tion, This information will be defined on a PC and uploaded |

into the CMC using a data loader

The Aircraft Configuration Report

Two reports will be available, one called the Equipment

Configuration Report und the other ealled the Software Load

able Equipment Configuration Repo. Both are accessible

trough the Avionies Configuration Repor item of the main

tenance men (Figure 10).

BM The Equipment Configuration Report presents each

equipment name with ils ATA reference, Functional ftem

Number (FIN), Part Number (P/N) andif any, Seri Number

database | reference and database 2 refe

Ell Phe Software Loadable Equipment Configuration Re- |

[port makes itecasier to manage the configuration of the soft

ware loadable equipment and associated diskettes The istof |

equipment included! inthis second repor is uploaded in the |

EMC, anda PCis used forthe definition of he lst Thisreport

reflects the following parameters: Disk number, Equipment |

Pas

eon Tenure Taz

ARCA el

teed

8 FAST / NUMBER 16

Esa Set as Ean CSTE

MAINTENANCE |

EQUIPMENT CONFIGURATION REPORT

AIRCRAFTIDENTIFICATION :F -wwas | PRINTING DATE: 260092 To: 1690

source ‘COMPUTER IDENTIFICATION

ATA NAME Pn, sn bent BiNe

226ae Eonso;2e0000200 Eovong0

2iai3s Vooouo21s654789 784612 |

2isie4 cpr

216334 Poe

‘000232103408300 895418

(000232103408200 695419

708218496123036 000118 a

1382996181201 004

name, FIN, P/N, Sofware reference (if any), database 1 | The listofadvisories and flags is shown in the previous table

reference (if any) and the database 2 reference (if any) (see | and they will be represented on the PFR as mentioned below,

Figure 11), with the associated Universal Coordinated time (i.e. GMT)

; and flight phase

Advisory and Flag recording function ea

This function adds to the Post FI

i Report the red flags

io tne Re FILENE Re pont he ss ATA: 2260 1847

displayed on the Primary Flight Display and Navigation Dis- FLAGONCAPT PFD CRUISE

play as well as the advisories displayed on the System Display ‘SPD Lait 06

(SD) page. Only flags not covered by warnings are considered ATA: 9453 1886

and they will be complementary information to the basic FLAGONCAPTND CRUISE

ECAM ‘warnings and Maintenance Status presented in the ao ss

cockpit effect column of the E ATA 21 34 2017

Steet coleman ne ROAM: ‘ADVISORY. ‘APPROACH

(CABIN ALTITUDE or

Downloading function

‘The purpose of this function is to download on to a diskette

the following reports for further analysis:

>Post Flight Report

>Previous Leg Report

3Class 3 Report

>System Bite Report

OServicing Report

> Avionics Configuration Report.

Each downloading will create an MS-DOS ASCII file

which name will be the aircraft identification followed by an

jon of the report, AIWN.MPF" where MPE

represents the Maintenance Post Plight repor.

‘Thisarticle has presented the A330/A340 on-board maintenance

-ept which benefits from A320 experience and whose fea-

s bring the system to the level of definition stated as an

‘objective by the ARINC 624 report, On-board Maintenance

System,

“The A330/A340 maintenance philosophy iseffectively built

around a standardised English language-based user interface.

I allows storage of BITE system fault data within each LRU

and provides ground test capabilites for LRU replacement.

Additional capabilities, such as the Servicing Report and the

Flagand Advisory function, are being designed to further help

the maintenance personnel.

Finally the A330/A340 maintenance system is integrated

with a new Trouble Shooting Manual design including BITE

assisted faultisolation procedures as described in the following

in this issue of FAST, dedicated to the evolution of the

trouble shooting manual. a

FAST / NUMBER 16 9

Evolution of the

TROUBLE SHOOTING MANUAL

for the A319/A320/A321/A330/A340

by Kenneth Johnson

Senior Engincer, Maintenance Documentation

Airbus Produet Support

Airbus Technical Publications

Department has just finished

retrofitting the concept of the

A330/A340 Trouble Shooting

‘Manual (TSM) 10 the A320.

This major endeavour was

initiated by Airbus to provide

Airlines with a common concept

TSM for the A319, A320, A321

A330 and A340 aircraft

The retrofit is being carried out in

parallel with production of the A340

TSM and the A330(A321 TSMs

‘manual contents for the A320.

