Professional Documents

Culture Documents

Equip Qualif Analyst

Equip Qualif Analyst

Uploaded by

BREWSKI0 ratings0% found this document useful (0 votes)

9 views8 pagesCopyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

9 views8 pagesEquip Qualif Analyst

Equip Qualif Analyst

Uploaded by

BREWSKICopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 8

Equipment qualification for demonstrating the fitness for

purpose of analytical instrumentation:

C. Burgess,* Dianna G. Jones and R. D. McDowall

B.IM. Limited, Rose Cottage, Walker Hall, Winston, Darlington, County Durham, OK

DLI2 3PN

Received 19th June 1998, Accepted 16th July 1998

Equipment qualification is the way to ensure that analytical equipment is fit for purpose. Qualification consists of

four basic elements. Design qualification or DQ (Specification of what exactly the analytical seientist requires the

{equipment to do). Installation qualification or IQ (Does the instrument Work to the manufacturer's spec

Operational qualification or OQ (Does the instrument work the way’ the analytial scientist wants i t0?) and

performance qualification or PQ (Does

and approach di

Qualification of analytical instruments cannot be achieved

through method validation. Equipment qualification provides

the foundation to develop, validate and run analytical methods

within the operating range measured. If method is developed

using parameters out of this range, then the analytical

instrument needs to be re-qualitied before method validation

‘can proceed.

Seven case studies of qualifying equipment, such as high-

performance liquid: chromatographs, environmental storage

equipment, centrifuges and pH meters illustrate the importance

of a structured and logical approach to the subject.

‘The Key clement that is missing in the majority of

laboratories’ approach to equipment qualification is that design

Qualification is often lacking. Hence, unsuitable and in-

appropriate equipment is purchased which can be difficult t0

‘qualify for its intended purpose

Introduction

Analytical sciemtists place great faith inthe readings and outputs

from their instruments. When unexpected or out-of-specitica-

tion results occur, the intial suspicion often falls on the sample,

the preparation technique or the analytical standard employed,

Rarely does the analytical scientist immediately question the

equipment. Indeed, the whole underpinning of method valida:

tion assumes that the analytical equipment which is used 4

acquire the experimental data is operating correctly and

reliably. We will return to What is meant by correctly and

reliably Title later

Some industries. which operate in a highly regulated

environment, such as the pharmaceutical industry, have placed

great emphasis on method validation in, for example, HPLC."

However, uni recently, there has been litle direct requirement

for assuring that the’ analytical instruments are working

Property.

The American Food and Drug Administration specifically

requites that ‘Laboratory controls shall inelude.....the

calibration of instruments, apparatus, gauges and recording

devices at suitable intervals in accordance with an established

Written program containing specific directions, schedules,

4 The opinions eyes in dhe fllowing area ar eel thse of the

curs ind Jo noe necessarily repescat the views of iter The Royal

Shetty of Chemis ote Editor of The Anlst

Continue to operate within the parameters monitored?). The background

cussed inthis paper has been developed primarily within the pharmaceutical industry.

limits for accursey and precision and provisions for remedial

action in the event accuraey andlor precision limits are not met.

Instruments. apparatus, gauges and recording devices not

‘meeting established specifications shall not be used.”

‘The major regulatory guidlines for Good Manufacturing

Practice (GMP) and Good Laboratory Practice (GLP) are

similarly vague. “Fitness for purpose” is the phrase that is

‘commonly used, but what docs this mean in practice? Only the

Pharmacopoeias*® and the Australian Regulatory Authoriy®

have been sufficiently worried by instrumental factors t0 give

Written requirements for instrument performance. Whilst these

guidelines are not consistent at least they are attempting 10

ensure consistent calibration practices between laboratories

In contrast, the ISO Guide 25 approach’ heavily focuses on

good analytical practices and adequate calibration of instra-

lly oF imernationally traceable standards

However, there has been a resurgence of interest in the

underlying dats quality by regulatory authorities, particularly

the FDA (Food and Drug Administration) in the USA.

following a major legal ruling*in 1993, This case has chan

the regulatory focus and put the laboratory fir

spotlight in terms of the assurance of the quality of the data it

produces. The details of the Barr ease need not concer us,

although it i useful to review the key features because of the

impact they had on FDA thinking in particular and regulatory

Perspectives in general

‘The Barr ruli

is

‘The most important point about the Bare ruling is that it was the

Fist time that the GMP regulations and their interpretation by

the FDA had been subjected 10a comprehensive judicial review.

