Professional Documents

Culture Documents

CE 3033 & 7052 - PRIMARY Exam 2018

CE 3033 & 7052 - PRIMARY Exam 2018

Uploaded by

Jules ArseneCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

CE 3033 & 7052 - PRIMARY Exam 2018

CE 3033 & 7052 - PRIMARY Exam 2018

Uploaded by

Jules ArseneCopyright:

Available Formats

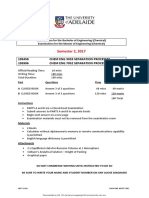

Examination for the Bachelor of Engineering (Chemical)

Examination for the Master of Engineering (Chemical)

Semester 2, 2018

105458 CHEM ENG 3033 SEPARATION PROCESSES

105996 CHEM ENG 7052 SEPARATION PROCESSES

Official Reading Time: 10 mins

Writing Time: 180 mins

Total Duration: 190 mins

Part Questions Time Marks

A CLOSED BOOK Answer 3 of 3 questions 60 mins 60 marks

B CLOSED BOOK Answer 3 of 3 questions 120 mins 120 marks

180 Total

Instructions

PARTS A and B are a Closed-book Examination

Submit answers to PARTS A and B in separate books

Begin each answer on a new page

Examination materials must not be removed from the examination room

Materials

2 Books

Calculator without alphanumeric memory or remote communications capability

is permitted

English language dictionary is permitted

Attachments

Enthalpy-composition Diagram for Ethanol-Water at 1 Atmosphere Pressure

Colburn's Analytical Solutions as a Chart

Graphical paper

DO NOT COMMENCE WRITING UNTIL INSTRUCTED TO DO SO

WRITE YOUR NAME AND STUDENT NUMBER ON ANY LOOSE DIAGRAMS

2018 Exam CHEM ENG 3033 & 7052

2

PART A

QUESTION A1 20 MARKS

Ethanol can be separated from water by extractive distillation using superheated steam1.

A plant in Port Adelaide has a waste stream of mixed ethanol and water, which is at a bulk

temperature of 60 OF and contains small amounts of inert matter, together with

superheated steam available at 1,218 Btu/lb water.

You are asked to professionally

a. Estimate the maximum ethanol concentration that could be achieved for a feed-stream

of 50:50 mol% [10 Marks]

b. Show that if a feed ratio of steam-to-ethanol of 1:2 is used there will be an overall 52 %

recovery of ethanol in the tops with resulting xN = 0.22 [5 Marks]

c. Determine how many actual stages will be needed if each equilibrium stage is 50 %

efficient. [5 Marks]

QUESTION A2 20 MARKS

a. The q-line for a given feed condition is defined by the intersection between operating

lines at the feed stage. Given

𝐿̅ − 𝐿

𝑞=

𝐹

Derive carefully

𝑞 𝑧𝑖

𝑦𝑖 = ( ) 𝑥𝑖 − ( )

𝑞−1 𝑞−1

[8 Marks]

b. In an actual stage the phases however do not reach equilibrium

i. With the aid of a carefully labelled diagram illustrate the relationship between the

compositions in an actual stage with those in an ideal stage [6 Marks]

ii. What factors influence the performance of an actual stage? [6 Marks]

QUESTION A3 20 MARKS

The two-film inter-phase mass transfer model is used in vapour-liquid separation processing

in packed columns.

a. With the aid of a carefully labelled diagram illustrate this two-film model. Be sure to

state any assumptions that you make [6 Marks]

b. Based on your diagram, derive an expression for the operating line for the packed

column [9 Marks]

c. Column packing is of various types - the function is to provide as large surface area as is

possible for contact of two phases. What are the five (5) main requirements of packing?

[5 Marks]

1

McCabe, W.L., Smith, J.C., Harriott, P., 2001. Unit Operations of Chemical Engineering, 6th edition McGraw-

Hill, NY, USA. ISBN: 0070393664.

Foust, A.S., Wenzel, L.A., Clump, C.W., Maus, L., Anderson, L.B., 1980. Principles of Unit Operations. John Wiley

& Sons, NY, USA. ISBN: 0471268976.

2018 Exam CHEM ENG 3033 & 7052

3

PART B

QUESTION B1 40 MARKS

A solids waste-steam from a plant in Whyalla is to be processed to extract a valuable oil. The

extraction will be achieved using a suitable solvent in a multistage counter-current leaching

plant. The feed-rate to the leaching plant will be 800 kg h-1. It will contain 50 wt% oil. The

1 kg solvent

balance behaves as inert sludge-solids. Bench-scale studies have shown that 1 kg solids sludge

will leave each unit of the multi-stage plant.