This article describes the A330}

A340 TSM and explains why the =

original A320 TSM was different < Wiy the double horn shape ?

The above process leads to an uneven distribution of water

droplet impacts on the leading edge (Figure 1).

iseasily conceivable that those which are right in the middle

would not be deflected very much and would impactinstead on.

the upper and lower sides of the leading edge. This starts the

double horn shape, which is a divergent process and which is

further enhanced by ram effect (Figure 2).

But ifthe droplets are very he:

deflection is limited, and ice aécretion takes place in an are

e (Figure 3)

Ram effect

‘The impact mechanism generates energy both in th

the water which generates arise in temperature. in 1s

fed by the friction of high speed air, this temper

1 highly dependent on speed (Figure 4).

Foraironly. the temperature rise is +4°C at 150 ktand +16°C

«at 300 kt at FLLOO, Its very important to take this temperature

rise into aecount for the assessment of ice accretion,

Significant icing is not possible if the speed is such that the

ram effect rings the leading edge temperature above zero! For

example, no significant ice accretion is possible

fircra speed is maintained at 300 kt

Run-back ice and shear forces

> What happens when an aircraft is flying in icing

‘atmosphere where leading edge temperature is positive ?

Dueto ram energy, waterdropletsdonot freeze on impact, but

explode into numerous litle globules which are blown by the

airflow along the wing surfaces. But wing surfacesaftof the area,

heated by ram energy are ata negative temperature and cool the

‘water down, Itoften happens that the cooling is quicker than the

blowing off and water freezes on the spot. This process is called.

“run-back ice” (Figure 5).

' of the blowing off process depends on the shear

forces present in the boundary layer. The faster the aircraft, the

cleaner the wing,

‘Sublimation

> Whar happens to an iced wing once the aircraft is out

of the cloud?

‘The situation is hardly ever considered, Ice will not sta

is because of sublimation, which is the direct change of water

from solid state 0 vapour. Once out of cloud, ice thickness will

necessarily decrease. The sublimation rate depends on relative

air humidity and may reach a rate of one millimetre per ten

minutes. This is quite an impressive figure, which is worth

considering for fights of long duration,

FAST / NUMBER 16

ae Sa

Double hom shape on wing leading eds:

Droplet path less curved

air path, due t9 inertia

a

SE

Airflow ines

Lighter droplets =——

deviate

eee

Although numerous icing events (about 100) were encoun

tered during the CASP Il experiment, very few were of

significant importance for aircraft flying at FL. 100, and none

at all if the speed was assumed 10 have been 300kt, This

surprising outcome results from a numberof factors unfavour-

able to icing, which have to be considered.

North Atlantic climatology

related to icing

Tiwas found that North Atlantic winter weather conformsto

itslegendary severity mainly at lower altitude. Theabsence of

‘orographic effects lets the frontal systems develop in a classi-

cal "horizontal" manner. Weather moves East rapidly. Pre-

cipitation of multiple types is heavy on the ground, but water

content at altitude remains moderate. Cumulo-nimbus clouds

rare, very small and with moderate activity

Stratiform clouds dominate and carry most of the SLW

which is farfrom evenly distributed in them, Most of the SLW

lies in the upper few hundred feet of the layers. Due to ever-

present micro convection, water content is extremely irvegu:

lar. If peak values can be impressive, average figures remain

moderate and so does the ice accretion. By definition, a

temperature inversion layer sits on top of every stratus cloud

layer (Figure 6).

The consequences for aircraft are of prime importane’

if icing is encountered, a small altitude change (a few

hundred feet) may relieve the threat, This is not conventional,

bout atmospheric physics are in operation !

© flying close tothe top ofa stratiform layer probably involves

the greatest risk of icing. Flying above the layer is much more

calm and the atmosphere is much dryer, thus prone to active

sublimation,

Size of icing clouds

‘Typical icing clouds are hardly ever extensive horizontally

even aking the worst case which would be to fly along a cold

{ront.Itisdifficltto quotea figure beforeall CASP results are

available, but itis clear that an aireraf flying a 300 kt would

never remain in icing cloud for more than @ few minutes

(and would have no ice accretion, due to speed). Repetitive

encounters are possible in an area where a complex weather

28

Figure 6

Typical CASP icing conditions

Aiinude

Relative

Iumidhty

305 + SLWe

100%

Icing upper layer

system sits, but not all would be a real threat. Ithas also been,

found that no firm correlation exists between cloud size and

droplet size.