‘The written decision covered 79 pages. As Judge Wolin decided

in favour of the FDA, this greatly strengthened their enforce-

‘ment activites as well as other regulatory aspects, The FDA

investigated Barr Laboratories over a peried of 4 years, having

noted deficiencies in their manufacturing. process validation.

FDA had issued Warning Letters to the company which were

effectively ignored. However, as a result ofthis investigation it

emerged that effectively the company was “testing into

‘compliance’, Pharmaceutical companies are required to register

the acceptable limits for release of product into the market

Analyst 1998123, 1879-1886 1879

and in others out-of-specification results were rejected or

ignored when batch release was undertaken,

‘One quotation from the FDA document will serve to illustrate

the agency's concern; ‘During the enforcement litigation, Barr

prepared reports on investigations into out-of specification

resulls on certain batches of some of its products. These

investigations reflect Barr's persistent efforts to avoid attribut-

ing out-of-specification results to process-related. problems

rather than identifying the causes of the out-of-specification

results and correcting them 10 prevent their recurrence.

Repeated similar out-of-specitication results implicating the

manufacturing process were attributed alternatively 10 operator

certor, equipment error oF laboratory error.”

(One ef the consequences of the case has been the thrusting of|

basic laboratory procedures and practices into the spotlight. tis

fnow an FDA requirement to investigate formally all outof-

specification results. Therefore, validation of methods and, for

the first ime, the qualification of analytical instrumentation. are

‘being heavily serutinised.

‘Such was the concern that FDA Guidance on QC Laboratory

Certification” was developed by former FDA Mid-Atlantic

Region NDAANDA Technical Operations Group Manager

Henry Avallone to help explain the concept of laboratory

certification to field office personnel. He identified eight main

areas to be addressed for laboratory certification: management

Systems; operating procedures: personnel training; data_ac-

‘countabilty; method validation: equipment; [cilites; cemtifica-

tion documentation.

This list will be very Familiar to those operating in an ISO,

Guide 25 (NAMAS or equivalent national agency) accredited

laboratory. Indeed, the majority ofthese items were not new 10

the pharmaccutical industry. What was new was an explicit

statement of requirements for the qualification of laboratory

equipment, “The qualification of laboratory equipment and the

jaitenance of such equipment, along with the adequacy of

standards, reagents and test solutions are of conver in the

certification ofa laboratory. For the microbiological laboratory

‘organism viability, media growth promotion, incubators, auto-

claves, hoods and automated equipment used for organism

identification all require qualification and calibration. There-

fore, it would seem that in order to certify a laboratory,

‘equipment should be listed, along with documentation that itis

Adequate and operating effectively for its intended purpose. Ibis

also. good laboratory practice to have a quality assurance

program that will assure that reference standards, buffer

Solutions, titrating solutions, reagents and other apparatus are

adequate and maintained properly. Fr some equipment, such as

HPLCS and test systems that they may be a part of, a holistic

approach rather than a qualification of each component part

such as 8 pump, may be used. This method! has been found

‘acceptable as written by Furman et al’!

Modular and holistic qualification

Furman er al, discussing the validation of computerised liquid

chromatographic systems, present the concept of modular and

holistic qualification. Modular validation isthe qualification of

the individual components of a system, such as the pump,

autosampler, column heater and detector of an HPLC, The

tuthors make the point that whilst ‘calibration of each modiule

‘may be useful for troubleshooting purposes. such tests alone

feannot guarantee the accuracy and precision of analytical

results”

‘Therefore the authors introduced the concept of holistic

validation, where the whole chromatographic system was also

‘ualified to evaluate the performance of the system.

1880 Analyst, 1998, 123, 1879-1886

‘The reader may question why such an approach is needed.