Practical plant economics necessitate that 95 per cent of the oil will need to be recovered as

a liquid of 30 wt% of the oil in the solvent.

As the consulting chemical engineer you are tasked to estimate the

a. Solvent feed-rate [15 Marks]

b Flow-rate of oil, solvent and solids in the plant underflow [10 Marks]

c. Using a graphical method, provide an estimate of the number of ideal stages that will

be needed. [15 Marks]

QUESTION B2 40 MARKS

You are the professional chemical engineer responsible at an established distillation plant

north of Adelaide that usually separates grape-waste feedstocks in a column with a total

condenser and total reboiler.

During a seasonal downturn, your company decides to test a new binary (A in B) feedstock

in its column that is operated at 16 OC and 1.13 atm. The feed to the column is a half vapour

30:70 mol% mix.

The information you have is that

i. Equilibrium data as mole fraction at column conditions is approximated by

1.8𝑥𝐴

(1 − 𝑥𝐴 )

𝑦𝐴 =

1.8𝑥𝐴

(1 + )

(1 − 𝑥𝐴 )

ii. It is required that the concentration of product A in the distillate be 95 mol%, and that

only 0.03 of all B is in the bottoms

iii. You use a practical value of rD = 9 and a Murphree vapour efficiency = 90%.

a. Estimate the number of equilibrium stages required in the column [20 Marks]

b. How many stages are in the

Enriching section? [10 Marks]

Stripping section? [5 Marks]

c. What is the location of the optimum feed stage? [5 Marks]

2018 Exam CHEM ENG 3033 & 7052

4

QUESTION B3 40 MARKS

In an existing process plant a tower is packed with Intalox® Ultra metal packing (1”). It is

planned the tower will be used to scrub methane (M), an unwanted greenhouse gas, from

air using available water supplies.

The inlet gas contains 4.5 v/v% M and will enter the packed tower at 0.69 kg s-1 per m2 of

bed cross-section. The water flow to the tower is 0.58 kg s-1 per m2. For a practical economic

performance, the scrubbed gas leaving the tower is to contain 0.1 v/v% M.

The plant chemist has provided a good estimate of equilibrium data (as mole fraction M

solubility in water under practical tower operating conditions) as

𝑦𝑀 = 1.117𝑀 + 4.027𝑀2

As the plant professional chemical engineer you are tasked to provide a good estimate of

the number of transfer units required for the tower duty based on the overall gas phase

resistance. In your answer you are asked to clearly state any assumptions you make.

[40 Marks]

END OF PAPER

2018 Exam CHEM ENG 3033 & 7052

5

2018 Exam CHEM ENG 3033 & 7052

6

2018 Exam CHEM ENG 3033 & 7052

7

Colburn's Analytical Solutions as a Chart

2018 Exam CHEM ENG 3033 & 7052

8

2018 Exam CHEM ENG 3033 & 7052

9

2018 Exam CHEM ENG 3033 & 7052

10

2018 Exam CHEM ENG 3033 & 7052

11

2018 Exam CHEM ENG 3033 & 7052

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5814)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (845)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Nautilus Box Boom Crane Reference ListDocument6 pagesNautilus Box Boom Crane Reference Listvipin_nair01100% (2)

- Week 4 - Theory - Isothermal Reactor Design Steady StateDocument39 pagesWeek 4 - Theory - Isothermal Reactor Design Steady StateJules ArseneNo ratings yet

- Week 5 - Theory - Unsteady State and Multiple ReactionsDocument39 pagesWeek 5 - Theory - Unsteady State and Multiple ReactionsJules ArseneNo ratings yet

- Week 2 (Final) - Theory - Conversion and Multiple Reactors1Document29 pagesWeek 2 (Final) - Theory - Conversion and Multiple Reactors1Jules ArseneNo ratings yet

- Week 1 (Final) - Introduction, Mole BalancesDocument51 pagesWeek 1 (Final) - Introduction, Mole BalancesJules ArseneNo ratings yet

- Exam 2017 Questions SeparationsDocument12 pagesExam 2017 Questions SeparationsJules ArseneNo ratings yet

- Stress Coping Mechanisms Article by Schwarzer EDocument3 pagesStress Coping Mechanisms Article by Schwarzer EJules ArseneNo ratings yet

- Ingenuity Project Blurb Factsheet 2020Document4 pagesIngenuity Project Blurb Factsheet 2020Jules ArseneNo ratings yet

