Professional Documents

Culture Documents

Air Tank Computation

Uploaded by

John MalonesOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Air Tank Computation

Uploaded by

John MalonesCopyright:

Available Formats

Another part of the air supply system is a storage tank.

The storage tank capacity, expressed in gallons, should be large

enough to smooth out intermittent peak loads.

Three Things Required to Size a Storage Tank:

1. System air requirements in SCFM

2. Desired differential (this is usually 20 psig. It is the cut in point subtracted from the cutout point of the

pressure switch)

3. The number of starts per hour

The formula used for tank sizing is:

“Off-Time” is determined as follows:

The number of starts per hour is usually selected as six or ten. Six results in longer off time. The longer off time means a

larger tank, which will be more expensive than a smaller tank. If initial cost is the most important criteria for selection, then 50%

run time and ten starts per hour should be used. If long life, less maintenance, and consequently lower cost over the life of the

system is the criteria for selection, then 33% run time and six or ten starts per hour should be used.

Using our example system requiring 1.096 SCFM, we can complete both possible selections (altitude compensation not

included).

Given: 50% run time

10 Starts per hour

2.192 SCFM

20-psig differential

= 6 x 0.5

= 3 minutes

= 36.2 gallons

Given: 33% run time

6 Starts per hour

3.28 SCFM

20-psig differential

= 10 x 0.67

= 6.7 minutes

= 120.87 gallons

You might also like

- Compressed Air SystemDocument3 pagesCompressed Air Systemlyheang0% (1)

- Air Compressor Sizing CalculationDocument1 pageAir Compressor Sizing CalculationJohn MalonesNo ratings yet

- Calculating Receivers in Compressed Air SystemsDocument4 pagesCalculating Receivers in Compressed Air Systemsdharwin100% (1)

- Encon Basement VentilationDocument15 pagesEncon Basement VentilationLuis Alfonso González VergaraNo ratings yet

- ColumnsDocument34 pagesColumnsharsh421No ratings yet

- Fixed Foam CalculationDocument4 pagesFixed Foam CalculationDiwakar NigamNo ratings yet

- Plumbing Guidelines For Sizing Grease InterceptorsDocument1 pagePlumbing Guidelines For Sizing Grease InterceptorsJosef MadronaNo ratings yet

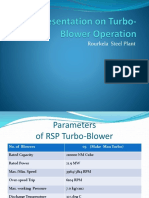

- Turbo-Blower Operation - PPSXDocument12 pagesTurbo-Blower Operation - PPSXSyed Safiur Rahman100% (1)

- Fixed Foam CalculationDocument4 pagesFixed Foam CalculationAhmad RiadusNo ratings yet

- How To Size A Hydropneumatic Tank in A Pressure Booster SystemDocument3 pagesHow To Size A Hydropneumatic Tank in A Pressure Booster SystemAnonymous mNQq7ojNo ratings yet

- Improving The Process For Sizing Reciprocating CompressorsDocument7 pagesImproving The Process For Sizing Reciprocating CompressorsKong LingweiNo ratings yet

- Gas Compression IIDocument13 pagesGas Compression IIAnuraag MulpuriNo ratings yet

- Pressure Tank CalculationDocument43 pagesPressure Tank CalculationRahman Faham67% (3)

- Control and Optimization of A Multiple Effect EvaporatorDocument6 pagesControl and Optimization of A Multiple Effect EvaporatorthanhndbNo ratings yet

- INDG1030 Chemical Plant Design - Assignment 3 (10 PT.) I Term 2019Document1 pageINDG1030 Chemical Plant Design - Assignment 3 (10 PT.) I Term 2019William VilelaNo ratings yet

- Simplified TDH WorksheetDocument3 pagesSimplified TDH WorksheetOthello ErejeNo ratings yet

- Design Capacity Calculation of 3X156 KPH Electro Chlorination SystemDocument2 pagesDesign Capacity Calculation of 3X156 KPH Electro Chlorination Systemshriyans5388100% (2)

- Equipment Selection & Design - 2Document5 pagesEquipment Selection & Design - 2Nabeel SiddiqueNo ratings yet

- Softener CalculationDocument4 pagesSoftener CalculationMarcoNo ratings yet

- CompAir SolenoidValvesDocument8 pagesCompAir SolenoidValvesSam JoseNo ratings yet

- Settling ChambersDocument2 pagesSettling ChambersAnonymous d3sWgsNo ratings yet

- SBR Plant Design PDFDocument8 pagesSBR Plant Design PDFvishuNo ratings yet

- Design Calculation of 61kld STPDocument4 pagesDesign Calculation of 61kld STPAminur Rahman100% (2)

- How To Size Hydropneumatic TankDocument3 pagesHow To Size Hydropneumatic TankfelipeNo ratings yet

- Control and Optimisation of A Multiple Effect Evaporator PDFDocument6 pagesControl and Optimisation of A Multiple Effect Evaporator PDFFanilo RazafindralamboNo ratings yet

- Foam Sprinkler System CalculationDocument5 pagesFoam Sprinkler System CalculationJitheesh Sahadevan75% (4)

- Basic Engineering Calculations-R1Document5 pagesBasic Engineering Calculations-R1Prashant HuddarNo ratings yet