‘One pragmatic reason is that in our experience it is necessary!

We cite an HPLC system that was qualified by us and the

jual modules were just within acceptable Timits. How-

‘ever, when a holistic test forthe whole system was carried out,

the system failed to meet the ‘suitability for use” criteria.

"The concept of holistic qualification is important as some

laboratories operate with a policy of modular equipment

purchase. Here they select components with the best or

‘optimum performance from any manufacturer. Furthermore, to

ensure optimum throughput, some of these latoratories may

swap components when they malfunction, Thus, over time, the

composition of system may change. Therefore, 10 assure

themselves and any regulatory bodies thatthe system continues

to function corectly, holistic qualification i vital

Some laboratory equipment requires maintenance and pre-

ventative maintenance (PM) programs should include such

‘equipment. For example, HPLC units, spectrometers and

autoclaves all require routine preventative maintenance. Reg-

lulations require that equipment include maintenance logs or

documentation. Therefore, laboratory cerification should pro-

vide for a review of the preventative maintenance program.

‘Management usually only sees the topmost layer of these

processes and is probably unaware of the ‘iceberg’ that

lunderlies them, This aspect is shown pictorially in Fig. 1,

wheteby only the tip ofthe iceberg is generally visible

‘What the Barr Ruling has done isto shift regulatory attention

‘downvvards into the data level which hitherto it had not overly

‘concerned itself with

Approaches to integrity of analytical results

“The “bottom up" approach is the one usually favoured by the

analytical specialists. Like “Lego'. the quality ofthe end result

is built in from the foundations up. In testing terms this is

illustrated in the diagram below (Fig. 2). These “Lego” bricks

‘re equivalent to the individual modules in any measurement

system, Each brick is qualified as suitable for use before the

‘next layer is built, In this way, integrity is assured all the way 10

the topmost layer. If firm foundations are not built, the

information generated will ot stand scrutiny. By following this

approach quality is bull in from the lowest level.

“The role of the instrument in providing the integrity of data is|

fundamental to the end result, If you cannot place your faith in

the reliability of the basic analytical signal within pre-

cemnatogaphy,

1

an

n

‘ dissin esting. efacve index, 831 > spe

ropocometry ad ight searing

Bruis Pharmescoporia 1983, Nppenic U:Inrared spctopot

rmaty, Ulmlet and Visible Spectophotometry (Pharm. Bur

Vo Absorpion Spectophaconett). HM Stationery Ofice,

ondoa. UR:

Anstalan Code of GMP for Therapete Gnads—Mevinal Prod:

fei; Appendix D, November 1991" Guidelines for Labortry

[IS 45. alton 2, May 1996, Accreditation for Chemical Labor:

Departmen of Heath and Haman Services Fo nd Dog Admin

stration [Docket No. 93N-0184, Barr Laborers, Ics Reta

‘Approve Certain Abreviated”Appicanions: Opportunity for a

Hering, ol 8,10, 102 riday, May 28,1998 81035, (Note)

106

The Gold Shoot, 94 28112).8

1. B. Furman, T.P Layoff ad RT Teall J. ADAC Bn 1994,

775), 1814

MFreeman, M- Leng, B. Morrison and RP. Munden, Phare

Technol Eur. November, 195

. Bedson and M. Sargent, Aceredtaion and Quay Assurance,

1906.26.

Good Automated Mamactaring Practice: Supplier Guide for

Validation of Autoated Systems tn Pharmaceuneal Manfaae,

‘erin 3, May 198 SPE,

CC Burges, Laborarry Automation and Information Management,

son 38

C Burgess. ia Spectophotometry, Luminescence and Colour

Science and Compliance, eC. Burgess and D.G. Tones, Evi,

“Ameria, The Neterands, 1995,

CHTAC Guide I, Iternational Guide 10 Qualicy im Analytical

Ghemisry. an did to Accretion Edition, August 1998

Euractem—UK Insrumenation Working Group, Gasdance om Rest

Prac forthe Equipment Qualification of Analtical samen

HPLC. $ Dratt May. 1398

‘Anavtcal Methods Commitee, Anal Pro, LSA 2H. 45 985,22,

128, 1986, 23,100, 1987, 24, 8 1987, 24.266, 1990, 27, 324, 199,

28,312, 1993, 3,256

‘Analytical Methods Commie, Anal 1997, 122,37

D Parson, LCG, 1994 123) 132

The Got Sher, 198,28 12,

(C-Butgss and RD. MeDowall, CGC fn, 1997, 102.87

FDA Process Validation Guidlines, 1997

RF. Tell, Proceedings of DART 94, Advanstar Commica:

‘ons, Amsterdam, Oca, 1938

AUMGConmelh, Mi, Canales and G, Lawler LC-GC Int, 1992, 82),

C Burgess. D. G. Jones and R. D. MeDowall, LE-GC fu

112). 79.

Phaemaceuical Inspection Convention, Principles of Qualification

sand Validation in Pharmaceutical Monafactre Document PH 196,

BBundersserand der Parmaretischen inte (PBI, Fanktt am

‘Main, Gemany, January 1996,

on,

Paper 8104070K

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5810)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- ISO+13485 2016F (Full Permission)Document46 pagesISO+13485 2016F (Full Permission)BREWSKI100% (4)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Etablissement Dun Protocole de Validation Du Remplissage Industriel Des Gelules Base Sur Lanalyse Des Risques AMDECDocument130 pagesEtablissement Dun Protocole de Validation Du Remplissage Industriel Des Gelules Base Sur Lanalyse Des Risques AMDECBREWSKINo ratings yet

- OQ & PQ Medical DeviceDocument13 pagesOQ & PQ Medical DeviceBREWSKI100% (1)

- Guide de Stage Officinal 26e Edition 2019Document167 pagesGuide de Stage Officinal 26e Edition 2019BREWSKINo ratings yet

- Operating Instructions Coding and Inspection Unit TQS-LM (Line Manager)Document94 pagesOperating Instructions Coding and Inspection Unit TQS-LM (Line Manager)BREWSKINo ratings yet

- SER Equirements Emplate OR A Ully Utomatic Pindle Apper: User Requirements Specification CapperDocument26 pagesSER Equirements Emplate OR A Ully Utomatic Pindle Apper: User Requirements Specification CapperBREWSKINo ratings yet

- URS Contents: Blank TemplateDocument11 pagesURS Contents: Blank TemplateBREWSKI100% (1)

- Process Validation and Revalidation in Medical Device ProductionDocument7 pagesProcess Validation and Revalidation in Medical Device ProductionBREWSKINo ratings yet

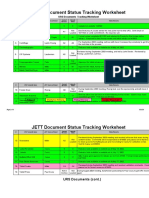

- JETT Document Status Tracking WorksheetDocument6 pagesJETT Document Status Tracking WorksheetBREWSKINo ratings yet

- NT - Akivision A CFRDocument60 pagesNT - Akivision A CFRBREWSKINo ratings yet

- 2011 Nord ExercicesDocument14 pages2011 Nord ExercicesBREWSKINo ratings yet

- U R T Foraw R L F: Ser Equirements Emplate Ide Ange Iquid IllerDocument23 pagesU R T Foraw R L F: Ser Equirements Emplate Ide Ange Iquid IllerBREWSKINo ratings yet

- Jett Urs P P: Reparation RocessDocument7 pagesJett Urs P P: Reparation RocessBREWSKINo ratings yet

- Cleaning Validation StandardDocument14 pagesCleaning Validation StandardBREWSKINo ratings yet

- NF 552 A1 PDFDocument9 pagesNF 552 A1 PDFBREWSKINo ratings yet

- Whitepaper Serialisation 150127Document3 pagesWhitepaper Serialisation 150127BREWSKINo ratings yet

- Change Control Risk AssessmentDocument1 pageChange Control Risk AssessmentBREWSKINo ratings yet

- Texwipe PDA Cleaning and Cleaning Validation Chapter19Document26 pagesTexwipe PDA Cleaning and Cleaning Validation Chapter19davincicode888100% (1)

- Indice de CarrDocument2 pagesIndice de CarrBREWSKINo ratings yet