- IPE Process Flow DiagramsDocument1 pageIPE Process Flow DiagramsJules ArseneNo ratings yet

- Flags - Climate ChangeDocument1 pageFlags - Climate ChangeJules ArseneNo ratings yet

- Boiler Perform CalculateDocument29 pagesBoiler Perform CalculateAnsarNo ratings yet

- Levenspiel C5 Problemas PDFDocument7 pagesLevenspiel C5 Problemas PDFbete_azmaveteNo ratings yet

- Ammonia Production BFDDocument1 pageAmmonia Production BFDMaya HarrisNo ratings yet

- Notes in Fire Technology Arson InvestigationDocument4 pagesNotes in Fire Technology Arson InvestigationTIPAY, EMELIE L.No ratings yet

- Man C01000-10 PDFDocument2 pagesMan C01000-10 PDFYeison Prasca MartinezNo ratings yet

- 1 s2.0 S0196890498000582 MainDocument10 pages1 s2.0 S0196890498000582 MainAnkit KumarNo ratings yet

- Worksheet 3Document2 pagesWorksheet 3Tsega IsraelNo ratings yet

- Tech Data: Vultrex Production & Drilling CompoundsDocument2 pagesTech Data: Vultrex Production & Drilling CompoundsJeremias UtreraNo ratings yet

- Tugas - 6 Senyawa AlkunaDocument3 pagesTugas - 6 Senyawa AlkunaBaiq ArinNo ratings yet

- ELIMINATOR® Liquid Line Filter Drier Types DCL and DML: Data SheetDocument16 pagesELIMINATOR® Liquid Line Filter Drier Types DCL and DML: Data SheetSouljah KhifferNo ratings yet

- Material Safety Data Sheet: Oxygen, CompressedDocument1 pageMaterial Safety Data Sheet: Oxygen, CompressedNuri Estiana AnggrainiNo ratings yet

- CryoquipWebBrochure PDFDocument16 pagesCryoquipWebBrochure PDFvenkateswaran k.sNo ratings yet

- Membrane Technology: A Presentation OnDocument128 pagesMembrane Technology: A Presentation OnGopi KrishNo ratings yet

- WehreDocument8 pagesWehreallovid0% (1)

- CdtechebDocument2 pagesCdtechebLuisColmonero0% (2)

- Moderate Pressure ProcessDocument4 pagesModerate Pressure Processkishna009No ratings yet

- Engineering Design Guidelines Flare Systems Rev3.4webDocument25 pagesEngineering Design Guidelines Flare Systems Rev3.4webAntonioNo ratings yet

- Liquid Argon MSDSDocument2 pagesLiquid Argon MSDSglobal bikramNo ratings yet

- Chm271 - Chapter 2 Thermochemistry - UpdatedDocument68 pagesChm271 - Chapter 2 Thermochemistry - UpdatedNurfarhanah AsyknNo ratings yet

- Eor Brochure 2012Document32 pagesEor Brochure 2012Juan Camilo Dangon MolanoNo ratings yet

- Fydp Final Report - TharushiDocument140 pagesFydp Final Report - TharushiharshaNo ratings yet

- Fuel Oil CombustionDocument35 pagesFuel Oil Combustionchaiya sonwongNo ratings yet

- Corrosion in Distillation ColuDocument5 pagesCorrosion in Distillation ColuOmar EzzatNo ratings yet

- RT 02A 13B 21 23709 00 (Material Selection Report)Document44 pagesRT 02A 13B 21 23709 00 (Material Selection Report)gharsallah mouna100% (1)

- Modular Hydrogen Plants: Hydro-ChemDocument12 pagesModular Hydrogen Plants: Hydro-ChemFahryPurnamaNo ratings yet

- Tas Institute of OilDocument7 pagesTas Institute of OilSheena DovenantNo ratings yet

- Control of Sulphur OxidesDocument10 pagesControl of Sulphur OxidesUmang sharmaNo ratings yet

- 10 - Latest Developments in Hydrocracking Catalysts Proceedings PDFDocument26 pages10 - Latest Developments in Hydrocracking Catalysts Proceedings PDFmujeebtalib100% (1)

- Berptann, and XU. : Coken, Shahak Organic Fluorine Compounds. Part Preparation Reactions Diethyl FluoromalonateDocument4 pagesBerptann, and XU. : Coken, Shahak Organic Fluorine Compounds. Part Preparation Reactions Diethyl FluoromalonateMailinkoNo ratings yet