Effects of speed and sublimation

It has been shown above that speed protects aireraft from

icing due to ram effect. The CASP II results confirm that

neither of the aircraft involved ever iced at their maximum

speeds, 230 and 250 kt respectively. Itwas aid that ram effect

‘may produce run-back ice, but it was found that the increased

level of sheur forces encountered at high speeds reduces run

back ice to negligible proportions.

In spite of everything, if an aircraft iced during an ETOPS

diversion, sublimation would significantly decrease the drag

penalty during the rest of the leg.

These results ean be expanded to include oceanie areas of

similar lariucdes.leing risksave necessarily aggravated by the

proxinity of mountains. ce accretion on jet airliners at

imediumiflight levels differsfrom the icing encounteredby light

aircraft flying at lower levels and speeds.

The research in noway alters the experience of icing gained

by the thousands of magnificent men and women who have

traversed the Atlantic in their light lying machines.

FAST | NUMBER 16

A new home for

AIRBUS CUSTOMERS’ SUPPORT

Product support, by its very nature, means going out to be with our Operators. This develops people who are at home all over

the globe. In the case of Airbus’ support staff this is true, but they have also been subjected to wanderings in Toulouse as,

The growth of the Airbus fleet has been reflected in the number of staff to suppor it, imposing office changes

and even, until recently, Support staff being installed on two different sites in Toulouse,

All has now changed with the delivery of the "BO

which reflects an im

however is not an end in itself. The new building brings all the Toulouse staff together and provides

them with an environment in which itis easier to wark even mor

Duilding in January this year. This magnificent structure

of modernity and openness, is an appropriate symbol of Support. Elegance

proximity

continu

to our Operators in the present difficult times,

‘The building has worked well from the initial occupation and will be an

‘exceptional working place. It has been designed with room for growth.

Once the present margins have been used, the modular design and

foundations already in place will allow another unit, and some

150 people, to be added without any need for significant

interference with those working in the buildin

Airbus Support staff will be able to move into the

2istcentury in offices that belong to that time

and also provide an e

\d modern communication means. This is essential to be able 1

| growing demands for support, asuppor' thats moreand more essential

cellent functional

base for their operations.

