Professional Documents

Culture Documents

Fabrication Inspection Checklist PDF

Fabrication Inspection Checklist PDF

Uploaded by

maaathan0 ratings0% found this document useful (0 votes)

5 views5 pagesOriginal Title

Fabrication inspection Checklist (2).pdf

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

5 views5 pagesFabrication Inspection Checklist PDF

Fabrication Inspection Checklist PDF

Uploaded by

maaathanCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 5

WARTSILA

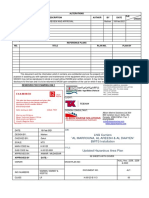

7.Fabrication Inspection Checklist

€

WARTSILA

EGCS FABRICATION CHECKLIST-SCR

EGCS HERR AS

Tem Checklist fem Description SUPPER] —WSZ_] Canmenioaa

a ees mam | RS | Se tin

+8

T | Supplier Name i Bowel

2_|PO Number 1s P03

3_| Drawing NO_& 4 “503 56-110 -1892-2]

‘General(igternal and external) Features

SEAR ALEC 8)

4 _ | Material identifcation to material Cerificate and -

material traceable OK 4 Y

HELA AR iso tt th Se BAL

5 | Material used meet to drawing OK (including

lifting lug material and location) y 1

HAL BM (Beh H HAG)

| All carbon steel material should be pre-treated

and primed (welding primer) OK y Y

SUR AD ALR a TIE Ra wil

7} Welder cerificate and WPS

PEMA E Y 1

| Fit up for welding —alignment &

roundness ,welding Preparation, location y Y

RMR RACH MIA OR

[it up for werding(iong & circ)

SEAR (BIER) y y

70 | fit up for header & top flange

REM! yy

TT [it up for nozzles) access hatchestincluding

cla iveat hoy few soe Y ly

ARIA FL B46 SRS A IRCA)

TZ] Tit up of internallextemal Y

EAE By Sh i & WSZAMUPE-003 fa FH y

S| installation of pipe

ERE y

Ta | fit up of pipe with lange

PRAOE ER SALE ED AB IB Y Y

ie

75 | PO Number welded onto tank, Drawing NO

stamped on tank y

SASFRTARRLEMTRE LIL, FHI, 1

hi, F35 35MM.

T5.1_| Welding deformation without legs, cannot Rave

the distorted Y

AMEE DS, KLG IR, AM Ane Yt

752 _| The leg plate according to the drawings to dl

through holes, and then in the cold after welding

eats ta y

TERM bros, meareces 4

ees

DocD: WSZ-CL/QA-401 Revision 004 age 10f5

(¢

WARTSILA,

Ttem ‘Checklist Item Description sUFF SZ

Ae eeme 7 oO | Ree

15.3 | The intemal circle roundness meets the |

requirements of tolerance, non deformation y Y

APMMDRACAERR, LAA

76} Weids Visual Inspection 100%

MAE aide 100%, 1% WSZWIPE-003 y Y

17 | Weld seam DP & UTtest complying with drawing

requirements. y 1

FERAL RE RE HO todd SAMIR.

78 [appearance

SPL, RURAL. Heh eD REDE Y Y

19 | hollows at end/starticomers of runs.

PRM A EIB IHG HAG OS Mh No

‘20 | undercut acceptable to spec.

ROR RA TRS Y Y

2 [holes or eaters

ete th Mo

2 weld cracking

tr Ah_|_ 0h

23 | slag removed

id y y

2a [spatier removed 4

Ste ea, _ Y

25 | atinding marks

Arab slik, shaw t Ara Mh_|_ wh

‘Dimension Inspection

Rite Y

‘26 | All main dimensions is OK V

| | amesetae ee y

27 Are All dimensions on connection joints al limit

PRLERPREADEA i

27a | Base Piate hole sz fo meat the requirements of

the drawings y

HWERIRTAS BRK

25 | Attached dimension yellow marked drawings

checked by Wartsila QC #8) BE RTE, Y

Wartsila QC 4441 # (QC aF RGM 2 that As)

28 [AI Sharp edges shall be ground to min (indlu

all the bolts holes ground/chamferred) OK

PAL RE AG AB BA RZ. ( AGRA ALAS Y

m8)

30 | All thread checked by thread gauge OK

ASR ARSE ALA / {

Doc ID: WS7-CYOA-401 Revision: 004

Page 2065

Ce

WARTSILA

Trem Checklist Item Description

Be ETH

es

WSZ

RABE

CamaRTORT

Referee

eeeuen

ms

Testing

BR

a

‘Whole unit air leak test witnessed & pass by

WSZ & Class (if requested)

ARIE KID iE WSZBClass( 40 &

Sy i

ye,

Pe

Z

“The weather 1s suitable for shotblasting &

painting ok (check moisture and temp.)

RALOT RY RMA (BEE RRA)

a

Check the roughness of the Blasted area, reach

to SA2%OK

HeB oh Hy BIKA 5] SA2.5

Primer and applied way meet spec, OK

Rib RABABLME RR

te |e |e

Ey

Primer OFT OK

RAT RAR

%

All stainless steel materials including welds, weld

affected areas and piping insides shall be

degreased, pickled and thoroughly flushed with

high pressure (more than 70 bar) water.