- AI SolutionsDocument5 pagesAI SolutionsSabaAkramMalikNo ratings yet

- Traffic Capacity Analysis & Signal TimingDocument4 pagesTraffic Capacity Analysis & Signal TimingLastri PasaribuNo ratings yet

- m13 l18 Grit Chamber ContdDocument6 pagesm13 l18 Grit Chamber Contdahmedmagdi2009No ratings yet

- Tank SizingDocument2 pagesTank SizingsamehNo ratings yet

- Method 6b PDFDocument9 pagesMethod 6b PDFMichael StevenNo ratings yet

- Chapter 2 Part 1Document11 pagesChapter 2 Part 1virajain100% (3)

- Layout Design of InverterDocument60 pagesLayout Design of InverterAlamgir MohammedNo ratings yet

- Encon Basement VentilationDocument15 pagesEncon Basement VentilationcyruskuleiNo ratings yet

- Drum Scrubber Ausimm PDFDocument11 pagesDrum Scrubber Ausimm PDFcumpio425428No ratings yet

- Flue Sizing OptionsDocument2 pagesFlue Sizing OptionsMarco Antonio Camacho Tezanos-PintoNo ratings yet

- Intake Air FilterDocument2 pagesIntake Air Filterary cahyonoNo ratings yet

- Rectangular Jet Air Nozzles and Swirler Improving Ignition and Flame FormationDocument24 pagesRectangular Jet Air Nozzles and Swirler Improving Ignition and Flame Formationhmaza shakeelNo ratings yet

- Design IFPDocument4 pagesDesign IFPAnzar HussainNo ratings yet

- Azeem Khan B00230817 Cstrs in Series Tht-2 Report DR Mojtaba MirzaeianDocument11 pagesAzeem Khan B00230817 Cstrs in Series Tht-2 Report DR Mojtaba MirzaeianAzeem KhanNo ratings yet

- ProcessDocument8 pagesProcesssterlingNo ratings yet

- Tool For Compressed Air CalculationsDocument5 pagesTool For Compressed Air CalculationsSohail PathanNo ratings yet

- Agilent-GC Method Development Presentations PDFDocument10 pagesAgilent-GC Method Development Presentations PDFformoviejuneNo ratings yet

- Disk Scheduling RevisitedDocument11 pagesDisk Scheduling RevisitedShrîdhâr ShãrmãNo ratings yet

- Final 222 2009 SolDocument6 pagesFinal 222 2009 SolNapsterNo ratings yet

- Assignment No. 7 Chemical Engineering Fluid Dynamics Session 2016 Due Date: 16 May-2018 Solve All The Questions. (As A Part of Assessment of CLO3)Document1 pageAssignment No. 7 Chemical Engineering Fluid Dynamics Session 2016 Due Date: 16 May-2018 Solve All The Questions. (As A Part of Assessment of CLO3)Muhammad Jawad IsmaeelNo ratings yet

- SQ - 4.7 - Pumps (Table Format)Document5 pagesSQ - 4.7 - Pumps (Table Format)Amitav MishraNo ratings yet

- Examples WorksheetDocument9 pagesExamples WorksheetBayisaGebreNo ratings yet

- Rule of CalculationDocument3 pagesRule of CalculationAchmad Farits FauziNo ratings yet

- Group 2 ReportDocument5 pagesGroup 2 ReportJo odNo ratings yet

- Polymath Repor1Document9 pagesPolymath Repor1Cer No Rus100% (1)

- Foam CalculationDocument11 pagesFoam CalculationJoshue AdeleNo ratings yet

- Numerical Methods for Simulation and Optimization of Piecewise Deterministic Markov Processes: Application to ReliabilityFrom EverandNumerical Methods for Simulation and Optimization of Piecewise Deterministic Markov Processes: Application to ReliabilityNo ratings yet

- Classical Approach to Constrained and Unconstrained Molecular DynamicsFrom EverandClassical Approach to Constrained and Unconstrained Molecular DynamicsNo ratings yet

- Marine Electrics Made Simple or How to Keep the Batteries ChargedFrom EverandMarine Electrics Made Simple or How to Keep the Batteries ChargedNo ratings yet

- Control of DC Motor Using Different Control StrategiesFrom EverandControl of DC Motor Using Different Control StrategiesNo ratings yet

- Mathematical and Computational Modeling: With Applications in Natural and Social Sciences, Engineering, and the ArtsFrom EverandMathematical and Computational Modeling: With Applications in Natural and Social Sciences, Engineering, and the ArtsRoderick MelnikNo ratings yet

- Calculate Gravity ForceDocument2 pagesCalculate Gravity ForceJohn MalonesNo ratings yet

- How To Calculate AccelerationDocument2 pagesHow To Calculate AccelerationJohn MalonesNo ratings yet

- How To Calculate ForceDocument3 pagesHow To Calculate ForceJohn MalonesNo ratings yet

- How To Calculate Spring ConstantDocument2 pagesHow To Calculate Spring ConstantJohn MalonesNo ratings yet

- How To Calculate Tangential ForceDocument1 pageHow To Calculate Tangential ForceJohn MalonesNo ratings yet