FAST | NUMBER 16

>

Locations COUNTRIES TELEFAX TELEPHONE siTa

ABU DHABI United Arab Emirates IL (2) 75306 ‘971 (2) 7087702

ADEN Yemen 967 (2) 232855 967 ADEAIDY

AMMAN Tord 962 (8) 31195 AMMBITX

ATHENS. Greece 30 (1) 9832479 30 (1) 9818581 ATHEYOA

ATLANTA USA (Ge0r 1 dou) 7637401 1 40s) 7620011 2

BAHRAIN — Basin 973 320584 973 327262 —BAnELOF

BANGKOK Thailand (6 @) 5311930 0 (2) 5310076 BKKZUTG

BOMBAY Inia 91 (22) 6113691 91 (22) 6128203 BOMEAAI

91 @2) 6117122 2) 6117187 ;OMYCIC

BUCHARE Romania 40140) 3125853 40,(1) 3126670 BUHDTRO

CAIRO Egypt 202 4183707 202 4183687 CAIESMS

CHICAGO USA dino) 1 (312) 6012406 1312) 6014602

COLOMBO Sn Lanks 94 (1) 453893 1) 455893 cuBai7

COPENHAGEN Denmark 45 32455596) 45 92477279 CPHBIX

DAKAR Senegal 221 201148 221 201615 DKRRIRK

DELHI Tea 31 Cin) Sas ity 5452033 DELEEIC

DOHA State of Que 974 32004

DUBAT United Arab Emirates 971 Ga) 82227 971 (4) 822519

DUBLIN Teeland 353 (1) Sis4822 353 (1) B#44322

FRANKFURT Germany 49 (69) 6964699 49 69) 696947

HO CHI MINH CITY VietNam 84 (8) d46a18, “$4 (8) 46419

HONG KONG. Hong Kons 852.747 BAO

HOUSTON USA Texas] T (713) 9853623

ISTANBUL Turkey 0 52 90 (212) 5740007

JAKARTA Indonesia 62 (2) 5501043 62 21) 3501993 IRTROX

JEDDAH Sau Arabia 966 (2) 6857712 86 (2) 6842864 IEDMISY

JOHANNESBURG 11) 9784309 (11) 9783361

KARACHI 21) a3 70600 KHIVEPK

KHARTOUM Sudan 239 (11) 75082 KRTBITX,

KUALA LUMPUR Malaysia oT. 60 (3) 7402470 KULBAMEI

KUWAIT Kuwait 965 434 968 47419, KWIEIKU

LAGOS Nigeria (U1) 900171 Ext 117 LOssOWT

LARNACA Cyprus 357 @) 6BISS 357 (a) 643181 LCABITX

LISBON Porugal 351 (1) BaTaads 351 (1) 807032 LISBICR

LONDON (EHR) England 44 (BI) 5626785 “4 ($1) 5626786

LOS ANGELES USA (Califor (G10) 2583422 1 G10) 2583420 LAXQCCO

LUTON England 44 82) 483826 44 (S82) 398706, LONBIX

MADRID Spain 34 (1) 3290708 34 (1) 3291447

MALTA Malta 386 M6 355 90x MLAEZKM

30

FAST / NUMBER 16

LocaTions

MANCHESTER

MANILA

MEMPHIS

MEXICO CITY

MELBOURNE

MIAME

MINNEAPOLIS

MONTREAL

Moscow

NAIROBL

NEW YORK

PARIS (CDG)

PARIS (ORY)

PHOENIX

Quito

ROME

SAN FRANCISCO

SAN JOSE

SEOUL

SHANGHAL

SHENYANG.

SINGAPORE

SOFIA.

TAIPEI

TASHKENT

TOKYO (IND)

TORONTO

TULSA

TONS ——

VANCOUVER

VIENNA

WINNIPEG

WINSTON SALEM _

XIAN

ZURICH

COUNTRIES

England

Philippines

USA

Mexic

Australia

USA |Florida

USA (Mino

Can

Russia

Kens:

USA (New York)

USA (Arizona)

Covch Repub

South Kore

haly

USA (Califomia)

Costa Ris

South Kore a

Peoples Republic of Chi

Peoples Republic of China

Singapore

Bulg

Taiwan

Urbekistan

Iran

Taga

Canada

“USA (OWahoma)

Tunisia

Canal

Austr

Canada

USA (North Carolin

Peoples Republic of China

‘Switzerland

y

TELEFAX

461) 4803240

TELEPHONE

a (61) 489315

(@) 8314s

1 01) 79768

5 Seta

6 6G) 382035

13 1 @05) 471 141

1 (612) 726041 14512) 7260431

T6514} 4226310 1(sl4) 2660

234. (2) 82: 254 2) &

(718) 4560700.

(1) 48642235

a) era

82 Gh 97169

503 12) 460656

506 412228

82.) 6643979

“86 1) 25566

86.24) 2725177

5 (5) 45380

86 (3) 3834718

$86 2) S504

TI) 552878

70 SL) 3747827

8772 SL (3) 57868770

8 (Gig) 6745413,

922581 5

216 (1) 750885

(604) 2763548 4) 9763776

13 3235 Tr103685

(204) 8372489) ‘9412008

(919) 7670784 1019} 7676300

86 (29) 4261203 BG (29) 729KS10

Thy 8102383 a1 (1) 812772

SITA

MANEEDP.

MNLEUPR

MEXVTMX.

YULEEAC

SVOEISt

NBOECKQ

PARBUX

ORYASAF

PROBUS,

PUSXSKE.

PCOYSAZ

SIOMALR

SELBIX

SOFGALZ

TPEBITX

TASDENY

THRMBIR

VYZBIIX

HDQMRAA

TUNTITL

YVRBITX

YWGMB,

ZRUZESR

ee

FAST | NUMBER 16

34

5

Raa

i

(EEL andiing an aircraft on the ground is a very serious business,

which is approached in different fashions by different aeroplane operators.