HKSES WSZ-WNPE-003reference,

AS. WSZ-WUPE-003 54 FAT ARS AEH 48

PEL, FARES AoE NAB Asis ARALIEA

KK (7Obar) #2.

Confirm the whether welding residual defect, and

the black residue, residual rust, splash, arc

scratch ete.

ADP DA DRE ARG OIE IG, DURE

Rake, OR, Kak, VARIES

7

‘All pickled and passivated paris are to be

checked for any residual acid and ferrite

contamination in accordance with HKSES WSZ-

‘WIIPE-003 in the presence of Wartsila QC.

BB WSZ-WUPE-003 5, Pr AAR OR LILO A

MG Wartsila OC RHPERE AAG RR TTR

1 Wartsila QC #88 # #4534 2 4] Server

a7,

‘The clear water rinse again surface, and use PH

test paper test the product surface is residual

acid

AGG, SPH ARAL A SRR

a2

The clear water rinse again surface, and use PH

test paper test the product surface is residual

acid

PHARM RE ES, RG LET MBIT ER

ARREARS

DocD: WSz-ClYQA-A01 Revision :008

Page of 5

€

WARTSILA

item Checklist tem Description SOREN] SZ Capea

a su a eben

an

Documentation

RRL

38 | Paint Report Review and Check?

RERSA GELS HE?

39_| Documentation reviewed and accepted.

EAR AR

Before Delivery to Our Workshop

ta

“40_| Shall check i all the loose parts are avalable

against parts lst of loose item and identified

before delivery to our workshop

SEAT CO 28 ARAB TAF EA BA

AGRA AHR,

i | Proper protection before transportation

Pieces eee

All products and parts after confirm qualified,

before delivery by the Wartsila QC QC hang

PASS card shipment

WAP BoA S, TH Wartsila

QC #.: QC PASS Her TH tt

a

Inspector Date

eee ~~ aM

Signature

Be

This checklist covers in-process inspection. It may be carried out at either the suppliers premises or at

HKSES as part of a Goods Inwards inspection

AEAMPTAABS, CHT AR MILL T & HKSES it Betz,

Remarks are to be noted on the reverse side of this sheet,

SRT RTART EH,

IS THE FABRICATION SUBJECT OF 2° OR 3" PARTY INSPECTION , Yes / No.

HAEHRESRO FARE DHM? RIS.

Date of Inspection.

een H

Inspected by Name. Signature,

BEA as

Representing Company/Classification Society,

Dasa

Doc: WSZ-CLYQA-401 Revision :004| Page 4 of 3

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5811)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Tax Invoice/Bill of Supply/Cash Memo: (Original For Recipient)Document1 pageTax Invoice/Bill of Supply/Cash Memo: (Original For Recipient)maaathanNo ratings yet

- Aalco Metals LTD - Aluminium Alloy DNV Certified Marine Extrusions Extrusions - 419Document3 pagesAalco Metals LTD - Aluminium Alloy DNV Certified Marine Extrusions Extrusions - 419maaathanNo ratings yet

- NominationDocument3 pagesNominationmaaathanNo ratings yet

- Cell GuideDocument1 pageCell GuidemaaathanNo ratings yet

- Hydro Marine Standard ItemsDocument9 pagesHydro Marine Standard ItemsmaaathanNo ratings yet

- BWTS Sampling Procedure V1Document5 pagesBWTS Sampling Procedure V1maaathanNo ratings yet

- Bts - Ets - E210349 Plan Dsme2238 Bwts Retrofit (H.00123-E-113)Document2 pagesBts - Ets - E210349 Plan Dsme2238 Bwts Retrofit (H.00123-E-113)maaathanNo ratings yet

- RestrictedDocument5 pagesRestrictedmaaathanNo ratings yet

- Salvage Bags PDFDocument4 pagesSalvage Bags PDFmaaathanNo ratings yet

- RestrictedDocument7 pagesRestrictedmaaathanNo ratings yet

- Diving AccessoriesDocument18 pagesDiving AccessoriesmaaathanNo ratings yet

- 2020.06.11 - 15-25-181143 Corrigendum - 2Document7 pages2020.06.11 - 15-25-181143 Corrigendum - 2maaathanNo ratings yet

- Crew Boat - 30M - General Arrangement - 13.11.19 PDFDocument1 pageCrew Boat - 30M - General Arrangement - 13.11.19 PDFmaaathanNo ratings yet

- HPV Hydrostatics Run2Document6 pagesHPV Hydrostatics Run2maaathanNo ratings yet

- Total Range: Expand Your Efficiency HorizonsDocument40 pagesTotal Range: Expand Your Efficiency Horizonsmaaathan100% (1)

- Main Foundation Leg Will Clash With Fire Pump Valve RouteDocument1 pageMain Foundation Leg Will Clash With Fire Pump Valve RoutemaaathanNo ratings yet

- Em Pmi375 T800 PDFDocument6 pagesEm Pmi375 T800 PDFmaaathanNo ratings yet

- Em Pmi375 T800 PDFDocument6 pagesEm Pmi375 T800 PDFmaaathanNo ratings yet

- United States Patent: Caro Et AlDocument13 pagesUnited States Patent: Caro Et AlmaaathanNo ratings yet

- Crew Boat - 30M - General Arrangement - 13.11.19 PDFDocument1 pageCrew Boat - 30M - General Arrangement - 13.11.19 PDFmaaathanNo ratings yet