In some countries where unemployment is high, woman power is used, with

| adequate (male) supervision of course, to keep the aircraft to the high standard

| ‘of cleanliness that today’s passengers have come to expect

Juikers G24 with three 310 horse-power Junke ‘linder in-line liquid cooled engines (1925)

In other, perhaps more mechanically minded countries, multi-purpose machines

are used. This very cost-conscious operator has grass-cutting equipment attached to its

tractors to ensure that the long journey between the terminal on one side of the aerodrome

a and the maintenance area on the other is not wasted. It is particularly interesting

and welcome to note that the welfare of the staff has not been forgotten in

the drive to cut costs - the wind direction indicator(WDI) on the tractor

allows the driver always to cut the grass in the direction best suited

to prevent the dust from blowing into his face

Such attention on the part of the management, to the detail

‘of human relations and morale building, is to be commanded

Eimear 274d shows the direction which other companies will have to

BF ‘ollow if they are to compete

Caproni 41° with dee 300 horse-power Isotta-Fraschin engines (1918)

In our view, 100% commitment to support is a 24-hour

responsibility.

A significant measure of Airbus Industrie’s commitment is that some 3,000 people are directly involved in support for

our constantly evolving family of civil aircraft. A total of 23 different languages are spoken by our staff, which indicates

‘the global scope of our act s in this vital part of the civil aviation market. A multi-million dollar investment

programme also ensures that our international support facilities will continue to match our increasing worldwide

customer base.

NT TU Tl

TAKING THE WORLD VIEW

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5814)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (845)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- BE-Aerospace - 35!10!60 Crew MaskDocument52 pagesBE-Aerospace - 35!10!60 Crew MaskJason JiaNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

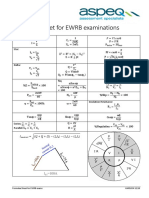

- Formulae Sheet For EWRB Examinations: For Examination Use OnlyDocument1 pageFormulae Sheet For EWRB Examinations: For Examination Use OnlyJason JiaNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- BE-Aerospace-Filter Replacement of Air ChillerDocument3 pagesBE-Aerospace-Filter Replacement of Air ChillerJason JiaNo ratings yet

- CMMIPL 25-20-04 Rev 1 - Series 200 DYNAMIC Electric Single Seat 2524.538Document66 pagesCMMIPL 25-20-04 Rev 1 - Series 200 DYNAMIC Electric Single Seat 2524.538Jason JiaNo ratings yet

- Notes BookDocument77 pagesNotes BookJason JiaNo ratings yet

- Solutions Manual For Electromechanical Dynamics: Mit OpencoursewareDocument171 pagesSolutions Manual For Electromechanical Dynamics: Mit OpencoursewareJason JiaNo ratings yet

- Er 38 Answers - 26 June 2010Document21 pagesEr 38 Answers - 26 June 2010Jason JiaNo ratings yet

- BE-Aerospace - 25!30!32 Air ChillerDocument164 pagesBE-Aerospace - 25!30!32 Air ChillerJason JiaNo ratings yet

- Notes BookDocument81 pagesNotes BookJason JiaNo ratings yet

- 2 Electricity Safety Regulations 2010Document183 pages2 Electricity Safety Regulations 2010Jason JiaNo ratings yet

- 1 Electricity Act 1992-2018Document187 pages1 Electricity Act 1992-2018Jason JiaNo ratings yet

- Helicopter Aerodynamics, Structures and SystemsDocument414 pagesHelicopter Aerodynamics, Structures and SystemsJason Jia100% (11)

- Flight Airworthiness Support Technology: J U L Y 2 0 0 7Document19 pagesFlight Airworthiness Support Technology: J U L Y 2 0 0 7Jason JiaNo ratings yet

- Flight Airworthiness Support Technology: J U L Y 2 0 0 5Document21 pagesFlight Airworthiness Support Technology: J U L Y 2 0 0 5Jason JiaNo ratings yet

- Flight Airworthiness Support Technology: December 2007Document23 pagesFlight Airworthiness Support Technology: December 2007Jason JiaNo ratings yet

- Fast35 PDFDocument23 pagesFast35 PDFJason JiaNo ratings yet

- Flight Airworthiness Support Technology: J U L Y 2 0 0 4Document21 pagesFlight Airworthiness Support Technology: J U L Y 2 0 0 4Jason JiaNo ratings yet

- Windshield Rain ProtectionDocument20 pagesWindshield Rain ProtectiontatomhNo ratings yet

- Flight Airworthiness Support Technology: J U L Y 2 0 0 3Document32 pagesFlight Airworthiness Support Technology: J U L Y 2 0 0 3Jason JiaNo ratings yet

- FAST26Document32 pagesFAST26JNo ratings yet